Hi again, i get this amp, i want to repair for personal use,( i have repaired like a dozen of other smaller amps, some of them are class d,) this is the biggest i Will try to repair.

I've been doing some tests.

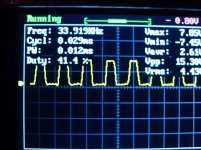

The ps irfp064n are blown and some driver transistors too, i replaced bad driver Ps transistors and i got nice 32 khz square signal, i have in hand irf3205 so for testing purposes i instaled 1 irf3205 per bank(4 in total), the ps worked good with rails of 84 and -84 volts in rectifiers pins, with no output transistors.

In the audio section i found 6 of the eigth fqa38n30 fets damaged, i have in hand stw45nm60 i think this could work, but i have not installed them because i have not worked in the amp this days, there are not another signs of damage ( caps looks good, resistors looks good the driver audio card has no overheating signs)

I have some questions, i hope some one can help me

1.- looking at the data sheet i found irfp064n and irf 3205 almost identical, some diference of course is the encapsulation size. Do you think i can use irf3205 instead of irfp064n with no other problem than the legs and clamp adapting work?

2.- in the audio section, similar question can i replace original with stw45nm60?, in current is 7 amp higher in voltage 300volts higher the rds and capacitances are similar

Some.other tips of this amp.in particular Will be apreciated

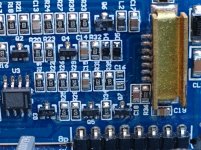

The board imaga is for another hifonics 2500 watts but is identical

Thank you!

I've been doing some tests.

The ps irfp064n are blown and some driver transistors too, i replaced bad driver Ps transistors and i got nice 32 khz square signal, i have in hand irf3205 so for testing purposes i instaled 1 irf3205 per bank(4 in total), the ps worked good with rails of 84 and -84 volts in rectifiers pins, with no output transistors.

In the audio section i found 6 of the eigth fqa38n30 fets damaged, i have in hand stw45nm60 i think this could work, but i have not installed them because i have not worked in the amp this days, there are not another signs of damage ( caps looks good, resistors looks good the driver audio card has no overheating signs)

I have some questions, i hope some one can help me

1.- looking at the data sheet i found irfp064n and irf 3205 almost identical, some diference of course is the encapsulation size. Do you think i can use irf3205 instead of irfp064n with no other problem than the legs and clamp adapting work?

2.- in the audio section, similar question can i replace original with stw45nm60?, in current is 7 amp higher in voltage 300volts higher the rds and capacitances are similar

Some.other tips of this amp.in particular Will be apreciated

The board imaga is for another hifonics 2500 watts but is identical

Thank you!

Attachments

If it's your personal amp and you don't intend to sell it, feel free to do whatever you wish. The 3205s with their smaller package will not transfer heat as well as the originals. It may be good enough for your needs.

The outputs can be difficult to sub. Sometimes FETs with almost identical specs won't work and FETs with significantly different specs will be fine. You may find something that's useful to others if you find a good sub.

Do you have enough of the original outputs to install 1 per bank to make sure that the output drivers survived?

The outputs can be difficult to sub. Sometimes FETs with almost identical specs won't work and FETs with significantly different specs will be fine. You may find something that's useful to others if you find a good sub.

Do you have enough of the original outputs to install 1 per bank to make sure that the output drivers survived?

Only two survived, i think the amp has Only two Banks, i could try to check if the output driver are ok, and only then tryng installing the subs, so if the amp do not work with this subs, i could be almost 100% that the problem is in the not original replaced transistors.

Thank you!! I Will coment if the amp worked, hoping more People find useful this thread.

Thank you!! I Will coment if the amp worked, hoping more People find useful this thread.

Thank you Perry for that info, i did not know, this driver card has no driver transistor, i Will have to check driver I.C.

Ic checked, results damaged 0 omhs between legs 3 and 5 i Will order chip, and wait it to arrive to continúe

Just an FYI. Order several of those ICs. They are very fragile and easily damaged by heat from the soldering iron.

They appear to be the most fragile. You have to prep everything to make the soldering process a momentary touch to each terminal. As soon as you touch the terminal, the solder should readily flow and then you immediately remove the heat.

Thank yo Perry and barber, if this reading of 0 omhs between 3 and 5 is ok, may be the chip is ok, because the next lowest values are 10 kohms between 3 and 4 and 10k betwwen 4 and 5 the other readings are higher.

Something suspicios is that a cap in the driver board is missing but apparently from factory, could some one confirm C16, if was missing Oem?., other thing i detected is a bad zener e250A shorted i tested with one leg out of the board. I Will post some pics

Something suspicios is that a cap in the driver board is missing but apparently from factory, could some one confirm C16, if was missing Oem?., other thing i detected is a bad zener e250A shorted i tested with one leg out of the board. I Will post some pics

Attachments

R64_2 is ok,

I changed The e250a and w ith The two fets installed The amp keeps protecting, With no uotput fets stays in green for various minutes.

The audio driver Ic gets Hot after about 3 or 4 minutes, after this The rail voltage drops and stays low after i power on and off The amp, is this normal?

I changed The e250a and w ith The two fets installed The amp keeps protecting, With no uotput fets stays in green for various minutes.

The audio driver Ic gets Hot after about 3 or 4 minutes, after this The rail voltage drops and stays low after i power on and off The amp, is this normal?

Also i checked the +15 and -15 regulators.

Even if there is no output fets the

,Ic gets hot i Wonder if this is normal?

Even if there is no output fets the

,Ic gets hot i Wonder if this is normal?

No. The test I posted isn't absolutely definitive but it's good for most failures.

It's possible that the IC failed internally and not from shorted outputs.

Is this the original or did you replace it?

It's possible that the IC failed internally and not from shorted outputs.

Is this the original or did you replace it?

Perry, quick question what temp do you set the iron to when soldering the 21844s?

On a side note i just had the same model with CL1 out of tolerance measuring 1 uF. I went through several 21844s before i decided to pull CL1 and check it. Replaced it with 8.2uF and amp worked fine.

C16 is not populated on the board I have. I still have the amp and may be able to reference something for you if needed.

On a side note i just had the same model with CL1 out of tolerance measuring 1 uF. I went through several 21844s before i decided to pull CL1 and check it. Replaced it with 8.2uF and amp worked fine.

C16 is not populated on the board I have. I still have the amp and may be able to reference something for you if needed.

Last edited:

You could likely use any temperature that makes the connection quickly. What's important is that the connection is made almost instantaneously. If you can do that at 650F, that's better than using 800F.

To ensure that the connection is made quickly, I scuff the bottoms and the tips of the the terminals with 400 grit sandpaper. A little flux on the paper ensure that it's worked into the legs.

Make sure that the solder pads have a thin, uniform layer of solder (preferably coated with flux).

Place the IC and tack diagonal legs, preferably on pads with heavy copper. Check alignment and if OK, solder the rest. You should be able to just touch the tips of the legs and the solder will flow essentially instantaneously. You don't need a lot of solder.

Every few connections, clean the tip and add a bit more solder.

For me, the best cleaner for the tip is dry denim. I use my jeans but whatever gets the tip perfectly clean is OK.

To ensure that the connection is made quickly, I scuff the bottoms and the tips of the the terminals with 400 grit sandpaper. A little flux on the paper ensure that it's worked into the legs.

Make sure that the solder pads have a thin, uniform layer of solder (preferably coated with flux).

Place the IC and tack diagonal legs, preferably on pads with heavy copper. Check alignment and if OK, solder the rest. You should be able to just touch the tips of the legs and the solder will flow essentially instantaneously. You don't need a lot of solder.

Every few connections, clean the tip and add a bit more solder.

For me, the best cleaner for the tip is dry denim. I use my jeans but whatever gets the tip perfectly clean is OK.

- Home

- General Interest

- Car Audio

- Hifonics BRX 3016.1 D Brutus