That's interesting about the threaded center holes. I never heard that the threaded center holes are part of the manufacturing process, and not intended for mounting, before. Some of mine are covered with the stickers, and others are not.They don't mention it in docs, on mine they where covered by a sticker, and according to soundimports they are for use during manufacturing and not intended for mounting.

So I think it seems clear that are not intended to be used at all, and exciters should actually be able to hold up themselves.

Regarding the ones with the four unthreaded perimeter holes (eg 25FHE, 30HESF), the Parts Express description of them as "screw down mounting tabs" more than suggests that they (could or should?) be used for mounting. But if so, how exactly do they intend, I still wonder? My best guess is still that they think you might screw through them into you panel. I sure don't care for that idea, though I've never tried it.

I do understand your frustration with the Dayton Audio and Parts Express communications. For myself it seems pretty clear now (regardless of what they might claim), that the ones that have only a single non-metallic spider (eg 25FHE, 25VT, 30HESF, etc) require external support by a brace/spine or similar, while the ones that include some secondary means of support for the body, like frog legs, or multiple spiders, or steel spiders (eg 25Q, 32U, 32Q) may not need such a brace.

I guess one exception might be that you could get away without a brace for the single spider type if they are used on a horizontal panel, like for a ceiling mounted speaker.

As I have shared before, I have (at least for now) settled on a brace type mount like Steve's images show, but with some foam between the back of the exciter and the brace. While there is nothing wrong with the simple rigid brace, I suspect that using the foam is a little more forgiving in terms the exact positioning of the brace relative to the panel, but with no apparent negative consequence. The only commercial DML panels I have in my possession (Armstrong Ceiling Tile Speakers) also used this type of mounting.

Eric

I get the impression that having been there you don't use this method any more and mount as they are intended to be mounted possibly with variations but essentially the same?with a rigid spine support.

Eric

Never understood those screw down tabs either. Of course for EPS they would not work, but not sure they make any sense for ply either.

I'm not at all frustrated with soundimports or Dayton. I'm communicating with soundimports and they have been honest, informative and helpful so far, and we are trying to work out extent and cause of damage. Well see what the conclusion will be, but so far they have been great.

I got better results with a softer suspension for my back brace as well, but do like the idea of being able to use them without any bracing as manufacturer suggests.

If it is not possible to use them that way as you say, then Dayton should really update their instructions or fix the design.

The Xite has no centre screw, nor screw down tabs, but is a hefty 40w 130g+ exciter. One would hope that will work unsupported since there isn't any means of supporting it?

Never understood those screw down tabs either. Of course for EPS they would not work, but not sure they make any sense for ply either.

I'm not at all frustrated with soundimports or Dayton. I'm communicating with soundimports and they have been honest, informative and helpful so far, and we are trying to work out extent and cause of damage. Well see what the conclusion will be, but so far they have been great.

I got better results with a softer suspension for my back brace as well, but do like the idea of being able to use them without any bracing as manufacturer suggests.

If it is not possible to use them that way as you say, then Dayton should really update their instructions or fix the design.

The Xite has no centre screw, nor screw down tabs, but is a hefty 40w 130g+ exciter. One would hope that will work unsupported since there isn't any means of supporting it?

Yeah, I have not read all of your posts in detail. Just like most people buying exciters. They probably watched the famous YouTube video with XPS and unsupported exciters, or followed the advice from manufacturer or distributor. Which says to use them unsupported.Leob.

This was a panel Christian made with a rigid spine support.

This subject keeps popping up.

It has been done like this for a reason .

This is an very old panel I have posted many times on this forum.

Steve.

Now it seems most of the users here thinks it is obvious that they need support, which just makes the situation a bit strange. If it is such common knowledge, why doesn't manufacturer and distributor know about it? I think it would be good if they do.

Hi Leob,It is same printed design I posted here and in the PA thread earlier, but I adjusted the angle of the arms slightly to minimize the pressure toward the plate, and now print it using dual material with soft material around the screws, and use polycarbonate screws instead of metal. This gives it a firm but slightly flexible grip.

The distortion happens also if I remove the bracing and have the panels lying flat, but now at least the bracing seems to have no detrimental effect apart from a slight sensitivity reduction. A bit disheartening to find that when I finally made a design I'm happy with, it turns out that problem remains anyway...and that it perhaps was all for nothing and support should not be needed at all!

It is a bit strange that from what I have seen they do not specify that they need to be supported in any way, and the screw hole is hidden behind a sticker. So I guess I have not mishandled them and the damage should be covered by their 5 year warranty...at least I can hope so 🙂

I will start going through and analyzing the exciters one by one and see how bad the situation is. But compared to when they where new it seems very hard to get any of them to play distortion free when vertically mounted. Perhaps it is still possible with just the right support for few of them, but they just don't seem reliable any more.

After driving my HESFs very hard on live gigs for a few months (peaking 2 x 500w into 8 x 40w drivers) I also experienced the drivers distorting more and more. The drivers are supported, hard, not just on a single brace, but as part of a perforated rear panel, so there's no sagging at all.

Also, nothing I could do about the distortion.

I thought I had blown them, but there's none of the characteristic smell. Weird. So I took the drivers apart.

No. Not blown. The voice coils are not even discoloured.

The problem was that the voice coil flanges that glue to the panel, were cracked. The flanges are half-broken off of the coil.

My next iteration (if I use HESFs again) will have 3-D printed inserts to reinforce that flange, and which might also give a better HF response as a side effect.

There's a paper by the German guy (name escapes me ATM) detailing the need for reinforcement of the coil former

This one 🙂There's a paper by the German guy (name escapes me ATM) detailing the need for reinforcement of the coil former

Attachments

Conclusion of this paper:

"Furthermore, based on this study, new exciter designs with particularly strong voice coil formers are conceivable to extend the usable frequency range of flat panel loudspeakers to highest frequencies."

Probably what has been implemented on the new Ben Zenker Xcite exciter. 🏆

We hope.

"Furthermore, based on this study, new exciter designs with particularly strong voice coil formers are conceivable to extend the usable frequency range of flat panel loudspeakers to highest frequencies."

Probably what has been implemented on the new Ben Zenker Xcite exciter. 🏆

We hope.

I been inspecting an exciter that is distorting, but could not detect any cracks in flange. Did you have to detach it to inspect properly?Hi Leob,

After driving my HESFs very hard on live gigs for a few months (peaking 2 x 500w into 8 x 40w drivers) I also experienced the drivers distorting more and more. The drivers are supported, hard, not just on a single brace, but as part of a perforated rear panel, so there's no sagging at all.

Also, nothing I could do about the distortion.

I thought I had blown them, but there's none of the characteristic smell. Weird. So I took the drivers apart.

No. Not blown. The voice coils are not even discoloured.

The problem was that the voice coil flanges that glue to the panel, were cracked. The flanges are half-broken off of the coil.

My next iteration (if I use HESFs again) will have 3-D printed inserts to reinforce that flange, and which might also give a better HF response as a side effect.

Yes, I cut the driver off the panel with a razor.Did you have to detach it to inspect properly?

The flange part is supposed to be glued to the inside of the VC about 2 or 3mm deep, but it detaches from the VC under fault.

If you manipulate the flange with your fingers you might see it move without the VC moving.

I had already cut the spiders off with a scalpel before I found the fault. And then it was easy to look for the fault in the other drivers.

In a previous post: (https://www.diyaudio.com/community/...s-as-a-full-range-speaker.272576/post-7526903), I showed how "tap testing" and impedance tests both showed peaks at the resonance frequencies of the panel. What I have found since is that I can also use the impedance test with multiple exciters to definitively identify the natural frequencies of the "higher order" modes, by judicious selection of the location and phase of each of the exciters, as shown in this set of impedance curves:

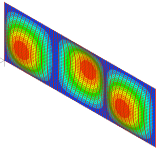

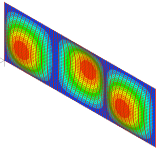

The set of curves at the bottom of the graph are the impedance results I shared in the earlier post. In those tests, I used a single exciter on a 14" tall by 48" wide PS foam panel supported by a frame around the perimeter, approximating "simple" supports. I placed the single exciter halfway up the 14" dimension and at various locations along the 48" dimension. At each position, several of the (1,n) modes were excited, and hence exhibit peaks in the impedance curve. And by overlaying all the individual impedance curves, the natural frequencies of the 1,1 to 1,9 modes are easily inferred (as labelled on the curves). For reference, the 1,3 mode is shown here.

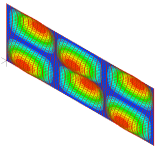

Now the fun part is that by using two exciters on the panel at the same time, with one placed about 3.5" above the centerline, and the other 3.5" below the centerline, and wiring the two exciters out of phase I was able to excite the (2,n) modes. The image below shows the 2,3 mode. Note that all the antinodes (red) are along lines halfway above or below the centerline, and that the top and bottom of the panel are out phase with each other at any position from left to right. As in the first set, by making several impedance tests with the two exciters at various locations (left to right), the resonance frequencies of the 2,n modes are revealed (see the middle set of curves in the plot above). Also, another neat thing is that the two exciters counterbalance the force on the panel in such a way that the 1,n modes revealed in the single exciter dataset completely disappear!

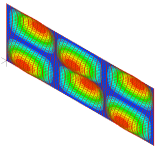

Further, by using 3 exciters, placing one at the centerline, and the other two 4.6" above and below the centerline the 3,n modes are revealed, as shown in the set of impedance curves at the top of the graph. In this case, the upper and lower exciters were in phase with each other, and out of phase with the middle exciter. And as before, the forces of the three exciters counterbalance in such a way that none of the 1,n or 2,n modes show up, but rather only the 3,n modes!

This reveals a neat feature of using the impedance test compared with the "tap test", which is that by judicious selection of the number of exciters, their location, and their phase, you can be more selective about which modes are excited, and hence be more certain about assigning a particular resonance frequency with the correct mode.

Eric

The set of curves at the bottom of the graph are the impedance results I shared in the earlier post. In those tests, I used a single exciter on a 14" tall by 48" wide PS foam panel supported by a frame around the perimeter, approximating "simple" supports. I placed the single exciter halfway up the 14" dimension and at various locations along the 48" dimension. At each position, several of the (1,n) modes were excited, and hence exhibit peaks in the impedance curve. And by overlaying all the individual impedance curves, the natural frequencies of the 1,1 to 1,9 modes are easily inferred (as labelled on the curves). For reference, the 1,3 mode is shown here.

Now the fun part is that by using two exciters on the panel at the same time, with one placed about 3.5" above the centerline, and the other 3.5" below the centerline, and wiring the two exciters out of phase I was able to excite the (2,n) modes. The image below shows the 2,3 mode. Note that all the antinodes (red) are along lines halfway above or below the centerline, and that the top and bottom of the panel are out phase with each other at any position from left to right. As in the first set, by making several impedance tests with the two exciters at various locations (left to right), the resonance frequencies of the 2,n modes are revealed (see the middle set of curves in the plot above). Also, another neat thing is that the two exciters counterbalance the force on the panel in such a way that the 1,n modes revealed in the single exciter dataset completely disappear!

Further, by using 3 exciters, placing one at the centerline, and the other two 4.6" above and below the centerline the 3,n modes are revealed, as shown in the set of impedance curves at the top of the graph. In this case, the upper and lower exciters were in phase with each other, and out of phase with the middle exciter. And as before, the forces of the three exciters counterbalance in such a way that none of the 1,n or 2,n modes show up, but rather only the 3,n modes!

This reveals a neat feature of using the impedance test compared with the "tap test", which is that by judicious selection of the number of exciters, their location, and their phase, you can be more selective about which modes are excited, and hence be more certain about assigning a particular resonance frequency with the correct mode.

Eric

I am glad that the exciters to be used in my project don't have any of the 'debated' mounting holes >

this keeps things simple.

For people considering bracing the exciters body, I suggest something less rigid than timber >

something slightly flexible - like garden hose could be the way to go.

Good luck all 🙂

this keeps things simple.

For people considering bracing the exciters body, I suggest something less rigid than timber >

something slightly flexible - like garden hose could be the way to go.

Good luck all 🙂

Eric

I don't have time to search through this forum, so I'm just uploading the video.

The two exciters are inphase but the panel positions are not !

Having them close together is not a guarantee of mutual coupling unless in push pull mode.

So careful consideration should be made as to where each exciter is placed ,when using multiple exciters

but even if you do find positions where the exciters are not fighting each other in the low frequencies, you will still have the problems of the exciters fighting with themselves at other higher frequencies all over the panel.

this is without the extra problems of comb filtering on the panel itself, making even more of a mess of the sound.

Steve.

I don't have time to search through this forum, so I'm just uploading the video.

The two exciters are inphase but the panel positions are not !

Having them close together is not a guarantee of mutual coupling unless in push pull mode.

So careful consideration should be made as to where each exciter is placed ,when using multiple exciters

but even if you do find positions where the exciters are not fighting each other in the low frequencies, you will still have the problems of the exciters fighting with themselves at other higher frequencies all over the panel.

this is without the extra problems of comb filtering on the panel itself, making even more of a mess of the sound.

Steve.

Attachments

Eric.I do think it's really odd that Dayton Audio is not at all clear about how you are supposed to use the holes on some of their exciters. Many have the threaded hole on the back in the center, and/or the four unthreaded holes around the perimeter. They do describe the four holes on the 30HESF-4 as "screw down mounting tabs" which does sound self explanatory, but I don't recall ever seeing anyone use them like that.

Eric

View attachment 1247183

I have always presumed that the four holes are to mount the exciters in a similar way as the podiums .

You drill a hole in the back brace the size of the magnet and use the four mounting holes to screw down the exciter in place.

Other than that ,they seem pretty useless.

I prefer to use some sort of silicone packing, it can be hard or soft as long as it prevents exciter out of balance wobble.

Steve.

Steve,I have always presumed that the four holes are to mount the exciters in a similar way as the podiums .

You drill a hole in the back brace the size of the magnet and use the four mounting holes to screw down the exciter in place.

Other than that ,they seem pretty useless.

That does seem like the most sensible way they could be used. Funny they don't explain or show that in any literature, as far as I have seen.

Eric

Well, the 32EP actually does have the "debated" threaded center hole, but indeed not the debated perimeter hold-down holes. That said, I have a couple of them myself and it does seem like the steel spider is stiff enough that no support brace is needed, although I have never used them for anything more than a few tests.I am glad that the exciters to be used in my project don't have any of the 'debated' mounting holes >

this keeps things simple.

From my experience, there is no harm and possibly some benefit to a somewhat compliant support brace for the exciters. I'm not exactly sure how you meant to use the garden hose, but anything that might resonate itself would not be ideal.For people considering bracing the exciters body, I suggest something less rigid than timber >

something slightly flexible - like garden hose could be the way to go.

Eric

HelloThere's a paper by the German guy (name escapes me ATM) detailing the need for reinforcement of the coil former

The paper I remember is from Benjamin Zencker but not about the mechanical resistance of the voice coil (it is at least what I kept in mind) to transmit the force to the membrane but because of the elasticity of the voice coil former which according to him a HF limiter.

Steve,Eric

I don't have time to search through this forum, so I'm just uploading the video.

The two exciters are inphase but the panel positions are not !

Having them close together is not a guarantee of mutual coupling unless in push pull mode.

So careful consideration should be made as to where each exciter is placed ,when using multiple exciters

but even if you do find positions where the exciters are not fighting each other in the low frequencies, you will still have the problems of the exciters fighting with themselves at other higher frequencies all over the panel.

this is without the extra problems of comb filtering on the panel itself, making even more of a mess of the sound.

Steve.

That is an interesting video, thanks, I remember it now.

But are you saying that what we are seeing in the video explains why one of four of Loeb's exciters has a problem?

Also, can you clarify some things about the video? What is the extra green wire going to each exciter? And what is the black thing mounted to the back of the one exciter? Is it on both exciters and are both exciters also nominally identical?

I do agree that careful consideration should be made as to location when using multiple exciters. But if done carefully, as shown in my recent post, using multiple exciters provides a lot of opportunity for controlling which modes are excited and which are not. So if done right, such control could potentially be used to benefit, rather than detract from, the sound.

Eric

Yes, but under regular heavy loading from a PA system, it's surely possible/probable that any weakness in the coil former will lead ultimately to failure or at least distortionHello

The paper I remember is from Benjamin Zencker but not about the mechanical resistance of the voice coil (it is at least what I kept in mind) to transmit the force to the membrane but because of the elasticity of the voice coil former which according to him a HF limiter.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker