A company called Rockler.com has brass threaded inserts of various sizes. Nice because they are non magnetic.

It is not possible to repair when such damage has occurred?

Is it an injury caused by playing too strong? Or without any box?

It may be possible to massage it to be less serious, but i had no luck. And coat or 2 of dilted Acrylic Gloss with a bit extra at the crease would extend the life.

This kind of thing is caused by an accident. ie i did very similar accidentily dropping the cardboard that covers them in the box just perfectly to create teh crease.

dave

Downside to very thin alloy cones unfortunately -they're quite vulnerable to accidental damage from even apparently minor strikes. Over an extended period it may (possibly) cause a stress-failure, but we're probably talking years. Technically it will asymmetrically change the resonant profile of the cone toward the upper end of its range before it (to an extent) decouples over to the central cap, but unless severe, I doubt it will be especially audible.

Put a thin metal washer or two between driver and box, to decouple the driver - and to counter the wooden character of the cabinet with a metal character.

Seal the resulting gap with e.g. thin foam.

Seal the resulting gap with e.g. thin foam.

A couple of thoughts about that:

-It's questionable whether a metal washer between a well-damped polymer basket with a sealing gasket, and a box, creates a mechanical decouple

-A properly designed cabinet should not have audible panel resonances in the first place

-Assuming, purely for the sake of argument, that both the metal washer and the cabinet were resonating (although I thought you were suggesting the former as a mechanical decouple ), and also assuming that a 'metal character' can in fact counter a 'wooden character', I would have thought you would need to do a very large amount of experimenting indeed to establish complimentary frequencies and amplitudes, and the types, dimensions & locations of the metals needed to do so. I'd be a mite surprised (worried) if a few washers caused such dramatic differences.

), and also assuming that a 'metal character' can in fact counter a 'wooden character', I would have thought you would need to do a very large amount of experimenting indeed to establish complimentary frequencies and amplitudes, and the types, dimensions & locations of the metals needed to do so. I'd be a mite surprised (worried) if a few washers caused such dramatic differences.

-It's questionable whether a metal washer between a well-damped polymer basket with a sealing gasket, and a box, creates a mechanical decouple

-A properly designed cabinet should not have audible panel resonances in the first place

-Assuming, purely for the sake of argument, that both the metal washer and the cabinet were resonating (although I thought you were suggesting the former as a mechanical decouple

), and also assuming that a 'metal character' can in fact counter a 'wooden character', I would have thought you would need to do a very large amount of experimenting indeed to establish complimentary frequencies and amplitudes, and the types, dimensions & locations of the metals needed to do so. I'd be a mite surprised (worried) if a few washers caused such dramatic differences.

), and also assuming that a 'metal character' can in fact counter a 'wooden character', I would have thought you would need to do a very large amount of experimenting indeed to establish complimentary frequencies and amplitudes, and the types, dimensions & locations of the metals needed to do so. I'd be a mite surprised (worried) if a few washers caused such dramatic differences.Yes. It does. 😉 I just didn’t want to cause unintentional offence. I don’t design enclosures like Silbury to be structurally resonant.

The material resonances of the wood-based casings are sonically unknowable, incalculable, unpreventable, significant, relevant. But also counterable;-)

...

...

@cumbb I would suggest you to open a dedicated thread about your practices. Me personally I will follow @Scottmoose and @planet10 suggestions.

Generally speaking (and as noted without in the least meaning to cause any offense) -I do know the baseline resonant properties of both my own designs, and the recommended materials used for their construction. That's why they are recommended. As a matter of fact, the resonant properties of most man-made wood based products (various forms of plywood, MDF, HDF, chipboard / particleboard, OSB, valcromat, panzerholtz & so on & so forth), along with averages for specified forms of hard & softwood (assuming close grain, minimal knots etc.) are a known quantity, with average MOE etc. values established to a high degree of consistency. The sheet materials in particular by nature of engineering requirement need to be produced to a high level of repeatability. From that & other testing, I / we (since they are Dave's too) know when & where a panel of specified material & given dimensions needs bracing in order to move their resonant modes out of the band where sufficient energy exists to cause audible excitation.The material resonances of the wood-based casings are sonically unknowable, incalculable, unpreventable, significant, relevant. But also counterable;-)

...

Last edited:

@Scottmoose I had an old version of the Silbury files and noticed few days ago that baffle bracing was indicated with a shorter measure. I have four seasoned pine-wood pieces that I can adapt to the needed dimensions for bracing. Can I use it?

The shorter works more or less as well, but the longer was introduced more 'for completeness'. 'Short' version 😉 is sure. And seasoned pine should be fine -although I'd suggest it's sealed to ensure consistency.

Pine can be a rigid old Hector. I remember GM once telling me about a pair of boxes he built about 25 years ago from seasoned pine taken from boards that were originally used in a barn for about 150 years. They had a stiffness-weight ratio roughly equivalent to aluminium.

Pine can be a rigid old Hector. I remember GM once telling me about a pair of boxes he built about 25 years ago from seasoned pine taken from boards that were originally used in a barn for about 150 years. They had a stiffness-weight ratio roughly equivalent to aluminium.

Thanks! I will use wood bisquits to fix it to the baffle and the other surface. The same I’m using for the rest of the cab.

I will drill a circle on the back of the speaker, with a small hole in the central panel to let the ethernet pair of cables to pass through, hole filled then with glue.

I’m lining the chamber behind the speaker, everything else is naked wood with no lining nor stuffing.

I will drill a circle on the back of the speaker, with a small hole in the central panel to let the ethernet pair of cables to pass through, hole filled then with glue.

I’m lining the chamber behind the speaker, everything else is naked wood with no lining nor stuffing.

Good start. You may (by design) find depending on system & room characteristics that you will need to add a little extra damping in the final stage of the horn expansion -they're a high-gain type by intent, since it's always easier to get rid of excess than increase what doesn't exist in the first place. 😉

Thanks, what should I hear to understand that I need damping? And you mean lining the sides or stuffing last “corner” and straight part?

@Scottmoose I had an old version of the Silbury files and noticed few days ago that baffle bracing was indicated with a shorter measure. I have four seasoned pine-wood pieces that I can adapt to the needed dimensions for bracing. Can I use it?

This brace was added after the first build (Victor) showed they were required.

as long as the brace is more or less continuous you will be fine. It really matters little if you make it out of 1 or 2 lengths. Do add some glue to the ends so the 2 shorter pieces essentially become one.

dave

Thanks,

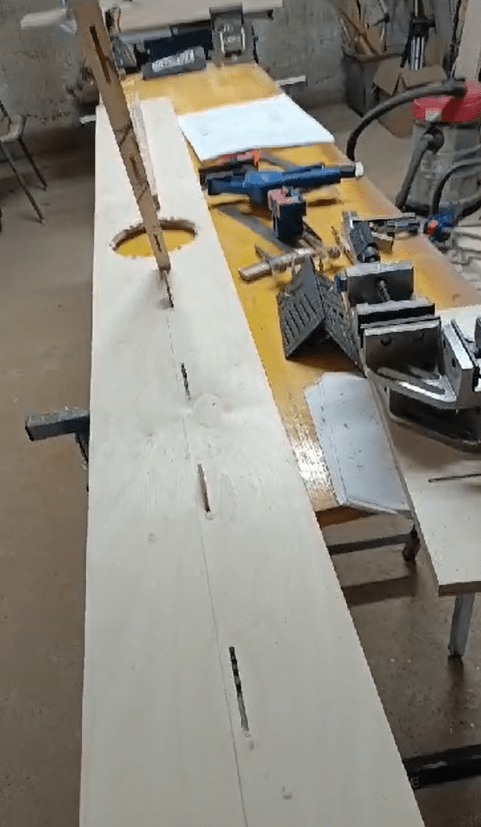

FHXL cabs are in 18 mm birch plywood. I added some glue to be sure the V-shaped panels were properly sealed, and I will add some bisquits as well.

Silbury is in 18 mm birch plywood except two small panels inside the cabinet that are in poplar plywood, and those four braces that will be in seasoned pine-wood (here below).

FHXL cabs are in 18 mm birch plywood. I added some glue to be sure the V-shaped panels were properly sealed, and I will add some bisquits as well.

Silbury is in 18 mm birch plywood except two small panels inside the cabinet that are in poplar plywood, and those four braces that will be in seasoned pine-wood (here below).

They were somewhat pre Civil War and just West of Sherman's March to Savannah, so survived at least 150 yrs according to the locals when I got them in '95. ~1 x 12 yellow pine that I had to tediously plane to 5/8" to get flat 'enough'.The shorter works more or less as well, but the longer was introduced more 'for completeness'. 'Short' version 😉 is sure. And seasoned pine should be fine -although I'd suggest it's sealed to ensure consistency.

Pine can be a rigid old Hector. I remember GM once telling me about a pair of boxes he built about 25 years ago from seasoned pine taken from boards that were originally used in a barn for about 150 years. They had a stiffness-weight ratio roughly equivalent to aluminium.

Anyway, some pics less planned clear coat, finished grills that never happened since Buzz/owner liked them 'as is' except for adding 1 x 2 hardwood tripod stands due to the need to protect them from falling on visiting family children and/or their pets and removed some of the damping to 'brighten' them up a bit due to his military damaged hearing.

- Home

- Loudspeakers

- Full Range

- A new pair of Silbury speakers: newbie questions