Yes exactly.

This case the baffle is double layer and is 38.5 mm thick.

So front mount with countersink, likely be much easier.

Also a rear bevel is possible but not full bevel.

Because the driver spacing is so close and mid chamber.

it is XPS so, in theory be easy to do since rear bevel could be done by hand.

This case the baffle is double layer and is 38.5 mm thick.

So front mount with countersink, likely be much easier.

Also a rear bevel is possible but not full bevel.

Because the driver spacing is so close and mid chamber.

it is XPS so, in theory be easy to do since rear bevel could be done by hand.

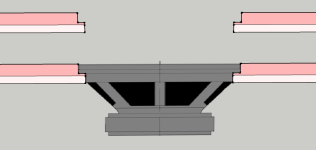

Quick rough drawing, sure youll get the overall concept.

its flush mounted with outer countersink so the gasket is flush to baffle.

You just do first circle cut to outer edge to the right depth.

Then second smaller circle for cutout.

This driver has deep ring shape to the rear basket,

looks like rear bevel not needed. Seen it on few drivers

almost like they intended it to be simple for rear or front mount

Thanks! WILCO.

I copy front mount, rebated to gasket height, not frame lip. It will simplify things if I don't have to mess with the gasket, and also if I don't have to relieve the woofer.

For the smaller one, previously, with a 17mm cedar baffle, I left peninsulas for the 4 mounting screws. I am thinking this time I might need to glue a hardboard or hard plastic insert in the rebate to mount the drivers to, so there is more relief for the back.

It looks like the center to center spacing might be just enough to allow mounting it at a 45 so the peninsulas are tied to the sides and the open areas point to the corners, I might mock that up to see.

I copy front mount, rebated to gasket height, not frame lip. It will simplify things if I don't have to mess with the gasket, and also if I don't have to relieve the woofer.

For the smaller one, previously, with a 17mm cedar baffle, I left peninsulas for the 4 mounting screws. I am thinking this time I might need to glue a hardboard or hard plastic insert in the rebate to mount the drivers to, so there is more relief for the back.

It looks like the center to center spacing might be just enough to allow mounting it at a 45 so the peninsulas are tied to the sides and the open areas point to the corners, I might mock that up to see.

Hi!

Sorry it's been a while, I had some training to attend and some physical therapy stuff that sucked up most of my time.

I have only made simple BSC circuits, so I would appreciate any preferences on assembling the cross-over - specifically the lay-out/geometry. I understand the inductors should be oriented so you can't see any other inductor through the center-hole, and try to balance short connections with the smallest number of joints. Anything else?

I have the first one test fit and standing, need to clean up the relief in the mid box, then figure out which order to start gluing it up. Still thinking through the sequence for the sides of the bottom cross aligned to the side stiffeners. (Foam is easier in some ways, but at this size it's become tricky in others, especially clamping.)

Recalling a discussion between @AllenB and @GM about sealed cabinets, I hot glued the back of the machine screw inserts used for mounting, but do I need to provide a pin hole somewhere (or trust that without caulking, I have a pin-hole somewhere anyway)?

I have the materials for the second, but will wait on this one, in case there are adjustments.

Sorry it's been a while, I had some training to attend and some physical therapy stuff that sucked up most of my time.

I have only made simple BSC circuits, so I would appreciate any preferences on assembling the cross-over - specifically the lay-out/geometry. I understand the inductors should be oriented so you can't see any other inductor through the center-hole, and try to balance short connections with the smallest number of joints. Anything else?

I have the first one test fit and standing, need to clean up the relief in the mid box, then figure out which order to start gluing it up. Still thinking through the sequence for the sides of the bottom cross aligned to the side stiffeners. (Foam is easier in some ways, but at this size it's become tricky in others, especially clamping.)

Recalling a discussion between @AllenB and @GM about sealed cabinets, I hot glued the back of the machine screw inserts used for mounting, but do I need to provide a pin hole somewhere (or trust that without caulking, I have a pin-hole somewhere anyway)?

I have the materials for the second, but will wait on this one, in case there are adjustments.

Woo Hoo

Hey good to see yah back, was wondering about you.

Well this is the fun part. Or at least one of the intimidating things

in your comments was the crossover.

There is a lot of guides online and sounds like you got the basics down

by not putting inductors to close and orientation of the poles can be changed.

this cabinet has so much room its even possible to put the LF section on separate board.

to keep the larger inductors away.

Ill take a look at the components see if I can come up with a helpful guideline/ layout .

Hey good to see yah back, was wondering about you.

Well this is the fun part. Or at least one of the intimidating things

in your comments was the crossover.

There is a lot of guides online and sounds like you got the basics down

by not putting inductors to close and orientation of the poles can be changed.

this cabinet has so much room its even possible to put the LF section on separate board.

to keep the larger inductors away.

Ill take a look at the components see if I can come up with a helpful guideline/ layout .

Here is what I was thinking in terms of layout. I don't (edit: know) what is audible, so I am trying to avoid a naïve decision with impacts or a undocumented tradeoff since I promised measurements. The copper ground wire bits are illustrative, but if it works I have plenty of insulated romex off-cuts. Or 14 ga stranded automotive wire. I have some wago connectors for the initial connections, not sure if wire nuts, crimped connectors (I have the basic, not the fancy compression pliers), or soldering is best here for the final version (I crimped everything before, but not sure that's the best way if someone is looking at the measurements).

For damping, I purchased "Acousta-Stuf". I can probably find some cheese-cloth if this needs a blanket or support system.

I also have cotton quilting batting (about 3mm thick), and I have some melamine foam blocks (I bought a big bag for cleaning before I realized they were just sandpaper).

I have most of the cabinet glued up, I left the top off for easier access.

I don't know that I will build something this big from foam again. It was great for little desktop speakers and things, but here it's been a pain and a little worried about how it's going to come out. Maybe if I find some cheap thin cladding to laminate on like the foam-board stuff.

The wife is actually cautiously excited, since they will fit on the top of the canning rack we might be able to rearrange the gym/garage for more room.

For damping, I purchased "Acousta-Stuf". I can probably find some cheese-cloth if this needs a blanket or support system.

I also have cotton quilting batting (about 3mm thick), and I have some melamine foam blocks (I bought a big bag for cleaning before I realized they were just sandpaper).

I have most of the cabinet glued up, I left the top off for easier access.

I don't know that I will build something this big from foam again. It was great for little desktop speakers and things, but here it's been a pain and a little worried about how it's going to come out. Maybe if I find some cheap thin cladding to laminate on like the foam-board stuff.

The wife is actually cautiously excited, since they will fit on the top of the canning rack we might be able to rearrange the gym/garage for more room.

It's raining so I built a first version.

A couple glue lines failed the flashlight test, so no testing until that's dry.

(Wondering how much trouble it would be to glue 1/8" ply on both sides of the 1/2" foam. Probably way more than just saving up for some Baltic Birch.)

A couple glue lines failed the flashlight test, so no testing until that's dry.

(Wondering how much trouble it would be to glue 1/8" ply on both sides of the 1/2" foam. Probably way more than just saving up for some Baltic Birch.)

Quick way to move forward and be able to hear things.

Once you have a more permanent layout connections can be soldered

and drill holes around components so zip ties can add additional hold down

strength.

for the most part you got working test rig.

position.

Either way almost close to getting sound, think a storm is rolling in where im at too

Once you have a more permanent layout connections can be soldered

and drill holes around components so zip ties can add additional hold down

strength.

for the most part you got working test rig.

That is pretty cool, sounds like they will be up higher, which should put the mids at ear level. which will work well for listeningThe wife is actually cautiously excited, since they will fit on the top of the canning rack we might be able to rearrange the gym/garage for more room.

position.

Either way almost close to getting sound, think a storm is rolling in where im at too

I haven't put any damping material inside, but I hooked up the drivers and sound! Yay!

Only one Dr. appointment today, but it's still too wet for any outside measurements. Plan to remove the drivers and put some stuffing inside.

On the stuffing and fine tuning from here on out, I am still that pig looking at a radio, so If you have preferences, please let me know. Otherwise I'll just try to tease some poly-fil and fill the small driver chamber. Not sure if I should fill the large chamber, or try one of those 'blankets' GM mentioned.

I have a DATSV3, but have to wait for the wife to finish her work and go somewhere as she has the only Windows machine.

For REW, I might be able to get a set of near-field measurements of the two drivers inside, but there is a lot of clutter in the garage/shop/gym.

And one funny thing: I just left it running a little while, at a decent volume on an AVR-S700W I got free because lightning hit the neighbor's house and the HDMI quit. Previously, the AVR ran six of the little PC68-4 speakers as I was testing them around Christmas ... but I noticed the amp was really heating up with this speaker, and eventually it went into protection mode.

Only one Dr. appointment today, but it's still too wet for any outside measurements. Plan to remove the drivers and put some stuffing inside.

On the stuffing and fine tuning from here on out, I am still that pig looking at a radio, so If you have preferences, please let me know. Otherwise I'll just try to tease some poly-fil and fill the small driver chamber. Not sure if I should fill the large chamber, or try one of those 'blankets' GM mentioned.

I have a DATSV3, but have to wait for the wife to finish her work and go somewhere as she has the only Windows machine.

For REW, I might be able to get a set of near-field measurements of the two drivers inside, but there is a lot of clutter in the garage/shop/gym.

And one funny thing: I just left it running a little while, at a decent volume on an AVR-S700W I got free because lightning hit the neighbor's house and the HDMI quit. Previously, the AVR ran six of the little PC68-4 speakers as I was testing them around Christmas ... but I noticed the amp was really heating up with this speaker, and eventually it went into protection mode.

I have a DATSV3

Be careful using any of the numbers from that to design a box.

dave

Wilco.

Is it still worth while to measure and report the DATSV3 data?

I probably have read the manual ways to measure and report, but any sense of it probably leaked out my ears. And I can't find or didn't grab my dad's analog multi-meter with the needle/mirror track that could be zeroed - I only have a couple digital meters with no notion of their accuracy or precision (they do seem generally good on repeated measurements, but I have not characterized them formally).

Is it still worth while to measure and report the DATSV3 data?

I probably have read the manual ways to measure and report, but any sense of it probably leaked out my ears. And I can't find or didn't grab my dad's analog multi-meter with the needle/mirror track that could be zeroed - I only have a couple digital meters with no notion of their accuracy or precision (they do seem generally good on repeated measurements, but I have not characterized them formally).

Is it still worth while to measure and report the DATSV3 data?

These units seem quite variable, the author’s algorithm uses the impedance curve to guess tha parameters as opposed to directly measuring them. Good for driver matching, but IME the kit we use at home is not as useful as most factory numbers (some are crap) are.

Keep in mind that the scalar T/S numbers we use are collapsed from a curve. Where the curve is collapsed is important.

dave

well for the most part the box is already built.

And already have TS data.

DATSV3 data would show the impedance curve with crossover.

So be a sanity check make sure there is no huge dips in impedance.

If there was wiring errors im sure overall sound be obvious.

Impedance curves are really my pet peeve. I shoot for flat as friendly as possible

and amplifier friendly. Some people accept 50 ohm peaks and 3 ohm dips.

absolutely not gonna be found in my designs.

He mentioned the amp overheated, so concern is some anomaly.

Which I doubt. Getting a 8 ohm woofer and 4 ohm wideband, some would assume

a possible dip.

But at high frequency or low frequency where class D's love to shut down.

I made sure the impedance curve was graciously friendly to a amp.

The impedance curve be even very friendly to a transformer tap.

pretty much sits around 7 ohms and just the woofer peak, nothing i can do about that.

any other dip in bandwidth is 11 to 5 ohms. pretty darn friendly curve.

shouldn't overheat a amp at all.

im curious what's happening , and likewise how the bass response is with the 12"

And already have TS data.

DATSV3 data would show the impedance curve with crossover.

So be a sanity check make sure there is no huge dips in impedance.

If there was wiring errors im sure overall sound be obvious.

Impedance curves are really my pet peeve. I shoot for flat as friendly as possible

and amplifier friendly. Some people accept 50 ohm peaks and 3 ohm dips.

absolutely not gonna be found in my designs.

He mentioned the amp overheated, so concern is some anomaly.

Which I doubt. Getting a 8 ohm woofer and 4 ohm wideband, some would assume

a possible dip.

But at high frequency or low frequency where class D's love to shut down.

I made sure the impedance curve was graciously friendly to a amp.

The impedance curve be even very friendly to a transformer tap.

pretty much sits around 7 ohms and just the woofer peak, nothing i can do about that.

any other dip in bandwidth is 11 to 5 ohms. pretty darn friendly curve.

shouldn't overheat a amp at all.

im curious what's happening , and likewise how the bass response is with the 12"

Last edited:

DATSV3 data would show the impedance curve with crossover.

That is always usual and somethign DATS should do just fine. It is the fine detail of the Fs and the 2 half voltage points on either side that are used to determine the T/S

dave

yeah exactly it is what it is.

But if I had one, or got one.

It was just a simple tool I wanted for impedance data.

just to confirm a reflex or what not.

and that is same value it holds in this situation.

long time ago as a teen when we farted around with piezo tweets.

would be interesting to see how it measures them. LOL

But if I had one, or got one.

It was just a simple tool I wanted for impedance data.

just to confirm a reflex or what not.

and that is same value it holds in this situation.

long time ago as a teen when we farted around with piezo tweets.

would be interesting to see how it measures them. LOL

mid chamber should be stuffed.

and curious about the bass.

made it large enough so it shouldn't be boomy.

Having played with high Qts drivers as a teen as well.

I feel I got pretty good at making them work and not being intimidated

like some can be. since behavor in a model is not the same as more common

drivers.

Anyhoo point is the bottom of the cab with the large high braces.

kinda a idea to be able to stuff the krap out of it only if needed.

otherwise the impedance peak was at 39 hz and Q pretty darn good.

in 140 liters

So was hoping for decent bass

and curious about the bass.

made it large enough so it shouldn't be boomy.

Having played with high Qts drivers as a teen as well.

I feel I got pretty good at making them work and not being intimidated

like some can be. since behavor in a model is not the same as more common

drivers.

Anyhoo point is the bottom of the cab with the large high braces.

kinda a idea to be able to stuff the krap out of it only if needed.

otherwise the impedance peak was at 39 hz and Q pretty darn good.

in 140 liters

So was hoping for decent bass

Edit: that AVR lost HDMI in a lightning strike, so could have just been a matter of time. I have an AIYIMA A07 to use.

Me and the kids teased out some Acousta-Stuf and packed the wide-band chamber, but I didn't line the insides with anything. Probably about 4 gallons fluffed into the box, I didn't think about weighing it until after.

Haven't done the woofer chamber yet. From trying to tease out the smaller chamber, that looks to be a bit of time.

I copy:

(1) go ahead and run the DATSV3, just to confirm the impedance trace. Probably tomorrow afternoon.

(2) Try the main chamber without stuffing? If so, I can probably get the laptop set up and some nearfield microphone at baffle REW traces tomorrow as well. The outside far-field runs are weather dependent (still periodic rain here).

Me and the kids teased out some Acousta-Stuf and packed the wide-band chamber, but I didn't line the insides with anything. Probably about 4 gallons fluffed into the box, I didn't think about weighing it until after.

Haven't done the woofer chamber yet. From trying to tease out the smaller chamber, that looks to be a bit of time.

I copy:

(1) go ahead and run the DATSV3, just to confirm the impedance trace. Probably tomorrow afternoon.

(2) Try the main chamber without stuffing? If so, I can probably get the laptop set up and some nearfield microphone at baffle REW traces tomorrow as well. The outside far-field runs are weather dependent (still periodic rain here).

Last edited:

ahhh thats right lighting strike amp LOL

keeps on ticking. but hopefully.

I had to double check parts list make sure everything was ok.

Switching to different amp should be good good test.

and impedance curve really show any issues.

either way moving forward, pretty good got sound and crossover.

keeps on ticking. but hopefully.

I had to double check parts list make sure everything was ok.

Switching to different amp should be good good test.

and impedance curve really show any issues.

either way moving forward, pretty good got sound and crossover.

RE: Amp. Ha! After it cooled down overnight, a relay on the power input board (before the big transformer) kept clicking, so I opened it up and was trying to identify the component. Touched it with a stick (too much metal in a mechanic's stethoscope) to confirm and it quit clicking and booted up. Might start a different thread to see if there's something to be done there.

Score so far: radio - 1, pig with stick - 1.

Score so far: radio - 1, pig with stick - 1.

- Home

- Loudspeakers

- Multi-Way

- 12" Woofer and 2.5" Wideband Cabinet Conception / Crossover