Jaxboy.

No ,the canvas art panel wasn't my idea ,I've forgotten again who's idea it was,my memory is getting pretty bad nowadays,but hopefully someone will remind us, as it was a good idea.

I did do something similar way back with a 2inch bandor driver on a sheet of polythene with limited success ,as long as you kept the volume way down low ,otherwise it all went bad🙁,

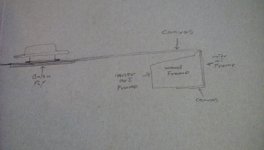

Here is a quick drawing of the frame of the art panel I have,I have no idea if all art frames are designed like this?

Not to scale obviously,art is not was never easy for me.

This seems to work well with no problems ,so far?

Steve.

No ,the canvas art panel wasn't my idea ,I've forgotten again who's idea it was,my memory is getting pretty bad nowadays,but hopefully someone will remind us, as it was a good idea.

I did do something similar way back with a 2inch bandor driver on a sheet of polythene with limited success ,as long as you kept the volume way down low ,otherwise it all went bad🙁,

Here is a quick drawing of the frame of the art panel I have,I have no idea if all art frames are designed like this?

Not to scale obviously,art is not was never easy for me.

This seems to work well with no problems ,so far?

Steve.

Attachments

And as you can see from my drawing I've gone and put the exciter on the wrong side of the panel 😕😀

I'm trying to do 10 thing at once.

The other half is driving me made😀

Steve.

I'm trying to do 10 thing at once.

The other half is driving me made😀

Steve.

Spedge,

It was OGKOG, starting on page 88, #877. I've seen on several posts people using bass exciters. Are they the BST-1 and -2? I would like to try and use one maybe in a corner about a foot from the wall to maybe replace the subwoofer. I don't remember which post I saw reference to bass exciters, and don't have the time to run them down in the 313 pages. It took about 45 minutes to find the OGKOG post.

It was OGKOG, starting on page 88, #877. I've seen on several posts people using bass exciters. Are they the BST-1 and -2? I would like to try and use one maybe in a corner about a foot from the wall to maybe replace the subwoofer. I don't remember which post I saw reference to bass exciters, and don't have the time to run them down in the 313 pages. It took about 45 minutes to find the OGKOG post.

Jaxboy.

Thanks.

I too spent at least 45minutes trying find posts by OGKOG but failed which made me late for the dentists,not a happy dentist😀

Which leads me on to a canvas picture hanging in his room .

Which I was slowly trying to move up to and casually have quick a feel .

I don't think this impressed him either,it was my first time with a new dentist😀

It was a square frame😱 so I was very lucky to get the frame that I did.

I'm sure you could make it work by pushing rubber or some sort of beading between the frame and canvas which would help stretch the canvas as well ?

Steve.

Thanks.

I too spent at least 45minutes trying find posts by OGKOG but failed which made me late for the dentists,not a happy dentist😀

Which leads me on to a canvas picture hanging in his room .

Which I was slowly trying to move up to and casually have quick a feel .

I don't think this impressed him either,it was my first time with a new dentist😀

It was a square frame😱 so I was very lucky to get the frame that I did.

I'm sure you could make it work by pushing rubber or some sort of beading between the frame and canvas which would help stretch the canvas as well ?

Steve.

Last edited:

Here is a snippet from a post by xit from the NXT....rubbish?? thread. From the creator of the podium sound panels:

Conventional cone loudspeakers propagate longitudinal waves. Longitudinal waves are highly coherent and binaurally correlated. Resonating DML type loudspeakers are transverse wave loudspeakers. Transverse sound waves are highly incoherent and binaurally decorrelated. It is simply impossible to propagate transverse waves with a conventional loudspeaker and conversely, it is impossible to propagate longitudinal waves with a resonating panel loudspeaker. No amount of DSP, loudspeaker placement, room treatment or other adjustments will change this simple fact. To reproduce natural sound, both types of loudspeakers are required.

Layered Sound is the term used to describe the process of combining a conventional and a distributed mode loudspeaker, to produce the same audio signal. This combination, when used in the correct configuration, delivers to the listener sound that is clear, spacious, better imaged and more pleasant to listen to.

This in a nutshell is what I have found. A combination of sub, bookshelfs, and DML are kick ***, covering everything. The addition of my DML's to what I thought was already a good sounding system is great. They just fill in every void I didn't even realize was there.

Conventional cone loudspeakers propagate longitudinal waves. Longitudinal waves are highly coherent and binaurally correlated. Resonating DML type loudspeakers are transverse wave loudspeakers. Transverse sound waves are highly incoherent and binaurally decorrelated. It is simply impossible to propagate transverse waves with a conventional loudspeaker and conversely, it is impossible to propagate longitudinal waves with a resonating panel loudspeaker. No amount of DSP, loudspeaker placement, room treatment or other adjustments will change this simple fact. To reproduce natural sound, both types of loudspeakers are required.

Layered Sound is the term used to describe the process of combining a conventional and a distributed mode loudspeaker, to produce the same audio signal. This combination, when used in the correct configuration, delivers to the listener sound that is clear, spacious, better imaged and more pleasant to listen to.

This in a nutshell is what I have found. A combination of sub, bookshelfs, and DML are kick ***, covering everything. The addition of my DML's to what I thought was already a good sounding system is great. They just fill in every void I didn't even realize was there.

Last edited:

Sonnar,

Listen to the Jennifer Warnes recording Spedge just put up. If you do your canvases, they will probably sound similar, and if so, you will have some excellently sounding speakers.

Spedge/Steve,

Thank you for your input. I listened to the recording with my favourite planar headphones I can say WOW!

This made me put on the back burner other materials that I was considering for the DML experience and head full steam for the canvas panels.

- For starters I jammed between the canvas and the wooden frame a self adhesive 6mm Open cell foam (used for window sealing).

- After that I put all around a bead of silicon.

See the attached pix.

Attachments

Sonner.

Hi.

Were you having some problems with the foam ,so you had to use the silicon to cure the problem ?

Steve.

Hi.

Were you having some problems with the foam ,so you had to use the silicon to cure the problem ?

Steve.

Here is a snippet from a post by xit from the NXT....rubbish?? thread. From the creator of the podium sound panels:

Conventional cone loudspeakers propagate longitudinal waves. Longitudinal waves are highly coherent and binaurally correlated. Resonating DML type loudspeakers are transverse wave loudspeakers. Transverse sound waves are highly incoherent and binaurally decorrelated. It is simply impossible to propagate transverse waves with a conventional loudspeaker and conversely, it is impossible to propagate longitudinal waves with a resonating panel loudspeaker. No amount of DSP, loudspeaker placement, room treatment or other adjustments will change this simple fact. To reproduce natural sound, both types of loudspeakers are required.

Layered Sound is the term used to describe the process of combining a conventional and a distributed mode loudspeaker, to produce the same audio signal. This combination, when used in the correct configuration, delivers to the listener sound that is clear, spacious, better imaged and more pleasant to listen to.

This in a nutshell is what I have found. A combination of sub, bookshelfs, and DML are kick ***, covering everything. The addition of my DML's to what I thought was already a good sounding system is great. They just fill in every void I didn't even realize was there.

While I agree with the majority of what he says .

Tectonic call the area of the exciter the primary radiating area ,this is where the initial pulse is sent out into the panel(from a pistonic type of driver).

On very rigid panels the output is heavily reduced,but on panels such as eps or thin card the panels can flex considerably and act more like a piston in this area.

Which I encourage sometimes by having a cone shape in the centre of eps and a dome in the centre of card

I believe this is why I prefer the sound of this type of panel because If done well ,it can produce both in just the right amount.

I did mention this many years ago on the NXT Rubbish thread but I still don't think the penny has dropped ,even for tectonic ?

A lot more should be made of this area as this primary area is very important.

When using an exciter coil ,a lot of bad sounds can be produced within the coil ,which I have also pointed out,but I don't believe that penny has dropped either?

Steve.

Sonner.

I should have said thanks for your comments,I'm glad you liked the sound, the panel is A good all rounder.

The only slight problem for me maybe is that it is a rigid balsa panel in the centre,but the panel does also move as a piston ,especially if you rigidly mount the exciter to a spine.

Some more thought needs to be put into this to get it just right I believe.

Once again thanks for your comments.

Steve.

I should have said thanks for your comments,I'm glad you liked the sound, the panel is A good all rounder.

The only slight problem for me maybe is that it is a rigid balsa panel in the centre,but the panel does also move as a piston ,especially if you rigidly mount the exciter to a spine.

Some more thought needs to be put into this to get it just right I believe.

Once again thanks for your comments.

Steve.

Sonner.

Hi.

Were you having some problems with the foam ,so you had to use the silicon to cure the problem ?

Steve.

I put the silicon just because I thought it would be a good idea to absorb the vibrations. Maybe it is an overkill...It cured for more than a week.

Next step is to glue the timber panel. I have a choice of

- balsa (10cm wide @ 3.4mm)

- round pine (10cm diam @ 3mm thick)

- the hexagonal sheets (pictured in a previous post)

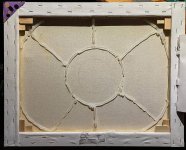

I also put some hot glue on the back in the pattern seen in the attached pic.

I also plan to coat the back with water based glue diluted in a ~ 2:10 ratio.

Any advice is highly appreciated.

Attachments

Last edited:

Ok, many days of reading, lots of good information, thanks.

I come from an aviation background, light aircraft, as well as many years maintaining the venerable herc, my personnel favorite.

The posts concerning canvas, sparked my interest, from the stand point of most light, bush type aircraft utilize fabric covering, ceconite or polyfiber, to name two. Both of these fabrics are tightened or shrunk via a household iron, when initial shrinking is complete, the "soundness" is very flat, very little feedback, after the first coat of, in the case of polyfiber, polybrush is applied, now it starts to sound more like a drum, a couple coats are needed to fill the weave and level the surface, now it is a drum, the tightness and responsiveness have been greatly improved. Previous to the poly ester fabrics, grade A cotton was used, water was applied to shrink and tighten the fabric, which of course raised the grain of the fabric, needed to be sanded prior to any additional "dope" being applied, dope, in this case were either nitrile or butyrate based, both did offer some tightening as well as sealing the surface, in preparation to final painting.

I offer this as information and as a challenge to those who are experimenting with differing materials. If you live near a small airport that services aircraft, drop in and explain what your doing, see if they do fabric covering, ask for a piece and give it a go. If I still lived in Alaska, I would do it in a heart beat, may have to have my old buddies send me some scrap pieces, and believe me, when covering a cub, there a lots of scrap pieces.

I come from an aviation background, light aircraft, as well as many years maintaining the venerable herc, my personnel favorite.

The posts concerning canvas, sparked my interest, from the stand point of most light, bush type aircraft utilize fabric covering, ceconite or polyfiber, to name two. Both of these fabrics are tightened or shrunk via a household iron, when initial shrinking is complete, the "soundness" is very flat, very little feedback, after the first coat of, in the case of polyfiber, polybrush is applied, now it starts to sound more like a drum, a couple coats are needed to fill the weave and level the surface, now it is a drum, the tightness and responsiveness have been greatly improved. Previous to the poly ester fabrics, grade A cotton was used, water was applied to shrink and tighten the fabric, which of course raised the grain of the fabric, needed to be sanded prior to any additional "dope" being applied, dope, in this case were either nitrile or butyrate based, both did offer some tightening as well as sealing the surface, in preparation to final painting.

I offer this as information and as a challenge to those who are experimenting with differing materials. If you live near a small airport that services aircraft, drop in and explain what your doing, see if they do fabric covering, ask for a piece and give it a go. If I still lived in Alaska, I would do it in a heart beat, may have to have my old buddies send me some scrap pieces, and believe me, when covering a cub, there a lots of scrap pieces.

Mexjerry.

I have to admit that when going around an aircraft museum or air show the temptation to tap on the the light fabric is a little too strong.

I always think mmmmmm I wonder what that would sound like with an exciter on it ?

The tightness and rigidity and lightness is incredible.

It is difficult to know how tight to make the panel and what type of application to use it for?

But interesting.

Steve

I have to admit that when going around an aircraft museum or air show the temptation to tap on the the light fabric is a little too strong.

I always think mmmmmm I wonder what that would sound like with an exciter on it ?

The tightness and rigidity and lightness is incredible.

It is difficult to know how tight to make the panel and what type of application to use it for?

But interesting.

Steve

Sonner.

I've been trying to wrap my head around the fact you've applied hot melt and silicon to the panel to cure a problem you don't even know you have ?

Doing this could even cause the problem to start with ?

You have done the last resort first ? Even before you have attached the exciter.

I used my 6x4inch balsa with an exciter as a test panel first to see how it sounded,and then made a few adjustments.

The 6x4 ply worked petty well above about 600hz or so ,and sounded pretty good xo at this point to my TLS.

So I knew I had a good panel to start with.

It was only then that I attached the test panel and exciter to the canvas.

The panel worked pretty well until I had the brainwave to coat the panel with cascamite,which is very rigid ,but what I did not realise is cascamite is also very brittle and cracks in thin layers.

End of project !!!!

Although the panel sounds good at a reasonable volume ,if I try to turn it up too high the cracks start to let themselves be known 🙁

Prepare to make mistakes ,try to do as little as possible to start with and then if necessary after careful listening you can make small adjustments and then listen again to make sure it is really improving the sound.

It helps if you have two panels ,but keep one fairly basic so that any adjustments can be closely monitored to make sure you are going in the right direction..

There is a lot of trial and error but if done in small stages with small adjustments hopefully not too much damage should be done.

Steve.

I've been trying to wrap my head around the fact you've applied hot melt and silicon to the panel to cure a problem you don't even know you have ?

Doing this could even cause the problem to start with ?

You have done the last resort first ? Even before you have attached the exciter.

I used my 6x4inch balsa with an exciter as a test panel first to see how it sounded,and then made a few adjustments.

The 6x4 ply worked petty well above about 600hz or so ,and sounded pretty good xo at this point to my TLS.

So I knew I had a good panel to start with.

It was only then that I attached the test panel and exciter to the canvas.

The panel worked pretty well until I had the brainwave to coat the panel with cascamite,which is very rigid ,but what I did not realise is cascamite is also very brittle and cracks in thin layers.

End of project !!!!

Although the panel sounds good at a reasonable volume ,if I try to turn it up too high the cracks start to let themselves be known 🙁

Prepare to make mistakes ,try to do as little as possible to start with and then if necessary after careful listening you can make small adjustments and then listen again to make sure it is really improving the sound.

It helps if you have two panels ,but keep one fairly basic so that any adjustments can be closely monitored to make sure you are going in the right direction..

There is a lot of trial and error but if done in small stages with small adjustments hopefully not too much damage should be done.

Steve.

Concerning the time it took to make Spedge's and my searches for OGKOG's posts makes me believe that diyaudio needs to revamp their search algorithm. When searching for "DML", for instance, you are given a very long list of posts, almost all of which have nothing to do with the subject of the search that you have to wade through before you finally get to subject area you requested. They need to maybe just give give you a compilation of all posts that contain the key word or the approximation of it. Also, they need to add a function to their search so that when you right-select a member, in that response it gives you a button to see all the member's posts. These two changes would save many, many hours of search time, and a huge amount of frustration. Maybe a moderator could bring this up to the appropriate person. It doesn't seem that this would be that hard a task to do, but the value of the change would be great.

mexjerry,

Concerning the fabric covering on light aircraft, if I were to go to a fabric store to get suitable fabric to replace the bright-white canvas on unpainted artist canvases for making a DML panel, what kind do you recommend? Do I want a tight weave, heavy or light, pure cotton or a blend, etc. It would let me get a pre-printed surface, allowing me to not have to put on a paint coating or gluing on a piece of paper, for instance, so I would have a not-bright-white fabric I could coat with water/glue. I was thinking of building my own frames so that I could get the exact size panel I want instead of settling for the generic sizes (which, by the way, might just be the perfect sizes for a DML panel). By building my own, they could be built stronger, and I could make the frame deep enough so that I would not have to make shims for the spline. Simply tilting the saw blade angle to less than 90* would also give me the chamfer needed for the canvas. Any help you or other members can give would really be appreciated.

Concerning the fabric covering on light aircraft, if I were to go to a fabric store to get suitable fabric to replace the bright-white canvas on unpainted artist canvases for making a DML panel, what kind do you recommend? Do I want a tight weave, heavy or light, pure cotton or a blend, etc. It would let me get a pre-printed surface, allowing me to not have to put on a paint coating or gluing on a piece of paper, for instance, so I would have a not-bright-white fabric I could coat with water/glue. I was thinking of building my own frames so that I could get the exact size panel I want instead of settling for the generic sizes (which, by the way, might just be the perfect sizes for a DML panel). By building my own, they could be built stronger, and I could make the frame deep enough so that I would not have to make shims for the spline. Simply tilting the saw blade angle to less than 90* would also give me the chamfer needed for the canvas. Any help you or other members can give would really be appreciated.

jaxboy

I suppose trial and error, I'm fairly certain of aircraft fabric, not so much of the fabric store stuff, just haven't checked whats available.

Here's a link to stits, manufacture of polyfiber I'm most familiar with:

FAQ's

"After the fabric is attached to the airframe, heat the iron to 200°F and smooth the edges down. Then, increase the temperature in 25° increments to shrink the fabric. You can stop at any time the fabric feels tight enough or go to 350° for the full pull. The Poly-Fiber will shrink 10 to 12% at 350°."

So you need to find a shrinkable fabric, with your desired pattern

Another link:

8 Easy Ways to Shrink Polyester

I think you will find, on bare, unfinished fabric, very little to no resonance, it will need some material to fill the weave.

I suppose trial and error, I'm fairly certain of aircraft fabric, not so much of the fabric store stuff, just haven't checked whats available.

Here's a link to stits, manufacture of polyfiber I'm most familiar with:

FAQ's

"After the fabric is attached to the airframe, heat the iron to 200°F and smooth the edges down. Then, increase the temperature in 25° increments to shrink the fabric. You can stop at any time the fabric feels tight enough or go to 350° for the full pull. The Poly-Fiber will shrink 10 to 12% at 350°."

So you need to find a shrinkable fabric, with your desired pattern

Another link:

8 Easy Ways to Shrink Polyester

I think you will find, on bare, unfinished fabric, very little to no resonance, it will need some material to fill the weave.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker