Covid.

A method I have used in the past which worked quite well ,was to glue something like a 1inch or whatever size xps or wood of whatever is needed to the top part of the panel,then glue a length of wood or whatever,between the xps and exciter.

A half spine as you might say ,this supports the exciter preventing voice coil sag ,wobble,and will be flexible enough to allow for the unavoidable panel warp which a full spine across the panel would not.

The wires can also be run up the half spine.

You could also ,with a bit of imagination use this as one of your mountings.

Obviously you can turn the panel and have it on the bottom.

Steve

A method I have used in the past which worked quite well ,was to glue something like a 1inch or whatever size xps or wood of whatever is needed to the top part of the panel,then glue a length of wood or whatever,between the xps and exciter.

A half spine as you might say ,this supports the exciter preventing voice coil sag ,wobble,and will be flexible enough to allow for the unavoidable panel warp which a full spine across the panel would not.

The wires can also be run up the half spine.

You could also ,with a bit of imagination use this as one of your mountings.

Obviously you can turn the panel and have it on the bottom.

Steve

Last edited:

frequency response of my panels

Hello again,

Here is my data of the ASX05408-HD-R exciter movement measured with a MTI non-contact capacitive probe that measurers physical displacement. Here is the link to the technology page:

I have the exciter point up on a metal base and the probe is 2mm above the ground plate. From this data I think that the effect one sees is more piston movement than Surface Acoustic Waves . Not sure that any of the small exciters can produce enough power to distort the panels in any meaningful way. The piston makes more sense in my mind since it is just F=ma and that can easily explain way plywood in not as loud as foam boards because of the mass one has to drive. The data also helps explain the HF drop off that the driver has to the panel.

Cheers

Steve

Hello again,

Here is my data of the ASX05408-HD-R exciter movement measured with a MTI non-contact capacitive probe that measurers physical displacement. Here is the link to the technology page:

I have the exciter point up on a metal base and the probe is 2mm above the ground plate. From this data I think that the effect one sees is more piston movement than Surface Acoustic Waves . Not sure that any of the small exciters can produce enough power to distort the panels in any meaningful way. The piston makes more sense in my mind since it is just F=ma and that can easily explain way plywood in not as loud as foam boards because of the mass one has to drive. The data also helps explain the HF drop off that the driver has to the panel.

Cheers

Steve

Attachments

DML OB

That is 3/4 inch thick plexi which I got at a commercial window glass company. The holes were machined on a CNC milling machine. Why plexi? I have a small listening area and wanted them to feel and look transparent. I also wanted to be able to switch out drivers without making a new huge OB panel. The black stands came from a Israeli company and are no longer made. I like this setup because I can switch any driver for any other type, make or brand when experimenting. Why the plexi DML’s? I tried XPS and was disappointed with extension above 8 k. I had several plexiglass sheets in .25, .125 and .375 thicknesses. After trying them I liked the .25 best. It seemed to have much better high end extension informally evaluated with a FFT and my ear. Thicker panel were progressively harder to drive. Plexi is not loud with with our low power exciters. I don’t have the ability to measure dB/W efficiency but since I biamp it is very easy to turn up the preamp volume and turn down the bass end of the crossover to compensate. I plan to use digital correction when I get it set up and will post results.

Dave, that's ridonkulously cool. Where do you get that plexiglass?

That is 3/4 inch thick plexi which I got at a commercial window glass company. The holes were machined on a CNC milling machine. Why plexi? I have a small listening area and wanted them to feel and look transparent. I also wanted to be able to switch out drivers without making a new huge OB panel. The black stands came from a Israeli company and are no longer made. I like this setup because I can switch any driver for any other type, make or brand when experimenting. Why the plexi DML’s? I tried XPS and was disappointed with extension above 8 k. I had several plexiglass sheets in .25, .125 and .375 thicknesses. After trying them I liked the .25 best. It seemed to have much better high end extension informally evaluated with a FFT and my ear. Thicker panel were progressively harder to drive. Plexi is not loud with with our low power exciters. I don’t have the ability to measure dB/W efficiency but since I biamp it is very easy to turn up the preamp volume and turn down the bass end of the crossover to compensate. I plan to use digital correction when I get it set up and will post results.

Covid.

A method I have used in the past which worked quite well ,was to glue something like a 1inch or whatever size xps or wood of whatever is needed to the top part of the panel,then glue a length of wood or whatever,between the xps and exciter.

A half spine as you might say ,this supports the exciter preventing voice coil sag ,wobble,and will be flexible enough to allow for the unavoidable panel warp which a full spine across the panel would not.

The wires can also be run up the half spine.

Hey, this was my idea first! Have to be honest, I have not ever tried this, but it is an idea I have considered and think has great merit. Some believe that the spine gives the exciter something to push against, but I don't think this is its true effect. I've compared spine/no spine before and seen little difference. But I do think that over time, voice coil sag could have a real effect. And some panels that otherwise work really well (plywood!) have a tendency to warp. But a rigid spine attached to a frame on two sides won't be able to accommodate much panel warp without distorting the voice coil. But a spine attached at only one side, especially if it's attached to the frame with a flexible attachment (say foam tape), should be able to accommodate warp and still be able to support the weight of the exciter and prevent sag.

Damn you for disclosing my patent! (kidding)

Eric

Covid.

A method I have used in the past which worked quite well ,was to glue something like a 1inch or whatever size xps or wood of whatever is needed to the top part of the panel,then glue a length of wood or whatever,between the xps and exciter.

A half spine as you might say ,this supports the exciter preventing voice coil sag ,wobble,and will be flexible enough to allow for the unavoidable panel warp which a full spine across the panel would not.

The wires can also be run up the half spine.

You could also ,with a bit of imagination use this as one of your mountings.

Obviously you can turn the panel and have it on the bottom.

Steve

Steve, thank you, this is a great suggestion.

Does this look more or less like your proposal?

Covid.

A method I have used in the past which worked quite well ,was to glue something like a 1inch or whatever size xps or wood of whatever is needed to the top part of the panel,then glue a length of wood or whatever,between the xps and exciter.

A half spine as you might say ,this supports the exciter preventing voice coil sag ,wobble,and will be flexible enough to allow for the unavoidable panel warp which a full spine across the panel would not.

The wires can also be run up the half spine.

You could also ,with a bit of imagination use this as one of your mountings.

Obviously you can turn the panel and have it on the bottom.

Steve

Or like this

Attachments

Tagis.

A photo of two would help to understand your tests,not sure what or where you are measuring?

I'm a bit dense myself this morning.

Veleric.

My first large thin cardboard panels used masking tape stretched from the top of the panel to the exciter,I had to do this as I only had ordinary double sided tape to stick the exciter onto the panel.

With this method of taking the weight of the exciter off the double sided tape ,the exciter would stay stuck to the panel for ages , but the masking tape did buzz a bit if I it didn't have some strips of foam attached.

My patent I think😀

Covid.

Yes this could work ,I wouldn't get too close to the exciter with the spacer,I originally thought you would have your exciter in a offset central area and would have a wooden spacer on the edge of the panel.

If it's a ply panel you are using ,xps for the spacer and the bridge might be a good idea ,so as to minimise the effects on the panel ,especially if you are you are mounting your spacer close to your exciter

Actually one of my patents ,sorry,ideas,was to find one of the favourable resonant positions on the panel ,usually somewhere between the length of the panel and the exciter,placing a wooden spacer here would have a positive effect (getting rid of a suckout)not a negative effect.

In your picture ,I'd have the exciter at the top end with the spacer on the top edge,of course the panel can be turned upside down with no I'll effects,but lying it on it's side could cause the bridge to sag.

Getting a bit too involved here.

Steve

A photo of two would help to understand your tests,not sure what or where you are measuring?

I'm a bit dense myself this morning.

Veleric.

My first large thin cardboard panels used masking tape stretched from the top of the panel to the exciter,I had to do this as I only had ordinary double sided tape to stick the exciter onto the panel.

With this method of taking the weight of the exciter off the double sided tape ,the exciter would stay stuck to the panel for ages , but the masking tape did buzz a bit if I it didn't have some strips of foam attached.

My patent I think😀

Covid.

Yes this could work ,I wouldn't get too close to the exciter with the spacer,I originally thought you would have your exciter in a offset central area and would have a wooden spacer on the edge of the panel.

If it's a ply panel you are using ,xps for the spacer and the bridge might be a good idea ,so as to minimise the effects on the panel ,especially if you are you are mounting your spacer close to your exciter

Actually one of my patents ,sorry,ideas,was to find one of the favourable resonant positions on the panel ,usually somewhere between the length of the panel and the exciter,placing a wooden spacer here would have a positive effect (getting rid of a suckout)not a negative effect.

In your picture ,I'd have the exciter at the top end with the spacer on the top edge,of course the panel can be turned upside down with no I'll effects,but lying it on it's side could cause the bridge to sag.

Getting a bit too involved here.

Steve

Davelang.

That looks like a well balanced exciter,jmc guitars ! mmmmm haven't seen that one around,you would obviously still have to be very careful with the type of wires and placement.

On my small light panels ,to an extent balance isn't a problem as the panel hangs off of the exciter .

Steve

That looks like a well balanced exciter,jmc guitars ! mmmmm haven't seen that one around,you would obviously still have to be very careful with the type of wires and placement.

On my small light panels ,to an extent balance isn't a problem as the panel hangs off of the exciter .

Steve

Pictures

Burnsville

Accidentally found some old photos on a first generation kindal,the picture quality would you believe,looks better,but it only has a camera on the screen side,hence my nut getting in the way.

No doubt you'll be seeing a lot more of that full set of golden locks!!!

This was some early experiments,large cling film on the panels ,i didn't think that worked well ,plus,the small paper strip, and at the time , the blu-tack to lower the oil can hump which spanned from 10k to 20k on this panel,if I remember correctly.

Thought I'd put these out there to give you an idea of what I was doing,hopefully I can get in my room and do some tests on this very panel.

Steve

Burnsville

Accidentally found some old photos on a first generation kindal,the picture quality would you believe,looks better,but it only has a camera on the screen side,hence my nut getting in the way.

No doubt you'll be seeing a lot more of that full set of golden locks!!!

This was some early experiments,large cling film on the panels ,i didn't think that worked well ,plus,the small paper strip, and at the time , the blu-tack to lower the oil can hump which spanned from 10k to 20k on this panel,if I remember correctly.

Thought I'd put these out there to give you an idea of what I was doing,hopefully I can get in my room and do some tests on this very panel.

Steve

Attachments

Burntcoil.

I thought I should explain the difference in sound that a strip of paper makes as it is not massive like adding large amounts of volume.

The recording I posted of the piano playing with recordings made in a tropical wood,is a good example.

I'm not sure if it was that exact track I was listening to,but this is my impressions of what I heard.

Without the strip I could here the water trickle and a bird making strange noises in the distance.

With the strip,the water seems to come alive,you could almost put your hand out and touch it.

The bird was still making the same odd tropical bird sound,(you can tell I know nothing about feathered birds,or any other types come to that) but now you could make out the reverberations through the tree's ,the sound went up and away ,way into the distance.

It was this spacial atmosphere and delicacy that I felt was missing from my ply panels,and the podiums,and heavy panels in general.

These low level sounds sounded cleaner and clearer with more realism as if you were there.

To be honest ,the first time I heard this CD on my eps panels I could not believe the clarity and realism of the trickling water,dml produces natural sounds so effortlessly.

Not just light delicate sounds,I have a test cd with close up machine gun fire!!!

I now know what it would be like to fire a machine gun in my room,a friend of my wife's who put his head round the door in disbelief said he could feel his teeth rattling in his head.

I'd also just like to make a point,that I don't just think this is a mutual conduction between the panel and the strip of paper like a passive ribbon,covering the whole exciter area doesn't work,specially.

At some point when sliding the paper across the exciter area there seems to be some sort of cancellation of the cancellations (General noise) going on in the centre coil area.

I have used this knowledge to help me deal with the problems on my lighter panels but in a different way.

Steve

I thought I should explain the difference in sound that a strip of paper makes as it is not massive like adding large amounts of volume.

The recording I posted of the piano playing with recordings made in a tropical wood,is a good example.

I'm not sure if it was that exact track I was listening to,but this is my impressions of what I heard.

Without the strip I could here the water trickle and a bird making strange noises in the distance.

With the strip,the water seems to come alive,you could almost put your hand out and touch it.

The bird was still making the same odd tropical bird sound,(you can tell I know nothing about feathered birds,or any other types come to that) but now you could make out the reverberations through the tree's ,the sound went up and away ,way into the distance.

It was this spacial atmosphere and delicacy that I felt was missing from my ply panels,and the podiums,and heavy panels in general.

These low level sounds sounded cleaner and clearer with more realism as if you were there.

To be honest ,the first time I heard this CD on my eps panels I could not believe the clarity and realism of the trickling water,dml produces natural sounds so effortlessly.

Not just light delicate sounds,I have a test cd with close up machine gun fire!!!

I now know what it would be like to fire a machine gun in my room,a friend of my wife's who put his head round the door in disbelief said he could feel his teeth rattling in his head.

I'd also just like to make a point,that I don't just think this is a mutual conduction between the panel and the strip of paper like a passive ribbon,covering the whole exciter area doesn't work,specially.

At some point when sliding the paper across the exciter area there seems to be some sort of cancellation of the cancellations (General noise) going on in the centre coil area.

I have used this knowledge to help me deal with the problems on my lighter panels but in a different way.

Steve

@Spedge,

Hi Steve

Its a very interesting addition to the DML toolbox and something I can and will experiment with. There is energy going into the Spedge-Passively-Augmented-Transducer ( SPAT. TM...probably) and so it must have some effect like the passive or, inelegant term, parasitic cones added to full range drivers.

As its close to the exciter and very low mass it will be easily excited. As it has a relatively large surface area we can assume good coupling with the air, so its going to be quite efficient at converting exciter energy into sound. Just where we would be in terms of whether it is adding to the signal, subtracting from the signal due to phase differences I have no absolutely no idea but any two vibrating surfaces in very close proximity must couple in some way.

Intriguing!

Burnt

P.S. I tend to avoid tropical birds. I have heard they are very expensive to run

Hi Steve

Its a very interesting addition to the DML toolbox and something I can and will experiment with. There is energy going into the Spedge-Passively-Augmented-Transducer ( SPAT. TM...probably) and so it must have some effect like the passive or, inelegant term, parasitic cones added to full range drivers.

As its close to the exciter and very low mass it will be easily excited. As it has a relatively large surface area we can assume good coupling with the air, so its going to be quite efficient at converting exciter energy into sound. Just where we would be in terms of whether it is adding to the signal, subtracting from the signal due to phase differences I have no absolutely no idea but any two vibrating surfaces in very close proximity must couple in some way.

Intriguing!

Burnt

P.S. I tend to avoid tropical birds. I have heard they are very expensive to run

Burntcoil.

The exciter had fallen off the tall panel ,then I spotted a 7inch square cc board with flaps ,which was 2mm thick ,so for a laugh I hooked it up.

Same principle.

Turned out not so easy to move the strip about as the panel kept moving about as I was trying to look at the deq ,microphone and strip at the same time 😕 and also the tape sticking to me and not the panel !!

It only takes a movement of a few mm to alter this response ,so with time maybe I could improve on this.

But as you see in the first deq pic from the left,there is a rising response from about 8 to 10k where there is a dip, the size and shape changes with different panels.

In the next pic you can see the response in the 8k to 10k region has increased and also we'll beyond 10k,the rising HF has been subdued.

This was why I was hoping you had a good response up to 10k , don't know how your eqing will affect this?

The 1inch strip is only half way across the 1inch exciter area !!

On some panels I have gone just over the half way point so this can change from panel and materials?

I do remember using one piece of tape and a shorter piece of paper about an inch or so but didn't follow up on this,I was more interested in my other panels.

I will see if I can do better on the ply panel.

Steve

The exciter had fallen off the tall panel ,then I spotted a 7inch square cc board with flaps ,which was 2mm thick ,so for a laugh I hooked it up.

Same principle.

Turned out not so easy to move the strip about as the panel kept moving about as I was trying to look at the deq ,microphone and strip at the same time 😕 and also the tape sticking to me and not the panel !!

It only takes a movement of a few mm to alter this response ,so with time maybe I could improve on this.

But as you see in the first deq pic from the left,there is a rising response from about 8 to 10k where there is a dip, the size and shape changes with different panels.

In the next pic you can see the response in the 8k to 10k region has increased and also we'll beyond 10k,the rising HF has been subdued.

This was why I was hoping you had a good response up to 10k , don't know how your eqing will affect this?

The 1inch strip is only half way across the 1inch exciter area !!

On some panels I have gone just over the half way point so this can change from panel and materials?

I do remember using one piece of tape and a shorter piece of paper about an inch or so but didn't follow up on this,I was more interested in my other panels.

I will see if I can do better on the ply panel.

Steve

Attachments

I was wondering how do you guys reattach the exciter once you want to move it? Would something of this kind work?

various 3M VHB™ PADS Self Adhesive DOUBLE SIDED Sticky Tape ~ CLEAR, BLACK, GREY | eBay

various 3M VHB™ PADS Self Adhesive DOUBLE SIDED Sticky Tape ~ CLEAR, BLACK, GREY | eBay

From your response results it could be something really simple like damping out an unwanted resonance. I will see if I can replicate the effect. It will take a few days as I'll have to see

how I can measure the effect using REW. Plus my little bird of paradise has given me a list!

Burnt.

how I can measure the effect using REW. Plus my little bird of paradise has given me a list!

Burnt.

First panel making sound

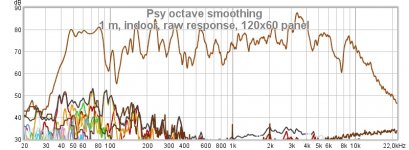

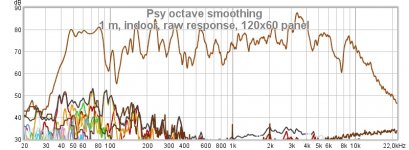

I like unconventional speakers, so when I saw this thread I felt like I had to try. After some communication with BurntCoil (thanks!) I ended up with a 120x60 cm panel from 4 mm pine plywood. I had it stained as I was staining other stuff at the moment (broom sticks for my daughters Harry Potter party):

I tried moving the exciter (Dayton DAEX32EP) around, but didn't hear any obvious differences, so I just chose a slightly off-center position and removed the protective strip from the adhesive. The panel is clamped at the bottom between two 45x70 mm studs (is that the correct word?) with some EPDM strips in between.

The sound is really nice with acoustic music, although it does lack the top octave (sizzle from cymbals and s-sounds from vocals). For electronic music and rock I feel they are a bit to "slow", i.e. the sounds are too long. I'm surprised that the panels reach so low. Here is the raw response (indoors):

If the weather allows it I'll make some outdoor measurements tomorrow.

Any hints on how to increase output above 10 kHz? Secondary small panel where the exciter is mounted? Treatment of plywood (lacquer)?

/Anton

I like unconventional speakers, so when I saw this thread I felt like I had to try. After some communication with BurntCoil (thanks!) I ended up with a 120x60 cm panel from 4 mm pine plywood. I had it stained as I was staining other stuff at the moment (broom sticks for my daughters Harry Potter party):

I tried moving the exciter (Dayton DAEX32EP) around, but didn't hear any obvious differences, so I just chose a slightly off-center position and removed the protective strip from the adhesive. The panel is clamped at the bottom between two 45x70 mm studs (is that the correct word?) with some EPDM strips in between.

The sound is really nice with acoustic music, although it does lack the top octave (sizzle from cymbals and s-sounds from vocals). For electronic music and rock I feel they are a bit to "slow", i.e. the sounds are too long. I'm surprised that the panels reach so low. Here is the raw response (indoors):

If the weather allows it I'll make some outdoor measurements tomorrow.

Any hints on how to increase output above 10 kHz? Secondary small panel where the exciter is mounted? Treatment of plywood (lacquer)?

/Anton

Onni.

Your panels have reached higher than most using this exciter.

You could try my strip of paper trick and see if it brings a bit of sparkle back.

Panel resonance.

You could be suffering from strong standing waves from top to bottom ,an easy way to offset this would be to tilt the panel in the bottom vice (easy way) so there isn't any parallel sides top to bottom,or saw the top off at an angle 😱

Or clamp the panel higher up on one side if you think it looks odd.

Tagis.

To be honest I don't understand what you are trying to show,it could be me being a bit dense,but.

Looking at the plot ,all I can see is low frequencies produce large movements and high frequencies produce small movements?Standard coil motions?

Burntcoil.

Oh dear,the dreaded LIST.....!!!

Your panels have reached higher than most using this exciter.

You could try my strip of paper trick and see if it brings a bit of sparkle back.

Panel resonance.

You could be suffering from strong standing waves from top to bottom ,an easy way to offset this would be to tilt the panel in the bottom vice (easy way) so there isn't any parallel sides top to bottom,or saw the top off at an angle 😱

Or clamp the panel higher up on one side if you think it looks odd.

Tagis.

To be honest I don't understand what you are trying to show,it could be me being a bit dense,but.

Looking at the plot ,all I can see is low frequencies produce large movements and high frequencies produce small movements?Standard coil motions?

Burntcoil.

Oh dear,the dreaded LIST.....!!!

Raph.

If you want to do short term testing of different panels, the method I used was to use masking tape to support the weight of the exciter magnet , suspended from the top edge of the panel.

You could use any bog standard roll of double sided tape to hold the coil to the panel short term ,I also used foam on the masking tape to stop LF buzzing noises,if using down that low.

Not sure of the weight of this exciter but the lower grades of eps would have problems supporting the weight of an unsupported exciter, literally ripping the polystyrene off of the panel.

And have some sort padding on the floor should the exciter falls.

Of course you could use the lead out wires to support the weight of the exciter.

This is what I used to do as I was always swapping panels,but my exciters only weighed 85grm.

Steve

If you want to do short term testing of different panels, the method I used was to use masking tape to support the weight of the exciter magnet , suspended from the top edge of the panel.

You could use any bog standard roll of double sided tape to hold the coil to the panel short term ,I also used foam on the masking tape to stop LF buzzing noises,if using down that low.

Not sure of the weight of this exciter but the lower grades of eps would have problems supporting the weight of an unsupported exciter, literally ripping the polystyrene off of the panel.

And have some sort padding on the floor should the exciter falls.

Of course you could use the lead out wires to support the weight of the exciter.

This is what I used to do as I was always swapping panels,but my exciters only weighed 85grm.

Steve

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker