After building a proven design I want to make the deep plunge. And big plunge it is.

Having several bookshelf 2-way speakers I would like to go 3-way for this one.

I think it would not be easy to bring it to a success myself, but if some with enough experience would like to guide and help me out that will be much appreciated.

Troels PMS http://www.troelsgravesen.dk/PMS.htm is very appealing to me and would like to use is as inspiration for my design. It has many challenges.

Before spending heaps of money on it, I would like to make some proper simulation to see where we can land.

BOX design :

What I like about the PMS design is the limited depth of the speaker making it look like a panelspeaker.

For my design I will not go as wide but limit it to 400mm/ 16".

Hight will be 1050mm / 41.5" and depth around 130mm/5.2"

This would give an estimated volume of 26L for the woofer and 6L for the mid's.

DRIVERS :

Troels used ScanSpeak discovery drivers for his design. Good drivers but I have the impression that SBacoustic has the best price/quality ratio for this segment of drivers at the moment.

They are actually also a cheaper so that helps as well.

My drivers choice:

Tweeter : SB26ADC

Mid : SB15MFC30-8

Woofer : SB23NBAC45-8 in a 25L closed box -> -3db =50Hz

Design goals :

Closed box design, sloped baffle

85-87db sensitivity. cabinet will be placed close to the back wall.

Crossover point : Target 300Hz - 3kHZ

Low order crossover if possible.

Impedance : minimum 5ohm

Using VituixCAD

Before starting buying drivers I would like to start with manufacturer traced curves to see where we land. This way I can order drivers and crossover parts for startpoint at the same time to lower costs. During listening and real measurements tests I can order the necessary components locally. But those will be more expensive then.

What I figured out so far :

baffle slope of 8degrees will make a difference of 150mm/5.9" in dept between top and bottom

Driver layout : From TOP FROM tweeter Y Z T

Tweeter : -125 925 0 0 8

MID : -259 -134 -133 -19 8

Woofer : - 564 -439 -435 -62 8

For driver acoustic center I had to make some assumptions : not sure if I come close enough.

Tweeter : 0

MID 5" : 80us / 28mm

Woofer 8" : 110us /38mm

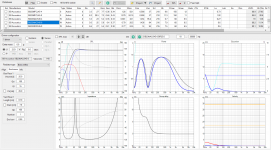

I traced the drivers from the manufacturer website. Traces are attached below.

Those IEC baffle traces I used in the diffraction tool from VituixCAD to generate full space traces.

Each driver was placed in it exact location on the baffle with the mic in the centre. axis distance = 300mm.

Below the different traces. For the woofer a merged was made as well.

ZMA files were created based on the manufacturer traces. For mid and woofer adapted to the different volume in the enclosure module from VituixCAD.

Thats what I have so far.

I dont know if this is sufficient to start thinking about crossover design or some other things need to be tackled first.

Having several bookshelf 2-way speakers I would like to go 3-way for this one.

I think it would not be easy to bring it to a success myself, but if some with enough experience would like to guide and help me out that will be much appreciated.

Troels PMS http://www.troelsgravesen.dk/PMS.htm is very appealing to me and would like to use is as inspiration for my design. It has many challenges.

Before spending heaps of money on it, I would like to make some proper simulation to see where we can land.

BOX design :

What I like about the PMS design is the limited depth of the speaker making it look like a panelspeaker.

For my design I will not go as wide but limit it to 400mm/ 16".

Hight will be 1050mm / 41.5" and depth around 130mm/5.2"

This would give an estimated volume of 26L for the woofer and 6L for the mid's.

DRIVERS :

Troels used ScanSpeak discovery drivers for his design. Good drivers but I have the impression that SBacoustic has the best price/quality ratio for this segment of drivers at the moment.

They are actually also a cheaper so that helps as well.

My drivers choice:

Tweeter : SB26ADC

Mid : SB15MFC30-8

Woofer : SB23NBAC45-8 in a 25L closed box -> -3db =50Hz

Design goals :

Closed box design, sloped baffle

85-87db sensitivity. cabinet will be placed close to the back wall.

Crossover point : Target 300Hz - 3kHZ

Low order crossover if possible.

Impedance : minimum 5ohm

Using VituixCAD

Before starting buying drivers I would like to start with manufacturer traced curves to see where we land. This way I can order drivers and crossover parts for startpoint at the same time to lower costs. During listening and real measurements tests I can order the necessary components locally. But those will be more expensive then.

What I figured out so far :

baffle slope of 8degrees will make a difference of 150mm/5.9" in dept between top and bottom

Driver layout : From TOP FROM tweeter Y Z T

Tweeter : -125 925 0 0 8

MID : -259 -134 -133 -19 8

Woofer : - 564 -439 -435 -62 8

For driver acoustic center I had to make some assumptions : not sure if I come close enough.

Tweeter : 0

MID 5" : 80us / 28mm

Woofer 8" : 110us /38mm

I traced the drivers from the manufacturer website. Traces are attached below.

Those IEC baffle traces I used in the diffraction tool from VituixCAD to generate full space traces.

Each driver was placed in it exact location on the baffle with the mic in the centre. axis distance = 300mm.

Below the different traces. For the woofer a merged was made as well.

ZMA files were created based on the manufacturer traces. For mid and woofer adapted to the different volume in the enclosure module from VituixCAD.

Thats what I have so far.

I dont know if this is sufficient to start thinking about crossover design or some other things need to be tackled first.

Attachments

-

PMS SBacoustics TRACED.rar37.1 KB · Views: 134

-

SB15MFC30-8=30cm axis distance.rar250.3 KB · Views: 114

-

SB26ADC=30cm axis distance.rar243.5 KB · Views: 115

-

ZMA cabinet volume.rar17.9 KB · Views: 110

-

SB23NBAC45-8=30cm axis distance.rar513.5 KB · Views: 117

-

SB Acoustics SB15MFC30-8.pdf477.4 KB · Views: 106

Last edited:

Initial Thoughts: Why closed box? Vented will give much better low end

An Alu cone driver will make the crossover more complex, I'd be inclined to go for paper or poly for less complexity

25 Litres is too small for most 8" drivers, they generally require 35-40 L minimum

An Alu cone driver will make the crossover more complex, I'd be inclined to go for paper or poly for less complexity

25 Litres is too small for most 8" drivers, they generally require 35-40 L minimum

Not sure if you're aware, but Troels' design is based on this: https://www.stereophile.com/floorloudspeakers/105sonus/index.html

Someone who used the poly version mentioned it wasn't so good. The aluminium was a better choise. I dont know if the aluminium is more complex to be integreted when I want to use it to around 300Hz.Initial Thoughts: Why closed box? Vented will give much better low end

An Alu cone driver will make the crossover more complex, I'd be inclined to go for paper or poly for less complexity

25 Litres is too small for most 8" drivers, they generally require 35-40 L minimum

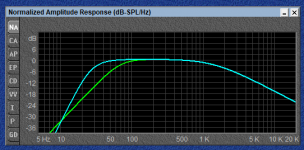

I made some sims in WINISD between closed and vented trying to make the box as small as possible.

smallest BR I could make was 32L. In that case there was a slight bass bump from 50-120Hz. I gain 2-2,5db.

I do have a room null around 40Hz though. (just tested by ear using tone sounds and walking around in the room to notice the difference. Best I could do with measuring tools. )

Green is BR in 32L box

Yellow is passive radiator in 25L box

Red is closed in 25L box.

Group delay is lowest with closed

So considering those I thought closed is good.

I really like to keep the design with shallow dept, not wider then 40cm. So I is difficult to squeeze in a high volume.

I could make it taller, but increasing the hight with 10cm will make the distance from side and top to center tweeter almost the same.

I was thinking to make the cabinet straight in the back and not slanted.

From lets say halve hight to the bottom over a width of around 20cm.

This also could be used to make the cabinet more stable.

But it will not do any justice to the aesthetic of this design. But it is the back though...... Can also make it triangle shape.

But all this makes the complex woodwork even more complex.

Thinking Thinking.

Still early days.

This is why I brought my project so I can get some considerations from others. Thanks for thinking with me.

Last edited:

Yes Im curious about this kind of design. I never heard one...Don't see them in commercial designs but from what I've read the sound characteristics they have intrigues me.A wide baffle is worthwhile.

Thanks I didnt read that one.Not sure if you're aware, but Troels' design is based on this: https://www.stereophile.com/floorloudspeakers/105sonus/index.html

They use a waveguide in their design? Would it be an option? I think there is a 3D-printed version waveguide for this SB26ADC tweeter.

It would add a lot of complexity for me I guess. 😕

My version will a baby version of this one 😎

They also use an aluminium woofer with poly mids.

I noticed that my driver layout input was corrupted So I try to put it in a table.

Is the estimation for the accoustic center of the driver any good?

I looked at the manufactured construction and came up with these values now. 🤔

Tweeter : 0

MID 5" :80us / 28mm => 66us/23mm

Woofer 8" :110us /38mm => 90us/31mm

| Driver | Distance from TOP | Distance from Tweeter | Y for driver VituixCAD | Z for driver VituixCAD | T for driver VituixCad |

| Tweeter | -125 | 0 | 0 | 0 | 8 |

| Mid | -259 | -134 | -133 | -19 | 8 |

| Woofer | -564 | -439 | -435 | -62 | 8 |

Is the estimation for the accoustic center of the driver any good?

I looked at the manufactured construction and came up with these values now. 🤔

Tweeter : 0

MID 5" :

Woofer 8" :

I built my own version too, basically same dimensions as Troels. If you go wide baffle, I think you should go all the way, not only 40cm. With a narrover baffle you probably need to raise the XO frequency between W & M to incorporate the baffle step compensation at the XO frequency.

Make sure you brace and damp it well, big panels are important to keep from vibrating. I would also recommend some kind of asymmetric shaped box for the mid, and move the box it away from the woofer to give the woofer some space to 'breathe', space is pretty tight in the shallow box.

Looking forward to follow your build!

Make sure you brace and damp it well, big panels are important to keep from vibrating. I would also recommend some kind of asymmetric shaped box for the mid, and move the box it away from the woofer to give the woofer some space to 'breathe', space is pretty tight in the shallow box.

Looking forward to follow your build!

I would have expected the BR to drop faster in output than CB? (24db/oct vs 12db/oct)Someone who used the poly version mentioned it wasn't so good. The aluminium was a better choise. I dont know if the aluminium is more complex to be integreted when I want to use it to around 300Hz.

I made some sims in WINISD between closed and vented trying to make the box as small as possible.

smallest BR I could make was 32L. In that case there was a slight bass bump from 50-120Hz. I gain 2-2,5db.

I do have a room null around 40Hz though. (just tested by ear using tone sounds and walking around in the room to notice the difference. Best I could do with measuring tools. )

Green is BR in 32L box

Yellow is passive radiator in 25L box

Red is closed in 25L box.

View attachment 1010354

Group delay is lowest with closed

View attachment 1010355

So considering those I thought closed is good.

I really like to keep the design with shallow dept, not wider then 40cm. So I is difficult to squeeze in a high volume.

I could make it taller, but increasing the hight with 10cm will make the distance from side and top to center tweeter almost the same.

I was thinking to make the cabinet straight in the back and not slanted.

From lets say halve hight to the bottom over a width of around 20cm.

This also could be used to make the cabinet more stable.

But it will not do any justice to the aesthetic of this design. But it is the back though...... Can also make it triangle shape.

But all this makes the complex woodwork even more complex.

Thinking Thinking.

Still early days.

This is why I brought my project so I can get some considerations from others. Thanks for thinking with me.

Thanks, yours look great. I planned something simular. Dark in the middle and light on the sides, makes them look slimmer.I built my own version too, basically same dimensions as Troels. If you go wide baffle, I think you should go all the way, not only 40cm. With a narrover baffle you probably need to raise the XO frequency between W & M to incorporate the baffle step compensation at the XO frequency.

Make sure you brace and damp it well, big panels are important to keep from vibrating. I would also recommend some kind of asymmetric shaped box for the mid, and move the box it away from the woofer to give the woofer some space to 'breathe', space is pretty tight in the shallow box.

Looking forward to follow your build!

View attachment 1010363

I had to make some compromises on the width. 40cm is the max for me.

11600/40 = 290. So baffle step start around 300Hz hence my idea to cross there.

How did you brace yours? Im thinking to use metal if possible. Dont know if it is a good idea.

Just for not losing to much volume, as Im short of it already.

Tweeter level or just below.What listening distance and height are you aiming for?

With base under the speaker, will be raised a little. From floor I aim for 950-975mm

Listening distance around 2,7m

I checked it again. The graphs are correct in WinISD. At least I dont see any mistake in them.I would have expected the BR to drop faster in output than CB? (24db/oct vs 12db/oct)

The tuning frequency of the BR is low though....25Hz. Maybe that is the reason?

Don't do this. The traced data contains too many variables to do anything but get an idea of the type of crossover that might work and if the design is feasible. Buy the drivers if the simulation works out OK, then build a prototype or the actual box, then measure, design and buy crossover parts.Before starting buying drivers I would like to start with manufacturer traced curves to see where we land. This way I can order drivers and crossover parts for startpoint at the same time to lower costs.

An attempt to have BR in 25L box tuned to 30Hz. Gives a wide Db bump of 2db around 70Hz.

I did some re-calculation of the bruto volume.

I will land somewhere around 32-35L BRUTO for this box. I assume I loose 6-7l for the mid compartment. Then still need to add brasing and woofer. 🤔

cone excursion is better

group delay is a bit higher. Dont know what is the audible consequence of it.

I did some re-calculation of the bruto volume.

I will land somewhere around 32-35L BRUTO for this box. I assume I loose 6-7l for the mid compartment. Then still need to add brasing and woofer. 🤔

cone excursion is better

group delay is a bit higher. Dont know what is the audible consequence of it.

Last edited:

Thanks for the tip.Don't do this. The traced data contains too many variables to do anything but get an idea of the type of crossover that might work and if the design is feasible. Buy the drivers if the simulation works out OK, then build a prototype or the actual box, then measure, design and buy crossover parts.

If i can order all the parts in 1 time it is still acceptable. It weighing parts and shipping cost vs part cost locally.

After building prototype, how many additional parts you need? Can you limit it to only some resistors?

Or based on the prototype simulation add some coils and capacitors 1 value up or down?

It would be nice if there are many same value parts in the crossover. 🙂 A new design goal 😛

Only when you have the measurements in the cabinet can you design a proper crossover. The parts you actually order may have nothing in common with the simulated values.Thanks for the tip.

If i can order all the parts in 1 time it is still acceptable. It weighing parts and shipping cost vs part cost locally.

After building prototype, how many additional parts you need? Can you limit it to only some resistors?

Or based on the prototype simulation add some coils and capacitors 1 value up or down?

It would be nice if there are many same value parts in the crossover. 🙂 A new design goal 😛

There is something odd with those WinISD sims, a bass reflex eventually has to rolloff at 24dB/oct even if the initial slope is different.

A 25 litre box tuned to 25Hz with a similar SB driver needs a port 67cm long 😱

A vented box for max flat tuning is around 67 litres.

Bassbox and Vituix simulations of similar SB drivers attached

Attachments

Panel width 40 vs 60cm doesn't make a big difference. I suggest making the backside angled so that the box is like a triangle. It helps to tame internal reflections and suppress resonances. Many ways to install internal braces. I support closed box, room response will be better than most people can imagine, and minimal EGD give super bass quality! Consider SB29 too!

http://www.loudspeakerdatabase.com/SB/SB29NRX75-6

http://www.loudspeakerdatabase.com/SB/SB29NRX75-6

There isnt so much difference between VituixCAD and WinISD.Only when you have the measurements in the cabinet can you design a proper crossover. The parts you actually order may have nothing in common with the simulated values.

There is something odd with those WinISD sims, a bass reflex eventually has to rolloff at 24dB/oct even if the initial slope is different.

A 25 litre box tuned to 25Hz with a similar SB driver needs a port 67cm long 😱

A vented box for max flat tuning is around 67 litres.

Bassbox and Vituix simulations of similar SB drivers attached

Box 25L and tuned to 25Hz also gives a port of 67cm when diameter is 68mm.

With 47mm it will be 30cm. Air velocity is still controlled.

f3 goes from 49Hz closed to 43Hz BR. Is it worth it?

- Home

- Loudspeakers

- Multi-Way

- First project : Troels PMS with SBacoustic drivers ; advice and help most welcome