Tests have shown that solid rubber is not very usefull in sandwich panels. What we need is a viscous material, because this turns mechanical work into heat, what we want. Rubber is very good in conserving mechanical energy. Compare it to punching into a bread dough and then into a rubber ball. The dough will absorb the punch, the ball will fly away.

There are quite some types of technical glue that work very well if applied to give a 1-2mm fill between two materials. As far as I remember, 3/4"or 19mm wood panel, 2mm glue and 2mm aluminum gave very good results while keeping weight acceptable. Tiles instead of aluminum work well, too, but make even medium sized boxes very heavy. These sandwich panels are used in ship building, where noise transmission is always a problem and weight matters, too. As far as I know, the well known Sikaflex glues are well suited for diys sandwiches, comb spatulas are fine for getting an even coating. A 4x4mm spatula will give something like a 2mm viscous layer for example.

If you want to know if the glue material is suited, form a ball, let dry and throw it on a hard floor. Compare it bouncing back to a solid rubberball. Most of you will know the result of solid rubber.

In this thread resonances inside volumes sometimes are mixed up with panel resonances, we have to keep that separate. I'm writing about panel resonances and the panels ability to transfer sound/ noise to the outside of the cabinet.

There are quite some types of technical glue that work very well if applied to give a 1-2mm fill between two materials. As far as I remember, 3/4"or 19mm wood panel, 2mm glue and 2mm aluminum gave very good results while keeping weight acceptable. Tiles instead of aluminum work well, too, but make even medium sized boxes very heavy. These sandwich panels are used in ship building, where noise transmission is always a problem and weight matters, too. As far as I know, the well known Sikaflex glues are well suited for diys sandwiches, comb spatulas are fine for getting an even coating. A 4x4mm spatula will give something like a 2mm viscous layer for example.

If you want to know if the glue material is suited, form a ball, let dry and throw it on a hard floor. Compare it bouncing back to a solid rubberball. Most of you will know the result of solid rubber.

In this thread resonances inside volumes sometimes are mixed up with panel resonances, we have to keep that separate. I'm writing about panel resonances and the panels ability to transfer sound/ noise to the outside of the cabinet.

But we don't, don't we.

The most thorough accelerometer measurements of loudspeakers I've seen have been a dozen or so points distributed somewhat evenly over a side panel. Often, it's just a few, or even just 1 point. And even with many points, we usually get no information about phase, only velocity.

Acoustical differences between structures in the far field, corresponding to a typical listening position, is the relevant information. If it isn't provided voluntarly, it's very likely because it cannot be provided, because the differences become negligible in the far field.

Whatever, for those with an interest this is how the unwanted sound from speaker cabinets is typically measured by speaker companies like KEF and B&W in the presence of the much louder sound from the drivers. There are several similar publications around if one googles. In practise it is rarely done because simulations are quicker and more useful due to providing the shapes of the problematic modes. The shapes show where best to place damping to effectively reduce the amplitude of the resonance or where to place stiffness to change the shapes into more amenable ones. Since the simulations provide pressure and velocity everywhere it is common to take one or two measurements with a vibrometer to check things are as expected.

For strictly panel vibration if you want to have zero vibration there is no other way than stiffness (hard bracing)In this thread resonances inside volumes sometimes are mixed up with panel resonances, we have to keep that separate. I'm writing about panel resonances and the panels ability to transfer sound/ noise to the outside of the cabinet.

Damping only work with excitation and it is because the panel vibrate that the energy is converted in heat.

(but it might be easier/chipper to reach an acceptable level of damping rather than going stiff)

You can eliminate outside vibration using a "box in a box" but the interior will vibrate. That what "sandwich" panels do but with a viscous material instead of air.

I don't think it is good to separate inside resonance and panel vibration.

Inside cabinet resonance can be decrease with for example felt pad.

It means that the material absorb the wave and the panel is less excited.

If the material is amazingly good no vibration will occur on the panel and you have solved your panel vibration issue ...

By the way, stiffening panels means that the wave will bounce on the panel.

Leading to more internal resonance and you only have replace your issue by an other one.

Here we have the crux of cabinet design - different frequencies require strategies to combat resonances. To expect a single driver to cover 50-3kHz for example requires too many driver and enclosure compromises.And on the larger boxes i find those resonaces colour the bass, and “bloat” it out.

dave

Stiffness for LF; damping for MF is my motto!

Whatever, for those with an interest this is how the unwanted sound from speaker cabinets is typically measured by speaker companies like KEF and B&W in the presence of the much louder sound from the drivers.

As I said, acoustic impact in the far field, in the presence of the much louder sound from the drivers, has to be demonstrated. If the differences in movement of the structure measured by accelerometers cannot be detected in a meaningful way acoustically at the listening position, they are meaningless. And such evidence has never been presented.

Here's an article by Visaton showing perfect acoustic behavior of the enclosure (smooth frequency response, clean decay chart) in the far field with 5€ of damping wool -> https://www.visaton.de/de/service/technische-grundlagen/bedaempfung-von-gehaeusen . You may of course continue to waste considerable effort and cost for nothing by designing the most convoluted structures for your speakers for no measureable benefit beyond that, or letting yourself get scammed into buying similar ready-made designs via pseudoscience marketing from commercial manufacturers. Your time, your money - not mine.

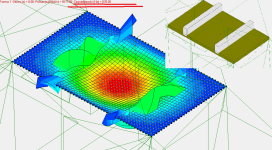

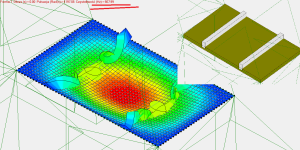

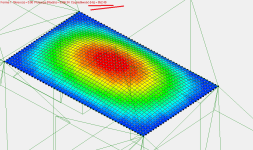

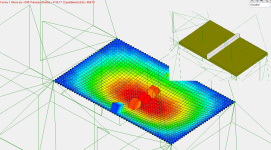

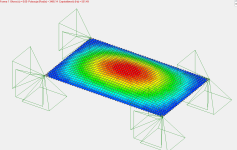

hi, i'm not sure if this will help with further discussion, but attached are simple simulation for 30x50cm wood panel.

simulation shows first resonant frequency (depends on geometric characteristic of panel). panel and braces are made bor wood (resonant freq. will look different for PLY or MDF). also it doesnt take boundary condditions into calculation (but what i did should be ok. for simple enclosure)

for 18mm wood -> 1st resonant freq. is ~550Hz

for 18mm wood with 1brace (20x30mm) > ~660Hz

for 18mm wood with 2braces (20x30mm) > ~680Hz (probably braces are too weak to stiffen panel or too far from the middle)

for 18mm wood with 2braces (30x50mm) -> 880Hz

for 30mm wood -> 850Hz

so bracing helps a lot. but it have to be done properly. Also it's very important if braces are made from one piece to stiffen all the perpendicular panels or from single element for each panel (worse).

simulation shows first resonant frequency (depends on geometric characteristic of panel). panel and braces are made bor wood (resonant freq. will look different for PLY or MDF). also it doesnt take boundary condditions into calculation (but what i did should be ok. for simple enclosure)

for 18mm wood -> 1st resonant freq. is ~550Hz

for 18mm wood with 1brace (20x30mm) > ~660Hz

for 18mm wood with 2braces (20x30mm) > ~680Hz (probably braces are too weak to stiffen panel or too far from the middle)

for 18mm wood with 2braces (30x50mm) -> 880Hz

for 30mm wood -> 850Hz

so bracing helps a lot. but it have to be done properly. Also it's very important if braces are made from one piece to stiffen all the perpendicular panels or from single element for each panel (worse).

Attachments

The cabinet resonance can be generated by the pressure waves inside of the cabinet, and mechanically generated by the swinging mass of the driver.

If the resonance mechanically generated then this resonance needs to be reduced as much as possible near to the generator. Baffle needs to be decoupled from the rest of the cabinet.

The pressure waves generated panel vibration is a different story.

If the resonance mechanically generated then this resonance needs to be reduced as much as possible near to the generator. Baffle needs to be decoupled from the rest of the cabinet.

The pressure waves generated panel vibration is a different story.

Exactly, because the extra mass of the brace can make it worse.so bracing helps a lot. but it have to be done properly

Worst case the brace start to swing, and works as a new resonance generator. I saw it several times when I was did my speaker cabinet FEA simulation

... and the port, including resonances.acoustic impact in the far field, in the presence of the much louder sound from the drivers,

Hi, How to do that? Can you point to an existing build, to get an understanding.Baffle needs to be decoupled from the rest of the cabinet.

Sandwich baffle. MDF+Neoprene+PlywoodHi, How to do that? Can you point to an existing build, to get an understanding.

MDF front baffle

Sandwich baffle

I’ve attached a short video when I did my speaker cabinet. I fixed the accelerometer onto the sidewall of the cabinet. You can see on the graph, how the amplitude was reduced by the sandwich construction.

... and the port, including resonances.

Correct - everything that would be considered direct radiating surface.

Port resonances are very visible in a free field far field measurement btw. - so, a good example within this discussion for what counts (can actually be measured in the far field = can be heard at the listening position) vs. what doesn't (can't be measured in the far field = can't be heard at the listening position).

How did you mount it with the neoprene rubber? Did you just glue it with silicone? Just shot Brad nails through it into the MDF? Bolts?I used the multi material approach as well. In my case the baffle was made with 22mmMDF, 3mm neoprene rubber, and 18mm plywood. MDF and plywood have different structural strength, it means deforming in different way. The neoprene rubber internal friction eating up the deformation difference, and damping the swing.

I'm finding with the rubber layer that now I don't have the traditional wood glue to create strength under tension. Only compression strength is left

It's important to brace the cabinet within reason and to provide the bass driver with damping rubber

ring to reduce driver frame movements being transmitted to panel structures. Dynaudio did that job

well with 24W75.

Further improvement is constrained layer damping cross brace.

https://www.diyaudio.com/community/...ing-to-absorb-bass-geddes.351376/post-7981499

ring to reduce driver frame movements being transmitted to panel structures. Dynaudio did that job

well with 24W75.

Further improvement is constrained layer damping cross brace.

https://www.diyaudio.com/community/...ing-to-absorb-bass-geddes.351376/post-7981499

I used contact glue.How did you mount it with the neoprene rubber?

The driver was bolted only to the outside MDF layer, and only the inside Plywood layer touched the rest of the cabinet. Baffle was also fixed by bolts, but the bolts was isolated from the MDF via bushings.

Gaslo mentions he used bushings in the post above. I have used bolts with rubber washers. The trick is that the bolts or brad nails can't be allowed to couple the two layers or all the vibration will just transfer through the connectors.How did you mount it with the neoprene rubber? Did you just glue it with silicone? Just shot Brad nails through it into the MDF? Bolts?...

Also, Turbowatch2 makes the correct claim that any sandwich material needs to be viscous. Sorbothane is an obvious material but quite expensive. But finding information on the viscoelastic measures for neoprene, butyl rubber, etc, is difficult. I thought I had found at one time that neoprene was not viscous and butyl was, but I have not been able to confirm that.

Neoprene is viscoelastic, so it has elastic and viscous properties as well.

Study of neoprene viscoelastic behavior

Maybe not the best material for this usage, but it is used as a vibration damping material in industry.

Study of neoprene viscoelastic behavior

Maybe not the best material for this usage, but it is used as a vibration damping material in industry.

hi, i'm not sure if this will help with further discussion, but attached are simple simulation for 30x50cm wood panel.

simulation shows first resonant frequency (depends on geometric characteristic of panel). panel and braces are made bor wood (resonant freq. will look different for PLY or MDF). also it doesnt take boundary condditions into calculation (but what i did should be ok. for simple enclosure)

for 18mm wood -> 1st resonant freq. is ~550Hz

for 18mm wood with 1brace (20x30mm) > ~660Hz

for 18mm wood with 2braces (20x30mm) > ~680Hz (probably braces are too weak to stiffen panel or too far from the middle)

for 18mm wood with 2braces (30x50mm) -> 880Hz

for 30mm wood -> 850Hz

so bracing helps a lot. but it have to be done properly. Also it's very important if braces are made from one piece to stiffen all the perpendicular panels or from single element for each panel (worse).

Bracing isolated panels can be rather misleading not only because the boundary conditions used are not represenative of panels in speaker cabinets but also because when you glue up 6 panels to make a cabinet, cut holes in the baffle, bolt heavy drivers around those holes the problematic resonances (i.e. the ones radiating loudly at the listening position) tend to involve the drivers bouncing about on the baffle. There are resonances where the motion consists largely of panels moving but they tend to be higher in frequency, lower amplitude and not radiating directly at the listening position. After the one or two problematic modes have been addressed to reduce their magnitude, change their shape, shift their frequency,... what remains should be inaudible in use if the load carrying structure has reasonable damping, the baffle is of reasonable stiffness and nothing unreasonable is done to provoke cabinet motion. Different speaker configurations (e.g. small bookshelves, large monkey coffins,...) tend to require different degrees of effort to push the cabinet resonances down to inaudible levels.

Bracing isolated panels can be rather misleading not only because the boundary conditions used are not represenative of panels in speaker cabinets but also because when you glue up 6 panels to make a cabinet, cut holes in the baffle, bolt heavy drivers around those holes the problematic resonances (i.e. the ones radiating loudly at the listening position) tend to involve the drivers bouncing about on the baffle.

Yes. It is a hard problem to analyze / simulate correctly. Not impossible, but hard. Someone who knows what they are doing with FEA needs to spend some time on a given design in order to arrive at a valid analysis.

A few years ago, there was a similar discussion. @ViniWerkel posted an interesting analysis that included the boundary effects. One of the conclusions is that once boundary effects are modelled, the strategy of increasing wall thickness becomes a very effective way to increase stiffness.

I see that my conclusion from my last post was probably calculated with a modle wich was too simple, i just did the quick maths for a simple one and two span beam. So today i used a program for very simple 2D stress resultants calculations. A 3D calculation would of course be more accurate but i'd assume we would get similar results). I modeled a 500 x 500 mm wooden square ( about 19.5") of 18mm (~3/4") and 36 mm thickness. The Square has perfectly stiff edges, which actualy makes a big difference in deflection. I also ran the Program with pivoting joints and derived at similar numbers as...

If the resonance mechanically generated then this resonance needs to be reduced as much as possible near to the generator. Baffle needs to be decoupled from the rest of the cabinet.

Decoupling the baffle with drivers bolted to it will turn it into a sounding board which is unlikely to be wise. A better idea might be to decouple the drivers from the baffle but this reduces the mass the moving cones react against which tends to be fine for tweeters, debatable for mids and a problem for woofers.

- Home

- Loudspeakers

- Multi-Way

- Bracing VS Damping