Dynaudio 24W75, passive radiator 21W-SL and D28/2, built 1995 and reworked 2002.

Paiinted this colour recently (red front).

Paiinted this colour recently (red front).

Hi.

I’ve read through all this, but don’t recall much of any talk about directivity.

Any users of this speaker that can comment on this?

I usually like to mull around the room, as opposed to sitting, locked in to a “sweet spot”.

I’ve read through all this, but don’t recall much of any talk about directivity.

Any users of this speaker that can comment on this?

I usually like to mull around the room, as opposed to sitting, locked in to a “sweet spot”.

I can only talk about the crossover I made for the TC9FD. But more generally since this speaker uses a large "tweeter", you can expect the treble to drop off if you're not in front of it.

But that’s for treble. The midrange is what’s important for vocals and for soundstage and image - those are quite nice over a wide sweet spot. If you really want something for the whole room, Omni speakers or a Karlsonator with a K aperture will do well here.

I’m only really concerned about directivity through the midrange.

I’d still like to see a power response and directivity graph of some kind.

I’d still like to see a power response and directivity graph of some kind.

You might look at the post by Byrtt back here where he did a pretty careful study of the 10F driver using Vituix CAD.

https://www.diyaudio.com/community/threads/10f-8424-rs225-8-fast-waw-ref-monitor.273524/post-6075827

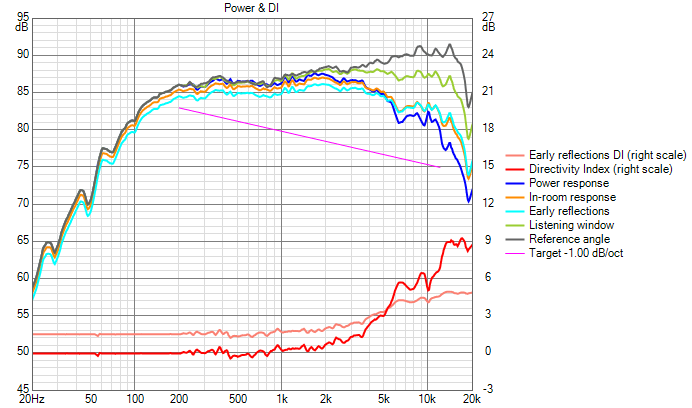

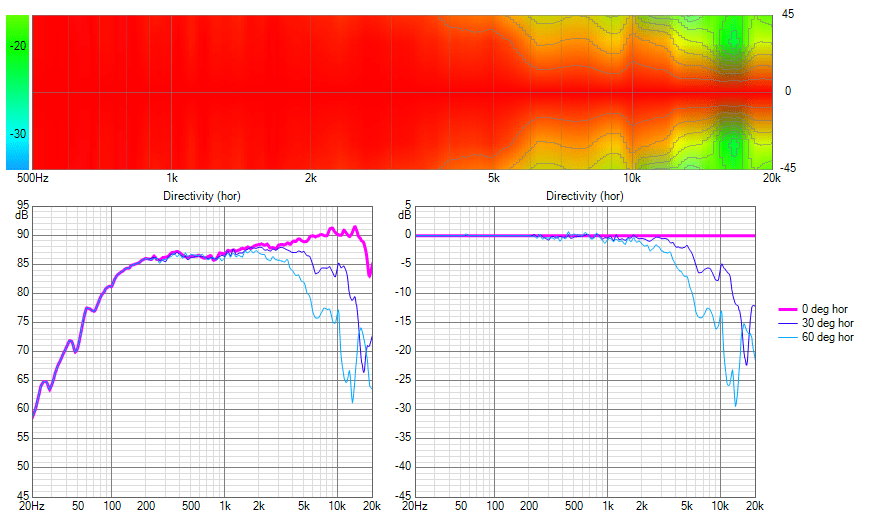

Spinorama’s:

As the XO point for the 10F is 900Hz, all the directivity info above is good.

As many people know, the 10F is perhaps one of the finest midrange drivers ever made at any price.

https://www.diyaudio.com/community/threads/10f-8424-rs225-8-fast-waw-ref-monitor.273524/post-6075827

Spinorama’s:

As the XO point for the 10F is 900Hz, all the directivity info above is good.

As many people know, the 10F is perhaps one of the finest midrange drivers ever made at any price.

I didn't look at it extensively, but SBA also has a new 7.5" coax driver. The MT19CP-8.Just a confirmed observation that the Tang Band W8-2314 coaxial is a drop in fit for the TL cabinet here (same cutout, same bezel, same screw holes) and the TS parameters are also a match. I have heard that it makes superb bass in this cabinet. I have developed a crossover for it in case anyone is lucky enough to have this driver and wants a point source multi-way TL speaker.

Might be an option for the hard to get TB coax right now.

Don't know if they would be a good fit for this though. I have some time this afternoon here. I'll try to see how they go in a TL.

What's your experience with RS225-8 when sealed? Since there is no dust cap and the driver isn't hermetic around the phase plug don't you have any artificial whistling and chuffing? My experience with sealed enclosures is that it should be sealed for good, otherwise even a leaky screw thread will provide you with chuffing/whistling.

I'd really like to go a sealed route with RS225, but this thing bugs me.

I'd really like to go a sealed route with RS225, but this thing bugs me.

is with this design the woofer supposed to be at ear level instead of the fullrange?

looking into building a diy wideband speaker and really like the transient-perfect/linear phase approach 🙂

looking into building a diy wideband speaker and really like the transient-perfect/linear phase approach 🙂

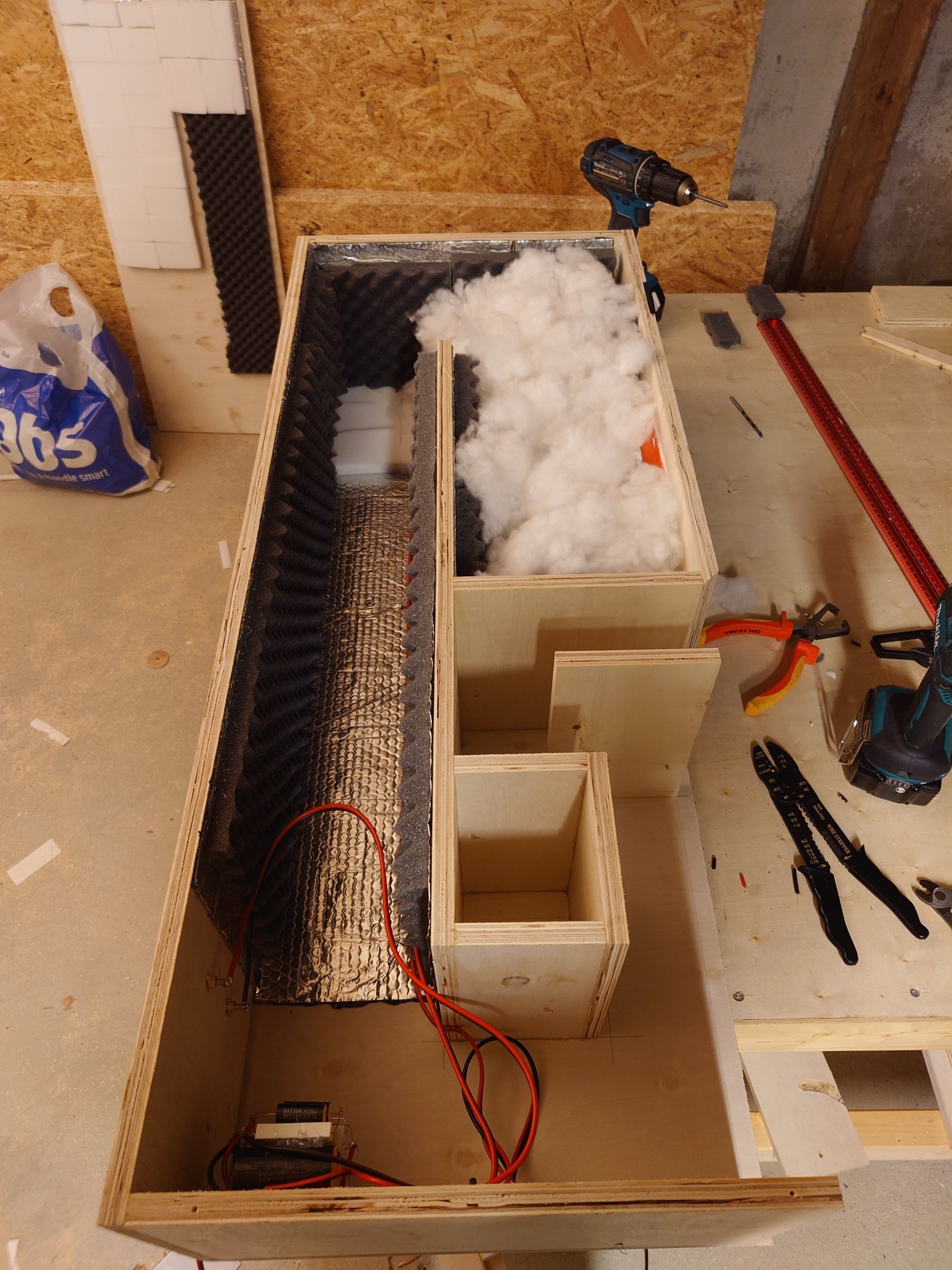

Starting to finish up my build. Made a few mistakes, but it's my first speaker-build so I feel I'm allowed to 😉

The biggest one being that its in 15mm and not 18mm ply. They will be rebuilt at some point in 18mm MDF when I have the time. For now it has been a very good learning experience.

I have a few questions though.

Nr 1: For me it feels like the stuffing is going to collapse and fall down the rear chamber if i stuff more than just the front chamber. Do I need to add some sort of support for it to keep in place?

Nr 2: I dont have access to a DATS to measure when I have "enough" stuffing. Do other people here have any good tips on how to know? I have UMIK and REW to measure with. I have measured in-room, 1m on-axis and the response okay.

Nr 3: What about the last few bends in the TL, have people been covering this with foam/bitumen or is it only the front chamber and the rear part that is important?

Nr 4: My tops starts to taper off around 12k Hz. Is this to be expected?

Lastly, thanks to all that have helped/contributed to the design of the speaker. I have had it playing about 10-15 hours now and they sound quite good so far. Last bit of fine tuning needed and I think they are mint.

The side panel that is exposed to the bitumen has been covered with foam after the picture was taken.

The biggest one being that its in 15mm and not 18mm ply. They will be rebuilt at some point in 18mm MDF when I have the time. For now it has been a very good learning experience.

I have a few questions though.

Nr 1: For me it feels like the stuffing is going to collapse and fall down the rear chamber if i stuff more than just the front chamber. Do I need to add some sort of support for it to keep in place?

Nr 2: I dont have access to a DATS to measure when I have "enough" stuffing. Do other people here have any good tips on how to know? I have UMIK and REW to measure with. I have measured in-room, 1m on-axis and the response okay.

Nr 3: What about the last few bends in the TL, have people been covering this with foam/bitumen or is it only the front chamber and the rear part that is important?

Nr 4: My tops starts to taper off around 12k Hz. Is this to be expected?

Lastly, thanks to all that have helped/contributed to the design of the speaker. I have had it playing about 10-15 hours now and they sound quite good so far. Last bit of fine tuning needed and I think they are mint.

The side panel that is exposed to the bitumen has been covered with foam after the picture was taken.

You don’t need stuffing past the first 180deg turn. Maybe add some eggcrate foam on the bottom floor panel of the TL.

What do you mean your tops only go to 12kHz? If using 10F, should go to 16kHz or so.

You only need the bitumen/Noico butyl sheets in the front chamber. You can add it to the back panel if you like but probably not needed.

Good luck!

What do you mean your tops only go to 12kHz? If using 10F, should go to 16kHz or so.

You only need the bitumen/Noico butyl sheets in the front chamber. You can add it to the back panel if you like but probably not needed.

Good luck!

- Home

- Loudspeakers

- Full Range

- 10F/8424 & RS225-8 FAST / WAW Ref Monitor