The reason I would use ports over slot (if I ever went that way) would be to use a power port style exit like that shown in the picture above. I just feel a big flared port gives a smoother transition into the room than a slot.

However some designs are just too big or unworkable to use a port and then a slot becomes the obvious choice.

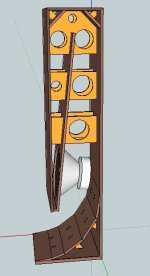

Have rejigged my drawing to look closer to the Gjallerhorn dimensions. Takes the height up to 2.2 meters but reduces the depth down from .6m to .45m

Would leave the base at .6m x .6m to give better stability. Yes did briefly look at a tube sub but they really don't appeal to me.

However some designs are just too big or unworkable to use a port and then a slot becomes the obvious choice.

Have rejigged my drawing to look closer to the Gjallerhorn dimensions. Takes the height up to 2.2 meters but reduces the depth down from .6m to .45m

Would leave the base at .6m x .6m to give better stability. Yes did briefly look at a tube sub but they really don't appeal to me.

Attachments

The reason I would use ports over slot (if I ever went that way) would be to use a power port style exit like that shown in the picture above. I just feel a big flared port gives a smoother transition into the room than a slot.

You can put a large roundover (aka flare) on a slot port easier than a round port, with a kerf, cut dowel, section of pipe, etc. Kerfed ports are the preferred method in car audio.

Not heard the term kerf before but from a quick image search that seems like a straight piece of material with parallel cut slots in it to allow the material to bend. While I didn't know what it was called I was actually wondering if I could use that in my current cabinet design to keep a constant horn increase.

I don't see why it wouldn't work especially if I fill the cavity behind it with something like expanding foam to keep the sound pressure from bending it.

Edit:

Actually nothing would stop me putting something like an epoxy glue in the slots to help keep it rigid after it is built and in place.

I don't see why it wouldn't work especially if I fill the cavity behind it with something like expanding foam to keep the sound pressure from bending it.

Edit:

Actually nothing would stop me putting something like an epoxy glue in the slots to help keep it rigid after it is built and in place.

Last edited:

I've never done it myself, but kerfing seems like a useful skill for all sorts of speaker building. I used a 2" dowel cut into quarters to make a 1" roundover on my 2.5x15" port (37.5 in^2 area).

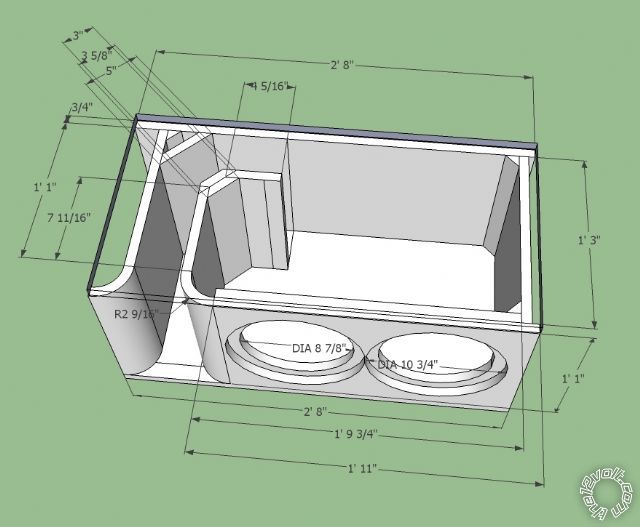

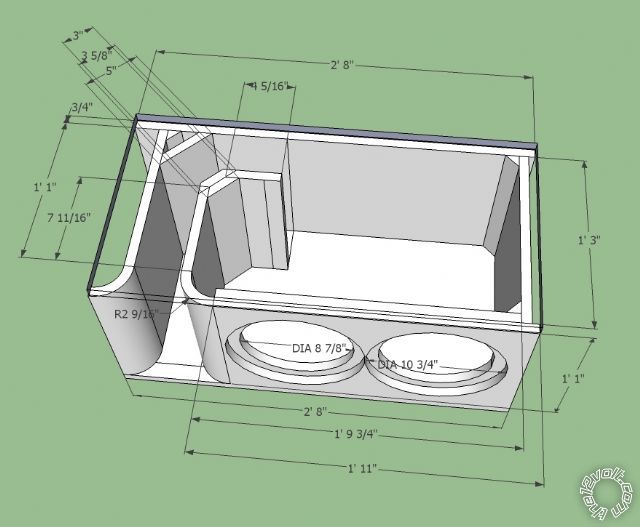

Here is good example of a well designed sub with a kerfed port and 90 degree turn. Obviouly you would scale it up for home theater. Only thing I would do different is to use plywood and roundver the internal end of the port.

good subwoofer enclosure design? - Page 1

Here is good example of a well designed sub with a kerfed port and 90 degree turn. Obviouly you would scale it up for home theater. Only thing I would do different is to use plywood and roundver the internal end of the port.

good subwoofer enclosure design? - Page 1

The net "box" volume after subtracting all that waste in the slot makes this design inefficient in size vs output.

A piece of plastic drain pipe would certainly allow a smaller, lighter, cheaper, box.

A piece of plastic drain pipe would certainly allow a smaller, lighter, cheaper, box.

The net "box" volume after subtracting all that waste in the slot makes this design inefficient in size vs output.

A piece of plastic drain pipe would certainly allow a smaller, lighter, cheaper, box.

The area on that port is around 66.5 in^2. Where do you plan on getting 9" plastic pipe for a reasonable price, and how do you propose making a 90 degree turn with it to get proper length?

And clearly, there are ways to make a slot port which are much more space efficient, such as my PA subs. To get the equivalent port area (37.5" in^2) here would require a 7" round port or qty 3 4" round ports, which would actually be harder to fit and construct.

Last edited:

turbodawg, I have to admit they look nice and sexy.

Another detail for newbies in trouble with port dimensions is the internal flares ("that ensure low frequency efficiency while eliminating noise caused by port turbulence" JBL/M2), what I wouldn't care so much if the ports are turned to the back, away from the listener.

Another detail for newbies in trouble with port dimensions is the internal flares ("that ensure low frequency efficiency while eliminating noise caused by port turbulence" JBL/M2), what I wouldn't care so much if the ports are turned to the back, away from the listener.

Yes I have to admit seeing those well designed flares makes me think twice about dismissing a flared port so quickly. Nothing would stop you putting a bit of quad (think square wood cut across diagonals into 4 triangles) in each of the corners to cut down on low pressure spots and make it more of a octagon, or better yet the same thing you can get in a hardware store with a scallop already taken out of it making it more round.

Did a bit more of a search on kerf and came across some very smooth looking cabinets.

Did a bit more of a search on kerf and came across some very smooth looking cabinets.

Attachments

@ turbodawg

WOW, you've certainly blown out the margins on my monitor with the screenie in Post # 46 😱

Maybe you've got a 100" monitor 😀

WOW, you've certainly blown out the margins on my monitor with the screenie in Post # 46 😱

Maybe you've got a 100" monitor 😀

SS,

that's a BLH.

The front is not horn loaded.

Yep there not mine, I just was using them as example of kerf usage.

I have however redesigned the proposed cabinet to what I believe is a hog scoop.

Attachments

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- 2 x PR vs Ported