I don't like to stress the basket.

In my example with the PR2 woofs, the threaded rods supply the opposite sense.

dave

In my example with the PR2 woofs, the threaded rods supply the opposite sense.

dave

Yes that is fair enough, I reckon it would be ok on a strong cast frame though. Are the rods in tension, compresion or at zero load.

If you look at the shelf brace vrs the vertical brace, based on this research (and example data) there is about ~150%* less energy available to excite the panel with the vertical brace. * (if i got the ratio calculated correctly -- (100^2-160^2)/100^2).

dave

This I understand. My current bracing method is to use two horizontal braces above and below the driver to tie the box together and vertical braces to break up panel modes.

Bob

Member

Joined 2009

Paid Member

you could also epoxy a bracket or piece of birch ply to the back of the magnet and then bolt this to a holey brace. Of course, you'll need to use it in box where one of the panels can be removed to access the bolt.

.........the brace will cycle between 250N and 150N of compressive force and never go to 0 N load. The driver will always be braced with load

This type of mass loading is the most desirable and combined with a motor support cross brace if it's heavy, especially if it's a wide BW driver app. An adjustable one such as Herb's allows for fine adjustment since you only want just enough pressure to hear an audible difference.

Of course the cab must be rigid to minimize the preload pressure and maintain it over time, so all six sides must be tied together at least in driver location area to keep it from 'breathing'/bowing over time.

GM

Attachments

I don't like to stress the basket.

In my example with the PR2 woofs, the threaded rods supply the opposite sense.

dave

Hmm, the basket is stressed by gravity and diaphragm oscillation, so ideally needs something to counteract this.

GM

Hmm, the basket is stressed by gravity and diaphragm oscillation, so ideally needs something to counteract this.

the force of gravity on the basket/magnet is constant and the movement of the diaphragm is variable and passes through the mounting ring to the baffle and backwards to the magnet. If a secure mechanical connection is made to the 'holy brace' (new spelling due to the fervent discussion 😀) it shouldn't even require a lip to support the magnet and thus gravity is dealt with.

Although I think you have a few Altec horns lying around that cant support their +20lbs CD on the back GM 😀 - wish I had a set 🙁

Last edited:

Yes that is fair enough, I reckon it would be ok on a strong cast frame though. Are the rods in tension, compresion or at zero load.

Tension (just a bit)

dave

This type of mass loading is the most desirable and combined with a motor support cross brace if it's heavy, especially if it's a wide BW driver app. An adjustable one such as Herb's allows for fine adjustment since you only want just enough pressure to hear an audible difference.

GM

This looks excellent, basically what I had in mind.

I should have realised earlier, that if I put the rod in compression then I don't need to drill and tap the back of the driver.

I will see what I can do to impelement it. In fact I will build this, next week

Last edited:

Member

Joined 2009

Paid Member

Just listening to the 5.6 Cabinet with and without EQ.

I have not listened to it for about a week because of all the work have been doing.

This thing (AN15) absolutely kicks butt. No bullsh1t

I have not listened to it for about a week because of all the work have been doing.

This thing (AN15) absolutely kicks butt. No bullsh1t

Last edited:

Member

Joined 2009

Paid Member

Not a massive difference actually.

I could live with either. I am trying to optimise the ported version.

I will make some longer ports

I could live with either. I am trying to optimise the ported version.

I will make some longer ports

Member

Joined 2009

Paid Member

in the simulations I did, I also found little benefit of using a port in terms of bass extension - the box is simply too small (my simulation wanted me to use a 1,600 litre box if going vented !!!!!). Try stuffing the port slightly, to make it more aperiodic.Not a massive difference actually.

I could live with either. I am trying to optimise the ported version.

I will make some longer ports

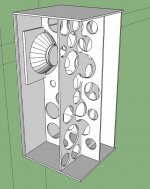

I'm adding some filets into the corners to strengthen the joints. I round off the corner of the filet where it goes into the corner of the box because there's invariably some glue that has squeezed out of the joint on the main box and the rounded off filet will allow for some clearance and ensure that the filet makes good contact with the side panel and front baffle.

The box looks like an empty shell - there's a fair bit of bracing to go in here yet.

Not so easy finding a clamp for the filets though...

Attachments

Last edited:

Quite. With the 12in models (AlNiCo aside, which I'd prefer not to think about in this Vb), you'd probably do OK pitching for a < 35Hz Fb. The 15in model? Er, no. 🙄

Member

Joined 2009

Paid Member

so, how about a big holey brace vertical front to back ?

That looks great!! Is it off centre? Also can you make the brace flat where it touches the magnet?

If you can work out how to add 2 more horizontal holey braces that 'slot' into the main vertical brace that contact all 4 vertical walls, and again space them randomly - now the would be cool 😀

Next up how about 2 holey braces that slot into the main vertical brace, but at angles (different for each brace) from front to back? 😱

To totally blow your mind & wood working skills take those 2 holey braces and spin them on 2 axis to random angles - maybe low point towards front right corner and high point to back left corner

Member

Joined 2009

Paid Member

I'll give some thought to the idea of an angled brace. My original thinking was just to have two vertical braces, one front to back, the other side to side. Neither of them divide the box into equally halves of course, they are both offset. I'd shape the front-to-back brace around the magnet better.

Attachments

- Home

- Loudspeakers

- Full Range

- A Big'un - the Audio Nirvana Super 15