Whew! I'm only up to post #711, but so far pretty much all the music I've heard people talk about listening to on their DML's is acoustic or at least somewhat laid back. I could see really enjoying some Neil Young or some Grateful Dead on them, but I can't help wonder how good they sound with more aggressive styles of music - distorted guitars, electronic, complex layering of many tracks, etc. Can anyone comment from experience?

In theory, DMLs will sound good with that kind music because they fill the room with uncorrelated reflections. Yet, DMLs will sound bad with that kind of music because they don't produce low end.

In practice, DMLs sound amazing with distorted guitars and complex electronic because you add a sub or two or three.

yellow

4evrplan.

if you are concerned that dml is restricted in output ,similar to planar and statics don't be,as long as you match the exciter to the panel and use a sub or LF driver to help with the low end there should be no problem.

these two recordings were played at high volume.

the distortion in, here come the fleas(brings back memories) is on the cd,downloaded from youtube, an electric storm,white noise.

yellow might have gone into clipping a few times while recording,but i think i got away with it,feel free to crank it up.

steve

4evrplan.

if you are concerned that dml is restricted in output ,similar to planar and statics don't be,as long as you match the exciter to the panel and use a sub or LF driver to help with the low end there should be no problem.

these two recordings were played at high volume.

the distortion in, here come the fleas(brings back memories) is on the cd,downloaded from youtube, an electric storm,white noise.

yellow might have gone into clipping a few times while recording,but i think i got away with it,feel free to crank it up.

steve

Attachments

OK Spedge, nice stuff! What was the source, speaker, mic and recorder used for this?

geo

Oh and as to your suggestion to maybe try double width of my panels...thats one of my options, also double height as well and I have enough panels to even try double width and height (28.5" x 96") 🙂 but I wonder if one 20W exciter would drive that much eps...hmmm maybe a driver per panel...it would be interesting if pva could hold such a structure together as well and how the pva would be able to transfer the vibrations between panels...but somehow I think WAF maybe a no-go.

Quick story: I was playing cd of Blue Train by Coltrane the other day and my daughter came in the house and asked where the music was coming from, did I buy some new speakers and why did I have styrofoam sheets standing in the middle of the living room. I asked her how it sounded and she said its good but where are the speakers? She even walked behind the panels and asked where the speakers were again. She thought I might have hidden some speakers in the fireplace behind the DML's lol...so I guess I might be doing something right. She was very confused by where the sound was coming from and couldnt beleive it came from the styrofoam.

geo

Oh and as to your suggestion to maybe try double width of my panels...thats one of my options, also double height as well and I have enough panels to even try double width and height (28.5" x 96") 🙂 but I wonder if one 20W exciter would drive that much eps...hmmm maybe a driver per panel...it would be interesting if pva could hold such a structure together as well and how the pva would be able to transfer the vibrations between panels...but somehow I think WAF maybe a no-go.

Quick story: I was playing cd of Blue Train by Coltrane the other day and my daughter came in the house and asked where the music was coming from, did I buy some new speakers and why did I have styrofoam sheets standing in the middle of the living room. I asked her how it sounded and she said its good but where are the speakers? She even walked behind the panels and asked where the speakers were again. She thought I might have hidden some speakers in the fireplace behind the DML's lol...so I guess I might be doing something right. She was very confused by where the sound was coming from and couldnt beleive it came from the styrofoam.

Geo.

I'm just using HI-Q app for recording stereo on my old galaxy note 4.

Converting from m4a to mp4 on VLC,that's it.

Ziggy used to use one 10watt exciter on an 8x4ft x10mm hd eps ,and I have used 2ft 6ins x7ft x25mm 70grade (I think)eps with my 10watt exciter with no problem,exactly the same output as my 2x4 but goes lower.

Steve

I'm just using HI-Q app for recording stereo on my old galaxy note 4.

Converting from m4a to mp4 on VLC,that's it.

Ziggy used to use one 10watt exciter on an 8x4ft x10mm hd eps ,and I have used 2ft 6ins x7ft x25mm 70grade (I think)eps with my 10watt exciter with no problem,exactly the same output as my 2x4 but goes lower.

Steve

Geo.

The only problem with very large panels is the amount of time that it takes to stop vibrating,basically the drum effect, the bigger the drum ,the deeper and longer they resonate.

Another reason to XO before you reach the natural resonance in the low end, most of the time you would not notice it when playing music , but every now and then something would set it off and you would notice it.

I have glued broken panels together many times with watered down pva and the bond is much stronger than the eps .

The only problem could be how tight the two flat straight surfaces match ,ideally they should butt up together with no gaps.

When the water has evaporated pva is very light but strong you wouldn't know it was there and transmits the sound well,the reason I use pva to coat my panels is to help the sound propagate across the panel and not to dampen it as many seem to think?

Although I was thinking of this the other day with two small panels I want to join.

I usually coat the panels in a 50x50mix including the edges, which does stiffen the panel edges,a bit like an invisible frame,so by gluing two panels together I would have three areas of stiffening, two on the outside and one on the inside, Could this be a help or hindrance?

It probably won't make any difference to the sound but you don't know until you try.

Good story by the way🙂

Steve

The only problem with very large panels is the amount of time that it takes to stop vibrating,basically the drum effect, the bigger the drum ,the deeper and longer they resonate.

Another reason to XO before you reach the natural resonance in the low end, most of the time you would not notice it when playing music , but every now and then something would set it off and you would notice it.

I have glued broken panels together many times with watered down pva and the bond is much stronger than the eps .

The only problem could be how tight the two flat straight surfaces match ,ideally they should butt up together with no gaps.

When the water has evaporated pva is very light but strong you wouldn't know it was there and transmits the sound well,the reason I use pva to coat my panels is to help the sound propagate across the panel and not to dampen it as many seem to think?

Although I was thinking of this the other day with two small panels I want to join.

I usually coat the panels in a 50x50mix including the edges, which does stiffen the panel edges,a bit like an invisible frame,so by gluing two panels together I would have three areas of stiffening, two on the outside and one on the inside, Could this be a help or hindrance?

It probably won't make any difference to the sound but you don't know until you try.

Good story by the way🙂

Steve

Spedge, those all sound really good, as far as I can tell listening through cheap headphones on my phone. I went back and listened to the Melena track too, and i really enjoyed that one. I can hear your room, but even so, the percussion really pops, and I listened to the end.

I really want to build a pair of these, but I'll have to spend almost nothing on them and hang them on the wall, otherwise the WAF is 0. That means 1) a single inexpensive exciter per panel, 2) cheap panel material, 3) use of my existing stereo w. built in amp, and 4) no subs or crossovers. I'm trying to decide if it's even worth it.

One of the more wild ideas I had was to mix pigments into PVA/water mixture and to commission a painter friend of mine to paint them. I have several of her paintings, so they'd hopefully match stylistically, though how they'd compare to oil paintings is anyone's guess.

I really want to build a pair of these, but I'll have to spend almost nothing on them and hang them on the wall, otherwise the WAF is 0. That means 1) a single inexpensive exciter per panel, 2) cheap panel material, 3) use of my existing stereo w. built in amp, and 4) no subs or crossovers. I'm trying to decide if it's even worth it.

One of the more wild ideas I had was to mix pigments into PVA/water mixture and to commission a painter friend of mine to paint them. I have several of her paintings, so they'd hopefully match stylistically, though how they'd compare to oil paintings is anyone's guess.

4evrplan.

Not sure about hanging eps on the wall without an LF driver to support the low end?

There are other options ,such as the full range canvas panel ,ideal for painting or my rigid ply might work against the wall ok? With some damping behind the panel maybe.

You could have the panel swing out into the room on some kind of arm for serious listening?

Or even, if you have ordinary speakers ,you could run them in series With the panels, similar to layered sound ,for the best of both worlds? No xo needed but matching db could be a problem?

I'm sure there are other options others may be able to offer ,these are just a few suggestions I can think of, off hand.

Steve

Not sure about hanging eps on the wall without an LF driver to support the low end?

There are other options ,such as the full range canvas panel ,ideal for painting or my rigid ply might work against the wall ok? With some damping behind the panel maybe.

You could have the panel swing out into the room on some kind of arm for serious listening?

Or even, if you have ordinary speakers ,you could run them in series With the panels, similar to layered sound ,for the best of both worlds? No xo needed but matching db could be a problem?

I'm sure there are other options others may be able to offer ,these are just a few suggestions I can think of, off hand.

Steve

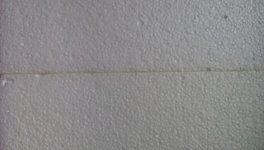

Exp panels

This is the smaller panel on the left that I have been recording,it was damaged when I found it,but as you can see,I have been using it for testing.

Also I have glued together the two small eps panels just to see what happens.

I used thick pva hoping to fill the gaps,but afterwards thought it may have been better to have scuffed the two surfaces and used thinner glue,the two fluffy surfaces would have filled the gaps better?with hardly any glue?

Oh well.

Steve

This is the smaller panel on the left that I have been recording,it was damaged when I found it,but as you can see,I have been using it for testing.

Also I have glued together the two small eps panels just to see what happens.

I used thick pva hoping to fill the gaps,but afterwards thought it may have been better to have scuffed the two surfaces and used thinner glue,the two fluffy surfaces would have filled the gaps better?with hardly any glue?

Oh well.

Steve

Attachments

In the photo of the panel I used for recording,I used three AA batteries to reduce the dip in response in the 300hz to 100hz region,two on the front one on the back,and now sharply rolls off at the 100hz mark.

The clothes peg in the top right was to stop the corner buzzing .

I find the easiest way to mount the small eps panels is with an old dish sponge shown in top of the photo(they are softer when old!)This also stops the panel waving about ever time I walk by.

Steve.

The clothes peg in the top right was to stop the corner buzzing .

I find the easiest way to mount the small eps panels is with an old dish sponge shown in top of the photo(they are softer when old!)This also stops the panel waving about ever time I walk by.

Steve.

Two into one

The panels are now stuck together.

If I did this again I would definitely scuff the surface and probably use a 50x50mix ,pva especially when thinned will not readily attach to the surface of eps,it will form globules, I will attach the exciter in the monacor position which is the nxt patent,as I prefer the more central position for the exciter.

I will leave the panel for a few more days to dry before doing some serious testing .

A warning ,that this is for eps and not xps,as xps will seal the moisture in and not dry.

But you can scuff the surface of xps and also eps and coat with pva,which will absorb and harden the surface well.

Steve

The panels are now stuck together.

If I did this again I would definitely scuff the surface and probably use a 50x50mix ,pva especially when thinned will not readily attach to the surface of eps,it will form globules, I will attach the exciter in the monacor position which is the nxt patent,as I prefer the more central position for the exciter.

I will leave the panel for a few more days to dry before doing some serious testing .

A warning ,that this is for eps and not xps,as xps will seal the moisture in and not dry.

But you can scuff the surface of xps and also eps and coat with pva,which will absorb and harden the surface well.

Steve

Attachments

Two into one

This panel is slightly smaller than the one I have been using for the recordings.

It feels like a totally different breed of panel,this one is very rigid ,the other is so much lighter and is wobbly.

It will be very interesting to see how they sound and measure.

I will run them side by side and make comparisons.

I have slightly gone off track by using an exciter that has lost its foot,so the coil is mounted directly on the panel,not that I noticed vast amounts of difference in the past,but then I have not done identical tests panels(the cheep sell off exciters I bought years back have two problems ,one is the wires break ,causing buzzing then failure,the other is the foot comes loose,also causing buzzing)you can spend a long time pulling the panel apart only to find its the exciter!

I have sanded and coated the panel with one coat so far of 50x50 pva mix,I did round the sharp edges of the panel a little bit that's all.

I will now glue the foam sponge in place for mounting the panel and that's then finished.

Steve.

This panel is slightly smaller than the one I have been using for the recordings.

It feels like a totally different breed of panel,this one is very rigid ,the other is so much lighter and is wobbly.

It will be very interesting to see how they sound and measure.

I will run them side by side and make comparisons.

I have slightly gone off track by using an exciter that has lost its foot,so the coil is mounted directly on the panel,not that I noticed vast amounts of difference in the past,but then I have not done identical tests panels(the cheep sell off exciters I bought years back have two problems ,one is the wires break ,causing buzzing then failure,the other is the foot comes loose,also causing buzzing)you can spend a long time pulling the panel apart only to find its the exciter!

I have sanded and coated the panel with one coat so far of 50x50 pva mix,I did round the sharp edges of the panel a little bit that's all.

I will now glue the foam sponge in place for mounting the panel and that's then finished.

Steve.

Decidedto try and make a honeycomb composite panel using spread-tow weave carbonfibre. I will be aiming to use just one single sheet of carbon fibre ifpossible on either side of the 3mm Nomex aramid honeycomb to keep the weightdown as much as possible so that it's not too hard to drive. I'll be using a wetlay technique to make the individual sheets (I don't want to pay for expensivevacuum pumps etc. as this could be a failed experiment). Once I receivethe kit, I'll post some pictures of the process. The size of the panelI'm looking to make will be approximately 400mm x 500mm.

Ipurchased a 250mm x 200 x 1.1mm carbon fibre panel from Amazon fortesting. I attached a DAEX25FHE-4 exciter. One thing I found wasthat if the panel is free-floating, there is too much ring, but even holdingthe panel with hands makes this go away. I will be looking to mount the compositepanel once made in a frame to increase the bass and try and get rid of any ringing. Not sure if the honeycomb will dampen thepanel or not. Will test various methodsof mounting the panel.

Ihad remembered some posts about using canvas frames and a round piece of wood,so looked out a 300mm x 400mm canvas painting one of my kids made andpositioned the 200mm x 250xx carbon fibre plate against it. Volumeincreased, and I was immediately surprised about how much bass this small panelproduced. I didn't attach it properly, as don't want to damage thepainting, but I’m going to purchase some canvas's of varying sizes to try out,as I was impressed with the sound quality.

Has anyone else tried combing any othermaterials instead of canvas that increases the volume and bass, but doesn't loseany detail? As an experiment, before making the composite, I will tryusing a larger spare single sheet of the spread tow carbon fibre sheet (lessthan .25mm thick) and mount on a temporary frame and try an exciter attached.On its own, I suspect that it will be too flexible, but might combine well withthe smaller carbon fibre sheet in a similar way to the canvas panel

Ipurchased a 250mm x 200 x 1.1mm carbon fibre panel from Amazon fortesting. I attached a DAEX25FHE-4 exciter. One thing I found wasthat if the panel is free-floating, there is too much ring, but even holdingthe panel with hands makes this go away. I will be looking to mount the compositepanel once made in a frame to increase the bass and try and get rid of any ringing. Not sure if the honeycomb will dampen thepanel or not. Will test various methodsof mounting the panel.

Ihad remembered some posts about using canvas frames and a round piece of wood,so looked out a 300mm x 400mm canvas painting one of my kids made andpositioned the 200mm x 250xx carbon fibre plate against it. Volumeincreased, and I was immediately surprised about how much bass this small panelproduced. I didn't attach it properly, as don't want to damage thepainting, but I’m going to purchase some canvas's of varying sizes to try out,as I was impressed with the sound quality.

Has anyone else tried combing any othermaterials instead of canvas that increases the volume and bass, but doesn't loseany detail? As an experiment, before making the composite, I will tryusing a larger spare single sheet of the spread tow carbon fibre sheet (lessthan .25mm thick) and mount on a temporary frame and try an exciter attached.On its own, I suspect that it will be too flexible, but might combine well withthe smaller carbon fibre sheet in a similar way to the canvas panel

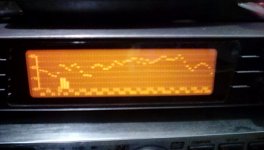

Two into one does work!

Something I noticed on the recording that is not that bad from my seating position was that the close mic recording of the sssssss sounds were more pronounced .

I tried to figure out why the mic was picking this out,I've tried putting my hands all over this panel but annoyingly it refuses to change its response .

I even held a very large cushion in front of the panel,with very little change,so concluded it must be to do with reflections.

I have noticed for some years now,that reflections can cause harsh sounds now and again,for instance a loud TA sound can give a very painful slap in my ears,but moving my head to one side ,the harshness has gone,damping on the wall sorted it.

I know all the experts say dml does not suffer from wall reflections,but in my experience they do,just in a different way.

I suffer more because my panels are only 2ft from the side walls,so I can get very strong reflections now and again.

But anyway ,the difference in the response of these two panels might help show part of the problem.

The two pics on the left show the old panel ,first from the left side of the panel second in front.

The same for the new panel,the first from the left side the second in front.

You notice the rising response to the peek ,right where the ssssss problem is.

It is practically the opposite of the reflection response you would expect from an ordinary speaker.

This reflection could alter the in room response ,and I think that is what the mic was picking up from the position it was in ,close to the panel and wall.

Oh well,just to now.

Steve

Something I noticed on the recording that is not that bad from my seating position was that the close mic recording of the sssssss sounds were more pronounced .

I tried to figure out why the mic was picking this out,I've tried putting my hands all over this panel but annoyingly it refuses to change its response .

I even held a very large cushion in front of the panel,with very little change,so concluded it must be to do with reflections.

I have noticed for some years now,that reflections can cause harsh sounds now and again,for instance a loud TA sound can give a very painful slap in my ears,but moving my head to one side ,the harshness has gone,damping on the wall sorted it.

I know all the experts say dml does not suffer from wall reflections,but in my experience they do,just in a different way.

I suffer more because my panels are only 2ft from the side walls,so I can get very strong reflections now and again.

But anyway ,the difference in the response of these two panels might help show part of the problem.

The two pics on the left show the old panel ,first from the left side of the panel second in front.

The same for the new panel,the first from the left side the second in front.

You notice the rising response to the peek ,right where the ssssss problem is.

It is practically the opposite of the reflection response you would expect from an ordinary speaker.

This reflection could alter the in room response ,and I think that is what the mic was picking up from the position it was in ,close to the panel and wall.

Oh well,just to now.

Steve

Attachments

I'll try and explain this a little better,I was in a rush when I wrote the last post.

The old panel has a very similar response from the side and front.

The new panel has a sloping response from the side,this was the worst case response just to show the problem,this response when recording was bouncing straight back from the side walls to the microphones,but where I was sitting it sounded ok.

The new panel has a very detailed sound,and is more efficient than the old panel,the image in the recording had drifted to the right.

As for the pva glue holding the two halves together affecting the sound waves going across the panel,I can't hear or measure anything nasty going on,looks pretty normal.

I have now coated the sides with pva ,will see if that makes any difference.

I will move on to see if I can improve the response a little, it should be possible to reach 10k with 25mmm eps before hitting the slope,usually!

I know the pictures are poor quality but they do show the shape of the responses well ,which is what I wanted to show.

Steve

The old panel has a very similar response from the side and front.

The new panel has a sloping response from the side,this was the worst case response just to show the problem,this response when recording was bouncing straight back from the side walls to the microphones,but where I was sitting it sounded ok.

The new panel has a very detailed sound,and is more efficient than the old panel,the image in the recording had drifted to the right.

As for the pva glue holding the two halves together affecting the sound waves going across the panel,I can't hear or measure anything nasty going on,looks pretty normal.

I have now coated the sides with pva ,will see if that makes any difference.

I will move on to see if I can improve the response a little, it should be possible to reach 10k with 25mmm eps before hitting the slope,usually!

I know the pictures are poor quality but they do show the shape of the responses well ,which is what I wanted to show.

Steve

Stimper

You need to look at this patent,it should give you some ideas for your project.

Steve

You need to look at this patent,it should give you some ideas for your project.

Steve

Thanks Steve, this is exactly what I was looking for. I will read in more detail and see if I will be able to do something similar.

Do you know of an actual product that has been made using this approach?

Really appreciate your help letting me know about this patent. 👍

Do you know of an actual product that has been made using this approach?

Really appreciate your help letting me know about this patent. 👍

Stimper.

I can't say that I have seen anything similar to this patent except for the diy canvas picture frame project.

I had thought of using other materials for the same project and maybe trying to improve things a little.

But as it stands ,it gives a good performance for a very reasonable price, I still have another 3 frames left to play around with which only cost a few pounds on ebay.

Spending vast amounts on high tech materials is no grantee of an improvement in sound ,I have found.

A lighter thinner mesh might be worth a try,with some sort of coating,fiberglass, or something softer?or both?

It's how far you want to go and how many ideas you have,its addictive.

Steve

I can't say that I have seen anything similar to this patent except for the diy canvas picture frame project.

I had thought of using other materials for the same project and maybe trying to improve things a little.

But as it stands ,it gives a good performance for a very reasonable price, I still have another 3 frames left to play around with which only cost a few pounds on ebay.

Spending vast amounts on high tech materials is no grantee of an improvement in sound ,I have found.

A lighter thinner mesh might be worth a try,with some sort of coating,fiberglass, or something softer?or both?

It's how far you want to go and how many ideas you have,its addictive.

Steve

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker