I also just came across this post and the post referenced in it.I just came across this post of mine on page 170, while looking for wall recordings (side tracked again ) 🤣

And remembered that I never followed up as usual with my findings.

I found that the reflection peak from the close wall, could be sorted by simply turning the panel on its 🙃

It seems obvious now as all the pro panels i have seen are mounted on their sides(tectonic and others).

Basically when the panel is on its side, the close wall sees a fuller frequency response, so reflects the fuller sound back into the room, from both left and right.

When standing upright the wall only sees the reduced frequency response,from the thinner side , it is not an artificial peak, but a drop off of response below the peak, (I hope this makes sense?).

When the panel is on its side you will get a fuller sound spread across the audience at a venue.

And all reflections from side walls will be the same.

In my room the walls are close to the panels, so when the panel is on its side,it reflects the fuller sound back into the room towards me.

Now the peak is firing down into my carpet and up to the ceiling which is further away from the panel.

This one strong reflection from the ceiling will also be absorbed somewhat by the carpet ,hopefully ,it would seem ?

This panel sounded fine when turned on its side,problem solved😁.

I now always mount my small panels on their sides for this reason.

Sorry it took me so long to mention this.

I look forward to any feedback on this and any thoughts.

Steve.

This hints at why tectonic have their panels mounted on the sides for better audience sound coverage.

This is one of the problems that can affect the performance of tall thin panels also.

Especially close to side walls without wall damping of some sort.

Steve.

So for Atmos spatial cues to translate, I need HF extension out to 12khz or so…….is there a suggested exciter that can get there while still extending down to 90hz?Mister audio.

You have to remember that these recordings were made with me standing on a chair holding the exciter in my hand with a piece of wood screwed onto the exciter (see pictures).

The microphone on the first 2 recordings was at least 2m away with my hand and body and big head in the way.

The third recording was me still holding and moving the exciter around the wall ,but with the microphone in my other hand for a closer recording.

The hdn8 has a poor hf response above 10k ,I did make frequency plots of this exciter somewhere in this forum, mentioning that it was not my favourite exciter and had too much loud vibrating plastic .

But it seemed to work better on the wall than on the panels.

Plus I hope you were listening on good headphones for the best sound quality and not over speakers?

I keep forgetting to mention this 😃

Steve.

Dolby's production spec is 20hz to 20khz +/-3dB. In practical terms all speakers the same except for the LFE channel - 20-120hz but at +10db compared with the rest. The E in LFE stands for effects. A more usual bass limit due to cost and size is 40Hz may be -3dB. Satellites 80 or 90Hz, -3dB again. Centre much the same. Top end always tends to be 20Khz.

I suspect that most people just like me would find that at some point in the HF range they get a feeling in their ears rather than hearing a clear tone - even young ears. The same can happen at the LF end at some point. Still part of the listening experience really.

I had a set up like this one some years ago and was surprised by the quality of the sound

https://www.panasonic.com/my/suppor...ntertainment/audio/home-theatre/sc-xh333.html

Different world - speakers manufactured specifically for them and then add digital processing. This was from before units tended to come with a mic to allow calibration. The 5,1 effects were very noticeable. Far better than a separates system I have also used. That could be down to the AV receiver - Sony. No amp specific speakers.

I suspect that most people just like me would find that at some point in the HF range they get a feeling in their ears rather than hearing a clear tone - even young ears. The same can happen at the LF end at some point. Still part of the listening experience really.

I had a set up like this one some years ago and was surprised by the quality of the sound

https://www.panasonic.com/my/suppor...ntertainment/audio/home-theatre/sc-xh333.html

Different world - speakers manufactured specifically for them and then add digital processing. This was from before units tended to come with a mic to allow calibration. The 5,1 effects were very noticeable. Far better than a separates system I have also used. That could be down to the AV receiver - Sony. No amp specific speakers.

I was in the middle of experimenting with this type of mounting.Thank you AjohnL

Below some pictures browsing on the net with "Warfdale loudpanel" search

The internal pictures are from oldschoolVlad posted in AudioCircle. I remember now the view of the crimping method of the exciter on the membrane.

View attachment 1229146

I used small cut up pieces of a matchstick and glued them on to the coil foot.

I did not get around to comparing with a similar panel and exciter.

So I have no conclusion 🙄

I have hardly been in my room for the last year or so.😭

I only returned from New York a couple of weeks ago ,and have just got back from North Wales, what a contrast 😃

Steve.

The thing that interests me about them is size and claimed frequency response and gains from larger in the few instances where this has been measured. Music needs to go lower. I have hoped to find out what material was used on the panel. It's stiff, currently I know no more.

I've also wondered if some sort of mid to tweeter arrangement is possible. As dirt cheap used I bought one of these sets.

Rather old, probably misused, worn out so in some respect pass. The tone control is simply a volume control on the woofer. Amp dubious. Playing Heart's Dream Boat Anne and some of her lower register is lost but clear apart from that. The panels are corex. I assume the ribs run along the longer length. That based on a paper that dismantled one. The panel housing have a curved long edge. Metal, panel enclosed but the back is heavily perforated with fairly small holes. This wouldn't help with the tooling up costs needed to make them. What they did may just be down to looks or may have a purpose.

An old thread mentioning dsp's. Fairly fi 2 in 4 out is very cheap these day. Seems recording can be made and software can then sort things out including room effects - LOL how well pass.

https://www.diyaudio.com/community/threads/nxt-exciter-on-mylar-diaphragm.178543/page-2

I've also wondered if some sort of mid to tweeter arrangement is possible. As dirt cheap used I bought one of these sets.

Rather old, probably misused, worn out so in some respect pass. The tone control is simply a volume control on the woofer. Amp dubious. Playing Heart's Dream Boat Anne and some of her lower register is lost but clear apart from that. The panels are corex. I assume the ribs run along the longer length. That based on a paper that dismantled one. The panel housing have a curved long edge. Metal, panel enclosed but the back is heavily perforated with fairly small holes. This wouldn't help with the tooling up costs needed to make them. What they did may just be down to looks or may have a purpose.

An old thread mentioning dsp's. Fairly fi 2 in 4 out is very cheap these day. Seems recording can be made and software can then sort things out including room effects - LOL how well pass.

https://www.diyaudio.com/community/threads/nxt-exciter-on-mylar-diaphragm.178543/page-2

AjohnL.

Post 25 and linked post 16 describe the DML sound pretty well.

They have obviously listened to quality DMLs.

Steve.

https://www.diyaudio.com/community/threads/nxt-exciter-on-mylar-diaphragm.178543/post-2394635

Post 25 and linked post 16 describe the DML sound pretty well.

They have obviously listened to quality DMLs.

Steve.

https://www.diyaudio.com/community/threads/nxt-exciter-on-mylar-diaphragm.178543/post-2394635

Hello Steve,This post reminded me of something I was going to post some time ago but I was put off.

in this patent, you can see the weights 38 in figs 6 -8 and response in fig 9.

https://patents.google.com/patent/U...=priority:19610101&oq=inventor:+A+Cohen++1961

I have made a quick drawing of the way I probably would have implemented this( in the left drawing) using the weight points as mounting points, as usual two for the price of one😁 I love it when that happens 😆

The exciter, panel , and weighting points become one with no edge mounting and damping.

Frames for protection and edge damping points can be added as needed or wanted.

The exciter and panel are supported on the same brace for single point mounting to a stand.

In a modern panel I would probably do something similar to the top drawing .

The panel mounting points ( weighted areas) would be chosen for best performance filling in the dips in response somewhere around the 200hz point of there abouts.

I would probably round the corners as the exciter and mounting points would probably cause excessive visitation in this area.

It turned one of my panels corners into a fan 😧 i had to use a wooden brace to stop the corner vibrating.

Below in the third drawing ,is a small panel I made which was less than 12inches .

I use 4 wooden dowels glued to the panel and supporting frame,and on which the exciter was also mounted.

These 4 dowels extended the response of the panel to somewhere in the 100hz region, this worked for this panel.

I personally do not use these methods for my panels (so far , never say never 😁 ).

But they can be a useful tool for serious problem panels or pro work 😁.

I will not be doing tests as I am happy with my panels as they are.

I will be doing some tests at some time with a similar - ish idea but I'll have to see how it works on a larger panel ( I know it worked on a small panel ) I will have to see?

The picture will be on a following post as I cannot post using my phone 😩 so there will be no words.

Steve.

I am going through the posts of this thread to update the history file (not done since last year October). I found your post. I am not sure to understand your proposal but what is clear for me is the interest in the Cohen biphonic loudspeaker which is the object of the patent you linked. There are electronic World papers about it.

Among the interesting point : the attenuation of the rear wave. Here for the bass response. In an other site, the rear wave is attenuated by 2.5dB. To link also with the bandwidth limitation by Goebel on the rear (4kHz)

To come back to the weights you pointed (n°38 in the patent), it is exactly the content of the paper and patent from Tectonic about BMR : some peaks and dips appear in the FR due to the mass of the voice coil of the exciter which change the modes. This cause an uneven FR. the smooth FR is restored thanks to additional weights (rings in the case of a circular membrane). The Tectonic paper makes an introduction to a method to find the location of the weight (not their mass).The Tectonic patent covers also the case of rectangular plate. The weight from your idea might be too important.

Christian

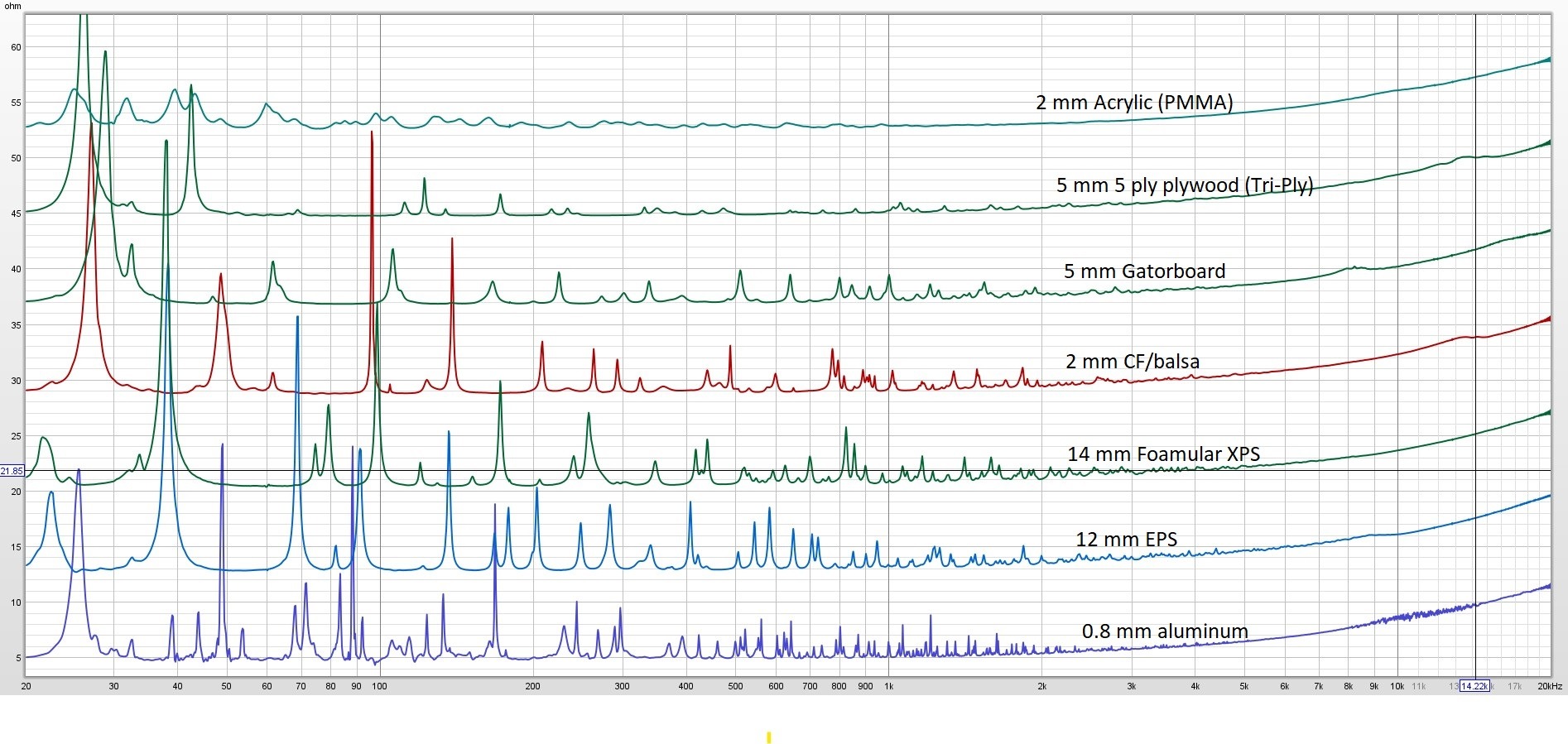

As I mentioned in a previous post, I recently built an impedance rig to allow me to make impedance measurements using REW. In that post I showed that the frequencies of the peaks in the impedance curve correspond to the natural frequencies (resonance frequencies) of the panel.

The results of another set of tests are shown below. Here I measured the impedance curves for various panel materials. All the panels tested were approximately 400 mm x 580 mm, with the same exciter (DA-25FHE) attached near the 40%/40% position. The panels were hung freely from two wires (or tape strips). I would not normally make a "speaker" this way (hanging from strings, without any frame), but the purpose of the test was to examine the materials themselves, without any other influence.

I stacked them in order based on the height and sharpness of the resonance peaks. I think it's pretty reasonable to assume that the sharper and taller the peaks are, the lower the panel material's internal damping is. On that basis, these results seem to show that the acrylic panel has pretty strong damping, followed by the plywood. Interestingly, my CF balsa composite appears to have quite low damping, similar to XPS and EPS. Aluminum, unsurprisingly, appears to have the least damping.

Eric

The results of another set of tests are shown below. Here I measured the impedance curves for various panel materials. All the panels tested were approximately 400 mm x 580 mm, with the same exciter (DA-25FHE) attached near the 40%/40% position. The panels were hung freely from two wires (or tape strips). I would not normally make a "speaker" this way (hanging from strings, without any frame), but the purpose of the test was to examine the materials themselves, without any other influence.

I stacked them in order based on the height and sharpness of the resonance peaks. I think it's pretty reasonable to assume that the sharper and taller the peaks are, the lower the panel material's internal damping is. On that basis, these results seem to show that the acrylic panel has pretty strong damping, followed by the plywood. Interestingly, my CF balsa composite appears to have quite low damping, similar to XPS and EPS. Aluminum, unsurprisingly, appears to have the least damping.

Eric

Thank you Eric for sharing you results. First time we have a material comparison by the impedance measurement.As I mentioned in a previous post, I recently built an impedance rig to allow me to make impedance measurements using REW. In that post I showed that the frequencies of the peaks in the impedance curve correspond to the natural frequencies (resonance frequencies) of the panel.

The results of another set of tests are shown below. Here I measured the impedance curves for various panel materials. All the panels tested were approximately 400 mm x 580 mm, with the same exciter (DA-25FHE) attached near the 40%/40% position. The panels were hung freely from two wires (or tape strips). I would not normally make a "speaker" this way (hanging from strings, without any frame), but the purpose of the test was to examine the materials themselves, without any other influence.

I stacked them in order based on the height and sharpness of the resonance peaks. I think it's pretty reasonable to assume that the sharper and taller the peaks are, the lower the panel material's internal damping is. On that basis, these results seem to show that the acrylic panel has pretty strong damping, followed by the plywood. Interestingly, my CF balsa composite appears to have quite low damping, similar to XPS and EPS. Aluminum, unsurprisingly, appears to have the least damping.

Eric

For XPS, EPS : are thy row or coated as usually recommended for DML use?

For the aluminum, the peaks seem smaller then the EPS, XPS or CF/balsa one. Is it a reading effect?

Christian

Hi Christian.

This was the part of this patent that I was most interested in, at the time.

He found that the mass loading the panel roughly half way between the exciter point and the edge of the panel, filled in the bad dip in the response at 200hz .

This is basically the same method i use to find these points on my small panels, but i use my fingers while watching the response change ,in real time.

it is very simple.

The first part also describes the bowing in the centre of the panel , which i regard as the direct radiating part of the DML panel ( pistonic in nature 😀).

This is where most of the hf above 10k comes from on an EPS panel.

steve.

quote.

When the vibratile system 22 is thus relatively stifiiy clamped, and energized at its central point by voice coil form 18, the vibratile system bows in and out with maximum excursion at the central driven point, and the degree of excursion gradually diminishes towards the peripheral edges. It may be thus generally classified as a clamped piston bowed at the center. It is well known in the art of physical vibrations of membranes that when a clamped membrane is thus energized there are set up various nodes of vibrations with trough and peaks determined by the energizing frequency, by the shape of the diaphragm, and by the physical constants of the material of the membrane. Whereas such nodes of vibrations are relatively well known for standard circular; and homogenous membranes, the determination of such nodes and anti-nodal points can be determined only by approximate empirical methods for other than symmetrically contoured areas. For the type of fiat vibratile systems which has been reduced to practice in this invention where one side of the vibratile system is approximately one and one half times the length of the other, and where the piston overall dimension is approximately 15" X 22", the node of vibration is such that at approximately 200 cycles per second there is a pronounced anti-resonance in the acoustic response of the system as indicated by the dotted curve of FIG. 9

By exploring the vibrations of the panel with a sound probe, it was found that there were anti-nodal points of vibration very nearly equidistant between the furthermost clamped extremities of the panel and the voice coil driving point. To eliminate the anti-nodal vibration areas, it is feasible to load these points with masses of proper weight that will cause the overall modal vibration display to change. The effect of adding these masses 38 (shown in FIG. 8) is to eliminate the pronounced acoustic drop at 200 c.p.s. and to smooth out the overall response curve as a whole as indicated by the solid curve of FIG. 9. This invention thus teaches a method whereby it is possible to improve and make uniform the vibration of irregular piston shapes by probing them acoustically for anti-nodal points, and then mass loading these points to upset their anti-resonance effect.

This was the part of this patent that I was most interested in, at the time.

He found that the mass loading the panel roughly half way between the exciter point and the edge of the panel, filled in the bad dip in the response at 200hz .

This is basically the same method i use to find these points on my small panels, but i use my fingers while watching the response change ,in real time.

it is very simple.

The first part also describes the bowing in the centre of the panel , which i regard as the direct radiating part of the DML panel ( pistonic in nature 😀).

This is where most of the hf above 10k comes from on an EPS panel.

steve.

quote.

When the vibratile system 22 is thus relatively stifiiy clamped, and energized at its central point by voice coil form 18, the vibratile system bows in and out with maximum excursion at the central driven point, and the degree of excursion gradually diminishes towards the peripheral edges. It may be thus generally classified as a clamped piston bowed at the center. It is well known in the art of physical vibrations of membranes that when a clamped membrane is thus energized there are set up various nodes of vibrations with trough and peaks determined by the energizing frequency, by the shape of the diaphragm, and by the physical constants of the material of the membrane. Whereas such nodes of vibrations are relatively well known for standard circular; and homogenous membranes, the determination of such nodes and anti-nodal points can be determined only by approximate empirical methods for other than symmetrically contoured areas. For the type of fiat vibratile systems which has been reduced to practice in this invention where one side of the vibratile system is approximately one and one half times the length of the other, and where the piston overall dimension is approximately 15" X 22", the node of vibration is such that at approximately 200 cycles per second there is a pronounced anti-resonance in the acoustic response of the system as indicated by the dotted curve of FIG. 9

By exploring the vibrations of the panel with a sound probe, it was found that there were anti-nodal points of vibration very nearly equidistant between the furthermost clamped extremities of the panel and the voice coil driving point. To eliminate the anti-nodal vibration areas, it is feasible to load these points with masses of proper weight that will cause the overall modal vibration display to change. The effect of adding these masses 38 (shown in FIG. 8) is to eliminate the pronounced acoustic drop at 200 c.p.s. and to smooth out the overall response curve as a whole as indicated by the solid curve of FIG. 9. This invention thus teaches a method whereby it is possible to improve and make uniform the vibration of irregular piston shapes by probing them acoustically for anti-nodal points, and then mass loading these points to upset their anti-resonance effect.

Christian,Thank you Eric for sharing you results. First time we have a material comparison by the impedance measurement.

For XPS, EPS : are thy row or coated as usually recommended for DML use?

For the aluminum, the peaks seem smaller then the EPS, XPS or CF/balsa one. Is it a reading effect?

Christian

True, the three you mentioned all have one or two peaks that are higher than any of the peaks in the aluminum. I'm not sure I'd put much weight on individual peaks, but still, it is indeed surprising to me that the they are not more differentiated from the aluminum.

The PS foam results I included where uncoated. But I did also test another XPS panel that was coated with several coats (four as I recall) of PVA/water. Unfortunately, it is not a perfect comparison with any other panels as the coated panel was much thicker (25 mm vs 14 mm) and the corners were rounded. Results are shown below with the 25 mm coated/rounded XPS panel in red, and the 14 mm uncoated panel in green.

For the thicker panel, the peaks are fewer within any given frequency band, but that would be expected as the thicker panel is much stiffer, and hence all the natural frequencies are more spread out. But as far as the sharpness of the peaks, the effect of the coating (if any) is not dramatic.

Eric

Hello Steve.Hi Christian.

This was the part of this patent that I was most interested in, at the time.

He found that the mass loading the panel roughly half way between the exciter point and the edge of the panel, filled in the bad dip in the response at 200hz .

This is basically the same method i use to find these points on my small panels, but i use my fingers while watching the response change ,in real time.

it is very simple.

The first part also describes the bowing in the centre of the panel , which i regard as the direct radiating part of the DML panel ( pistonic in nature 😀).

This is where most of the hf above 10k comes from on an EPS panel.

steve.

quote.

When the vibratile system 22 is thus relatively stifiiy clamped, and energized at its central point by voice coil form 18, the vibratile system bows in and out with maximum excursion at the central driven point, and the degree of excursion gradually diminishes towards the peripheral edges. It may be thus generally classified as a clamped piston bowed at the center. It is well known in the art of physical vibrations of membranes that when a clamped membrane is thus energized there are set up various nodes of vibrations with trough and peaks determined by the energizing frequency, by the shape of the diaphragm, and by the physical constants of the material of the membrane. Whereas such nodes of vibrations are relatively well known for standard circular; and homogenous membranes, the determination of such nodes and anti-nodal points can be determined only by approximate empirical methods for other than symmetrically contoured areas. For the type of fiat vibratile systems which has been reduced to practice in this invention where one side of the vibratile system is approximately one and one half times the length of the other, and where the piston overall dimension is approximately 15" X 22", the node of vibration is such that at approximately 200 cycles per second there is a pronounced anti-resonance in the acoustic response of the system as indicated by the dotted curve of FIG. 9

By exploring the vibrations of the panel with a sound probe, it was found that there were anti-nodal points of vibration very nearly equidistant between the furthermost clamped extremities of the panel and the voice coil driving point. To eliminate the anti-nodal vibration areas, it is feasible to load these points with masses of proper weight that will cause the overall modal vibration display to change. The effect of adding these masses 38 (shown in FIG. 8) is to eliminate the pronounced acoustic drop at 200 c.p.s. and to smooth out the overall response curve as a whole as indicated by the solid curve of FIG. 9. This invention thus teaches a method whereby it is possible to improve and make uniform the vibration of irregular piston shapes by probing them acoustically for anti-nodal points, and then mass loading these points to upset their anti-resonance effect.

This patent is a treasure. Thank you for the guidance (reading a patent in English is not my favorite task!).

This extract matches fully with what is explained by Tectonic in its paper introducing the BMR principle. The weights are added at antinodes.

What is funny putting the 2 papers together is the patent propose a practical method :

- Find in the FR the dip

- Play this frequency and find the antinode (place with minimum of emission). Tool : a mic close ot the membrane... or a pipe as just read yesterday as you suggested in a post to detect the source of parasitic noise in an axciter

- Add a mass there (value to be determined by several test)

All of that fill the hole in my understanding : "commercial DML have additional mass, not mine... why?"

Christian

Christian,This extract matches fully with what is explained by Tectonic in its paper introducing the BMR principle. The weights are added at antinodes.

I'm not so sure that is correct. From the Graham Bank BMR patent (https://patentimages.storage.googleapis.com/1d/e6/29/d4bdc6e58aff65/US7916878.pdf):

Here, I understand the "locations" mentioned above to be referring to the locations at which to place weights (or drive means). But here in the patent Bank appears to be saying they should be added at (or near) the nodal lines of the highest mode to be balanced, rather than at antinodes. Or am I missing something?

Eric

Hello Christian."commercial DML have additional mass, not mine... why?"

Christian

Can you explain this quote for me please, I'm not sure what you meant?

A BMR is basically a bending wave panel that goes down to pistonic motion to produce a full range driver , if mounted in a box.

Using your finger's to find the best position for the mass weights is easy , if you have a small panel, not so easy on a large panel.

You can vary your grip from a light gentle touch to a hard pinch.

I try to stay near the edges as moving closer to the exciter can tend to alter the sound too much in the higher regions, in a bad way .

It is difficult to generalise about all panels as they tend react differently.

Steve.

Hmm... Possible I made a link too quickly... but I would surprise that the same problem (dip in the FR) has 2 opposite solutions.Christian,

I'm not so sure that is correct. From the Graham Bank BMR patent (https://patentimages.storage.googleapis.com/1d/e6/29/d4bdc6e58aff65/US7916878.pdf):

View attachment 1231755

Here, I understand the "locations" mentioned above to be referring to the locations at which to place weights (or drive means). But here in the patent Bank appears to be saying they should be added at (or near) the nodal lines of the highest mode to be balanced, rather than at antinodes. Or am I missing something?

Eric

For now, this evening, it is cake cooking for my colleagues tomorrow. I will try to go further in the comparison by the end of the week.

Christian

I have in mind different pictures of commercial DML, starting by Tectonic that have local weights added. Sorry I can't collect the different brand names or pictures now. It is just in my last design that I started to experiment to "finger method" but in this case it is by changing the exciter location (same by looking at the RTA while the panel is playing a pink noise) I found the smoother FR.Can you explain this quote for me please, I'm not sure what you meant?

A BMR is basically a bending wave panel that goes down to pistonic motion to produce a full range driver , if mounted in a box.

So thinking to this old patent (Cohen), the pictures of commercial DML like Tectonic, the BMR where several rings of mass are added to restore the initial modes of a free disc. This solution of added inertia seems quite frequent.

This thread is so long. I was just wondering has someone used DML speakers as surround speakers?

I haven't, but you remind me to pull my finger out and install my rear speakers - after moving house.

--------------------------------------------------------------------------------------------------------------

I think a point worth making re. above measurements & results is that exciters do have

their own natural resonance (Fs) , so results at or below Fs are really quite academic.

The Dayton EX32's I am soon to use have a Fs of 395Hz. This makes it obvious to use a woofer.

( The panel mass will reduce Fs , but how much = variable )

Maybe panel weight is a parameter people should start using ?

I would love to see other peoples information re. other exciters Fs figures. 🙂

--------------------------------------------------------------------------------------------------------------

I think a point worth making re. above measurements & results is that exciters do have

their own natural resonance (Fs) , so results at or below Fs are really quite academic.

The Dayton EX32's I am soon to use have a Fs of 395Hz. This makes it obvious to use a woofer.

( The panel mass will reduce Fs , but how much = variable )

Maybe panel weight is a parameter people should start using ?

I would love to see other peoples information re. other exciters Fs figures. 🙂

Last edited:

Not really, but I have noticed that spatial imaging is fantastic, and use them in a quad setup but with a stereo signal.This thread is so long. I was just wondering has someone used DML speakers as surround speakers?

Sorting out DSP unit and soundcard now so I can do actual surround playback on them since I think they will really shine at that.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker