I suspect an entirely steel cabinet has the potential to be superior to a wood type, because of a greater ability to transmit audio waves.

If that was indeed a fact, why would it matter in a damped line (which is what you want in a speaker of this type).

jeff

@dave cool, i was thinking a triangular pyramid would be kinda wide at the top same as the voigt pipe is, but it is interesting that you think it would work. even to make it out of wood could be an improvement to avoid the shortfalls of the original.

@jeff putting technical matters aside as i don't have a good understanding of them i can appreciate the effect the steel has in my speaker. the audio leaps out of nowhere, it's almost shocking.

you seem to be implying that a damped line merely removes the negative waves, without admitting that by doing so it boosts the positive waves.

if there is unwanted resonance, then there should also be the possibility of anti-resonance, where a cabinet is designed to cancel out errant resonances, not merely absorb them in dampening.

If a cabinet is designed to favour anti-resonance then it should have a favourable output.

It is most likely that a pyramidal cabinet would not favour anti resonance but it would be interesting to try. perhaps there is software that can model such a thing.

when i did physics in school i learned about how two waves on water can meet and cancel out, producing calm water. this is what i understand to be anti resonance.

@jeff putting technical matters aside as i don't have a good understanding of them i can appreciate the effect the steel has in my speaker. the audio leaps out of nowhere, it's almost shocking.

you seem to be implying that a damped line merely removes the negative waves, without admitting that by doing so it boosts the positive waves.

if there is unwanted resonance, then there should also be the possibility of anti-resonance, where a cabinet is designed to cancel out errant resonances, not merely absorb them in dampening.

If a cabinet is designed to favour anti-resonance then it should have a favourable output.

It is most likely that a pyramidal cabinet would not favour anti resonance but it would be interesting to try. perhaps there is software that can model such a thing.

when i did physics in school i learned about how two waves on water can meet and cancel out, producing calm water. this is what i understand to be anti resonance.

i believe i referred to the metronome already. although it has no parallel sides like the voigt pipe i believe that a 5 sided or 3 sided metronome could have interesting properties.

I got my visaton bg20 today, didn't realise they would be so large. will have to carve a bit out of the internal cabinet sidewall to make it work.

I got my visaton bg20 today, didn't realise they would be so large. will have to carve a bit out of the internal cabinet sidewall to make it work.

Last edited:

i believe i referred to the metronome already. although it has no parallel sides like the voigt pipe i believe that a 5 sided or 3 sided metronome could have interesting properties.

Not really, they're still some form of conical horn with the basic shape for best eigenmode decay in this post: About to dive into a steel voigt pipe build

I was badly sunburned yesterday so i spent the day in the shade installing the new visaton bg20. thanks to Davor d who suggested them.

I ran it side by side with my old driver and my old damaged one was terrible in comparison, no treble at all, and the matching resistors made them have a muddy sound. these should do me for a long time. I'd like to play with equalisation to make up for the bass notch these pipes are reputed to have.

I ran into a few hitches installing the drivers. when i went to open one cabinet the silicone i used to seal the plywood delaminated it. luckily i had enough plywood left over to replace it, and i hadn't assembled the second cabinet.

I handled one cabinet roughly and end up bending the terminal plate on the bg20 to 90 degrees from factory. it's too late to straighten it now, didn't notice the issue until i assembled the second. i hope the braided wire will not tear the cone.

I did recess a cut into one sidewall, but i expect i could have got away with less. the driver is maybe 3mm wider than the internal dimensions of the pipe.

I guess this is the end of the thread, as i doubt i will make any further changes. If anyone wants to reproduce the composite design, then by all means do so. I would recommend changing the internal width to 25cm from 20cm to fit this driver though.

I'll leave a recording of the composite pipes here, the same track as before with the ringing pipes.

I ran it side by side with my old driver and my old damaged one was terrible in comparison, no treble at all, and the matching resistors made them have a muddy sound. these should do me for a long time. I'd like to play with equalisation to make up for the bass notch these pipes are reputed to have.

I ran into a few hitches installing the drivers. when i went to open one cabinet the silicone i used to seal the plywood delaminated it. luckily i had enough plywood left over to replace it, and i hadn't assembled the second cabinet.

I handled one cabinet roughly and end up bending the terminal plate on the bg20 to 90 degrees from factory. it's too late to straighten it now, didn't notice the issue until i assembled the second. i hope the braided wire will not tear the cone.

I did recess a cut into one sidewall, but i expect i could have got away with less. the driver is maybe 3mm wider than the internal dimensions of the pipe.

I guess this is the end of the thread, as i doubt i will make any further changes. If anyone wants to reproduce the composite design, then by all means do so. I would recommend changing the internal width to 25cm from 20cm to fit this driver though.

I'll leave a recording of the composite pipes here, the same track as before with the ringing pipes.

Attachments

>I handled one cabinet roughly and end up bending the terminal plate on the bg20 to 90 degrees from factory. it's too late to straighten it now, didn't notice the issue until i assembled the second. i hope the braided wire will not tear the cone.

If it's what I'm imagining, you might want to find a way to release the tension on those little wires going into the cone...

Either simply bend it back into the factory position with a little epoxy for reinforcement (unsure why too late?), or solder little extensions from the terminals, having first removed the braided wire from each, then attaching to the extensions. Delicate work there, but could be done.

Otherwise on a good bass note, somethings going to tear - or eventually fray and disconnect in time. Good luck!

If it's what I'm imagining, you might want to find a way to release the tension on those little wires going into the cone...

Either simply bend it back into the factory position with a little epoxy for reinforcement (unsure why too late?), or solder little extensions from the terminals, having first removed the braided wire from each, then attaching to the extensions. Delicate work there, but could be done.

Otherwise on a good bass note, somethings going to tear - or eventually fray and disconnect in time. Good luck!

Not totally relevant but I was thinking before that these kind of aluminium boxes could be made into a sealed or BR enclosure pretty conveniently for anyone interested in metal enclosures. Largest size is about 12L.

I handled one cabinet roughly and end up bending the terminal plate on the bg20 to 90 degrees from factory. it's too late to straighten it now, didn't notice the issue until i assembled the second. i hope the braided wire will not tear the cone.

Iam glad to hear you are satisfied with BG20.

If I remember well, BG20 terminal is riveted to a small tin carrier. If you carefully grasp the carrier with pair of narrow pliers it should be possible to bend it back.

Braided wire that goes to the cone must be loose, othervise it will be damage after longer period od use.

I have fixed the bent terminal now by pushing with my fingers. it was a difficult repair as even though the silicone had not fully cured since yesterday, it still delaminated the plywood when i went to disassemble the cabinet. since i was short on wood i got an anglegrinder and cut the wood across above and below the speaker. after i cut out a new baffle, i tapered the edge so that i could put silicone in the join. I hope that i have not damaged the rest too much but i think the bolts i am using should stop any vibration around where it delaminated.

It's just as well that i did the repair as the wire braids were rubbing against the steel frame of the driver and would have shorted through eventually, blowing my amp.

i noticed that the thick feedwire was trapped between the magnet and the rear of the enclosure. if i was to repeat the build then i would ensure the hole for the feed wire was above the driver. I think it shouldn't cause any problems down the line though, as movement will be minimal. I also put a snap tie on the cable to prevent the terminals bending again.

Due to the difficulty with disassembly i did not experiment with stuffing. i hope the same effect can be achieved with equalisation, which i have accomplished with the basic bass and treble controls on my amp.

i expect those metal enclosure boxes would be considerably expensive, though i'd say diecast aluminium would have excellent properties.

It's just as well that i did the repair as the wire braids were rubbing against the steel frame of the driver and would have shorted through eventually, blowing my amp.

i noticed that the thick feedwire was trapped between the magnet and the rear of the enclosure. if i was to repeat the build then i would ensure the hole for the feed wire was above the driver. I think it shouldn't cause any problems down the line though, as movement will be minimal. I also put a snap tie on the cable to prevent the terminals bending again.

Due to the difficulty with disassembly i did not experiment with stuffing. i hope the same effect can be achieved with equalisation, which i have accomplished with the basic bass and treble controls on my amp.

i expect those metal enclosure boxes would be considerably expensive, though i'd say diecast aluminium would have excellent properties.

Last edited:

>Due to the difficulty with disassembly i did not experiment with stuffing. i hope the same effect can be achieved with equalisation...

Not going to happen. Why?

If you look at the undamped (un-stuffed) response of a tuned length of pipe, the FR pattern vaguely resembles a comb, like you comb your hair with. Those notches - the points where the FR dives to zero - are extremely difficult to address electronically. Certainly the ordinary bass / treble controls just arent setup to do this.

The easy way is to stuff the line so the notches either dont occur, or only occur in a far less exaggerated way. Realizing this, many builders make their cabinets with some sort of access panel, or the whole back comes off. So the stuffing can be adjusted in a practical way.

It's a hard lesson. I've built two cabinets where getting the stuffing setup in a good way was half the whole project effort! Both, I have to go through the speaker baffle opening - which means the driver has to come off. No adhesive there - yet.

Try installing a catch basket (to keep the stuffing from falling down past 2/3 length) by reaching your arm through a narrow driver cutout, with a shallow cabinet wall behind, then fishing around down in there to find screw holes drilled (later, after I realized...) from the outside of the enclosure...then cranking 'em down, 1/8th turn at a time, with a stubby phillips driver. Oops, dropped it - now I have to tip the cabinet...

Planning how you're going to address the stuffing is as much as planning the build dimensions of the whole cabinet - in this "quarter-wave" type of speaker. Enough said.

Not going to happen. Why?

If you look at the undamped (un-stuffed) response of a tuned length of pipe, the FR pattern vaguely resembles a comb, like you comb your hair with. Those notches - the points where the FR dives to zero - are extremely difficult to address electronically. Certainly the ordinary bass / treble controls just arent setup to do this.

The easy way is to stuff the line so the notches either dont occur, or only occur in a far less exaggerated way. Realizing this, many builders make their cabinets with some sort of access panel, or the whole back comes off. So the stuffing can be adjusted in a practical way.

It's a hard lesson. I've built two cabinets where getting the stuffing setup in a good way was half the whole project effort! Both, I have to go through the speaker baffle opening - which means the driver has to come off. No adhesive there - yet.

Try installing a catch basket (to keep the stuffing from falling down past 2/3 length) by reaching your arm through a narrow driver cutout, with a shallow cabinet wall behind, then fishing around down in there to find screw holes drilled (later, after I realized...) from the outside of the enclosure...then cranking 'em down, 1/8th turn at a time, with a stubby phillips driver. Oops, dropped it - now I have to tip the cabinet...

Planning how you're going to address the stuffing is as much as planning the build dimensions of the whole cabinet - in this "quarter-wave" type of speaker. Enough said.

Last edited:

Managed to stuff both cabinets with sheeps wool, from my dads suffolk cross ewes, not the long haired type as recommended by mr voigt. I needed less than one fleece to do both. I did notice that i had to turn down the bass closer to mid position and up the treble closer to mid position on my amp from where i had it before, so it seems that it has done something positive. I'm not sure what a frequency comb sounds like. my pipes sound ok and that's the main thing.

I'm worried that i packed the wool too tightly, i did not want it to fall down, but the higher frequencies are still there so i guess it's ok.

I'm worried that i packed the wool too tightly, i did not want it to fall down, but the higher frequencies are still there so i guess it's ok.

I noticed that i was missing out on a lot of bass and some fine music details with the extra stuffing so i removed most of it. i left in some to reach between the top of the cabinets and halfway between there and the driver. treble knob is still at 12 0 clock so i think it's a good compromise, even if the bass knob is at 4 0 clock. the voigt pipe design was never intended to emphasize bass i read though, it treats all frequencies equally.

I didn't notice much of a problem with a frequency comb effect and the bass notch seems to be gone too with the noticeably larger bg20. the bass reaches down as low as it needs to and does not decrease in volume with decreasing pitch, like it did before with the car speakers.

maybe the composite construction reduces the comb effect.

could someone explain to me why the voigt pipe is not vented on the rear like the frugelhorn. all the documentation on speakers i've found states that the purpose of a cabinet is to separate the positive waves from the negative. by putting the vent on the opposite side that would surely make it more efficient?

I didn't notice much of a problem with a frequency comb effect and the bass notch seems to be gone too with the noticeably larger bg20. the bass reaches down as low as it needs to and does not decrease in volume with decreasing pitch, like it did before with the car speakers.

maybe the composite construction reduces the comb effect.

could someone explain to me why the voigt pipe is not vented on the rear like the frugelhorn. all the documentation on speakers i've found states that the purpose of a cabinet is to separate the positive waves from the negative. by putting the vent on the opposite side that would surely make it more efficient?

You're probably needing to use the LF tone control because the BG20 wants a larger pipe volume to produce more gain (output). Composite construction has nothing to do with pipe harmonics though I'm afraid, although it's very effective at reducing panel resonance, which is a separate matter.

Re vent location, the easiest way of looking at this is to consider a regular vented box. Your pipe performs a similar task, but with detail differences which aren't important purely for the sake of this narrow point. They're basically phase-inverters. The output from the rear of the cone is 180 degrees out of phase with that from the front. The air inside the box basically acts like a spring, connecting the back of the driver with the air in the port / vent. However, the transfer of motion via that air-spring is not instantaneous: it takes a small amount of time, and that short delay brings the two outputs back into the same phase at low frequencies.

Re vent location, the easiest way of looking at this is to consider a regular vented box. Your pipe performs a similar task, but with detail differences which aren't important purely for the sake of this narrow point. They're basically phase-inverters. The output from the rear of the cone is 180 degrees out of phase with that from the front. The air inside the box basically acts like a spring, connecting the back of the driver with the air in the port / vent. However, the transfer of motion via that air-spring is not instantaneous: it takes a small amount of time, and that short delay brings the two outputs back into the same phase at low frequencies.

An ML-Voigt does not care whether the terminus is front, rear or side, except for dealing with room loading. The output of the FH mouth is much larger bandwidth than the resticted terminus in an ML-V and what the wall does has significantly more impact on the response.

dave

dave

I was blaming the steel in the cabinet for giving me a headache until i started to play with an equalizer and fixed the issue. however, the software solution is introducing pops and clicks.

is there a way to do a linear roll off from 8khz to 18khz using discrete components. just trying to get some value out of my budget speakers here, without shelling out for a hardware equalizer.

the treble knob is a help, but not as useful as i'd like, impacts the audio too much without addressing the issue.

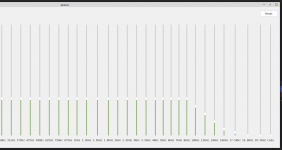

you can look at the attached eq sliders to see what values i have them set at.

is there a way to do a linear roll off from 8khz to 18khz using discrete components. just trying to get some value out of my budget speakers here, without shelling out for a hardware equalizer.

the treble knob is a help, but not as useful as i'd like, impacts the audio too much without addressing the issue.

you can look at the attached eq sliders to see what values i have them set at.

Attachments

- Home

- Loudspeakers

- Full Range

- About to dive into a steel voigt pipe build