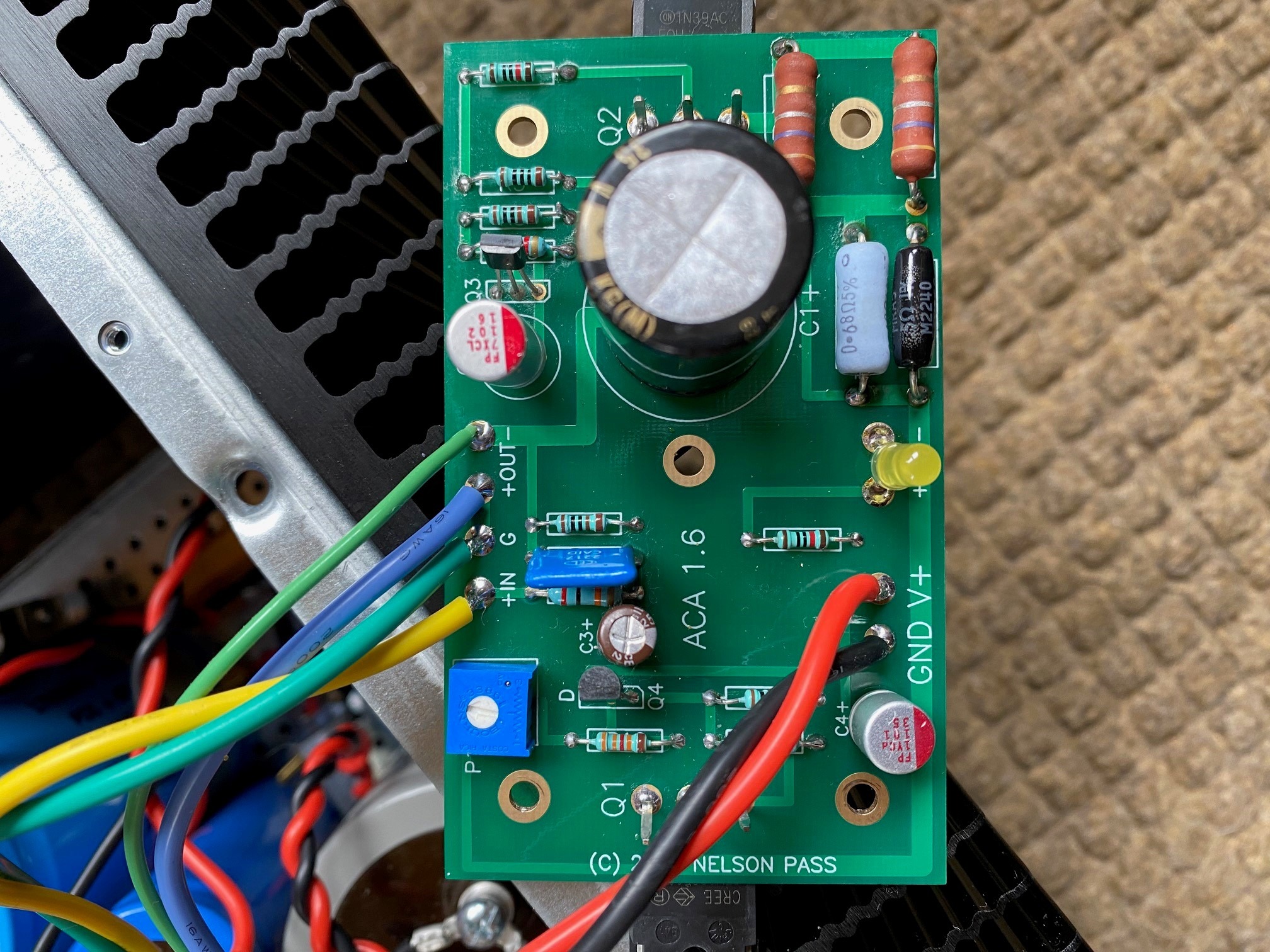

I would also shorten the wires and twist the (+) and (-) wires together to minimize loop areas.

I would consider 18ga stranded copper to be the minimum power wiring for an ACA class amp. PTFE (Teflon) insulation is great for not melting at soldering temperature. Looks skinny compared to standard plastic insulation.

Definitely run + and - wires together to minimize loop area. Twisting accomplishes this.

Definitely run + and - wires together to minimize loop area. Twisting accomplishes this.

Thanks Zen Mod. What gauge wire minimum do you advise?hope those wires are just mock-up

good for preamp, not so for amp, even if just little ACA

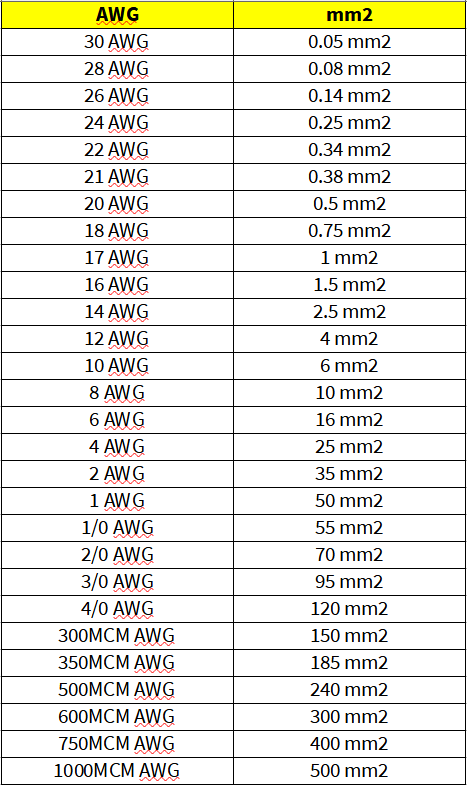

When i see ”gauge”, ”AWG” im thinkin: What kind of a completley confused, half blind monkey invents a ”system” that gives the greater cable area a lower number…🙂

The definition of wire diameters in the AWG (American Wire Gauge) system was introduced in 1857 by Joseph Rogers Brown (1810-1876) at Brown & Sharpe.What kind of a completley confused, half blind monkey invents a ”system” that ...

;-)

First of all: I would not use any boards.

Then: I would not use sockets and plugs and eyelets.

And: I would not use "double mono" psus, channel separate psus.

First of all: I would not use any boards.

Then: I would not use sockets and plugs and eyelets.

And: I would not use "double mono" psus, channel separate psus.

To all of you audio wizards and constructive advisors: Yes the existing wires are 18 gauged and Teflon insulated so they do look under spec. Subsequent posts containing the AWG information and history helpful. I have thus ordered up 16 AWG teflon and will also change the topography see textbook diagram upper left schematic. Yes also to twisting.I would consider 18ga stranded copper to be the minimum power wiring for an ACA class amp. PTFE (Teflon) insulation is great for not melting at soldering temperature. Looks skinny compared to standard plastic insulation.

Definitely run + and - wires together to minimize loop area. Twisting accomplishes this.

Update: 16AWG wiring Linear Power Supply wiring installed, thank you. Powered up again, blew a 3A fuse (the Disspante 3A stock EIC integrated socket / switch fuseholder came with 10A fast and 3A slow. Replaced 3A w/ 5A fast, that issue solved for now. This is a dual monoblock parallel ACA single chassis. LPS making 27.7V at the PCB V+.

Powered the amp up again, on startup the C1 on one board immediately smoking at its base. 4700uf Nicochon Gold Fine 35V.

I've ordered a replacement from Mouser, actually two of them in case. When it arrives, shall I simply swap in the new one and re-power, or do you have any diagnostic suggestions?

Please note the offending smoking cap is correctly oriented re polarity.

Powered the amp up again, on startup the C1 on one board immediately smoking at its base. 4700uf Nicochon Gold Fine 35V.

I've ordered a replacement from Mouser, actually two of them in case. When it arrives, shall I simply swap in the new one and re-power, or do you have any diagnostic suggestions?

Please note the offending smoking cap is correctly oriented re polarity.

I have not heard from Jim how the pcb's are attached to the heat sinks, but I see that the 1 mounting hole next to C4 is tied into the ground plane. I question whether having the ground plane in contact with the heat sink could be a problem?well, something is wrong connected, if there was Badaboom with cap

pics, clear ones

My ACA came with the nylon standoffs, so my ACA never had any electrical contact with the sink. I guess that is not a problem, or at least I never have had any hum or smoking C1 problems. I was just trying to figure out why Jim's C1 smoked on his one channel parallel dual mono. I guess either the cap was defective, or there is some other undiscovered reason for the failure. Thanks for your input Zen Mod🙂

Did the mosfet on the right side in the second photo in post #1333 suffer some damage as well?

Dennis,

Very good question and keen observation. Can you inform how I might test it in situ? I can do that and report back. Thank You,

Jim

Very good question and keen observation. Can you inform how I might test it in situ? I can do that and report back. Thank You,

Jim

Update: I replaced the C1 with an identical, new cap. Refitted the board, powered up. Magic smoke. This time observed more closely in brighter light. R3 and R4 in the end may have been the source, the light blue resistor got super hot and both brown. The black resistor may also have cooked. In looking at the schematic now suspect Q1 as the fault. This was an old stock 44N10 - what do folks think? The culprit?

One more is being shipped in, I'm thinking I'll replace Q1 and have another go.

Unless I can get some better insight here for a more scientific QA method.

Please note the photo doesn't accurately reflect how brown the R3 and R4 turned.

Thanks in advance!

One more is being shipped in, I'm thinking I'll replace Q1 and have another go.

Unless I can get some better insight here for a more scientific QA method.

Please note the photo doesn't accurately reflect how brown the R3 and R4 turned.

Thanks in advance!

check all semis in situ with diode test (DMM) for shorts

if suspicious, pull it from pcb, test again

same with resistors.... if suspicious, lift one leg, recheck

if suspicious, pull it from pcb, test again

same with resistors.... if suspicious, lift one leg, recheck

- Home

- Amplifiers

- Pass Labs

- ACA amp with premium parts