Yes.

You could even pop for the AN-3222 (300VA) for ~$7 more.

I think the shipping is the same for either one. ($11 USA)

You could even pop for the AN-3222 (300VA) for ~$7 more.

I think the shipping is the same for either one. ($11 USA)

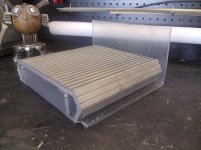

Well, pushing on with the task at hand. I was slooooowwwwlly able to bend the acrylic sheet and make it fit to where I was somewhat satisfied. I wasn't able to take any "during" pictures as it was done on my lunch break while at work tonight. I have to say that it takes a lot of patience to get it to fit tight. Overall I'm quite happy with it. Now I just have to cut and trim the leftovers and decide on how I want to mount the hardware.😀

Attachments

Looking forward to seeing what you come up with. I like the last chassis you built.

This is going to prove to be a (pita). Wanted to make this a 2 piece enclosure but, it's gonna be difficult to wire up and still be neatly wired

Gonna have to think it through before i cut anything.

Thank you for the last enclosure.... think I might use it for the computer still.

I got some parts for my newest build on the way. They have to come from China, so I guess I can sit back and wait a couple of weeks! 😉 I now need to explorer enclosures and cases.

Does anyone have a list of suppliers of enclosures they have used in the past, that has a good selection and broad variety. I know Mouser has quite few, but there may also be some smaller, less known vendors too that I'm not aware of. Who's had success with vendors of nice looking cases at reasonable prices? Names? Thx in advance.

Does anyone have a list of suppliers of enclosures they have used in the past, that has a good selection and broad variety. I know Mouser has quite few, but there may also be some smaller, less known vendors too that I'm not aware of. Who's had success with vendors of nice looking cases at reasonable prices? Names? Thx in advance.

Now seeing your further work on that case, check the dimensions on the transformers as you might have to stay within a certain VA rating to get it to fit inside. AN-3222 datasheet shows 2.9" height, but maybe a little more with the rubber mounting pads. AN-2222 is 2.3" + pads.

Well the internal height of the main case is 1 7/8" but, I have been kicking around ideas for a separate case for the power supply. I've been looking around at other builders layouts and I really like the separate case look. I was thinking something like a 4" id aluminum pipe tower of some sort. (I can get pipe from 1" to 8" at work. steel,chrome molly or aluminum)

On a side note I was looking around for something a little different to wire things up with and came across this

Test Lead Wire - Silicone Test Lead Wire - Pomona Silicone Test Lead Wire - Cal Test Silicone Test Lead Wire

Price is pretty good and I was just thinking."if it's good for test leads then why not audio?" I know it's not Teflon coated but, for a guy on the cheap I thought I would try it.

Any positive or negative thoughts on this wire???

On a side note I was looking around for something a little different to wire things up with and came across this

Test Lead Wire - Silicone Test Lead Wire - Pomona Silicone Test Lead Wire - Cal Test Silicone Test Lead Wire

Price is pretty good and I was just thinking."if it's good for test leads then why not audio?" I know it's not Teflon coated but, for a guy on the cheap I thought I would try it.

Any positive or negative thoughts on this wire???

Even the lesser 200VA transformer has a diameter of 4.5", then add a little space around it for ventilation purposes, and the holes or slits for convective cooling either in the pipe or top and bottom panel. Toroidal transformers don't have a strong magnetic field but what there is, is along the axis so people generally mount them oriented so nothing else is along the axis, though their general shape and the shape of a rack chassis case also makes this easier.

Test lead wire would work, but you're paying a bit more for the silicone and higher strand count /flexibility that isn't needed. Electrically any wire of adequate gauge should be fine, on the cheap you could pick up a few feet of stranded wire from a hardware store for under $4 though you have less choice on what color it is, but if you'll settle for black that's easy to find.

Edit: With the price of copper continuing to rise, maybe hardware store wire is $5 now... but I like to support the local mom 'n pop hardware stores as they carry things nobody else does locally.

Test lead wire would work, but you're paying a bit more for the silicone and higher strand count /flexibility that isn't needed. Electrically any wire of adequate gauge should be fine, on the cheap you could pick up a few feet of stranded wire from a hardware store for under $4 though you have less choice on what color it is, but if you'll settle for black that's easy to find.

Edit: With the price of copper continuing to rise, maybe hardware store wire is $5 now... but I like to support the local mom 'n pop hardware stores as they carry things nobody else does locally.

Last edited:

Thanks for taking the time and offering feedback. I have a ton of different wires laying around the garage and at work. I'll look around and see what I come up with. I've also noticed guys using various gauge wires implemented into their designs. Is there a drawback to using all the same gauge? I have noticed guys using "cat" cable for inputs.

Sorry for all the "noob" questions here. Just want it right the first time ya know😎

Sorry for all the "noob" questions here. Just want it right the first time ya know😎

No drawback, so long as that gauge isn't too small for the power rails. Well to be fair, there are all kinds of myths, legends, and snake oil out there when it comes to what is important for audio wiring. I don't want to stir up arguments because some claim certain things sound different (no matter what that certain difference is!) but I can't hear any difference and people tell me I have pretty good hearing.

Generally people just use what they have lying around or buy some in bulk and then it's cheaper to use a little lower gauge than something really needed instead of buying several different gauges of wire or keeping stock of many gauges. Plus there's the mechanical aspect, lower gauge wire is just more durable, all else equal can withstand more bending too but at some point the wire is just too big for the particular connector you want to solder it to.

CAT network cable is convenient because it's already in twisted pairs, instead of using shielded cable on low level signal lines. If the runs are inside a shielding metal (grounded) case, you won't have the RF pickup you would externally unless you're stuffing RF radiating circuitry into the amp case too.

Generally people just use what they have lying around or buy some in bulk and then it's cheaper to use a little lower gauge than something really needed instead of buying several different gauges of wire or keeping stock of many gauges. Plus there's the mechanical aspect, lower gauge wire is just more durable, all else equal can withstand more bending too but at some point the wire is just too big for the particular connector you want to solder it to.

CAT network cable is convenient because it's already in twisted pairs, instead of using shielded cable on low level signal lines. If the runs are inside a shielding metal (grounded) case, you won't have the RF pickup you would externally unless you're stuffing RF radiating circuitry into the amp case too.

Last edited:

Thanks for clearing it out a little for me. Like I said, I can get my hands on alot of different types of wire. I'll just have to play around a little untill I find something I like

I prefer wire that takes the heat from the soldering iron without melting.

Although you can't really tell until you try it, unless it's silicon etc.

Although you can't really tell until you try it, unless it's silicon etc.

I prefer wire that takes the heat from the soldering iron without melting.

didn't even think of that......guess that's the whole point of asking questions

^ well, it depends on the situation. I can't speak for all situations but personally if I find insulation melting it was a poorly tinned soldering iron, though I factor for a slight shrinkage when I trim back insulation, and if a few millimeters of insulation loss is a factor I put a piece of heat shrink tubing on the wire a distance away then after soldering, slide it into place and shrink it.

Having written that, I have never found a need for any particular wire insulation, EXCEPT in situations where the particular use required it. For example when I rebuilt a hot dog cooker for a non-profit org. it needed silicone insulation, fiberglass sheath too, and crimped onto the heating element. The high heat prevented use of solder or any other wire type. If you don't have this kind of high temperature, there isn't necessarily any need for wire that tolerates it, it's more a matter of building method. It is fair and reasonable to spend more on parts if your building method makes that quicker... but there's a difference between what is needed and what is optimal for any particular person's building method.

Having written that, I have never found a need for any particular wire insulation, EXCEPT in situations where the particular use required it. For example when I rebuilt a hot dog cooker for a non-profit org. it needed silicone insulation, fiberglass sheath too, and crimped onto the heating element. The high heat prevented use of solder or any other wire type. If you don't have this kind of high temperature, there isn't necessarily any need for wire that tolerates it, it's more a matter of building method. It is fair and reasonable to spend more on parts if your building method makes that quicker... but there's a difference between what is needed and what is optimal for any particular person's building method.

Last edited:

well it's a good thing i got a 1 lb. spool of solder coming and a whole mess of wire laying around.......better get practicing!

Another thing... what would be the best iron to use for this type of circuit building? wattage wise, would a variable wattage (40w max) be good?

Another thing... what would be the best iron to use for this type of circuit building? wattage wise, would a variable wattage (40w max) be good?

I'm starting to sound like I get a commission - I don't - but I have had very good luck and great sound with this stranded silver plated copper Wire from ApexJr. Just ordered a bunch more yesterday.

I'm actually setting up my latest build with extra pins and sockets to facilitate testing various wires to see if I can hear any differences. I'll eventually finalize with direct point to point (no sockets or pins) in any event.

Wire

I'm actually setting up my latest build with extra pins and sockets to facilitate testing various wires to see if I can hear any differences. I'll eventually finalize with direct point to point (no sockets or pins) in any event.

Wire

My soldering tip has nothing to do with it at all, cheap wire melts fast, also not all wire is designed to be soldered. 😉

Some insulation melts too easy, some not at all.

Like anything else some are good, some are bad.

You don't want to feel rushed and risk a potential cold solder joint.

Once the solder melts onto the joint, I hold it for another 2 or 3 seconds. The whole process takes about 4 seconds.

Some insulation melts too easy, some not at all.

Like anything else some are good, some are bad.

You don't want to feel rushed and risk a potential cold solder joint.

Once the solder melts onto the joint, I hold it for another 2 or 3 seconds. The whole process takes about 4 seconds.

- Status

- Not open for further replies.

- Home

- Amplifiers

- Chip Amps

- 3886 Ebay kit Build