Why do you want wider dispersion (fair question).

The thing is that a good waveguide doesn't have a sound of it's own, so it isn't a goal unto itself. It comes down to such things as dispersion. Narrow dispersion when done well tends to clean things up due to reduced reflections.

The thing is that a good waveguide doesn't have a sound of it's own, so it isn't a goal unto itself. It comes down to such things as dispersion. Narrow dispersion when done well tends to clean things up due to reduced reflections.

Member

Joined 2009

Paid Member

I am building a single mono speaker, and have found wide dispersion works well for that. Rather than see the room as the enemy, I embrace it.

Bigun, you were talking about 'loading' the bigger cone. Which is what a horn might do. But IMO you don't need (or necessarily want) significant loading. A shorter waveguide that simply guides or contains the big cone's radiation into a smaller angle will, as a result, concentrate that radiation - i.e. giving a higher SPL.

Provided the waveguide's angle is wider than the wizzer cone's beaming, the latter shouldn't be massively affected. Though wizzer cones tend to be a compromise, with significant diffraction, and so their unwanted diffraction will likely be affected by the waveguide. Potentially for the worse if directed forward or causing HOMs.

Provided the waveguide's angle is wider than the wizzer cone's beaming, the latter shouldn't be massively affected. Though wizzer cones tend to be a compromise, with significant diffraction, and so their unwanted diffraction will likely be affected by the waveguide. Potentially for the worse if directed forward or causing HOMs.

Last edited by a moderator:

Just adding another subjective comment, but related to the topic. It is regarding Troy Crowe’s horn no. 1548. In his YouTube clip of the horn paired with the AER BD3 driver that has a whizzer cone, he mentions “it projected quite a wide coverage and wasn’t beamy at all..”

Link to YouTube below. Scroll to 2:48.

Link to YouTube below. Scroll to 2:48.

Member

Joined 2009

Paid Member

Member

Joined 2009

Paid Member

So, returning to this design I am mostly settled on the idea of an OS Waveguide for the A55 driver and nominally with a 45 degree cone angle (to the extent that it's reasonable to describe an OS as a cone of course). My assumption, based on inputs above, is that I need not worry too much about this driver having a whizzer when it comes to using it like this (there being other issues with whizzers is not the subject). There are the usual questions about how I might construct it but I also seek the wisdom of others regarding a couple of questions that extend the scope of this thread:

a) is there value in a round-over of the Waveguide mouth ?

b) does an OS Waveguide benefit from a resonant & closed back-chamber, or is it sufficient to absorb the back-wave without specifically trying to load the back of the cone in any way ?

a) is there value in a round-over of the Waveguide mouth ?

b) does an OS Waveguide benefit from a resonant & closed back-chamber, or is it sufficient to absorb the back-wave without specifically trying to load the back of the cone in any way ?

Last edited:

OS is indicated to bring a plane wave (flat wavefront) out to spherical, which at 90 degrees is just about right for many applications. Being for all intents and purposes conical, there is a jump to full space. A roundover can be more a requirement here than with other horns with some dependence, for example, on how the size you build it supports the output at the mouth.

Any horn may see limitations where wavelengths get smaller than the throat and present an uncertain wavefront, as you can have with a fullrange driver used this way. This is not the typical application for OS but it should work well apart from this.

I wouldn't overdo the stuffing if possible, but you shouldn't ignore it since it won't be possible to make the chamber small enough to be non-modal in this case.

Any horn may see limitations where wavelengths get smaller than the throat and present an uncertain wavefront, as you can have with a fullrange driver used this way. This is not the typical application for OS but it should work well apart from this.

While all horns load to the surrounding air, this aspect is largely ignored when designing OS waveguides. I'd recommend using hornresp to assess the response you get from the rear chamber.does an OS Waveguide benefit from a resonant & closed back-chamber,

I wouldn't overdo the stuffing if possible, but you shouldn't ignore it since it won't be possible to make the chamber small enough to be non-modal in this case.

Member

Joined 2009

Paid Member

One option that I had in mind, if not seeking a resonant back chamber is something to absorb the back-

wave like the B&W guys developed

wave like the B&W guys developed

Loading type horns tend to lose some of their efficiency when you absorb the back wave. Fortunately, hornresp allows you to test absorption.

For my front waveguides for the Lowther DX65 drivers, I use loosely fitted insulation to absorb much of the backwave. I do so because of an article which found that lossy absorption of the backwave sounded best compared to a sealed enclosed backchamber and also compared to a complete open backwave.

Member

Joined 2009

Paid Member

Thanks folks, I'm just gonna make me a waveguide then, lossy backwave included. Need to figure out how to make it, but that's part of the fun.

That file does not seem to open....

Holm, Sverre; Reduction of distortion in conical horn loudspeakers at high levels; Convention Paper, Audio Engineering Society; May 7-10 2009 Munich Germany.

Holm, Sverre; Reduction of distortion in conical horn loudspeakers at high levels; Convention Paper, Audio Engineering Society; May 7-10 2009 Munich Germany.

“The leaky back was made from a semi-permeable material. The leaky rear chamber shall present to the element the same acoustic impedance as the horn in front of it, but with minimal radiation. The design goal may also be stated as an emulation of a speaker element with the same horn at the rear of the element as in the front. Since this is unrealistic due to the size, the goal is to present to the speaker element the same acoustic properties as if there were a second horn in the back. The back chamber resembles that of the variovent which is also a semi-permeable opening. It goes back to a patent from 1931 [9] which describes a damping element. The resemblance is in the material used for creating acoustic resistance and the controlled leakage that it produces. The difference is at least in two aspects: the relatively small size of the back chamber that the variovent occupies, and the purpose for using it.”

OK…but what do I use and how do I make one for my horns?

I’ve been playing with these wooden conical petal horns that have an “embellished” roll over at the mouth.

I’m using a Fostex 108ez because it’s what I had that fit the 3” throat (no adapters for CDs as of yet).

It was a “what if” exercise, so I didn’t bother with any back chamber (I had run Oris 200 horns with an unsealed back chamber lined with a 1/2” foam lining as well.)

I was surprised and pleased with how the horns “floated”sound into the space without the beaming that was driving me crazy while running 8” drivers in the Oris horns.

So now I’m kind if hung up on them and trying to pull the project together better.

I’ve got one more shot I’m hoping to take at getting the SLOB bass panels working better with what looks like a better choice of GRS 8” subwoofer driver I just picked up during Parts Express’ Memorial Day sale. I will probably revise the wings on the baffles as well and I’m considering driving them with my Hypex amps.

Having the low end of the horns playing cleaner is an attractive idea since they are crossing around 300Hz which I think is a stretch for the 108ez as they are running with no chamber.

I’ve got other issues with the top end to solve too as the Fostex T90A aren’t really performing how I’d like across a variety of material. I think a reflected/diffused or omni directional type of solution may work better.

I am also talking to Istvan at Sonido about the possibility of a custom driver for these horns.

It doesn’t look like a field coil would be possible without cutting the throat (which I don’t want to do) his smallest FC would be 175mm.

There is a 145mm alnico that I’ve asked about and he is supposed to be running some models with measurements and data I provided for the horns.

In the mean time I keep tinkering…any ideas on the “leaky” back chamber?

Maybe a disc shaped plate I can sandwich between the driver and horn with a piece of 6-8” PVC pipe attached with no back cover that would allow different amounts of 1/2” foam to be stacked behind the driver?

OK…but what do I use and how do I make one for my horns?

I’ve been playing with these wooden conical petal horns that have an “embellished” roll over at the mouth.

I’m using a Fostex 108ez because it’s what I had that fit the 3” throat (no adapters for CDs as of yet).

It was a “what if” exercise, so I didn’t bother with any back chamber (I had run Oris 200 horns with an unsealed back chamber lined with a 1/2” foam lining as well.)

I was surprised and pleased with how the horns “floated”sound into the space without the beaming that was driving me crazy while running 8” drivers in the Oris horns.

So now I’m kind if hung up on them and trying to pull the project together better.

I’ve got one more shot I’m hoping to take at getting the SLOB bass panels working better with what looks like a better choice of GRS 8” subwoofer driver I just picked up during Parts Express’ Memorial Day sale. I will probably revise the wings on the baffles as well and I’m considering driving them with my Hypex amps.

Having the low end of the horns playing cleaner is an attractive idea since they are crossing around 300Hz which I think is a stretch for the 108ez as they are running with no chamber.

I’ve got other issues with the top end to solve too as the Fostex T90A aren’t really performing how I’d like across a variety of material. I think a reflected/diffused or omni directional type of solution may work better.

I am also talking to Istvan at Sonido about the possibility of a custom driver for these horns.

It doesn’t look like a field coil would be possible without cutting the throat (which I don’t want to do) his smallest FC would be 175mm.

There is a 145mm alnico that I’ve asked about and he is supposed to be running some models with measurements and data I provided for the horns.

In the mean time I keep tinkering…any ideas on the “leaky” back chamber?

Maybe a disc shaped plate I can sandwich between the driver and horn with a piece of 6-8” PVC pipe attached with no back cover that would allow different amounts of 1/2” foam to be stacked behind the driver?

Last edited:

Member

Joined 2009

Paid Member

My plan (those are nice horns by the way!) is a stuffed transmission line for the back chamber. This is what I showed above, by B&W.

Chromenuts, something like a PVC tube could work well, but I would not use PVC as it is resonant. May be find an appropriate sized sonotube as the cardboard is low resonance. Then try filling it with different amounts of foam or insulation. I think that an important change in your case is to avoid the full midrange backwave bouncing off the back wall and mucking up the sound coming from the front of the horn.

I think that something that mimics a simple transmission line that would absorb much of the rear wave but not put too much backpressure on the back of the cone, would also work well.

I think that the sweet spot is adding resistance to the back of the cone that matches the resistance of the horn on the front of the driver - I think that the balanced resistance is how to lower distortion. If the backwave can be delayed enough it would then provide some ambiance to the speaker, much like a properly designed and damped room that delays the secondary reflections.

I think that Hornresponse allows you to model something like this.

I think that something that mimics a simple transmission line that would absorb much of the rear wave but not put too much backpressure on the back of the cone, would also work well.

I think that the sweet spot is adding resistance to the back of the cone that matches the resistance of the horn on the front of the driver - I think that the balanced resistance is how to lower distortion. If the backwave can be delayed enough it would then provide some ambiance to the speaker, much like a properly designed and damped room that delays the secondary reflections.

I think that Hornresponse allows you to model something like this.

Unfortunately, I’m barely able to use Hornresp…I managed a few half-baked models with various horns and drivers I have using the kick-start article. Even then, I found all the back chamber entries very confusing.

Hornresp has evolved so much since then and I haven’t used it regularly. I really don’t get along with computers very well and tend to walk away.

I did attempt a quick model of the conical horns by taking measurements of them but ignoring the rollover at the mouth.

I used the published parameters of the Fostex 108ez just to try and get an idea as to what to expect.

I think I just left the back chamber parameters empty since I didn’t intend to use one. I thought David McBean had advised this when I had previously asked about modeling my Oris horns similarly with an open back chamber.

Really, for any of this to be valid I should take measurements of my drivers with DATS and understand more what I am doing with the various back chamber parameters.

Hornresp has evolved so much since then and I haven’t used it regularly. I really don’t get along with computers very well and tend to walk away.

I did attempt a quick model of the conical horns by taking measurements of them but ignoring the rollover at the mouth.

I used the published parameters of the Fostex 108ez just to try and get an idea as to what to expect.

I think I just left the back chamber parameters empty since I didn’t intend to use one. I thought David McBean had advised this when I had previously asked about modeling my Oris horns similarly with an open back chamber.

Really, for any of this to be valid I should take measurements of my drivers with DATS and understand more what I am doing with the various back chamber parameters.

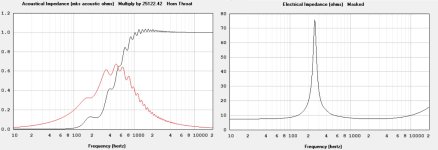

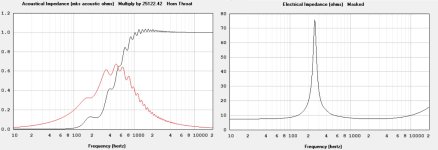

Reactance annulling isn't quite the same when you're doing it for a waveguide, and much of the acoustic loading region is within the fullrange driver's acoustically large region. The driver resonance is largely below the loading region and as can be seen, the waveguide doesn't add significantly large impedance peaks.. although it can create variations if you try different waveguide strategies.

- Home

- Loudspeakers

- Multi-Way

- Front loaded Horn - how does that work with whizzer cones?