Thanks a lot fluid.. 🙂

So get the cabinet, do the impedance sweep (I have a dayton DATS v3, so will use it) and figure out the unwanted resonances, and that decides the damping strategy. Got it.. 🙂

I will search around for rubber/sorbothane feet.

I saw rubber sheets added to the walls of the cabinet in your build. What is the purpose of it? Is it just to add mass to the entire structure and lower the frequency at which panel vibrations occur? (Troels also discusses about using bitumen sheets here: http://www.troelsgravesen.dk/cabinet-damping.htm)

In the meanwhile, inspired by augerpro's simple driver isolation method, I managed to source some 2.5mm thick nitrile rubber O rings for using with screws for driver attachment to baffle. Don't know how effective this specific O ring might be in this case. But I will try it out. 🙂

Regards

Vineeth

So get the cabinet, do the impedance sweep (I have a dayton DATS v3, so will use it) and figure out the unwanted resonances, and that decides the damping strategy. Got it.. 🙂

I will search around for rubber/sorbothane feet.

I saw rubber sheets added to the walls of the cabinet in your build. What is the purpose of it? Is it just to add mass to the entire structure and lower the frequency at which panel vibrations occur? (Troels also discusses about using bitumen sheets here: http://www.troelsgravesen.dk/cabinet-damping.htm)

In the meanwhile, inspired by augerpro's simple driver isolation method, I managed to source some 2.5mm thick nitrile rubber O rings for using with screws for driver attachment to baffle. Don't know how effective this specific O ring might be in this case. But I will try it out. 🙂

Regards

Vineeth

For me it was both mass and some shear damping and because I had a sheet of it lying around getting in my way. Do you really want your cabinets to be even heavier?I saw rubber sheets added to the walls of the cabinet in your build. What is the purpose of it? Is it just to add mass to the entire structure and lower the frequency at which panel vibrations occur?

I would not try and isolate the woofers from the box with O rings. It is the midrange and tweeters that suffer from cabinet induced vibration. In your case with a split construction the two cabinets can be isolated from each other quite well with a damping sheet or feet placed between them.In the meanwhile, inspired by augerpro's simple driver isolation method, I managed to source some 2.5mm thick nitrile rubber O rings for using with screws for driver attachment to baffle. Don't know how effective this specific O ring might be in this case. But I will try it out. 🙂

There is a document somewhere that Andrew Jones wrote where the effects were studied and they chose not to isolate the woofer as it sounded better directly connected.

I really don't want that.. 😀Do you really want your cabinets to be even heavier?

:O Oh.. ok..I would not try and isolate the woofers from the box with O rings. It is the midrange and tweeters that suffer from cabinet induced vibration. In your case with a split construction the two cabinets can be isolated from each other quite well with a damping sheet or feet placed between them.

I thought the driver isolation will help the woofers also by reducing the energy transferred by the woofer to the cabinet through the screws in the 400Hz -700 Hz frequency range (this maybe useful if I try to use this woofer cabinet in a 2/2.5 way configuration with a horn crossed over around 1kHz) and wont affect the very low frequencies (when I use this cabinet as just a woofer module for another 2 way top module) from discussion here: https://www.diyaudio.com/community/...n-methods-shootout-thread.356130/post-6799214

But if the isolation does something bad (audibly) at the very low frequencies then I need to reconsider the idea. Since I have these O rings already, I will just try it out and see what audible differences it makes..

Never any harm in trying for yourself, in reality a small rubber O ring like that is not going to do very much, to decouple a driver properly needs more.

Here from the horses mouth

https://www.diyaudio.com/community/threads/how-to-brace-a-speaker-cabinet.235908/post-4210469

https://www.diyaudio.com/community/threads/how-to-brace-a-speaker-cabinet.235908/post-4191876

Linkwitz

https://www.linkwitzlab.net/frontiers_2.htm#N

audioxpress and Andrew Jones article attached

Here from the horses mouth

https://www.diyaudio.com/community/threads/how-to-brace-a-speaker-cabinet.235908/post-4210469

https://www.diyaudio.com/community/threads/how-to-brace-a-speaker-cabinet.235908/post-4191876

Linkwitz

https://www.linkwitzlab.net/frontiers_2.htm#N

audioxpress and Andrew Jones article attached

Attachments

Since you're using the woofer to frequencies well in the panel resonance range, I would try the driver isolation and compare vs without it. I think you will probably prefer it as the panel resonances are high amplitude in a more sensitive region for the ear than any disadvantages at low frequency might be heard. The O-ring on the screw is surprisingly effective (about 4dB in my testing) but also requires mounting the driver with a similarly damped gasket. Thicker than the usually thin layer attached to the driver from the factory. Thicker rubber (2 mm or so) is easy to find, but in my testing I used 1.5 or 2 mm sorbothane sheets.

I also use the sorbothane feet that fluid mentioned on my boxes.

The aluminum-backed damping sheets you posted will also work very well.

I also use the sorbothane feet that fluid mentioned on my boxes.

The aluminum-backed damping sheets you posted will also work very well.

Isolating the drivers won't destroy the bass anymore than it it will significantly improve the midrange. The real world audible effects are subtle. But that does not mean that subtle isn't important in the long term either. I went to a lot of trouble to magnet mount the midrange in the Orion vs having it screwed directly to the panel in LX521. Given the other differences in the speakers I couldn't really tell you if it made any difference or not. Linkwitz wanted to isolate the large movement of the biggest drivers which was done in LX521 with the bridge mount for the top panel. When your woofer is your midrange then it becomes much less clear what to do. Brace and damp the panel or try and avoid the energy getting in through isolation.But if the isolation does something bad (audibly) at the very low frequencies then I need to reconsider the idea. Since I have these O rings already, I will just try it out and see what audible differences it makes..

To really test for yourself you need to build two different cabinets one with and one without and have some way of changing between them quickly. Listening to it one way one day then coming back the next after swapping them over, do you hear a difference, and then if you do, is it really because of the change?

To really test for yourself you need to build two different cabinets one with and one without and have some way of changing between them quickly. Listening to it one way one day then coming back the next after swapping them over, do you hear a difference, and then if you do, is it really because of the change?

Very very tricky question.. 😀

When I find the current XPS foam box for the woofer itself sounding so nice, to the extent that I wonder why I made these heavy cabinets for them, I can imagine the (probable) subtleness in the difference caused by a minute O ring in this setup.. 😀

I will just mount the woofer without O rings first, take frequency response, impedance, distortion measurements (if possible) and play some bass oriented and mid oriented tracks that I am familiar with for sometime. Then I will unscrew and mount the woofers again this time with O rings. Repeat the previous tests again. If at all I can see/hear any differences/everything stays the same as before, O rings stay. Otherwise O rings go.. 😀

Still searching around for Sorbothane feet.

Seems very very hard to get it.. 😀

The only reasonable option I could find was this: https://www.amazon.in/Isolate-Sorbo...cphy=9061994&hvtargid=pla-1387474888287&psc=1

But somehow, I doubt about its capabilities given its 0.25inch thickness and their big claims (about the kind of weight that can be supported) as shown in specs. In the worst case, I can just buy it and try out since it is not very costly.

Another crazy idea that I am wondering about is making a multilayer sandwich feet using 2-3 layers of 6mm ply discs and joining them together using CLD glue which I have lying around 😀

I don't know if it will actually make any useful difference since I am not sure about the problem itself🤔

I thought the purpose of the feet is to reduce the speaker moving around due to all the activity of the woofers and the resulting forces exerted on the cabinet. Keep the cabinet anchored to the surface where it is placed.

Maybe this is some grey area where much thinking doesn't do any good and one has to really do experiments and figure out.. 😀

Seems very very hard to get it.. 😀

The only reasonable option I could find was this: https://www.amazon.in/Isolate-Sorbo...cphy=9061994&hvtargid=pla-1387474888287&psc=1

But somehow, I doubt about its capabilities given its 0.25inch thickness and their big claims (about the kind of weight that can be supported) as shown in specs. In the worst case, I can just buy it and try out since it is not very costly.

Another crazy idea that I am wondering about is making a multilayer sandwich feet using 2-3 layers of 6mm ply discs and joining them together using CLD glue which I have lying around 😀

I don't know if it will actually make any useful difference since I am not sure about the problem itself🤔

I thought the purpose of the feet is to reduce the speaker moving around due to all the activity of the woofers and the resulting forces exerted on the cabinet. Keep the cabinet anchored to the surface where it is placed.

Maybe this is some grey area where much thinking doesn't do any good and one has to really do experiments and figure out.. 😀

Last edited:

sorbothane is very good but expensive and sometimes difficult to find locally

audio is a bit niche. You may have find more luck finding alternatives in commercial rubber/cork mat or feet.

There are plenty of them for use in damping commercial equipment such as plumbing; washing machines, clothing driers, sofa’s, furniture etc.

This is something I’ve personally used under my bass bin with dual 10” subwoofers per box. Weight: too heavy for 1 man lift

https://www.amazon.com.au/Slipstick-CB511-Protector-Furniture-Rubber/dp/B002A2JUJ8/ref=mp_s_a_1_1?crid=32TWOWNFHFQE3&keywords=slipstick+cb511&qid=1653797017&sprefix=slipstick+cb511,aps,282&sr=8-1

some o-rings that I use under the screws of the midrange drivers:

https://www.bunnings.com.au/syneco-3-22mm-o-rings-assorted-set-225-pieces_p0328987

Just some examples that you may or may not find locally but you get the idea… think outside the box, my friend.

Otherwise someone can sell you an audiophile USB cable…

audio is a bit niche. You may have find more luck finding alternatives in commercial rubber/cork mat or feet.

There are plenty of them for use in damping commercial equipment such as plumbing; washing machines, clothing driers, sofa’s, furniture etc.

This is something I’ve personally used under my bass bin with dual 10” subwoofers per box. Weight: too heavy for 1 man lift

https://www.amazon.com.au/Slipstick-CB511-Protector-Furniture-Rubber/dp/B002A2JUJ8/ref=mp_s_a_1_1?crid=32TWOWNFHFQE3&keywords=slipstick+cb511&qid=1653797017&sprefix=slipstick+cb511,aps,282&sr=8-1

some o-rings that I use under the screws of the midrange drivers:

https://www.bunnings.com.au/syneco-3-22mm-o-rings-assorted-set-225-pieces_p0328987

Just some examples that you may or may not find locally but you get the idea… think outside the box, my friend.

Otherwise someone can sell you an audiophile USB cable…

Last edited:

Thank you for this suggestion. 🙂sorbothane is very good but expensive and sometimes difficult to find locally

audio is a bit niche. You may have find more luck finding alternatives in commercial rubber/cork mat or feet.

There are plenty of them for use in damping commercial equipment such as plumbing; washing machines, clothing driers, sofa’s, furniture etc.

This is something I’ve personally used under my subwoofers with dual 10” subwoofers per box.

https://www.amazon.com.au/Slipstick-CB511-Protector-Furniture-Rubber/dp/B002A2JUJ8/ref=mp_s_a_1_1?crid=32TWOWNFHFQE3&keywords=slipstick+cb511&qid=1653797017&sprefix=slipstick+cb511,aps,282&sr=8-1

These kind of vibration control feet for washing machines and furniture are available in many varieties around here too..

I will get one of those and try out.

An example of Without and with foam gasket between a pure midrange driver and cabinet was shown in earlier post:

https://www.diyaudio.com/community/threads/a-3-way-design-study.376620/page-20#post-7013432

this in example of what you can sometimes measure but may not necessarily hear.

On the other hand, Sometimes you can hear something but may not be able/know how/where to measure it.

https://www.diyaudio.com/community/threads/a-3-way-design-study.376620/page-20#post-7013432

this in example of what you can sometimes measure but may not necessarily hear.

On the other hand, Sometimes you can hear something but may not be able/know how/where to measure it.

Last edited:

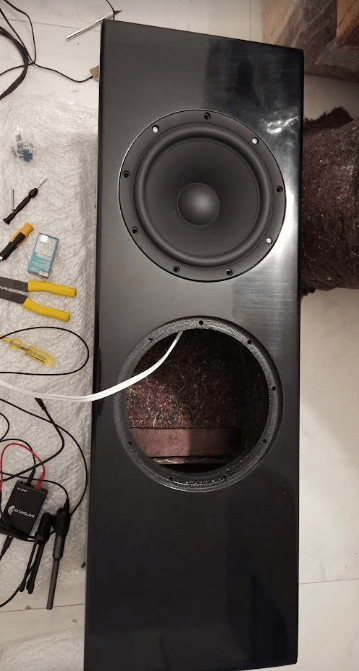

So I applied some damping material in the boxes and tried to get some nearfield frequency response and impedance measurements of a Satori WO24P-8 woofer fixed in the upper box of the cabinet as shown below.

Here is what the inside of the box looks like now with the driver removed:

Basically I glued some Alubutyl damping sheets that I had on the side and back walls. Then covered it with 10mm thick acoustic felt material.

Then I noticed two impedance bumps one around 230Hz and around 460Hz. In order to try to get rid of them, I put 25mm thick 8+ type melamine foam pad that I had on the top of the cabinet as seen in above pic, one at the bottom of the cavity and one piece somewhere around 1/3rd of the height. I also put a loose roll of polyfill on top of that as seen in above pic.

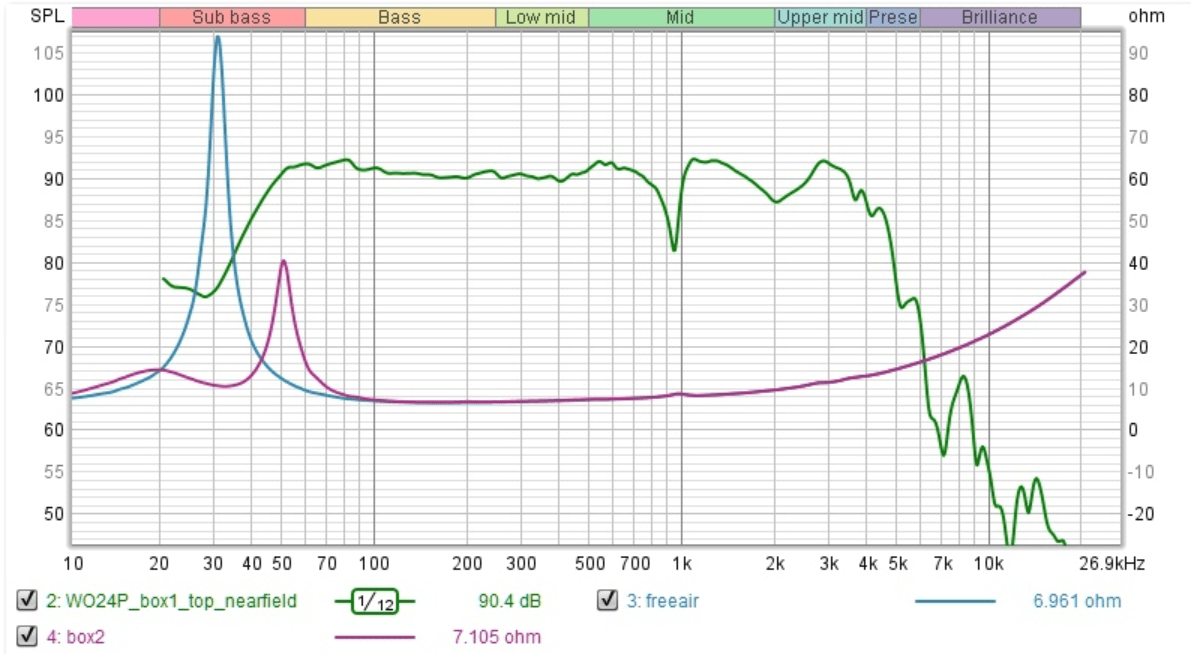

Here are the impedance measurements of the driver in free air and and box as treated above.

Also shown in the nearfield frequency response of the driver

Now the impedance blips around 230Hz and 460 Hz seems ?to be gone.

what all useful information can we get from above plots???

I am also yet to fill th8e enclosure.

what do we get we get from filling the enclosure?

Here is what the inside of the box looks like now with the driver removed:

Basically I glued some Alubutyl damping sheets that I had on the side and back walls. Then covered it with 10mm thick acoustic felt material.

Then I noticed two impedance bumps one around 230Hz and around 460Hz. In order to try to get rid of them, I put 25mm thick 8+ type melamine foam pad that I had on the top of the cabinet as seen in above pic, one at the bottom of the cavity and one piece somewhere around 1/3rd of the height. I also put a loose roll of polyfill on top of that as seen in above pic.

Here are the impedance measurements of the driver in free air and and box as treated above.

Also shown in the nearfield frequency response of the driver

Now the impedance blips around 230Hz and 460 Hz seems ?to be gone.

what all useful information can we get from above plots???

I am also yet to fill th8e enclosure.

what do we get we get from filling the enclosure?

If one of the woofers was out like in the picture it wouldn't tell you much, if they were both in then there is a leak which is seen by the double hump in the impedance.

The dip at 950 corresponds to an impedance blip but nearfield measurements are usually not that accurate above 400Hz and dip is probably from that. Otherwise pretty well behaved but with the slight bass lift it could sound a bit boomy.

Filling the enclosure will increase the apparent volume of the box and change the tuning.

The dip at 950 corresponds to an impedance blip but nearfield measurements are usually not that accurate above 400Hz and dip is probably from that. Otherwise pretty well behaved but with the slight bass lift it could sound a bit boomy.

Filling the enclosure will increase the apparent volume of the box and change the tuning.

Thanks fluid 🙂If one of the woofers was out like in the picture it wouldn't tell you much, if they were both in then there is a leak which is seen by the double hump in the impedance.

The dip at 950 corresponds to an impedance blip but nearfield measurements are usually not that accurate above 400Hz and dip is probably from that. Otherwise pretty well behaved but with the slight bass lift it could sound a bit boomy.

Filling the enclosure will increase the apparent volume of the box and change the tuning.

There is also a very small hole in the piece that separates the two driver boxes through which the wire comes out. I will close it fully, then attach the 2nd driver also and take measurents again. Each driver has a 35ish litre sealed box of its own in the big enclosure. so even without the second driver, the current driver is supposed to have a sealed box of its own.

The 950Hz dip is there even in the drivers natural response. This is also seen in hificompass's measurements. I thought it is caused by the Surround of the driver itself.

The nearfield measurement is not baffle step adjusted. Part of the bass lift seen the plot is due to not adjusting for that i think. I will create the the baffle step adjusted pic using vituixcad ad post it soon.

Also is loosely teased out polyfill enough for enclosure filling?. The current box tuning frequency looks to be around 50Hz.

Last edited:

The dip at Hificompass is about 1dB at the same frequency yours is more like 10 and quite high Q.

At 1k you are in the difficult to measure with high resolution range for gated measurements and nearfield becoming unreliable so you would have to cross correlate all the different measurements to try and work out what is going on.

I would try a piece of fibreglass or something like that placed in the middle of the enclosure between top and bottom on a brace if you have one near there. That might help kill or at least reduce any problems from the long dimension.

You don't have to fill the enclosure at all.

It is hard to see when the impedance traces are overlaid but check to see if the blips are at the same place as they are in free air. If not they come from the cabinet and you will need more damping or bracing if you want them gone.

At 1k you are in the difficult to measure with high resolution range for gated measurements and nearfield becoming unreliable so you would have to cross correlate all the different measurements to try and work out what is going on.

I would try a piece of fibreglass or something like that placed in the middle of the enclosure between top and bottom on a brace if you have one near there. That might help kill or at least reduce any problems from the long dimension.

You don't have to fill the enclosure at all.

It is hard to see when the impedance traces are overlaid but check to see if the blips are at the same place as they are in free air. If not they come from the cabinet and you will need more damping or bracing if you want them gone.

This plot I got from hificompass. normalized nearfield for the same driver. It shows a deep notch around 1kHz similar to mine.The dip at Hificompass is about 1dB at the same frequency yours is more like 10 and quite high Q.

Hificompass impedance measurement zoomed in (it shows that blip around 1kHz and sort of its integer multiples):

Yellow plot below is my baffle step adjusted response and green, the not adjusted one as earlier.

The impedance bump around 950Hz is there in both the free air plot and the driver in box plot.

Both curves are overlapping there. This is why I thought it is driver related.

Actually the long dimension already has 3 pieces of 25mm thick melamine foam and 30ish cm long roll of polyfill in a cylinder like shape with the round face of the cylinder having a diameter of about 15cm. All this did get rid of bigger impedances bumps which were there earlier at 230Hz and 460 Hz.I would try a piece of fibreglass or something like that placed in the middle of the enclosure between top and bottom on a brace if you have one near there. That might help kill or at least reduce any problems from the long dimension

I am not allowed to bring fibreglass material inside home as people at home are worried about its potential health hazards. Hence all this circus with other alternative material.. 😀

Also this driver is brand new. Its fs also looks to be around 30Hz from above blue impedance plot which is different from the published 24Hz fs.

So once I start using the driver more. Will these parameters change?

Last edited:

I speculate the 1kHz dip might be cone edge resonance or surround resonance or how it is called? edge moves at opposite phase than center of the cone and destructive interference happens, especially on-axis. How big is the driver? distance from mic (close miced) to edge is about half wavelength? Is it in far field response as well? Thats quite a deep notch anyway

edit. foundit https://hificompass.com/en/speakers/measurements/satori/satori-wo24p-8

The blip is not bad on farfield response, perhaps it is some resonance because impedance blip and magnified with distance from mic to cone edge when close mic. Frequency of dip changes perhaps just with distance from mic to dustcap.

edit. foundit https://hificompass.com/en/speakers/measurements/satori/satori-wo24p-8

The blip is not bad on farfield response, perhaps it is some resonance because impedance blip and magnified with distance from mic to cone edge when close mic. Frequency of dip changes perhaps just with distance from mic to dustcap.

Last edited:

There is that deep notch in nearfield response, impedance bump around the same frequency, steep rise in even and odd order harmonic distortion in the different harmonic distortion plots all around the same frequency. It seems to be distance dependent as the 315mm HD plots at hificompass show lesser rise in distortion compared to the 20mm measurement. Also far field frequency response don't show such pronounced dip.The blip is not bad on farfield response, perhaps it is some resonance because impedance blip and magnified with distance from mic to cone edge when close mic. Frequency of dip changes perhaps just with distance from mic to dustcap.

The other thing we have to keep in mind is what fluid said about nearfield measurements becoming not really trustable at such high frequencies.

But there is something going on around that 1kHz frequency 😀

I wonder what exactly is the cause of all this.. 😀 Maybe there are multiple things happening. The driver breakup is starting around 3kHz.

1kHz being a subharmonic may also be seeing rise in distortion components due to that. Just speculating.....

Last edited:

Yeah its fun try and imagine what might it be, but its gonna be there nevertheless and swapping driver is only way to change it. But hey isnt't it stop band of the woofer box in your application? so doesn't matter much anyway.

It would be nice to know what it is, how much does it matter in application and how to spot it from measurements if it does matter, or distinguish from other possible phenomena if it doesn't. Lets see if some one knows what it is 😀 I wonder if and how it shows up in a spinorama if you make one.

It would be nice to know what it is, how much does it matter in application and how to spot it from measurements if it does matter, or distinguish from other possible phenomena if it doesn't. Lets see if some one knows what it is 😀 I wonder if and how it shows up in a spinorama if you make one.

- Home

- Loudspeakers

- Multi-Way

- A 3 way design study