The previous post was about a plan for a larger aluminium cabinet for a 6'5" driver. Meanwhile I have an ongoing construction for a smaller cabinet for 5.25" units (135 to 150mm). This has a 8mm thick U channel for the front and half the sides, the rest being 12mm plywood. Volume is 11 litres. It lacks a proper top and bottom but I've sealed it pretty well just to try it out. The units are from a Wharfedale Programme 30D-6 which is thin MDF and around 5.5 litres vented. 9mm for the sides and back and 15mm for the front. No internal damping.

So I've got one new alu box up and running. The first thing that struck me immediately is that it's quite a bit quieter than the original Wharfedale Programme 30Ds from which I transplanted the units and crossover. This was very striking. So I'm listening to the original on the left and the new aluminium enclosure on the right. Doesn't really work for stereo since the sound is louder on the left. So I listened to Kempe's mono Meistersinger. I like it just from the new cabinet - it's much cleaner.

So clearly with the original Programme 30Ds there's a fair bit of sound coming from the cabinet itself. I was shocked by just how much the cabinet was contributing.

So early days - I need to finish the other cabinet and make proper tops and bottoms. But it's clear that the cabinet plays a major role in the total sound of the speaker. Night and day in this case.

Could you guys give me some feedback on this - how much sound comes out of the box and not the speaker units? And anything else relevant about box materials and build?

So I've got one new alu box up and running. The first thing that struck me immediately is that it's quite a bit quieter than the original Wharfedale Programme 30Ds from which I transplanted the units and crossover. This was very striking. So I'm listening to the original on the left and the new aluminium enclosure on the right. Doesn't really work for stereo since the sound is louder on the left. So I listened to Kempe's mono Meistersinger. I like it just from the new cabinet - it's much cleaner.

So clearly with the original Programme 30Ds there's a fair bit of sound coming from the cabinet itself. I was shocked by just how much the cabinet was contributing.

So early days - I need to finish the other cabinet and make proper tops and bottoms. But it's clear that the cabinet plays a major role in the total sound of the speaker. Night and day in this case.

Could you guys give me some feedback on this - how much sound comes out of the box and not the speaker units? And anything else relevant about box materials and build?

Making some progress with my larger aluminium cabinet. I have the sides now cut to size. Cost of the aluminium was £99 plus shipping, not bad. This will be a really easy build - just need to add front, back, top and bottom. No gluing required, no interior bracing needed. Just bolt it all together with visco-elastic damping in between. I have Soudaseal MS Clear. Then add self-adhesive butyl damping sheets inside, Dodomat heavy butyl. This is something you can build in the kitchen of a mid-town apartment, which is what I have. Width is 240mm. Height without top and bottom is 305mm. Depth without front and back is 250mm. Front and back will be fastened together with something like M10 threaded rods. Woofer can be 165mm or 210mm. Volume is 16.6 litres similar to the Magico A1.

I'm liking this! Magico, here we come......

I'm liking this! Magico, here we come......

Last edited:

A modular design using this construction technique could be very successful for building very rigid and stiff cabinets. The trick will be to find a balance between good dampening and material thickness requirements. There's no reason this can't be successful. Not a common way to build an enclosure but a viable one given the goals.

I'm a sucker for weird enclosure construction methods, mainly composite and synthetic stone (Corian) material. I've cast my own bookshelf speakers from epoxy and also used laminated paper fibers. Nylon rope also works well for dampening inside walls filed with epoxy and fiberglass resin bonding methods using spheres molded from exercise balls. Lots of possibilities.

I'm a sucker for weird enclosure construction methods, mainly composite and synthetic stone (Corian) material. I've cast my own bookshelf speakers from epoxy and also used laminated paper fibers. Nylon rope also works well for dampening inside walls filed with epoxy and fiberglass resin bonding methods using spheres molded from exercise balls. Lots of possibilities.

<< A modular design using this construction technique could be very successful for building very rigid and stiff cabinets. The trick will be to find a balance between good dampening and material thickness requirements. There's no reason this can't be successful. Not a common way to build an enclosure but a viable one given the goals..... I'm a sucker for weird enclosure construction methods>>

Why don't you try this? It's just 6" aluminium U channel. Should be available in the States. It would be very simple to put together. No machining needed for the aluminium - just drill holes for the bolts. I was thinking the rest of the cabinet would be in 12mm plywood sheets with CLD, but could be anything including a sandwich of plywood and aluminium.

Why don't you try this? It's just 6" aluminium U channel. Should be available in the States. It would be very simple to put together. No machining needed for the aluminium - just drill holes for the bolts. I was thinking the rest of the cabinet would be in 12mm plywood sheets with CLD, but could be anything including a sandwich of plywood and aluminium.

I made aluminum subwoofer enclosures. Try to keep it away from its resonance frequency where it can be prone to higher levels of pinging sure to muck up higher range speakers too. https://www.crutchfield.ca/S-JHG7I3...mQBqvMt1K0Dcdstr2qRTMW9kG7IVpXqhoCeXkQAvD_BwE

I and am sure people remember the Minimus steel mini enclosures from Radio Shack? We'll I do and they had some similar kind of membrane on the inside of them, and as gasket material. Those have a sweet midrange they must of did some things right. I hated that they lack bass, I used to drill on them LoL.

Oh the dynamat works I love the over priced stuff in projects where acoustics are mingling with metal.

I had to shelf that project I want to get back to those tubs and finish and finish. It might be the most air tight subwoofer in existence? Not that it would make much or any difference.

I and am sure people remember the Minimus steel mini enclosures from Radio Shack? We'll I do and they had some similar kind of membrane on the inside of them, and as gasket material. Those have a sweet midrange they must of did some things right. I hated that they lack bass, I used to drill on them LoL.

Oh the dynamat works I love the over priced stuff in projects where acoustics are mingling with metal.

I had to shelf that project I want to get back to those tubs and finish and finish. It might be the most air tight subwoofer in existence? Not that it would make much or any difference.

Attachments

Last edited:

For damping I still like this stuff: 908 Black Jack DPM | Bitumen & Roofing Supplies UK | Everbuild

You can make as thick as you like by simply painting more layers although painting the inside of aluminium box section might be a bit awkward.

Water-based so no damaging fumes. Costs 30 quid for 5L at ToolStation.

You can make as thick as you like by simply painting more layers although painting the inside of aluminium box section might be a bit awkward.

Water-based so no damaging fumes. Costs 30 quid for 5L at ToolStation.

I've been tempted by cutting up some old Acetylene cylinders I have to build some enclosures with the right dampening method - these CrMo steel gas cylinders ring like a bell, but could be dampened sufficiently to work. Even just as pieces of audio art, they could be better with the correct amount of dampening.

Just be aware of the off-putting odor this stuff still can have. Its pretty stinky stuff out of the package. Im just very sensitive to smell.For damping I still like this stuff: 908 Black Jack DPM | Bitumen & Roofing Supplies UK | Everbuild

You can make as thick as you like by simply painting more layers although painting the inside of aluminium box section might be a bit awkward.

Water-based so no damaging fumes. Costs 30 quid for 5L at ToolStation.

Smells like fresh tarmac out of the tin though not all that strong but when dry there is no odour.

Also starts off dark brown and dries to black.

The smells I can't cope with are solvents and air fresheners, they give me a thumping headache.

Also starts off dark brown and dries to black.

The smells I can't cope with are solvents and air fresheners, they give me a thumping headache.

Metal has been proven to work. I thought of more, Anthony Gallo makes subs and satellite cabs in steel. I am still curious enough to crack some of those open to get a peek inside.

There's actually quite a long list of aluminium cabinets, e.g....

Magico

Piega

Thrax Lyra

Stenheim Alumine

RS Minimus

B&W LM1

Monitor Apex A10

Wilson Benesch P1.0

Technics SB-F3

Meridian DSP33

Genelec

Event Opal

Magico

Piega

Thrax Lyra

Stenheim Alumine

RS Minimus

B&W LM1

Monitor Apex A10

Wilson Benesch P1.0

Technics SB-F3

Meridian DSP33

Genelec

Event Opal

Don't be tempted down the 'more-is-more' route of adding damping material; the industry rule of thumb is that it should equal the mass of the panel being damped. Too much added mass could lower the enclosure's resonant frequency into the critical range.

I knocked up a pair of stainless steel biscuit tin speakers one morning using 4" Chinese full-range drivers and demoed them blind to my audiophile friend. After listening to a couple of tracks he commented: "Incredible imaging but not much bass. You've bought those Quad ESL53s you been promising yourself for ages, haven't you?"!

I knocked up a pair of stainless steel biscuit tin speakers one morning using 4" Chinese full-range drivers and demoed them blind to my audiophile friend. After listening to a couple of tracks he commented: "Incredible imaging but not much bass. You've bought those Quad ESL53s you been promising yourself for ages, haven't you?"!

In one room that had enough metal objects, combined with hard wood surface made me assume it might get overly bright, it sounded wide open and nice. Definitely, metal can work for you or against.

Brace accordingly and try to stick to a consistent layer of matt and full coverage.

I think its more critical to hault inner reflections.

But who knows, maybe some of them leave some surface exposed? You can always experiment with that.

BTW I knew about Magico metal.

How many on the list is British made?

Brace accordingly and try to stick to a consistent layer of matt and full coverage.

I think its more critical to hault inner reflections.

But who knows, maybe some of them leave some surface exposed? You can always experiment with that.

BTW I knew about Magico metal.

How many on the list is British made?

Reminds me of an anecdote Peter Walker once told in an interview....and demoed them blind to my audiophile friend. After listening to a couple of tracks he commented: "Incredible imaging but not much bass. You've bought those Quad ESL53s you been promising yourself for ages, haven't you?"!

They were at an exhibition demo'ing ESL63s. Afterwards somebody came up to him and said he owned an identical QUAD system but his sounded nowhere near as good and he concluded that it must be that special orange speaker cable Peter was using. After some back and forth Peter just gave it to him at the end of the exhibition.

What had really happened was that when they were packing up to travel to the show they forgot to bring speaker cable but found some Black&Decker mains cables in a skip and used that.

Backyard metal fabrication takes so much longer, and its extra hazardous, and hardly my favorite. Aluminum is my new least favorite to cut with a wheel. Since it has a low melting point it turns almost plasma. Its worse with fire. It sticks to your fresh new cut on the underside. I thought stainless was a pain, that became easy.

But aluminum looks so good buffed or brushed out.

This is my first time cutting myself with a grinder btw lol but it wasn't material related. It happened on the dismount while putting it down. One tiny wrong move with those and they make ya pay. Usually in higher dividends .

I'll be taking that piece to a waterjet. By the time I bought a circle saw for the guage holes ($100), I'll still need the radio cut out rectangular hole. I'm not doing that with a grinder its too dodgy. I will be pushing my luck on the warpage factor as well. I managed to keep it true but the thinner areas look like potential trouble.

But aluminum looks so good buffed or brushed out.

This is my first time cutting myself with a grinder btw lol but it wasn't material related. It happened on the dismount while putting it down. One tiny wrong move with those and they make ya pay. Usually in higher dividends .

I'll be taking that piece to a waterjet. By the time I bought a circle saw for the guage holes ($100), I'll still need the radio cut out rectangular hole. I'm not doing that with a grinder its too dodgy. I will be pushing my luck on the warpage factor as well. I managed to keep it true but the thinner areas look like potential trouble.

Attachments

Indeed, it's easy to machine 3mm or 4mm aluminium in the softer grades and use hole saws up to 40mm or so for things like amplifiers. Beyond that it's machine shop stuff. That's why I used aluminium U channel for the sides only. So the front and back can be wood to taste, like plywood with CLD or ply+MDF. You can cut into wood with a 145mm hole saw which is what you need for a 6.5" woofer. Basically my design just bolts together - you just need to drill the holes. I don't have a back yard in my 2nd floor apartment, so it had to be a simple kitchen build.

Or use a router table and lots of WD40 to cool the bits...

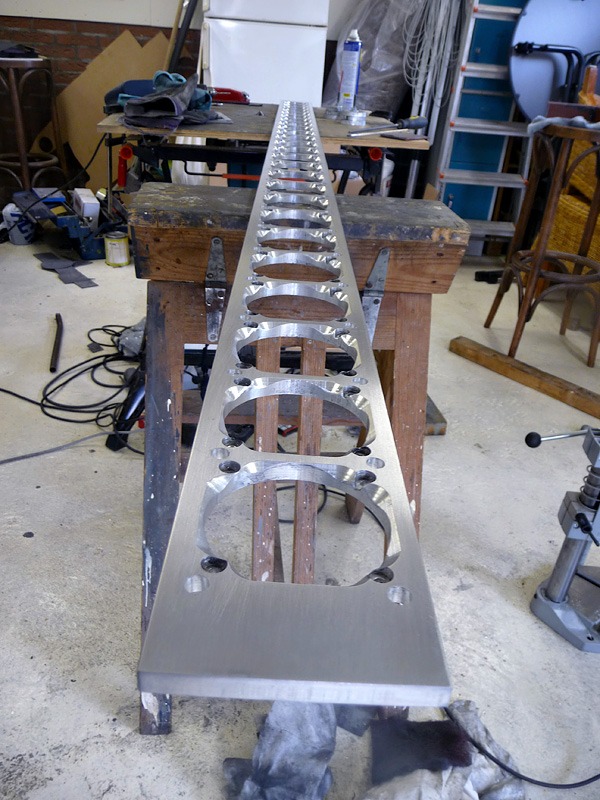

https://www.diyaudio.com/community/...range-line-array.242171/page-122#post-4823566

It took some experimenting but I managed to make these:

I machined up to 10 mm using HD bits, a router and a home made router table. Pré-cut all holes with a jigsaw.

That was a bit of a pain, I'll admit. But I made many more holes than you are planning on making 😀.

https://www.diyaudio.com/community/...range-line-array.242171/page-122#post-4823566

It took some experimenting but I managed to make these:

I machined up to 10 mm using HD bits, a router and a home made router table. Pré-cut all holes with a jigsaw.

That was a bit of a pain, I'll admit. But I made many more holes than you are planning on making 😀.

Wesayso,

50 holes like this, was it?

Diary of a madman... 😀 but aren't most of us in the similar school of thought? 🙂

50 holes like this, was it?

Diary of a madman... 😀 but aren't most of us in the similar school of thought? 🙂

Thats quite impressive. You are a patient man my friend.Or use a router table and lots of WD40 to cool the bits...

https://www.diyaudio.com/community/...range-line-array.242171/page-122#post-4823566

It took some experimenting but I managed to make these:

View attachment 1182622

View attachment 1182624

I machined up to 10 mm using HD bits, a router and a home made router table. Pré-cut all holes with a jigsaw.

That was a bit of a pain, I'll admit. But I made many more holes than you are planning on making 😀.

I always knew you can work aluminum with wood blades, but lower speeds would be more favorable when going powered. Stuff designed to cut wood material primarily in my mind would be too fast.

Call it a slight mental block but I'm ready to give it a try. I picture horrible things like the teeth grabbing and the peace flopping around and getting all warped. Along with a hellish squeal like when a bearing runs dry lol.

I'll fix it to some scrap, and try the jigsaw first, second a hack. One of those will get it done. I could eat the hundred for a CS. I use those from time to time.

Or a router. But I'd need to get creative for circle cuts that small, 2 1/2", I think.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- 2-way bookshelf with aluminium cabinet

![20230424_060724[6472].jpg](/community/data/attachments/1089/1089810-f26c011d6dd0e7746b81cbccf5a9fcf4.jpg?hash=8mwBHW3Q53)

![20230611_152235[7024].jpg](/community/data/attachments/1090/1090476-ddd4c955bc0498fb3e853f51d7b85b62.jpg?hash=3dTJVbwEmP)

![20230611_160547[7025].jpg](/community/data/attachments/1090/1090477-ca968f94a57d643cf5b6615b11479054.jpg?hash=ypaPlKV9ZD)