Hi,

Whomever read any of my threads can see I'm not fan of RCA connectors, for proper audio transfer one needs 3 pins. DIN and many other connectors can solve this, however XLR is standard, way overkill for line signals (in the past it was used also for speakers connections), but that is how it is.

XLR can be mounted in 2 ways:

1. from back of the panel: only round hole is needed for male, and one needs to open slot to fit release lever for female connector. But than thick panel cant be used.

2. from front of the panel; then they need round hole plus 4 precise slots around that hole.

I drill large holes and than use small file to make all needed slots. This is way too much time consuming to the extend I don't start project just because of that... If want to make preamp with 4 inputs and active 3 way XO inside + 2 line outputs, that's 16 XLR holes, several full working days just for back panel

Question is : how do you DIY holes for it? Anyone has faster and easier solution to just "print" XLR holes ? Same applies for power sockets.

Thanks and cheers,

Drazen

Whomever read any of my threads can see I'm not fan of RCA connectors, for proper audio transfer one needs 3 pins. DIN and many other connectors can solve this, however XLR is standard, way overkill for line signals (in the past it was used also for speakers connections), but that is how it is.

XLR can be mounted in 2 ways:

1. from back of the panel: only round hole is needed for male, and one needs to open slot to fit release lever for female connector. But than thick panel cant be used.

2. from front of the panel; then they need round hole plus 4 precise slots around that hole.

I drill large holes and than use small file to make all needed slots. This is way too much time consuming to the extend I don't start project just because of that... If want to make preamp with 4 inputs and active 3 way XO inside + 2 line outputs, that's 16 XLR holes, several full working days just for back panel

Question is : how do you DIY holes for it? Anyone has faster and easier solution to just "print" XLR holes ? Same applies for power sockets.

Thanks and cheers,

Drazen

Long ago we had a tool similar to this one.

https://www.hbm-machines.com/be-nl/...7434_&gad_source=1&gad_campaignid=18719825231

https://www.hbm-machines.com/be-nl/...7434_&gad_source=1&gad_campaignid=18719825231

Hi dear Netlist.

I used hydraulic punchers like this, don't have one do but I could DIY it with car lifting jack.

Problem as so far is that this tool will need 2 very hard dies to punch XLR , many holes in lets say 6mm alu plate. Puncher is 145€, tools probably another 300 . , wild guess as I couldn't find anything in google under "punching tool for XLR". Set up for punching 50 and more holes will probably be over 500€ . This is far too much for hobby, for most of folks....

I used hydraulic punchers like this, don't have one do but I could DIY it with car lifting jack.

Problem as so far is that this tool will need 2 very hard dies to punch XLR , many holes in lets say 6mm alu plate. Puncher is 145€, tools probably another 300 . , wild guess as I couldn't find anything in google under "punching tool for XLR". Set up for punching 50 and more holes will probably be over 500€ . This is far too much for hobby, for most of folks....

Yes, 6mm is thick. We used it for patch panel steel plates +/- 1mm thick.

Wishing you good luck. 🙂

Wishing you good luck. 🙂

Mostly, I use similar to these.

Middle one in the piccture all the way through.

When thick plates and a hole from somewhere in the middle step drill, I do it ½ from both sides.

Takes a while, but gets the job done.

https://www.autodoc.dk/amio/2237969...aPrUUdG4LMMe381qi_n9G3G7GS91r9VBoC2XIQAvD_BwE

Middle one in the piccture all the way through.

When thick plates and a hole from somewhere in the middle step drill, I do it ½ from both sides.

Takes a while, but gets the job done.

https://www.autodoc.dk/amio/2237969...aPrUUdG4LMMe381qi_n9G3G7GS91r9VBoC2XIQAvD_BwE

Most time i am using The Greenlee tools, but i think 6mm Alu is too much for them

And expensive...The Greenlee tools

Unless your profession will be hole-puncher. 😎

+1Mostly, I use similar to these.

In my experience, first drill a hole of the appropriate diameter (5-7 mm as in the example) with a regular drill bit and then use the step drill bit to enlarge the hole to the desired diameter.

As it is 6 mm thick aluminium, it is essential to use a drill with adjustable speed starting (and maintaining) a low speed and adding cutting oil.

Have a nice day with your job!

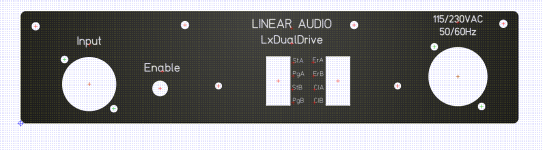

If you want to spend some money you can order a complete drilled and milled panel at schaefer.de (front panel express). Expect to spend about 50 euri.

They have a free simple program to draw the panel and things like XLR holes are in the library.

Jan

They have a free simple program to draw the panel and things like XLR holes are in the library.

Jan

Attachments

Depends on the XLR jack you use.

Should be 2 small holes and one oversize hole.

I don't use jacks that need a filed slot.

I use a step bit to drill large holes, small holes just center punch so the starting point is accurately centered.

Agree home audio line level, is overkill, no need for XLR

Balanced is for very long cable runs.

If done right they work, half the time doing live audio the ground gets lifted, ironically they tend to be more noisy.

With very long cable snakes from stage to board, they were helpful.

Half the time with line level rack effects or DI sends, useless more noisy

Should be 2 small holes and one oversize hole.

I don't use jacks that need a filed slot.

I use a step bit to drill large holes, small holes just center punch so the starting point is accurately centered.

Agree home audio line level, is overkill, no need for XLR

Balanced is for very long cable runs.

If done right they work, half the time doing live audio the ground gets lifted, ironically they tend to be more noisy.

With very long cable snakes from stage to board, they were helpful.

Half the time with line level rack effects or DI sends, useless more noisy

Hi Netlist,We used it for patch panel steel plates +/- 1mm thick.

I also have small pile of XLR patch bays, 1.5 mm thick with paint, and of course already drilled. Combining pieces of them does the job, but not so nicely . Besides not everyone has proaudio XLR patchbay's in garage laying around..... I believe many DIYers loose so much time doing this, and eventually they avoid superb XLR-s

Dear Dieter and Boydik,

you showed how to make round holes, that's fine but doesn't finish the job. My question and problem is how to easily make precise slots around those round holes to fit XLR nicely, without spending days with hand file?

Dear Jan, sure it's option to order ready panel at machinist with CNC mill, but that is for final designs that goes in some sort of quantity production.. Im asking to help myself and any diyer making home brew one off designs...

In any case mounting from back side limits panel thickness to some 2.5 mm and slot still needs to be filed for female connector release lever.

Hi WhiteD; just cheaper plastic Neutrik's are exclusively for mounting from backside (I don't say they are bad at all, actually recommended IMO) . More expensive cast metal housing Neutrik's can be mounted both ways.Depends on the XLR jack you use.

Should be 2 small holes and one oversize hole.

I don't use jacks that need a filed slot.

I use a step bit to drill large holes, small holes just center punch so the starting point is accurately centere

In any case mounting from back side limits panel thickness to some 2.5 mm and slot still needs to be filed for female connector release lever.

Agree it is overkill, but not for 3pin connection, but because it is huge and capable of 11A... But there is no other standard for 3 pins, DIN is obsolete unfortunately...Agree home audio line level, is overkill, no need for XLR

Sorry, I disagree with this. More noisy than what? From all my 40 years experience: differential, better balanced, coupling makes great deal in CMR . And common mode external noises are everywhere, including HIFI dedicated listening rooms, better to get rid of it, and 2 pin RCA simply cant do that..Balanced is for very long cable runs.

If done right they work, half the time doing live audio the ground gets lifted, ironically they tend to be more noisy.

With very long cable snakes from stage to board, they were helpful.

Half the time with line level rack effects or DI sends, useless more noisy

Agree of course within reason and done right.

Back in windows 98 days we still had to deal with CRT monitor noise.

So all the soundcards were for sure XLR.

Not to bad 24 bit 32 float 196 kHz

XLR obviously the analog in/out

Anyways step bit, center punch.

For diy be interesting to know if there is a custom punch for XLR

Being any panel manufacturer would punch for production. That would be punch machine.

Wonder if full on die available for screw/bolt type punches, that would save a lot of time

Cant tell if the punch die in #6 is just a circle. But something like that with the needed slot shape.

Back in windows 98 days we still had to deal with CRT monitor noise.

So all the soundcards were for sure XLR.

Not to bad 24 bit 32 float 196 kHz

XLR obviously the analog in/out

Anyways step bit, center punch.

For diy be interesting to know if there is a custom punch for XLR

Being any panel manufacturer would punch for production. That would be punch machine.

Wonder if full on die available for screw/bolt type punches, that would save a lot of time

Cant tell if the punch die in #6 is just a circle. But something like that with the needed slot shape.

Last edited:

This is for one-off. I always order one-off, sometimes 2 (stereo!).Dear Jan, sure it's option to order ready panel at machinist with CNC mill, but that is for final designs that goes in some sort of quantity production.. Im asking to help myself and any diyer making home brew one off designs...

Specifically for diy/home brew.

Jan

Hi, for 4 to 6 mm aluminium I use a drill press and then a mill plus cutting oil. Finally a file is used. It is time consuming but true Zen. It is a valuable part of the hobby to master metal work IMHO.

I have used Dremel tool with bits for aluminium + the Dremel 565 accessory. You still need to file a bit in the end, to get the hole fully square.

Dear people,

Seems as so far nobody has solution how to effectively and cheap punch XLR hole together with 4 slots needed.

I like Jean Paul's ZEN statement about small file, that's what I do now too, but sometimes 16 holes are too much Zen for me, my wife and son think the same 🤣 . What to hell is dad doing, meditating with piece of metal 🤣🤣

As so far Hugo has solution same as I do: pre-drilled patchbays, not for everyone as they are not exactly found on street every day, or easily adoptable to back panel.

Lets see if someone else comes with ingenious solution for this design from Liechtenstein that apparently rules audio universe. Guess if all Liechtensteiners are put together to manually file slots for Neutrik holes, it would not be enough manpower to satisfy world demand 😎

Cheers,

Drazen

Seems as so far nobody has solution how to effectively and cheap punch XLR hole together with 4 slots needed.

I like Jean Paul's ZEN statement about small file, that's what I do now too, but sometimes 16 holes are too much Zen for me, my wife and son think the same 🤣 . What to hell is dad doing, meditating with piece of metal 🤣🤣

As so far Hugo has solution same as I do: pre-drilled patchbays, not for everyone as they are not exactly found on street every day, or easily adoptable to back panel.

Lets see if someone else comes with ingenious solution for this design from Liechtenstein that apparently rules audio universe. Guess if all Liechtensteiners are put together to manually file slots for Neutrik holes, it would not be enough manpower to satisfy world demand 😎

Cheers,

Drazen

Well if several days of filing is cheaper than 50 euro, by all means, have a go at it! 😎

Jan

Jan

- Home

- Design & Build

- Construction Tips

- Making panel holes for XLR