Drazen, I used to make stuff like that with RCA. Then I got XLR equipment and slowly extended the setup to XLR stuff. I wanted to have a source selector/volume control but now with XLR inputs. Just when I thought that I knew what I wanted to build I found out accidentally I can do all that in the digital domain with my current audio player and only have 2 XLR cables going to my amplifier. Sounds stupid and maybe it is but it had totally not occurred to me that I could do it like that.

That's odd. My stepped bit will countersink between steps and I have used it that way numerous times. In my case a small countersink allows for a small shoulder on the RCA connector.Jean-Paul. Not exactly. That was the first attempt (I had another panel) and I first did several successful tests.

I purposely countersunk the hole, the step bit has nothing to do with it.

The step bit, as the name suggests, is stepped, but you may want an intermediate diameter and therefore you have to use a bit of inventiveness.

After mounting the connectors, any possible smudge is obviously completely invisible.

Yes Jan Paul, that works fine in my opinion if you only listen to digital stereo source. Quite few pro engineers said get rid of all that mess and install optical cables, so more elegant and no issues. It also allows for DSP speakers XO which is great.Just when I thought that I knew what I wanted to build I found out accidentally I can do all that in the digital domain with my current audio player and only have 2 XLR cables going to my amplifie

However I listen to stereo almost only from TT, sometimes FM radio live shows (3rd program, you are in germany, you have ARTE). Casually Spotify from phone into hifi, just to listen to new music. Only digital I do listen seriously is by watching movies. Copyright doesn't allow DIY decoders for movie multichannel music, you cant get multichannel digital signal out.... So I'm stick with analog dealing with signal. Unfortunately purely digital signal management eliminates turntables, FM and movies (for DIY))

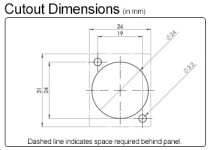

There are many XLR connectors that are only slightly different, depending on for instance the type of lock.23.6 mm to be (too) exact.

They did that to frustrate us.

Jan

Attachments

Oh I only use plastic Neutrik with silver plated contacts like NC3FPP and NC3MPP. Never occurred to me that different diameters exist. When I started with XLR the vast amount of different versions surprised me indeed. Just thought "WHY?".

Make that "fortunately" 🙂Unfortunately purely digital signal management eliminates turntables, FM and movies (for DIY))

Last edited:

Neutrik is relatively consistent in mounting hole sizing, when one learns how to make them holes easy as this thread asks. Also RCA, USB, LAN, multipin XLR like 4 pin for balanced headset, powercon, Speakon (in multipin variations to handle active speaker with remote amps))....... all can be fitted in almost 🤣 🤣 🤣 🤣 same opening covering all that little audio student needs. So it is not that bad.

For back mounting, 24mm hole should fit all I think. For front mounting, bit messy, as Jan posted.

For back mounting, 24mm hole should fit all I think. For front mounting, bit messy, as Jan posted.

Not necessarily, it depends on your relationship with digital audio. I'm using my old Technics SL-120 equipped with a high-output MC cartridge & black widow tonearm + a DIY preamp + a Presonus Studio 24C + camilladsp running on an Rpi5. The 24C's analog outputs connect to an SAE MKIII-CM I bought in the 80's. The main reason is to solve some FR issues with my DML panels and listening room. Those outweighed any personal concerns regarding the possible impacts of using a ADC/DSP/DAC approach.Unfortunately purely digital signal management eliminates turntables, FM and movies (for DIY))

I'll grant that any analog source doesn't fall into the "purely digital signal management" realm but it's not too difficult to DIY a hybrid system that sounds pretty good. But YMMV, my 73YO ears aren't going to hear stuff they did when I was 26.....

I believe it could depend on both the material you are drilling and the bit itself. If you use a bit for metal with wood maybe that's what happens, frankly I've never done it.That's odd.

However, it could also depend on whether you use a full or empty base under the sheet metal and whether you use a drill press, since AFAIK perpendicularity also matters.

Just as an example, in this video it seems that no countersink occurs.

I thought that Mini XLR connector is a thing. Wanted to use them one day...

https://www.switchcraft.com/mini-xlr-connectors/

https://www.ebay.de/itm/134127053792

Regarding stepped drill, always lower rpm with every step as the cutting speed increases rapidly. When working with material that's thicker than the step, finish from the other side. For accuracy, start with 2.5 - 3mm cobalt drill instead the stepped drill directly.

https://www.switchcraft.com/mini-xlr-connectors/

https://www.ebay.de/itm/134127053792

Regarding stepped drill, always lower rpm with every step as the cutting speed increases rapidly. When working with material that's thicker than the step, finish from the other side. For accuracy, start with 2.5 - 3mm cobalt drill instead the stepped drill directly.

Last edited:

Slots ? as in for the raised portion of the fitting ?

#1 For other work I have done (as jeweller) method is to layout then drill the appropriate size hole/s where each slot terminates.

#2 Then drill out the main hole for the body of the fitting.

#3 Finally, use a carbide burr (of the same size as in #1) in a 'Dremel' to create the slot by cutting back to the main hole of #2.

#1 For other work I have done (as jeweller) method is to layout then drill the appropriate size hole/s where each slot terminates.

#2 Then drill out the main hole for the body of the fitting.

#3 Finally, use a carbide burr (of the same size as in #1) in a 'Dremel' to create the slot by cutting back to the main hole of #2.

Uhhh, very difficult and very different subject, even XLR and rest of Neutrik is completely fine for digital audio, so that fits to subject of the thread.Not necessarily, it depends on your relationship with digital audio. I'm using my old Technics SL-120 equipped with a high-output MC cartridge & black widow tonearm + a DIY preamp + a Presonus Studio 24C + camilladsp running on an Rpi5. The 24C's analog outputs connect to an SAE MKIII-CM I bought in the 80's. The main reason is to solve some FR issues with my DML panels and listening room. Those outweighed any personal concerns regarding the possible impacts of using a ADC/DSP/DAC approach.

I'll grant that any analog source doesn't fall into the "purely digital signal management" realm but it's not too difficult to DIY a hybrid system that sounds pretty good.

New LP's are rarely marked AAA or DAA or DDA as they were at beginning of digital era. Now days I don't know if my new LP is from digital master or analog, frankly cant hear it neither except with clear vocals.

If I start to believe in inserting ADC-DSP-DAC in system, I would probably digitalize all records before 1980 and use only digital setup. However I don't believe it, Blind test between different modern DAC-s shows nothing, they are all "good" . When good TT set up is inserted in same blind test, magic of musician presence in the room appears ... don't know how but it was repeated several times with same album on CD and LP and different people, result is the same, vinyl is almost real thing IMHO, digital is reproduction.

Same magic appears when one listens live talk show over FM radio, normally our 3rd program in Europe that cares of sound and subjects are only art, music and literature, no adverts, news nor politics... Talking heads just appear as being talking 3D persons in your room. For whatever reason, I did not hear it from digital source yet....

Hi, If I got it right what you said, that's about same job as using sharp file of correct shape to make slots in aluminum, or??Slots ? as in for the raised portion of the fitting ?

#1 For other work I have done (as jeweller) method is to layout then drill the appropriate size hole/s where each slot terminates.

#2 Then drill out the main hole for the body of the fitting.

#3 Finally, use a carbide burr (of the same size as in #1) in a 'Dremel' to create the slot by cutting back to the main hole of #2.

When I am using my drill press for this purpose, I like to use shorter bits to start the pilot hole. Problem is that my floor standing Jet drill press has bad run out from the beginning, and the longer the bit the more it is evident. That also means that if it is an important drilling then I will clamp it to the drill press table. Lastly, again with the runout problem, you still have a hole that wanders. Yes, yes, time for a new drill press or possibly at least a better chuck. Sheesh.

I forgot to mention that I always used stepped drill with hand drill, preferably acu. Since you're making a big hole into the sheet metal, something can go wrong and personally I prefer to have the grip on what's going on. Therefore I mentioned decreasing the rpm EVERY step, but that apply mainly when you go over some 12mm and is not practical for drill presses without electronic regulation. Another reason to grab an acu.

What is wrong with 6,3mm TRS for balanced signal connections? You drill one hole…

Yup, drilling can get you hurt, no matter the choice of machine. We used to have to drill 4" holes in pipe with a large 'hand held' (more like it needed a tripod or something!) drill. Not safe, not recommended.

At least with the flat surface of a rear panel, your accuracy and safety go up. I sometimes use a center punch these XLR holes before drilling, but that also depends on the cutting angle of the bit. And with the XLR, filing extra notches just makes it tougher, especially in a file clogging metal like aluminum.

At least with the flat surface of a rear panel, your accuracy and safety go up. I sometimes use a center punch these XLR holes before drilling, but that also depends on the cutting angle of the bit. And with the XLR, filing extra notches just makes it tougher, especially in a file clogging metal like aluminum.

The even shittier connector.What is wrong with 6,3mm TRS for balanced signal connections? You drill one hole…

Please elaborate. It did and does it’s duties from telephone switch boards with bazillion times connecting and deconnecting to esoteric headphone cables and connections. Plus it’s found on every professional piece of recording gear and not to forget our beloved musical instruments. And in our hobby: how often is one going to switch cables? I like the XLR too, but mainly for microphone cables, because of the lock. It saves a microphone from falling at the end of the day. Not because of some difference in perceived quality.The even shittier connector

- Home

- Design & Build

- Construction Tips

- Making panel holes for XLR