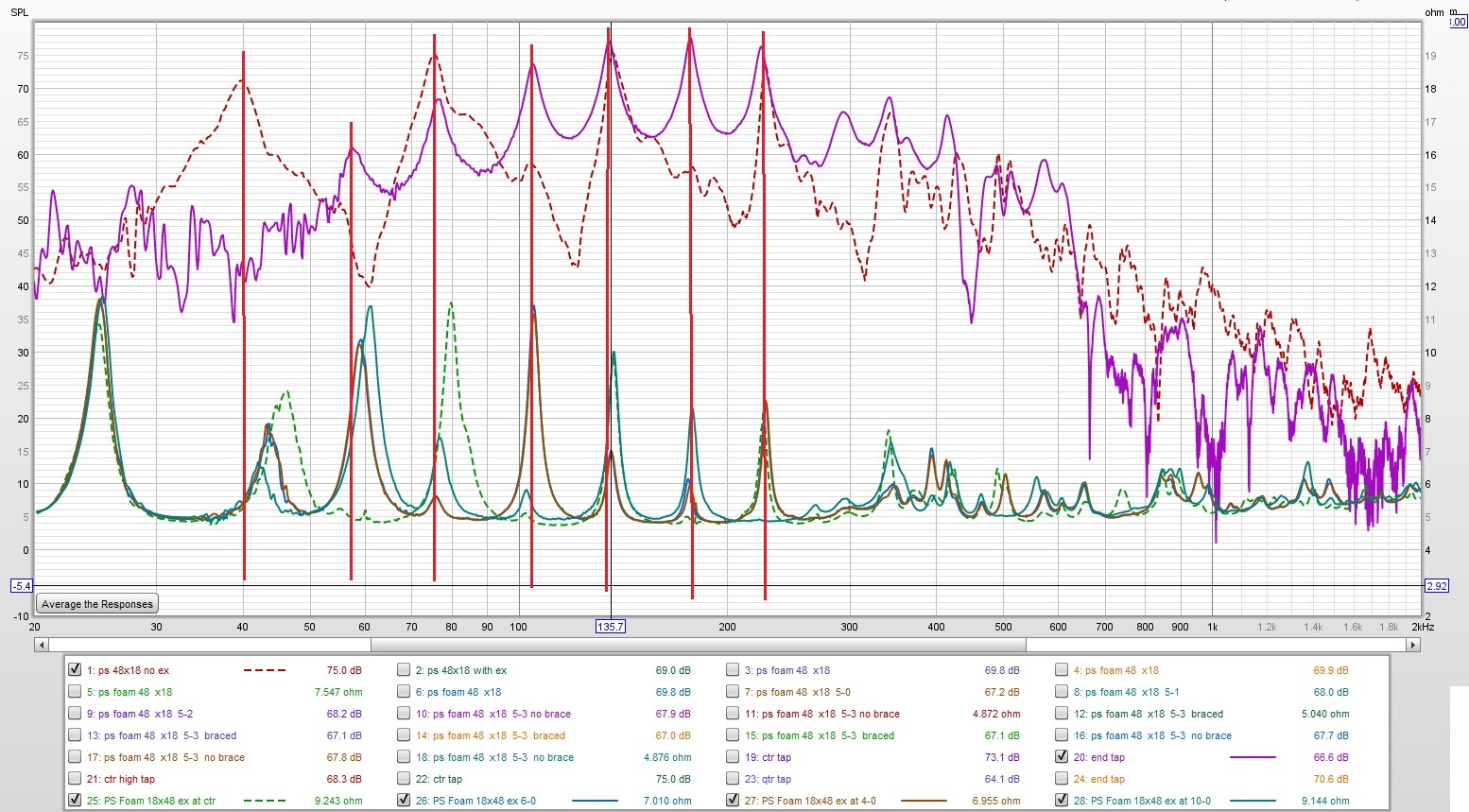

Hello Eric,Below are the results of a second test that I just performed, comparing SPL and impedance curves with and without a brace supporting the exciter. In the new test, I used a panel with a much lower fundamental frequency (about 43 Hz) than the panel in the previous test (about 100 Hz). The panel in the new tests is a 48"x18" panel of 14 mm thick XPS.

The dashed lines are the results with no brace, and the solid lines are the results with the brace. As in the previous test, the addition of the brace eliminates the impedance peak associated with exciter's mass and spider (at about 25 Hz in this case). Interestingly, the addition of the braces reduces height of the first several panel resonances as well.

Concerning the SPL, there appears to be some increase in bass output without the brace, particularly below about 60 Hz. In the previous test there was a similar (but much smaller) effect.

For me, evidence is building that the addition of brace does not increase bass output, but rather may actually decrease it. That said, I wouldn't consider the elimination of the brace to be a meaningful improvement to this panel, as to me this panel is really only "useable" above about 200 Hz (if at all).

View attachment 1241084

These results demonstrate another thing that I've observed fairly consistantly (but has nothing to do with the brace). Which is that if I build a panel with a fundamental frequency of about 80 Hz or higher, there is a chance (with the right aspect ratio, right suspension and right exciter placement) that the SPL response can be reasonably flat above the panel's fundamental frequency up to at least 5 kHz (or even 15 kHz). But If I build a panel with a lower fundamental frequency, I inevitably end up with a big gap in the frequency response between the fundamental and about 150 to 200 Hz. So while tuning the panel lower allows significant bass output, it's not what I consider "useful" output, The present panel is a good example of that, with the large dip in output between about 50 and 200 Hz. For this reason I've pretty muched stopped even trying panels like this where the fundamental is below about 80 Hz.

Eric

Happy to see you have a great use of the impedance measurement jig!

For now, my hypothesis is the height of the impedance peaks is driven by the damping. We could imagine when the magnet is free, the damping from the exciter (spider, voice coil suspension) can't fully played... just an hypothesis.

More puzzling to me is the peak just above 100Hz. The peak is important (low damping?) and the level low. In addition, your experience says when the panel is smaller, the bandwidth to the low frequency is lower (less LF) but the hole disappear which seems to say it is not a simple "translation" following mode but something happened that mask this hole.

Do you have clue/explanation about it?

Have you tried to see which mode is playing here?

In previous exchange with Steve, an hypothesis for this hole was a link with the environment like the floor. Have you tried in different speaker or mic height?

Anyway excellent demonstration!

Christian

Hi Christian.

The problem with the dip in the response in the 100hz to 300hz is not only in the room but also on the panel itself .

This is why I use my TLs to fill in this area, no matter where I roll off the panels.

Not all panels suffer this problem so generalizing is a bit of a problem.

Steve.

The problem with the dip in the response in the 100hz to 300hz is not only in the room but also on the panel itself .

This is why I use my TLs to fill in this area, no matter where I roll off the panels.

Not all panels suffer this problem so generalizing is a bit of a problem.

Steve.

Eric.

It would be good to compare the crate ply panels i have with this new ply, even though it is a bit shoddy.

Although my glued together crate panel is pretty shoddy too.

I was hoping it was a single ply core, so that I could test out the theory of having two different flexibilities in different directions.

This is something for the future when I get around to it.

I have hidden the panel behind the curtains with all the other panels, out of sight and out of mind of my wife 🤣

She will never notice 🤫

Steve.

It would be good to compare the crate ply panels i have with this new ply, even though it is a bit shoddy.

Although my glued together crate panel is pretty shoddy too.

I was hoping it was a single ply core, so that I could test out the theory of having two different flexibilities in different directions.

This is something for the future when I get around to it.

I have hidden the panel behind the curtains with all the other panels, out of sight and out of mind of my wife 🤣

She will never notice 🤫

Steve.

Christian,Hello Eric,

Happy to see you have a great use of the impedance measurement jig!

For now, my hypothesis is the height of the impedance peaks is driven by the damping. We could imagine when the magnet is free, the damping from the exciter (spider, voice coil suspension) can't fully played... just an hypothesis.

More puzzling to me is the peak just above 100Hz. The peak is important (low damping?) and the level low. In addition, your experience says when the panel is smaller, the bandwidth to the low frequency is lower (less LF) but the hole disappear which seems to say it is not a simple "translation" following mode but something happened that mask this hole.

Do you have clue/explanation about it?

Have you tried to see which mode is playing here?

In previous exchange with Steve, an hypothesis for this hole was a link with the environment like the floor. Have you tried in different speaker or mic height?

Anyway excellent demonstration!

Christian

Now that I have the impedance jig, I use it in parallel with just about every SPL measurement I take. As it turns out, the information from the impedance test is very similar to that from my tap tests. That is, the peaks in the response (in either case) correspond to the natural frequencies of the panel. Also, like in the tap test, the driving location is very important.

That is, in the tap test, as you recall, if I tap a location on a panel that is at an antinode for a particular mode, there will be a peak in the SPL response (close mic) at the frequency of that mode. But if I tap at an antinode for that same mode, there will be no peak in the SPL at the corresponding frequency.

The same thing happens in the impedance test, when you move the exciter around. See below the impedance test results (solid lines) for the same PS foam panel, with the exciter at four different locations on the panel. In each curve (offset for clarity), the peaks occur at (nearly) the same frequency, but the size of the peak varies. The peak at the lowest frequency (25 Hz) is always the same, because that's the resonance of the exciter itself. But the peaks at about 45, 60, 75, 105 Hz, etc, all vary in height depending on the location of the exciter. These peaks are the 1,1 and 1,2 and 1,3 and 1,4 modes of the panel. Note that the 1,2 (60Hz) and 1,4 (105 Hz) and 1,6 (175 hz) impedance peaks all disappear in the green curve at the bottom. That curve corresponds to the exciter at the very center of the panel, which is node for all of those (1,even) modes. Hence, those modes are not activated, and no peak in the impedance is evident.

Do note that the impedance peaks (especially for the fundamental at around 45 Hz) do shift around in frequency a bit. This is the effect of the exciter itself on the panel's natural frequencies. In the tap test (no exciter), the fundamental appears at about 40 Hz, so the presence of the exciter shifts it higher by up to about 6Hz (exciter at center). Note also that for the higher frequency modes, the influence of the exciter location on the frequency at which peak occurs is diminished. For example, for the 1,5 mode at 136 Hz, the peak occurs within +/-1 Hz regardless of the exciter location.

Regarding the "hole" in the SPL between 50 and 200 Hz: I have no doubt there is some effect of room modes. I have convinced myself that the room has a mode at about 120Hz, and that dip is evident for this panel as well. I'd have to do some more investigation to test if the rest of the dip could be the result of other room modes....

Eric

This plot compares two tap test results (the upper curves, without exciter)), with impedance test results for the same panel with the exciter at varous locations. The correlation is hard to ignore. For the lowest frequency peaks, the natural frequencies in the impedance results are at slightly higher frequency than the corresponding peaks in the tap test (due to the influence of the exciter mass and stiffness). But at higher frequency modes the natural frequencies are virtually identical in the two tests.

So both tests provide very similar information. Tap testing is a little better for fitting and refining my finite element models of panels and estimating their elastic properties, because no exciter is needed, and it's much quicker to simply tap/mic different locations on the panel than it is to remove and reattach an exciter.

But the impedance curves have a nice flat baseline which makes plotting easier, and have less noise in the data at the extremes of the frequency range. So both tests have their place.

Eric

So both tests provide very similar information. Tap testing is a little better for fitting and refining my finite element models of panels and estimating their elastic properties, because no exciter is needed, and it's much quicker to simply tap/mic different locations on the panel than it is to remove and reattach an exciter.

But the impedance curves have a nice flat baseline which makes plotting easier, and have less noise in the data at the extremes of the frequency range. So both tests have their place.

Eric

The measurement software (REW) is free even without buying the microphone!

The software can be used with any microphone that you can interface with your pc. But a usb mic like the umik-1 is probably the easiest to integrate.

The software can be used with any microphone that you can interface with your pc. But a usb mic like the umik-1 is probably the easiest to integrate.

kind of interesting, if I understand correctly, I'm picturing a piezoelectric sheet between 2 layers of mesh and the piezo sheet can only vibrate where the holes in the mesh are. So the vibrating points don't move about the panel. I wonder how "off axis" it sounds, compared to DML.

Hello Eric,This plot compares two tap test results (the upper curves, without exciter)), with impedance test results for the same panel with the exciter at varous locations. The correlation is hard to ignore. For the lowest frequency peaks, the natural frequencies in the impedance results are at slightly higher frequency than the corresponding peaks in the tap test (due to the influence of the exciter mass and stiffness). But at higher frequency modes the natural frequencies are virtually identical in the two tests.

So both tests provide very similar information. Tap testing is a little better for fitting and refining my finite element models of panels and estimating their elastic properties, because no exciter is needed, and it's much quicker to simply tap/mic different locations on the panel than it is to remove and reattach an exciter.

But the impedance curves have a nice flat baseline which makes plotting easier, and have less noise in the data at the extremes of the frequency range. So both tests have their place.

Eric

Thank you for those very informative posts.

I think we could explain the shift in frequency between tap test and impedance measurement by the local mass, stiffness and damping the exciter adds locally to the panel.

So for extracting data to feed FEM, tap test is probably more accurate. I should restart soon the FDM simulation of DML (I am in a renewal phase of my computer, the set up to have the tools correctly installed and organized is almost finished). This is something FDM allows to simulate with the view of the impedance curve.

I was thinking about method to make the difference between effects of modes of the panel and effects of the room. A way might be to play a known pistonic speaker at the same place in the room (the pistonic speaker doesn't suffer by itself of modes, its FR can be measured in close proximity). The point to check is the effect of the radiation on the result. If the pistonic speaker is in a box (closed or vented), it is at those frequencies a monopole where the DML is a dipole. A reference Open Baffle speaker would be probably better... under the condition it goes low enough without strange effect on the FR due to its baffle (my knowledge about OB are limited).

Christian

Been refining my solution for suspending the exciters, and seems to work well in that there is no distortion from misalignment and sensitivity is fine.

However it seems like with many of my exciters the damage from sagging is already done, and getting some distortion on high levels that wasn't there earlier, and which is not affected by the suspension/bracing as before.

So now I need to figure out which exciters are still ok, which is a little bit tricky. I guess I can do it using another plate material that dosen't get damaged when removing exciter, but quite a lot of work for 64 exciters 🙁

I'm wondering though if the distortion due to sagging is a design issue with the Dayton exciters, and if the lack of a mounting hole on the Xcite XT32-4 is an indication that they will not suffer the same issue. I would hate to have to replace all my exciters, but also a little bit fed up with trying to make a good suspension and having to ensure exciters has not sagged.

However it seems like with many of my exciters the damage from sagging is already done, and getting some distortion on high levels that wasn't there earlier, and which is not affected by the suspension/bracing as before.

So now I need to figure out which exciters are still ok, which is a little bit tricky. I guess I can do it using another plate material that dosen't get damaged when removing exciter, but quite a lot of work for 64 exciters 🙁

I'm wondering though if the distortion due to sagging is a design issue with the Dayton exciters, and if the lack of a mounting hole on the Xcite XT32-4 is an indication that they will not suffer the same issue. I would hate to have to replace all my exciters, but also a little bit fed up with trying to make a good suspension and having to ensure exciters has not sagged.

Leob.

In my experience, there are many different reasons why an exciter can start to sound distorted. Yes the spider could have sagged, and turning the panel upside-down could correct this problem for a while.

The exciter wobble or sag could have caused damage to the coil or shorting some coils out.

Or some of the coils could have come loose, from heat or overpowering.

Other problems could be the bond to the panel and foot could be starting to come loose, this can happen slowly over time, until it is slowly pict up.

Also the actual panel could be breaking up , the eps beads could be coming apart under stress from the coil foot.

A high grade eps panel would probably be a better choice, and be more robust.

I have also had many exciter feet come loose.

The coil can also come loose from the spider or even from the outer ring of the spider.

Basically anything glued together could be coming apart.

Also the exit of the coil leads could have come loose or broken.

The problem is that all these faults tend to sound the same to start with, usually only over time when they become far worse , can you finally trace them easily.

Hope this is of some help.

Steve

In my experience, there are many different reasons why an exciter can start to sound distorted. Yes the spider could have sagged, and turning the panel upside-down could correct this problem for a while.

The exciter wobble or sag could have caused damage to the coil or shorting some coils out.

Or some of the coils could have come loose, from heat or overpowering.

Other problems could be the bond to the panel and foot could be starting to come loose, this can happen slowly over time, until it is slowly pict up.

Also the actual panel could be breaking up , the eps beads could be coming apart under stress from the coil foot.

A high grade eps panel would probably be a better choice, and be more robust.

I have also had many exciter feet come loose.

The coil can also come loose from the spider or even from the outer ring of the spider.

Basically anything glued together could be coming apart.

Also the exit of the coil leads could have come loose or broken.

The problem is that all these faults tend to sound the same to start with, usually only over time when they become far worse , can you finally trace them easily.

Hope this is of some help.

Steve

Thanks for the tips Steve!

I have done fresh mounting on fresh plates, and still get the issue, so quite sure it is sagging. I'm not really sure if I really have burnt the exciters or it is just a defect that will happen with time. Last party I did push them to hard and for sure managed to burn a couple. But I noticed the sagging problem before that and had never observed really high temperature except a few due of them to being on the veranda in sunlight.

I guess they would have been fine if I supported them from the start, but since I didn't I fear the damage is done 🙁

I have done fresh mounting on fresh plates, and still get the issue, so quite sure it is sagging. I'm not really sure if I really have burnt the exciters or it is just a defect that will happen with time. Last party I did push them to hard and for sure managed to burn a couple. But I noticed the sagging problem before that and had never observed really high temperature except a few due of them to being on the veranda in sunlight.

I guess they would have been fine if I supported them from the start, but since I didn't I fear the damage is done 🙁

Hi LeobBeen refining my solution for suspending the exciters, and seems to work well in that there is no distortion from misalignment and sensitivity is fine.

Please share your detailing

Thanks

Eucy

It is same printed design I posted here and in the PA thread earlier, but I adjusted the angle of the arms slightly to minimize the pressure toward the plate, and now print it using dual material with soft material around the screws, and use polycarbonate screws instead of metal. This gives it a firm but slightly flexible grip.

The distortion happens also if I remove the bracing and have the panels lying flat, but now at least the bracing seems to have no detrimental effect apart from a slight sensitivity reduction. A bit disheartening to find that when I finally made a design I'm happy with, it turns out that problem remains anyway...and that it perhaps was all for nothing and support should not be needed at all!

It is a bit strange that from what I have seen they do not specify that they need to be supported in any way, and the screw hole is hidden behind a sticker. So I guess I have not mishandled them and the damage should be covered by their 5 year warranty...at least I can hope so 🙂

I will start going through and analyzing the exciters one by one and see how bad the situation is. But compared to when they where new it seems very hard to get any of them to play distortion free when vertically mounted. Perhaps it is still possible with just the right support for few of them, but they just don't seem reliable any more.

The distortion happens also if I remove the bracing and have the panels lying flat, but now at least the bracing seems to have no detrimental effect apart from a slight sensitivity reduction. A bit disheartening to find that when I finally made a design I'm happy with, it turns out that problem remains anyway...and that it perhaps was all for nothing and support should not be needed at all!

It is a bit strange that from what I have seen they do not specify that they need to be supported in any way, and the screw hole is hidden behind a sticker. So I guess I have not mishandled them and the damage should be covered by their 5 year warranty...at least I can hope so 🙂

I will start going through and analyzing the exciters one by one and see how bad the situation is. But compared to when they where new it seems very hard to get any of them to play distortion free when vertically mounted. Perhaps it is still possible with just the right support for few of them, but they just don't seem reliable any more.

Leob

I presume you've tried simply inverting the panels for a while to see if it corrects any sag effects?

I presume you've tried simply inverting the panels for a while to see if it corrects any sag effects?

Haven't tried with them unsupported and reversed yet, but will do that. But since I cannot make them work with support, that will not do me much good anyway, since then I guess with time they start sagging other direction as well when unsupported.

Hi Leob

The only way to guarantee no sag load on the assembly is to find the balance point of one of the exciters and arrange your mount detailing to suspend the group on that axis. Practically, that'll mean insetting your group mounting plate partway along the exciter housing

Should be easy enough with your printing method

Eucy

The only way to guarantee no sag load on the assembly is to find the balance point of one of the exciters and arrange your mount detailing to suspend the group on that axis. Practically, that'll mean insetting your group mounting plate partway along the exciter housing

Should be easy enough with your printing method

Eucy

Leob,

Can you remind me what exciters you are using?

Also, can you point me to your post(s) showing what your bracing looks like? I took a quick look myself for them but couldn't find them easily.

Not sure I can be much help, but I'm happy to look it over and see if anything comes to mind.

Eric

Can you remind me what exciters you are using?

Also, can you point me to your post(s) showing what your bracing looks like? I took a quick look myself for them but couldn't find them easily.

Not sure I can be much help, but I'm happy to look it over and see if anything comes to mind.

Eric

Last edited:

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker