I am lazy and sometimes hot melt them to the board. Sitting flat not hanging in a wall though. On a development speaker that won’t go anywhere, the board sits on a wad of fiberglass, no screws or anything!

xrk, couple of dumb newbie questions.. for your coardboard prototypes, how do you glue the seperate panels together, do you use wood glue, superglue or something else? is it good to duct tape them into place while the glue dries? is there a type of screw or bolt that's best to mount the drivers into cardboard? I have socket head cap machine screws and t-nuts.. that probably won't work right?

When you say a sealed FAST with a 3.5" full range in a dagger chamber, a dagger chamber is when you have the full range in its own seperate tiny box within the larger box for the woofer?

When you say a sealed FAST with a 3.5" full range in a dagger chamber, a dagger chamber is when you have the full range in its own seperate tiny box within the larger box for the woofer?

Use hot melt glue. It sets in 30 seconds and you hold it in place by hand until it hardens. Glue the internal pieces to one side with hot melt. Then glue the remaining side with slower settings white PVA and a lot of books on top to clamp it down. Read the foam core thread for tips. I use drywall screws. Add corrugated cardboard on back of foam for screws to bite into. Don’t over tighten. For heavy drivers you need to add thin wood facing. 3/16in subfloor plywood is good.

Dagger is a small sealed tall pyramid rear chamber. Use 5 sides if you can. Stuff it with fiberglass or polyfill. It acts as an acoustic black hole. It needs to be air tight from main woofer chamber.

Dagger is a small sealed tall pyramid rear chamber. Use 5 sides if you can. Stuff it with fiberglass or polyfill. It acts as an acoustic black hole. It needs to be air tight from main woofer chamber.

Yep, making sure I have the driver cutouts correct and that laser kerf is correct for side fitment.

Binding Post Plates

I'm thinking about putting anodized aluminum plates behind the binding posts to avoid any scratches and give it a more professional look. Parts-Express wants $11 each for them, so I started looking for a better option. I found plates on Amazon for laser engraving business, dog tags and stamping blanks. All for less than $1 each and in any color including: Gold, Silver, Black. They do need to be drilled but that's easy if you have a drill press.

I'm thinking about putting anodized aluminum plates behind the binding posts to avoid any scratches and give it a more professional look. Parts-Express wants $11 each for them, so I started looking for a better option. I found plates on Amazon for laser engraving business, dog tags and stamping blanks. All for less than $1 each and in any color including: Gold, Silver, Black. They do need to be drilled but that's easy if you have a drill press.

You're right. Might be fine if I leave the wood behind it, but I'll look at some of the other choices like the tags and engraving plates. These are for laser etched business cards.

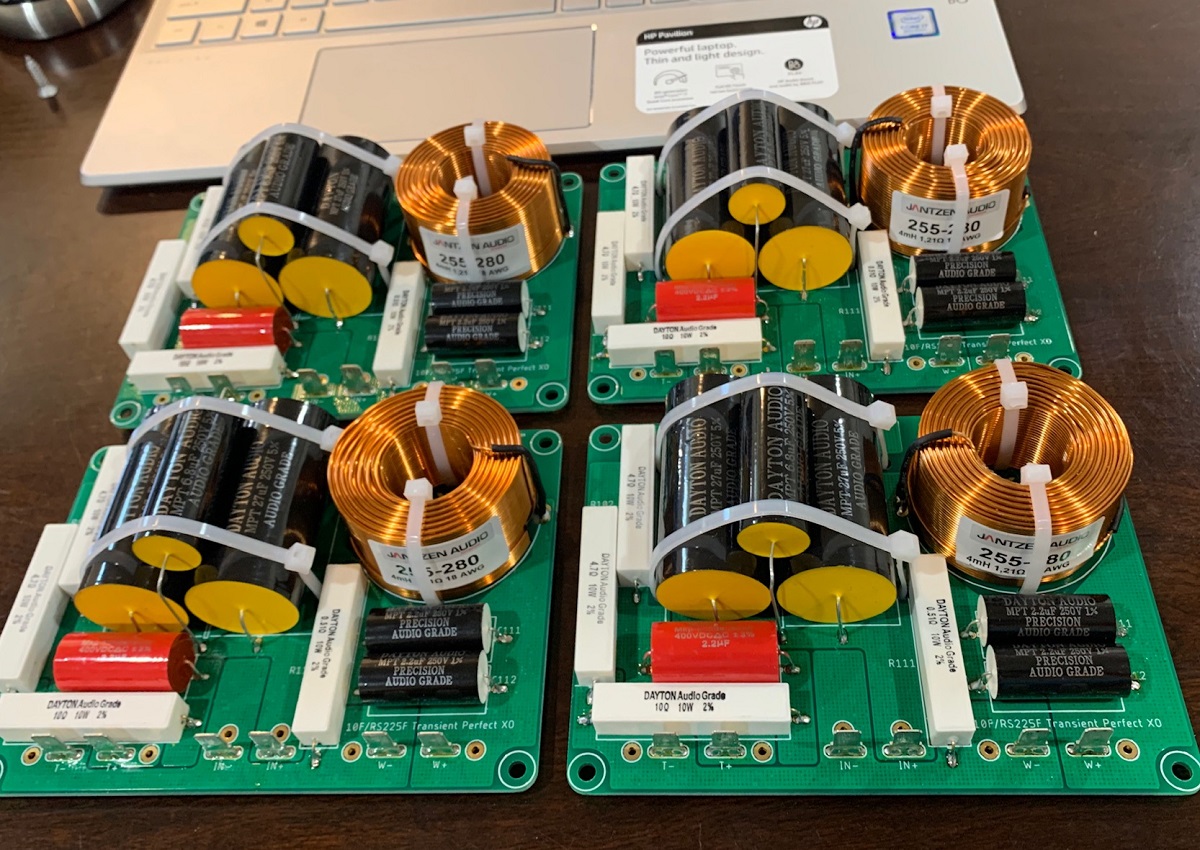

The XO's received their Faston tabs and subsequently tested with a 2-way FAST microTrynergy o make sure they work and make music. Then packed them up for shipment to Studiomic for installation into the TL cabinets. Hopefully this happens tomorrow and we may get first sound by Wednesday.

Testing with microTrynergy and Class A amp:

All four XO's tested and ready for shipping:

Testing with microTrynergy and Class A amp:

All four XO's tested and ready for shipping:

Attachments

That's a shame about your birdhouse, but a little off topic. The prototype FAST TL wood speaker is playing after a long day working on it. I two mistakes: I let the binding posts both touch the foil on some butyl sound insulation and I used an expensive amp to test it. The result was that the speaker did not make sound and my very expensive amp made smoke and one of the tubes got bright orange. I'll ***** the damage in the morning and send some pics.

silverD,

Nice work with the cross over.

StudioMic,

Hope nothing major with your amp, and you can get it fixed easily.

Nice work with the cross over.

StudioMic,

Hope nothing major with your amp, and you can get it fixed easily.

It's a McGary Audio SA2 that I smoked up. I just got it three weeks ago. I know Mike McGary personally and I'm sure he will fix it for me but it's going to be an embarrassing and humbling conversation. An important lesson was learned: never test a new speaker build on a good amp! It only takes a minute to hook it up to a $25 amp and make sure there are no crossed wires or crossover issues.

An important lesson was learned: never test a new speaker build on a good amp! It only takes a minute to hook it up to a $25 amp and make sure there are no crossed wires or crossover issues.

Amen!

Good luck.

Hi Studiomic,

So sorry to hear about your McGary amp - I hope it’s not a major repair. Hopefully just a burnt resistor. We all make mistakes like this on our DIY journey.

Looking forward to your pics and maybe listening impressions of a mono speaker. The same idea of using a cheap test speaker when hooking up a new amp for the first time. Although a DMM can check for things like close to zero DC offset before hooking up an amp for the first time. On a speaker or crossover, the DMM can check for non zero impedance. One time, I spent nearly a week trying to debug a perfectly good new amp because the O-scope coaxial cable I used for measuring the amp was internally shorted. A DMM check for zero ohms would have worked there too.

Thanks for assembling and testing the TL speaker. Good luck on the amp repair!

@SilverD,

Nice looking perf board crossover! Sounds like another 10F/RS225 FAST speaker is going to be playing soon.

So sorry to hear about your McGary amp - I hope it’s not a major repair. Hopefully just a burnt resistor. We all make mistakes like this on our DIY journey.

Looking forward to your pics and maybe listening impressions of a mono speaker. The same idea of using a cheap test speaker when hooking up a new amp for the first time. Although a DMM can check for things like close to zero DC offset before hooking up an amp for the first time. On a speaker or crossover, the DMM can check for non zero impedance. One time, I spent nearly a week trying to debug a perfectly good new amp because the O-scope coaxial cable I used for measuring the amp was internally shorted. A DMM check for zero ohms would have worked there too.

Thanks for assembling and testing the TL speaker. Good luck on the amp repair!

@SilverD,

Nice looking perf board crossover! Sounds like another 10F/RS225 FAST speaker is going to be playing soon.

Last edited:

- Home

- Loudspeakers

- Full Range

- 10F/8424 & RS225-8 FAST / WAW Ref Monitor