BHTX said:

Thanks, that looks good. Mine won't be quite the same as it's Beta 8A - this newer version has a purple tinted cone and the Eminence response curve is a little different (but just as good).

Simon

BHTX said:

The driver is APT-50. 80 is with a small plastic horn, and it gives that smooth response. Mine will be very different again as it's using an 8" DIY waveguide.

Simon

Ah.. guess that's what happens when I'm tired+lazy and don't take the time to read threads that I'm posting in.. lol.

Nice project. Cheers. 🙂

Nice project. Cheers. 🙂

I am interested on what you think those Mundorf bi-polars will sound like in the T-bass setup. I was thinking the same thing.

Me too, I expect them to work well, but I'll report on the overall bass quality as soon as I hear it. I somehow think I'll be spewing superlatives in a laughably gushing manner...

I'll probably make a small start on the woodworking / marking of panels this evening. I can't wait to get some tangible progress done now 😀

I'll probably make a small start on the woodworking / marking of panels this evening. I can't wait to get some tangible progress done now 😀

I'm extremely impressed Simon! It even LOOKS like it'll sound good! 🙄

A general question for those that've used it - how does this ply handle machining such as rebating drivers?

I'm soon ordering timber for my own OB and have only used MDF in the past, which of course is very good for routing. I'm wondering if ply causes any problems like roughness or splintering (limited router useage, here).

I will second others who comment on the dust problem. Not nice. That's without considering aesthetics and performance.

Simon, you make me wish I hadn't gone with the Silver Irises. Much more fun your way.

Stuey

A general question for those that've used it - how does this ply handle machining such as rebating drivers?

I'm soon ordering timber for my own OB and have only used MDF in the past, which of course is very good for routing. I'm wondering if ply causes any problems like roughness or splintering (limited router useage, here).

I will second others who comment on the dust problem. Not nice. That's without considering aesthetics and performance.

Simon, you make me wish I hadn't gone with the Silver Irises. Much more fun your way.

Stuey

Kind words, thanks, but we'll soon see how much fun this is. A friend who's built a few guitars has warned me that the plywood will be hard work to use, spintering etc. I'm also not 100% sure how I can turn the waveguides, but others have made such things so it must be possible! Myabe it's one to start a dedicated thread for.

I doubt this will be as good as Silver Irises, but hopefully very good anyway.

I'm drunk, I should not be replying to threads right now...!!!

Simon

I doubt this will be as good as Silver Irises, but hopefully very good anyway.

I'm drunk, I should not be replying to threads right now...!!!

Simon

Now it's morning and I badly need a cup of tea!! It's a (rare) sunny day here so I'm going to look at cutting the first waveguide discs. I'll need three panels to reach the desired depth. I'm thinking of cutting three discs - each smaller than the next - before gluing each to the next ready for finishing in the lathe.

I did do some work last weekend, and this, so I think it's high time I posted some evidence of progress!!

Last weekend I made a circle-cutting jig for my cheapo plunge router. I used a thin piece of plywood for this task. It's worth showing for those who have wanted to cut neat circles and rebates and wondered how it's done. I only just found this out last weekend

Last weekend I made a circle-cutting jig for my cheapo plunge router. I used a thin piece of plywood for this task. It's worth showing for those who have wanted to cut neat circles and rebates and wondered how it's done. I only just found this out last weekend

Attachments

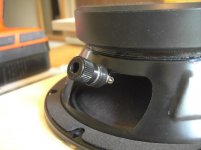

The picture shows how this works. The jig is screwed to the base of the router (a plastic cover is unscrewed and replaced by the new jig). A screw is driven through the jig and into the centre of the circle to be worked on. The router is turned around this screw to cut your rebates or cut-outs.

I tested the tool and jig on an MDF test-box I have lying around.

I tested the tool and jig on an MDF test-box I have lying around.

Attachments

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- 3 way open baffle with Eminence and Skytronic