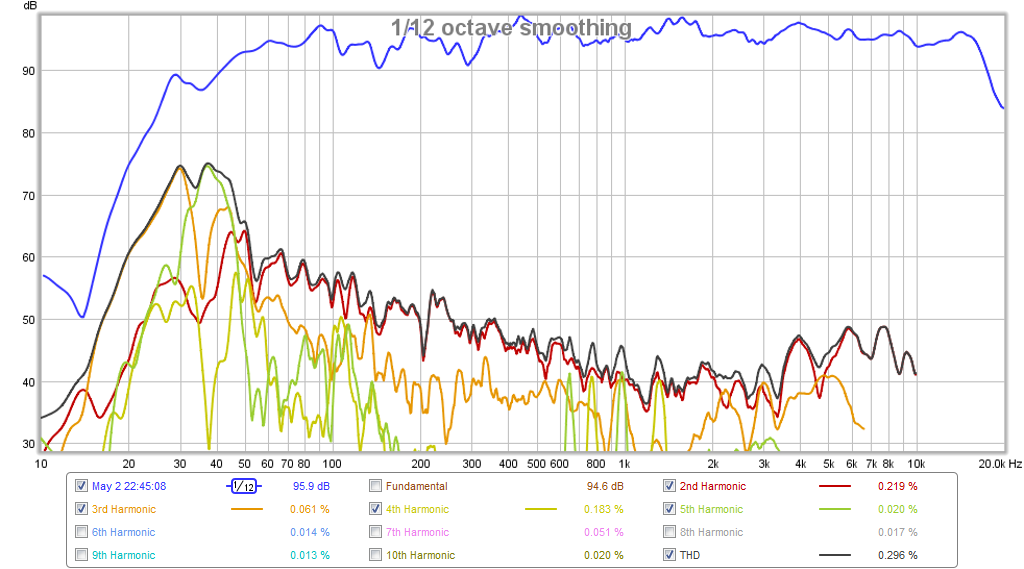

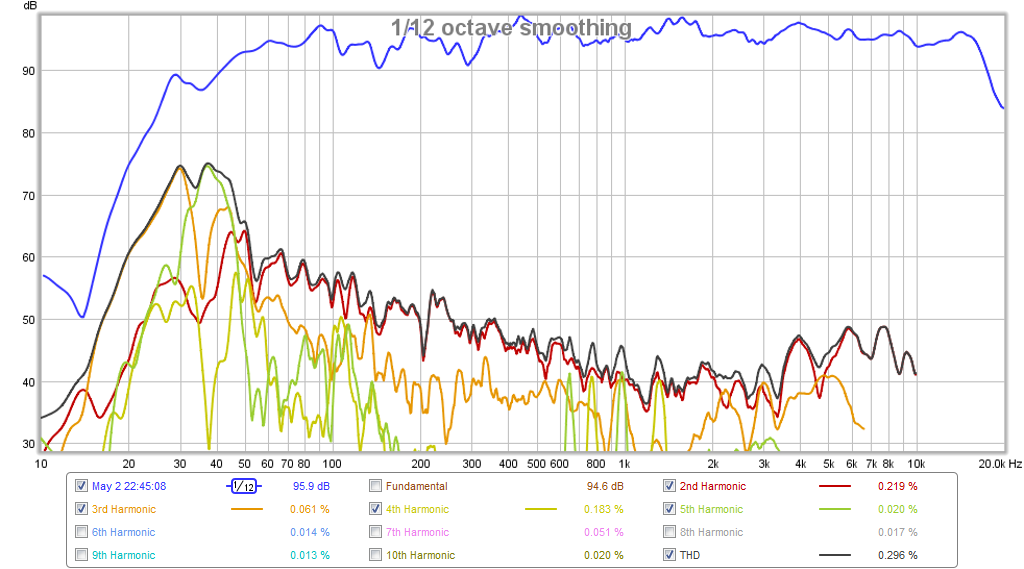

I took some new data here at 0.5m away (mic on axis of 10F) and 2.83v drive. Note that there is -6dB cut on the 10F and there is about -5dB of baffle step loss so even at 0.5m and 2.83v, the SPL is about 87dB (what it would nominally be at 1m without the padding or baffle step loss). I plotted it on a computer with a bigger screen so that the plot area is bigger and shows the HD curves more clearly. I turned the Linkwitz transform off but left a mild 5dB low-shelf from 100Hz on down.

The HD is still quite good at 0.25% at the 1.3kHz "peak" that I can see - which I think may belong to the 10F and not the RS225. Is there something else I am missing? [/IMG]

Those measurements are better, now the 4th and 5th harmonics clearly separate away from the second and third. The odd peaky nature in the higher harmonics between 600 and 1500Hz is odd and hints at a problem somewhere, any time the higher harmonics peak up like that, such as around 100Hz too, this hints at their perhaps being resonances occurring due to the less than rock solid cabinet, or possibly something in the room reverberating. HD due to cabinet issues isn't usually broadband and only occurs at specific frequency where the thing vibrates in sympathy with the driver.

5th element and xrk971,

Don't no exactly timeframe when RS225-8 came to market but can track builds at least 4 years back. Dayton Audio datasheet says revised 8/17/2014 and at same there is differences in data taken from that published datasheet and their product page for RS225-8. This makes me think can they have made some small product changes down the road, and if they have if then 5th element have worked with a older revision and xrk971 works with the last revision from 2014 datasheet which then leads to different measurements for distortion.

The distortion is caused by the amplification of distortion products due to the metal cone ringing at high frequencies. This hasn't changed between one and the other version. Adding to this there are a number of people who have build designs around the RS225 over on the HTguide forums and have tested their designs with the 'revised' version of the 225 and although slightly different, it's not different enough to stop those designs from working.

The third order peak will still be there in the newer version as it's a product of the speakers design.

Let me crank it up to 95 dB and see where distortion is. The pink foam box does vibrate some - that may be the cause of the 100Hz to 150Hz distortion. I recall adding constrained damping layer really helps. But -40dB to -50dB distortion is quite good and Iay just leave it alone.

Here is the distortion at 95dB, the behavior seems to be well controlled still, albeit the bass region is starting to show significant distortion at 60Hz is 1.7% and 4.1% at 50Hz. Need more cone surface area for lower distortion at lower frequencies.

I wonder if the rising HD is the foam XPS cabinet and not inherent in the driver?

I wonder if the rising HD is the foam XPS cabinet and not inherent in the driver?

Attachments

Last edited:

Slowly rising distortion with decreasing frequency is not unusual in bass drivers. For comparison here are my distortion measurements of an RS225 in a ~12 litre sealed cabinet at 7vRMS, which is about 8dB over standard, so pretty much 95dB nominal.

I did this sweep some time ago and as I was only interested in the lower range I stopped the measurement at 1kHz. Still as you can see things are quite a bit cleaner than with your plot.

I don't think the third order peak is presenting itself as a problem, which is nice to see. What bothers me though are the spikes of distortion at frequencies you would not expect to see it at.

The spikes centred around 1kHz are worrying as is the spike at 100Hz and then once again the large rise at 30-40Hz.

At the moment we do not know where the 1kHz spikes are coming from, with the 1st order electrical xover there is so much driver overlap that it could really be coming from anywhere. I would measure the drivers individually to see what's what.

The lower frequency spikes are most likely something vibrating, either the cabinet or something in the room. You can see a post about this here.

http://www.htguide.com/forum/showthread.php?42675-Speaker-Distortion

The peak in this case was caused by a loose driver screw. This was either causing air to chuff out through the hole, or causing the basket to vibrate. Neither are good and you can see the effects in his measurements.

Really though, small sealed cabinets with LTs applied are going to be exposed to rather large internal pressure changes, especially if you've got a bass driver with a healthy amount of xmax, like the RS225 has. If you like this approach and the RS225 then I would definitely recommend you build a nice solid box out of MDF or similar.

I know you were talking about reducing group delay earlier on by removing the high pass on the RS225, but really the increased group delay is simply a function of the high pass, this is a phase shift that occurs due to the roll off. This can be intrinsic to the drivers natural roll off or imposed on the system by a filter, it is not anything to be concerned about.

I did this sweep some time ago and as I was only interested in the lower range I stopped the measurement at 1kHz. Still as you can see things are quite a bit cleaner than with your plot.

I don't think the third order peak is presenting itself as a problem, which is nice to see. What bothers me though are the spikes of distortion at frequencies you would not expect to see it at.

The spikes centred around 1kHz are worrying as is the spike at 100Hz and then once again the large rise at 30-40Hz.

At the moment we do not know where the 1kHz spikes are coming from, with the 1st order electrical xover there is so much driver overlap that it could really be coming from anywhere. I would measure the drivers individually to see what's what.

The lower frequency spikes are most likely something vibrating, either the cabinet or something in the room. You can see a post about this here.

http://www.htguide.com/forum/showthread.php?42675-Speaker-Distortion

The peak in this case was caused by a loose driver screw. This was either causing air to chuff out through the hole, or causing the basket to vibrate. Neither are good and you can see the effects in his measurements.

Really though, small sealed cabinets with LTs applied are going to be exposed to rather large internal pressure changes, especially if you've got a bass driver with a healthy amount of xmax, like the RS225 has. If you like this approach and the RS225 then I would definitely recommend you build a nice solid box out of MDF or similar.

I know you were talking about reducing group delay earlier on by removing the high pass on the RS225, but really the increased group delay is simply a function of the high pass, this is a phase shift that occurs due to the roll off. This can be intrinsic to the drivers natural roll off or imposed on the system by a filter, it is not anything to be concerned about.

Attachments

5th Element - thanks for the data on yours. Looks like the foam cabinet rattle is getting the best of me here. I will have to make one out of something stiffer if I want to chase that down. I could also try some CLD on the panels. Prototyping with foam gets you far but at some point it just isn't heavy or stuff enough.

Laminate XPS with glass-fiber epoxy or carbon fiber and it will be considerably stiffer than MDF (such construction methods are used for ultralight aircraft and surfboards).

Although MDF is consistent and machines OK, it does not have good dampening characteristics, nor is it particularly strong.

Among woods, laminated bamboo is far stronger than MDF and has superior dampening. However, it does cost considerably more than MDF.

Meniscus sells an accelerometer option for the ATB measuring kit, which should make it easier to study flaws that your cabinet structure may have.

Accelerometer

ATB PC Pro

Although MDF is consistent and machines OK, it does not have good dampening characteristics, nor is it particularly strong.

Among woods, laminated bamboo is far stronger than MDF and has superior dampening. However, it does cost considerably more than MDF.

Meniscus sells an accelerometer option for the ATB measuring kit, which should make it easier to study flaws that your cabinet structure may have.

Accelerometer

ATB PC Pro

Although MDF is consistent and machines OK, it does not have good dampening characteristics, nor is it particularly strong.

Among woods, laminated bamboo is far stronger than MDF and has superior dampening. However, it does cost considerably more

apologies for being pedantic, but dampening makes thing wet, while damping removes vibrations.

Although MDF is consistent and machines OK, it does not have good dampening characteristics, nor is it particularly strong.

Among woods, laminated bamboo is far stronger than MDF and has superior dampening. However, it does cost considerably more

apologies for being pedantic, but dampening makes thing wet, while damping removes vibrations.

I don't know but Merriam Webster says firstly it is to diminish activity or vigor and secondly, is to make wet.

Dampen | Definition of dampen by Merriam-Webster

Last edited:

As the English language continues to loose precision, "damp" and "dampen" have become synonymous in common usage. But at my age, I will continue to consider "damp" to mean diminish activity and "dampen" to mean make wet.

Bob

Bob

So how does one say a material has more ability to attenuate vibrations?

"Material X has more damping properties"?

Back to the topic though, I think constrained layer damping (CLD) should have less harmonic distortion than plain pink XPS foam board. Just gluing a layer of 1/4-in Sureply flooring plywood on the external walls with either latex caulking or liquid nails should help a lot.

I did not realize that Sureply floor underlayment is made of nicely veneered birch. It actually looks very nice and the sandwich construction, if successful in reducing HD, may prove to be a very weight AND cost effective alternative to regular 18mm birch plywood. The 4x8 sheets of Sureply are about $20 ea IIRC. The material looks very fine and is flat and free of defects.

SurePly® Premium Underlayment :: Patriot Timber

"Material X has more damping properties"?

Back to the topic though, I think constrained layer damping (CLD) should have less harmonic distortion than plain pink XPS foam board. Just gluing a layer of 1/4-in Sureply flooring plywood on the external walls with either latex caulking or liquid nails should help a lot.

I did not realize that Sureply floor underlayment is made of nicely veneered birch. It actually looks very nice and the sandwich construction, if successful in reducing HD, may prove to be a very weight AND cost effective alternative to regular 18mm birch plywood. The 4x8 sheets of Sureply are about $20 ea IIRC. The material looks very fine and is flat and free of defects.

SurePly® Premium Underlayment :: Patriot Timber

apologies for being pedantic, but dampening makes thing wet, while damping removes vibrations.

This has been discussed to death,and in the end it was shown that either term is appropriate to define the action of the pilyfluff or whatever we put in our loudspeakers to deal with the back wave.

dave

So how does one say a material has more ability to attenuate vibrations?

"Material X has more damping properties"?

Yes exactly.

Another example. Shock absorbers on cars are sometimes called dampers, not dampeners.

Last edited:

This has been discussed to death,and in the end it was shown that either term is appropriate to define the action of the pilyfluff or whatever we put in our loudspeakers to deal with the back wave.

dave

Most of the time precision in language is a good thing to have. This may be a trivial example but it is one of the gradual erosions that we are seeing.

This "dampener" seems perfect for use inside a speaker enclosure.

http://www.amazon.com/GTMAT-Automotive-Sound-Dampener-50mil/dp/B00938FK5A

It might even help my FAST box reduce its HD.

http://www.amazon.com/GTMAT-Automotive-Sound-Dampener-50mil/dp/B00938FK5A

It might even help my FAST box reduce its HD.

It didn't quite do so well on metal, it is tested in this massive thread: Sound Deadening (CLD) Testing - Car Audio | DiyMobileAudio.com | Car Stereo Forum

Direct link to results

Compared to most others it looked like it didn't do anything useful. I used a similar product inside my enclosure, but choose one of the top performers from this test.

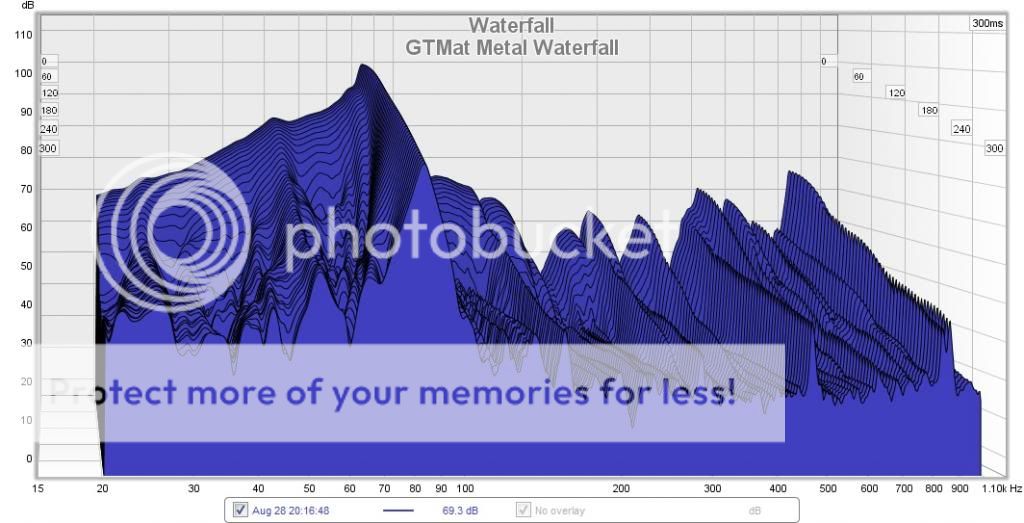

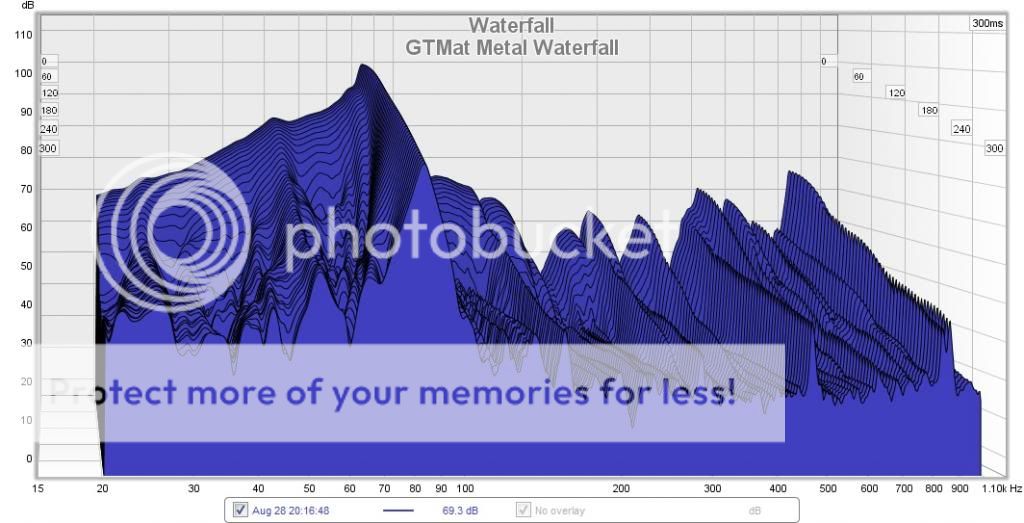

Original waterfall plot of bare metal:

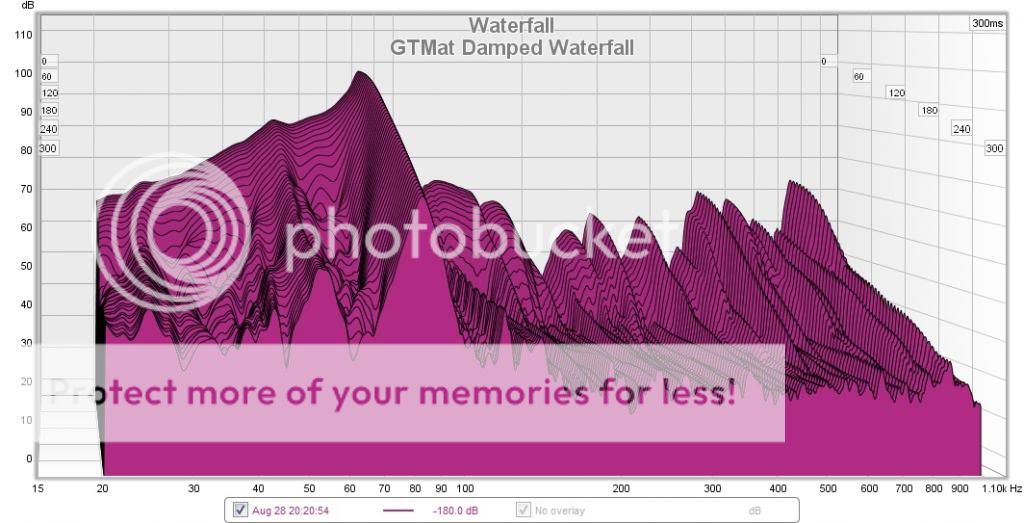

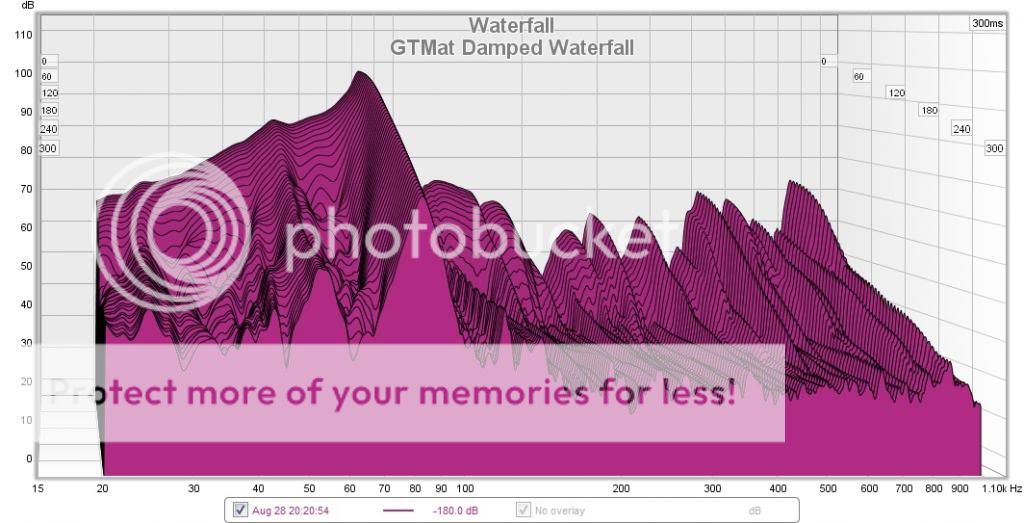

Waterfall after applying GTmat Pro:

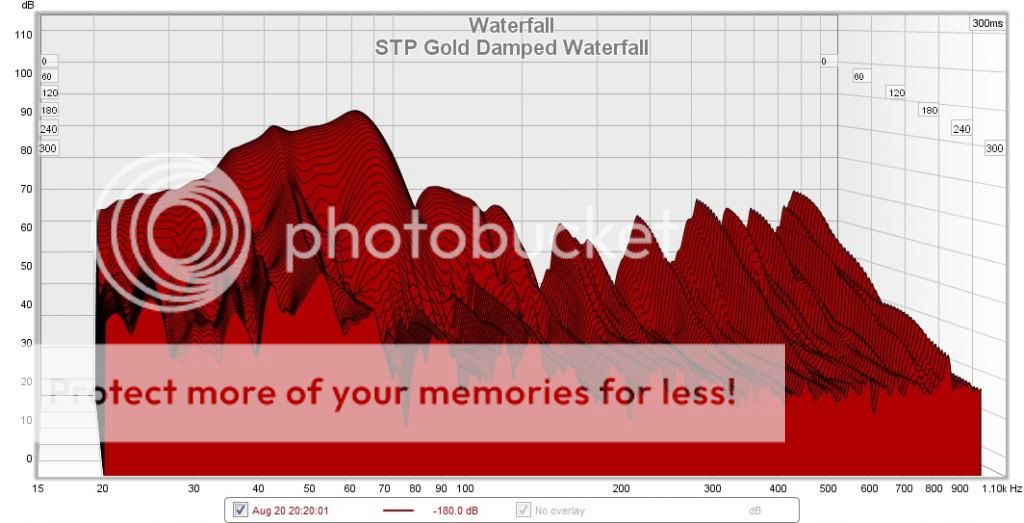

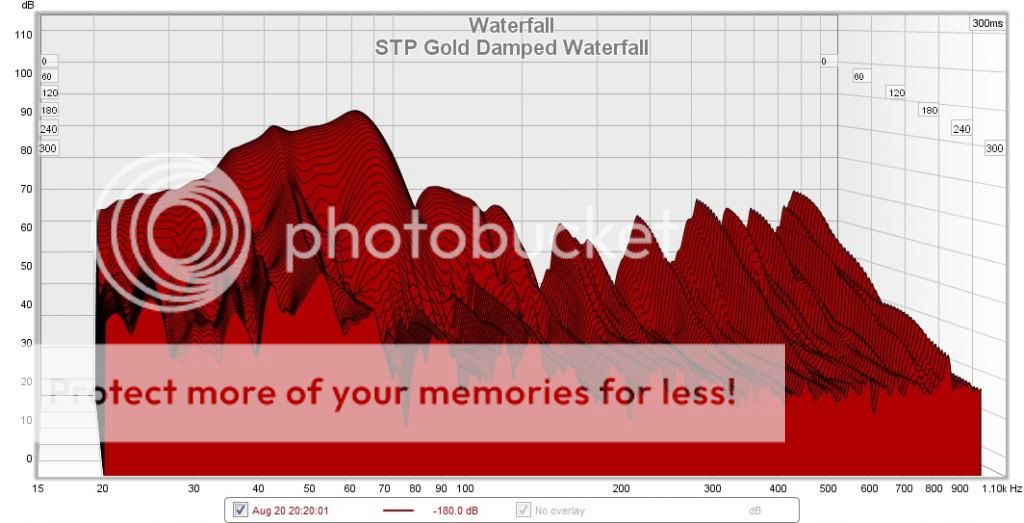

A good damping material looks something like this:

But all these tests were done on metal, no telling how they would perform on something else. Based on these plots I'd spend my money elsewhere 😉.

Direct link to results

Compared to most others it looked like it didn't do anything useful. I used a similar product inside my enclosure, but choose one of the top performers from this test.

Original waterfall plot of bare metal:

Waterfall after applying GTmat Pro:

A good damping material looks something like this:

But all these tests were done on metal, no telling how they would perform on something else. Based on these plots I'd spend my money elsewhere 😉.

Last edited:

Wesayso,

Thanks for the info. Spending money on tubes of latex caulking and wooden boards or even foam boards for CLD - which I know works.

Thanks for the info. Spending money on tubes of latex caulking and wooden boards or even foam boards for CLD - which I know works.

99 db should do it. 85 db is a good rms level, and the most dynamic pop recordings might peak 14 db above rms.

Ok that is good to know. With a single woofer and LT, this design maxes out at about 101dB. Amazing how a dedicated 8in pretty high quality woofer still can't reach 105dB required to be THX certified. That HT business is some loud stuff. I see dual 6.5in woofer 1in dome tweeter MTM setups all the time being used for HT and certified for THX. Are they really getting 105dB?

- Home

- Loudspeakers

- Full Range

- 10F/8424 & RS225-8 FAST / WAW Ref Monitor