I have a pair of aluminium square section 150x150mm and 530mm high, 3mm, which I want to make into a bookshelf speaker around 10ltr. This is an available size (6.5x6.6inch) so anyone could build it. Hole saws for the cutouts and I reckon on attaching top and bottom plates with 4 thick bolts going through the cab.

Question is how to treat the cabinet for resonances. Some kind of CLD is possible - e.g. bolt on two birch ply sides with something like green glue, rubber, vinyl, bitumen or whatever in between.

What would you do?

Question is how to treat the cabinet for resonances. Some kind of CLD is possible - e.g. bolt on two birch ply sides with something like green glue, rubber, vinyl, bitumen or whatever in between.

What would you do?

Depends on how you want to load it with drivers I guess. These are by B&O CX50s which you can see are most like your 3rd option:

https://www.diyaudio.com/community/threads/driver-for-b-o-cx50-3-25l-cabinet.377578/

With a steel baffle bonded in to take the drivers, but you could do this with wood. Works well for a small driver 2 way.

Option 1 would potentially work nice for a small TL full range enclosure like the Alpair units, something not dissimilar to the small frugal horn or pensil designs.

Rogers JR149 might be worth a look at for inspiration, they were an aluminium tube capped with wood ends and drivers in the side.

https://www.diyaudio.com/community/threads/driver-for-b-o-cx50-3-25l-cabinet.377578/

With a steel baffle bonded in to take the drivers, but you could do this with wood. Works well for a small driver 2 way.

Option 1 would potentially work nice for a small TL full range enclosure like the Alpair units, something not dissimilar to the small frugal horn or pensil designs.

Rogers JR149 might be worth a look at for inspiration, they were an aluminium tube capped with wood ends and drivers in the side.

I used to have a pair of JR149s so know those. I have Alpair 10s in a tall cabinet as well, but want to try a stand-mount in aluminium. Thanks for the B&O reference - very useful. There was also the Technics SB-F1. Quite a few aliminium cabinets are coming out of the woodwork. Also Piega of course.

Getting ready to do something with this project. Picture of the cabinet which is 508mm (20") high. Box section is 150mm by 150mm. Thickness 3mm.

The first step is to put some damping in it. As above, car damping self-adhesive butyl pads look the easy solution, applied to the inside. The alternative would be to add something like 9mm MDF to the outside of the box and use the butyl as constrained layer damping.

I could also add a second sheet of aluminium on the front to hold the drivers to make the front more solid. That would have the advantage of enabling different cutouts for different drivers. This would be a kind of experimental cabinet.

How should I proceed?

The first step is to put some damping in it. As above, car damping self-adhesive butyl pads look the easy solution, applied to the inside. The alternative would be to add something like 9mm MDF to the outside of the box and use the butyl as constrained layer damping.

I could also add a second sheet of aluminium on the front to hold the drivers to make the front more solid. That would have the advantage of enabling different cutouts for different drivers. This would be a kind of experimental cabinet.

How should I proceed?

Last edited:

You could have a look at Tabaq, a full range design. Some have <erk!d> over dispersion issues when used in say, their kitchen diner. Visaton W100S-8 plus a tweeter can be done. Or beef up dimensions more for W130S-8.

Tabaq is a tube 78cm tall though, so you'd need to construct a substantial "boot". Could also hold a crossover.

Tabaq is a tube 78cm tall though, so you'd need to construct a substantial "boot". Could also hold a crossover.

Thanks for the full range idea. Unfortunately I tried exactly that with an Alpair 10 and preferred a 2-way design. I didn't find a full range unit I really liked, and I must say I prefer more lossy cones like polypropylene or coated paper. I got tired of aluminium cones. Aluminium cabinets, yes, just not cones. I have my eye on something like a Monacor SPH130 mid-bass and maybe a ribbon tweeter. I have a pair of Fountek NEO CD-1 I'm going to try first in a Speedster in another cabinet I have. Then assess what to put in this aluminium cabinet.

Visaton W100S-8 plus a tweeter can be done. Or beef up dimensions more for W130S-8.

The Visaton W130S has quite a smooth frequency response. Have you used it? Basic coated paper and quite cheap. I haven't seen any crossover designs with it.

http://www.visatonshop.at/en/Single-Drivers-Accessories/Bass-Midranges/W-130-S-8-OHM.html

Detailed thread on the W130S-4:

https://www.diyaudio.com/community/threads/visaton-w130s-4-sc10n-8.390947/

I have zero expertise in speaker design, but you could perhaps model a folded transmission line (like the TABAQ) for the woofer with a couple sections of the tubing and include a tweeter/crossover.

https://www.diyaudio.com/community/threads/visaton-w130s-4-sc10n-8.390947/

I have zero expertise in speaker design, but you could perhaps model a folded transmission line (like the TABAQ) for the woofer with a couple sections of the tubing and include a tweeter/crossover.

Last edited:

I still don't know which way to go with these aluminium cabinets pictured above. There's almost nothing on DIY Audio about making aluminium speaker cabinets. My choices for damping the raw aluminium 3mm are -

1. Don't add plywood sides, just leave the alu box as it is and apply butyl car sound deadening sheets to most of the inside. Or some other product - suggestions welcome.

2. Add plywood sides and maybe back, and fix with something like silicone, Titebond Melamine glue or Sikaflex 221 or EBT+ or whatever

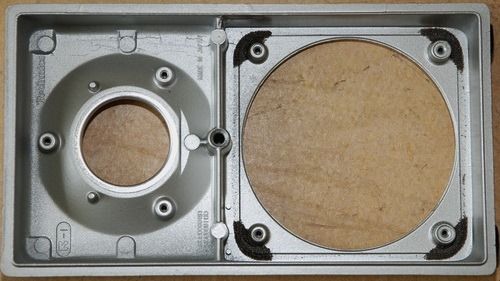

Butyl sheets - pic:

1. Don't add plywood sides, just leave the alu box as it is and apply butyl car sound deadening sheets to most of the inside. Or some other product - suggestions welcome.

2. Add plywood sides and maybe back, and fix with something like silicone, Titebond Melamine glue or Sikaflex 221 or EBT+ or whatever

Butyl sheets - pic:

I've been watching this Piega video from 3.50 and they used to use Idikell 4021/05 Heavy foil.

What material is Idikell exactly? Can't see it for sale in the UK. Here is a link, but they use new stuff now - anyone know what it is?

https://www.ampack.biz/eu-en/products/noise-protection-products/heavy-foils/idikell-402105

I'm more inclined to use adhesive sound deadening sheets, following Piega's example. There are the butyl sheets used in cars, cheap and available. Then bitumen sheets which smell - maybe OK in a cabinet. Dedshete was bitumen. Then Sorbothane which is more expensive.

I can't see Mass Loaded Vinyl in smaller adhesive sheets - the big sheets are expensive.

Choices..... ideas?

What material is Idikell exactly? Can't see it for sale in the UK. Here is a link, but they use new stuff now - anyone know what it is?

https://www.ampack.biz/eu-en/products/noise-protection-products/heavy-foils/idikell-402105

I'm more inclined to use adhesive sound deadening sheets, following Piega's example. There are the butyl sheets used in cars, cheap and available. Then bitumen sheets which smell - maybe OK in a cabinet. Dedshete was bitumen. Then Sorbothane which is more expensive.

I can't see Mass Loaded Vinyl in smaller adhesive sheets - the big sheets are expensive.

Choices..... ideas?

Dynamat Xtrme is thin aluminium sheet that has thin butyl rubber on one side with a self adhesive layer on the other side of the rubber

https://dynamateurope.com/portfolio/dynamat-xtreme/

You can buy it from various on-line places...

https://dynamateurope.com/portfolio/dynamat-xtreme/

You can buy it from various on-line places...

Here are speakers I built with aluminum cabs. I used Dynamat and they are dead dead.

https://www.diyaudio.com/community/...he-rs-minimus-11-could-look-this-good.293176/

https://www.diyaudio.com/community/...he-rs-minimus-11-could-look-this-good.293176/

spray with multiple layers of truck bedliner

I had a work truck with the bed sprayed with bedliner and it got hard and chipped off after two years. But that was outside all the time.

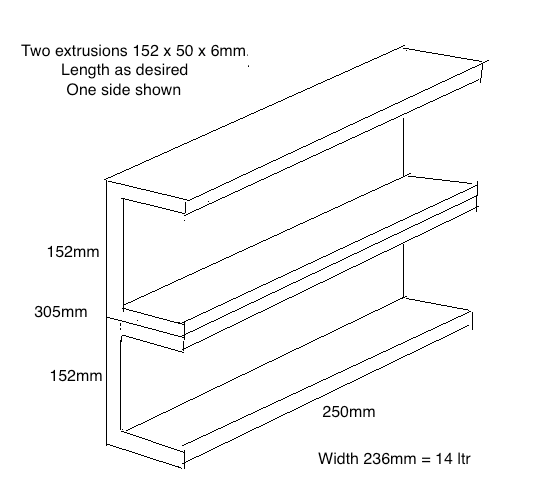

And now the fiendishly cunning plan......

This is for a 165mm mid-bass unit and 25mm tweeter. Hopefully it will be my "forever" speaker cabinet. Very heavy and Magico level construction. The extrusions are from Aluminium Online

https://www.aluminium-online.co.uk/product/6-x-2-x-1-4-x-5-16-aluminium-channel/

So the sides will be solid aluminium 6.4mm thick with a huge brace running front to back. Totally inert. Only the bottom and top need to be added. And then removable front and back held by threaded rods going front to back, so both removable for modifications. The port would be on the front or back if ported.

The cost in extrusions would be £110 plus carriage. Not too bad. The top, bottom, front and back would be something like marine ply or whatever with CLD. This is very adaptable. Total overkill, but why not!

What do you think?

This is for a 165mm mid-bass unit and 25mm tweeter. Hopefully it will be my "forever" speaker cabinet. Very heavy and Magico level construction. The extrusions are from Aluminium Online

https://www.aluminium-online.co.uk/product/6-x-2-x-1-4-x-5-16-aluminium-channel/

So the sides will be solid aluminium 6.4mm thick with a huge brace running front to back. Totally inert. Only the bottom and top need to be added. And then removable front and back held by threaded rods going front to back, so both removable for modifications. The port would be on the front or back if ported.

The cost in extrusions would be £110 plus carriage. Not too bad. The top, bottom, front and back would be something like marine ply or whatever with CLD. This is very adaptable. Total overkill, but why not!

What do you think?

- Home

- Loudspeakers

- Multi-Way

- 2-way bookshelf with aluminium cabinet