Yesterday evening I was reading this article about supertweeters: https://www.tnt-audio.com/casse/jb_supertweeter_e.html

What is your experience with them generally and with FHXL and Silbury?

Thanks

Roberto

What is your experience with them generally and with FHXL and Silbury?

Thanks

Roberto

It's completely dependent upon design & implementation unfortunately  so there's no single answer beyond that. Without a proper crossover in place, they will almost certainly have some destructive interference with the main unit over the transition band / shared BW before the main driver eventually rolls off, but how & what = see above, along with where you happen to be listening as this will also shift about depending on axis.

so there's no single answer beyond that. Without a proper crossover in place, they will almost certainly have some destructive interference with the main unit over the transition band / shared BW before the main driver eventually rolls off, but how & what = see above, along with where you happen to be listening as this will also shift about depending on axis.

so there's no single answer beyond that. Without a proper crossover in place, they will almost certainly have some destructive interference with the main unit over the transition band / shared BW before the main driver eventually rolls off, but how & what = see above, along with where you happen to be listening as this will also shift about depending on axis.

so there's no single answer beyond that. Without a proper crossover in place, they will almost certainly have some destructive interference with the main unit over the transition band / shared BW before the main driver eventually rolls off, but how & what = see above, along with where you happen to be listening as this will also shift about depending on axis.Thanks @Scottmoose ,

I’ve seen those have three switch to modify their response:

As far as I understand I should place them on top of the FHXL and on the side of the Silbury.

Do some of you use them, or stick with the FullRangers only?

Thanks again!

Roberto

I’ve seen those have three switch to modify their response:

As far as I understand I should place them on top of the FHXL and on the side of the Silbury.

Do some of you use them, or stick with the FullRangers only?

Thanks again!

Roberto

Roberto, speaking for myself only, after playing with several of the earlier MA models in both paper and metal cones, I determined I generally preferred the latter, and never felt the need for any augmentation at the top end.

If however you feel that need, or even simply want to experiment, then I think your supposition for proximity to acoustic centre of main wideband driver would prove most efficacious. That was the configuration used by our long departed friend Terry Cain with his BEN and Double BENs

If however you feel that need, or even simply want to experiment, then I think your supposition for proximity to acoustic centre of main wideband driver would prove most efficacious. That was the configuration used by our long departed friend Terry Cain with his BEN and Double BENs

Attachments

Thanks for the explanation and the examples.

The only serious speakers I’ve had so far are the Klipsch RF82 (could not be serious to some, but I still like them) and few weeks ago the FHXL with MA 11ms. Silbury will have MA 10.3.

FHXL have a far better midrange so far, even if I’m doing my tests with a TPA3116 class D based amp (far from optimal for the FR) as my tube amps are on the bench for tests. Klipsch have some more sparkle, that’s why I’m curious about supertweeters.

The only serious speakers I’ve had so far are the Klipsch RF82 (could not be serious to some, but I still like them) and few weeks ago the FHXL with MA 11ms. Silbury will have MA 10.3.

FHXL have a far better midrange so far, even if I’m doing my tests with a TPA3116 class D based amp (far from optimal for the FR) as my tube amps are on the bench for tests. Klipsch have some more sparkle, that’s why I’m curious about supertweeters.

As physically close as possible to the main unit is generally preferred

Given the necessarily large separation (reletive to the quarter wavelength of the XO frequency, you will get a lot of combing. Response from constructive and destructive cancelation usually means that teh response is onlky right in a very small volume of your listening room (head in a vise).

Seems to work out some of the time, you have to try it, and many find firing the tweeter upward or backward works better.

dave

Roberto, I’ve owned a fair representation of class D amps over the years, and am currently running a triad of A10.3 in front row of my HT rig powered by ICEPower AC200. While not quite as nuanced as Neurochrome Modulus 286 (my current favorite of class AB types I’ve heard in this system), on the occasions that I listen to some of the surprisingly good YT blues and jazz streams, the AC200 isn’t at all embarrassed in comparison to the Onkyo RZ740’s power amp stage.

Horses for courses, YMMV, different strokes, et cetera ad nauseam 😉

Horses for courses, YMMV, different strokes, et cetera ad nauseam 😉

I have a breeze audio TPA3116 (that I use most of the time) and an Aiyima A07 TPA3225.

But on the bench (already working, some improvements going on) I have two PP, one with 6V6GT and one with EL34.

In itinere there's a 12AT7&GU50/KT88 SE and a solid state single stage SE that I would like to dedicate to the full rangers.

But on the bench (already working, some improvements going on) I have two PP, one with 6V6GT and one with EL34.

In itinere there's a 12AT7&GU50/KT88 SE and a solid state single stage SE that I would like to dedicate to the full rangers.

Thanks again Dave!

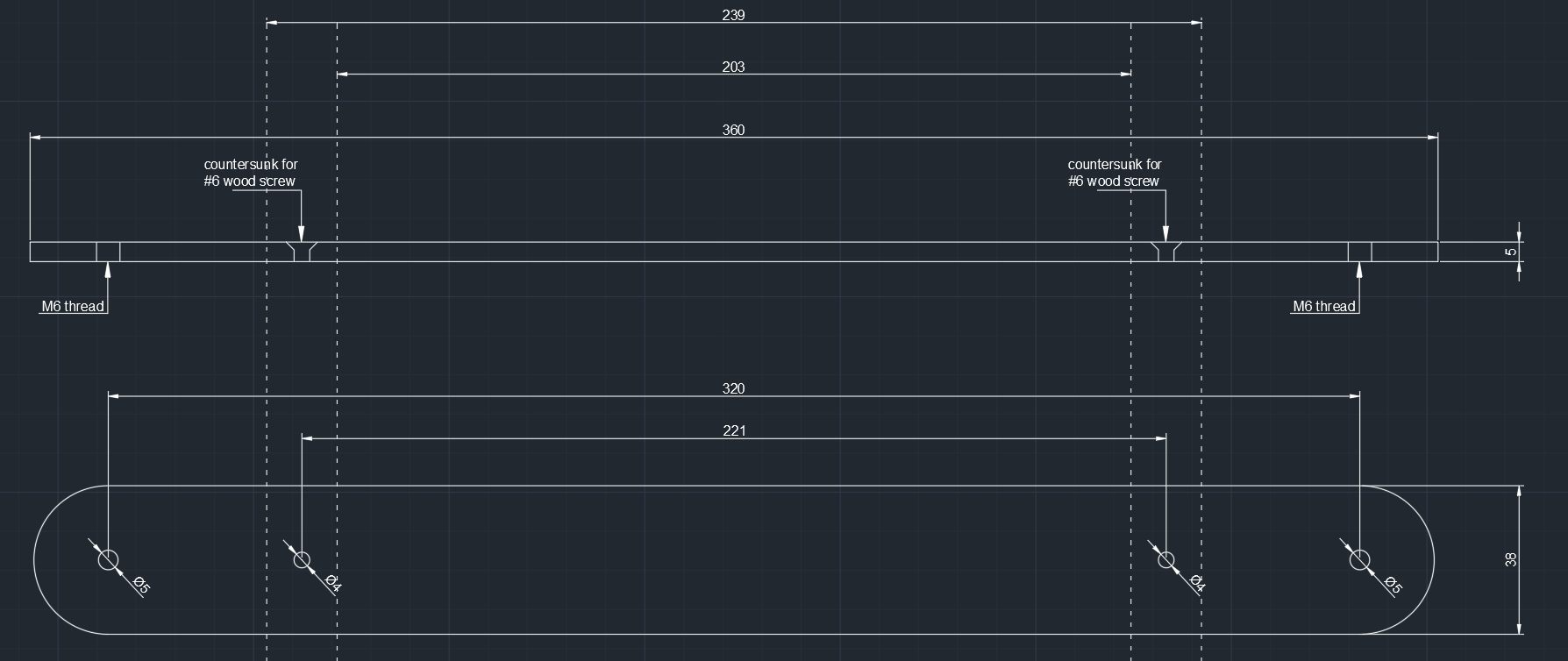

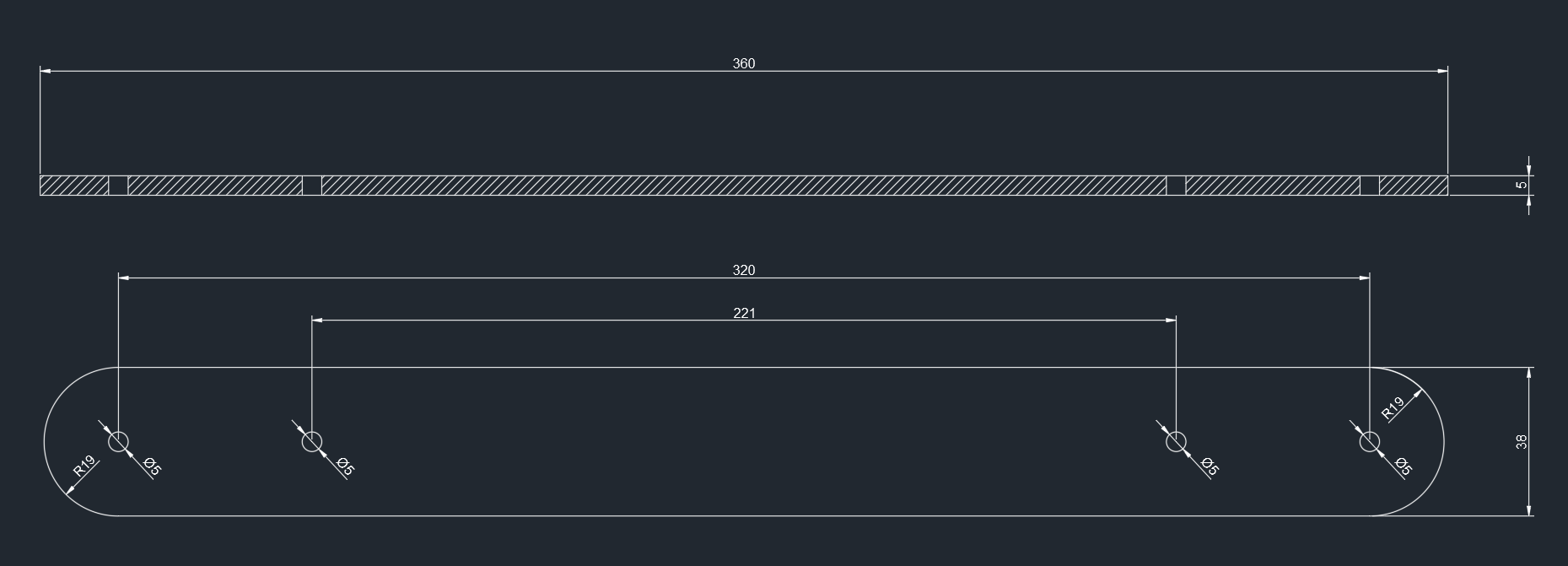

What about moving the wood screws inside lateral panels of the cabinets, in order to use longer screws?

Like this (dimensions in mm, side panels of the cabinet dashed):

What about moving the wood screws inside lateral panels of the cabinets, in order to use longer screws?

Like this (dimensions in mm, side panels of the cabinet dashed):

Last edited:

IIRC, those countersunk holes were located so as to be centered on the vertical side panels of the FH3 for which the were originally fabricated, and on my own installs the wood screws were probably 2” - 2 1/2”?

They were aluminium bar stock, so it was certainly easy enough to drill new holes should that have been necessary.

They were aluminium bar stock, so it was certainly easy enough to drill new holes should that have been necessary.

Last edited:

Indeed you are right @chrisb !

https://www.frugal-horn.com/downloads/frugel-hornMk3-1v0-060518.pdf

The centers of the vertical panels are around 6" apart in the FH3.

I will then use the below (simplified with 4 holes of 5 mm diameter, in order to thread for M6 and use 4,5 mm wooden screws):

I will order 8 of them, lasercut, as Silbury and FHXL have the same front width.

Countersunk will be done later on. Threads if needed.

https://www.frugal-horn.com/downloads/frugel-hornMk3-1v0-060518.pdf

The centers of the vertical panels are around 6" apart in the FH3.

I will then use the below (simplified with 4 holes of 5 mm diameter, in order to thread for M6 and use 4,5 mm wooden screws):

I will order 8 of them, lasercut, as Silbury and FHXL have the same front width.

Countersunk will be done later on. Threads if needed.

Last edited:

My guess is that’s entirely the luck of the draw on the slip matched flitches of rotary cut veneers on the top face of sheets, and in the case of the left enclosure on top photo from “sun-burn” due to extended storage of materials with partial masking from stacking, to which some species are more susceptible than others.

Looks like meranti or some other tropical species to me, but those are just guesses.

I was always more inclined towards vertical grain orientation, which dis make for creative cut plans for enclosures such as these with irregular shaped side panels. Some of the cut sheet plans in Dave’s drawings referenced above were layed out for than purpose. They needed be even more creative when highly figured species such as bookmatched American black walnut or cheery were used for final post veneering. Much fun.

Looks like meranti or some other tropical species to me, but those are just guesses.

I was always more inclined towards vertical grain orientation, which dis make for creative cut plans for enclosures such as these with irregular shaped side panels. Some of the cut sheet plans in Dave’s drawings referenced above were layed out for than purpose. They needed be even more creative when highly figured species such as bookmatched American black walnut or cheery were used for final post veneering. Much fun.

Last edited:

Thanks, my idea is more about keeping the wood as it is on the sides (see first picture at post #92: https://www.diyaudio.com/community/...speakers-newbie-questions.398826/post-7474296 ) and enhance the grains with a warmer general look, while having another colour on the front&rear (probably fitting the stainless steel & wood internal stair or the pellet stove).

Saw those earlier, and don’t think I complimented the workmanship. I hope you enjoy completing the project and the first playing - even with repeated build of similar enclosure designs, that first date was always fun.

Outriggers are ready, this evening they will be polished.

I made all holes with a diameter of 5 mm so the outer ones can be threaded for M6 and the inner ones fit 4,5 mm wood screws.

With the dimensions I used above, outriggers exceed 60 mm per side from side panels, being 360 mm wide totally.

More than enough for the FHXL, and still good for Silbury IMHO.

I made all holes with a diameter of 5 mm so the outer ones can be threaded for M6 and the inner ones fit 4,5 mm wood screws.

With the dimensions I used above, outriggers exceed 60 mm per side from side panels, being 360 mm wide totally.

More than enough for the FHXL, and still good for Silbury IMHO.

- Home

- Loudspeakers

- Full Range

- A new pair of Silbury speakers: newbie questions