I stand corrected.Not necessarily...

Which Thiele-Small parameters for the compression driver are necessary/enough to input?

Last edited:

@GMyour computer is not identifying the new downloaded files for some reason, and is resorting to opening the old ones instead.

Windows (sometimes) defines downloaded files as "not safe" and will not run exe-files.

By right-clicking the file and selecting "properties" there should be an "unblock" tick box at the bottom under "security" that allows execution of the file.

Yes, B&C ME10 horn is better than your existing horn.measurements of our horn and the ME10 off-axis in 10 degree increments

I suppose you need 90 degrees for good coverage, but if 60x60 degrees is good enough for your application, there are some very cheap plastic horns (smaller, too - 115x115 mm) here: https://www.masteraudionline.com/en/product/khd115/ (I didn't test them)

That is not so easy to get. We used to be able to design a horn purely on the input specifications without regard to the driver parameters. I tried quickly yesterday but I did not succeed. Over today I will read in the manual where this option has moved around to. If I find it I will post it here for kypti. As David posted and as I have also designed horns for high frequency it can be done. It has been a few years since I have designed a horn like this and David has changed the program quite a lot!I stand corrected.

Which Thiele-Small parameters for the compression driver are necessary/enough to input?

That is exactly why I asked that question.That is not so easy to get.

Be sure to try the Oblate Spheroid, Tractrix and Spherical horn types as these are generally better behaved.Thank you for your reply, but I've gone through several variants of existing horns for this driver (including this one) and I don't like them, either with the resulting frequency response or the uniformity of the decay, and really good solutions are large in size. I'm looking for a compromise between size and good frequency response, so I decided to design a horn that will satisfy my needs myself

So my question is, could "import room gain" be changed to something like "import general gain"

Answer: It's not going to happen 🙂.

We used to be able to design a horn purely on the input specifications without regard to the driver parameters.

Which Thiele-Small parameters for the compression driver are necessary/enough to input?

The same as for any other driver - Sd, Re, fs, Vas, Qes, Qms.

Normally the electro-mechanical equivalents would be used instead, but the manufacturer is unlikely to release that information.

Have you tried deleting the shortcut and creating a new one?

Perhaps first check the Properties of the old shortcut.

(I suspect that the new version of Hornresp.exe is not in the Target folder of the old shortcut).

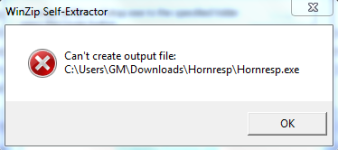

I did just now and got this error.....or do you mean create a new shortcut? If so I've forgotten how to if HR doesn't do it automatically.Have you tried deleting the shortcut and creating a new one?

Attachments

Last edited:

It's different from this, but appears to allow it.........@GM

Windows (sometimes) defines downloaded files as "not safe" and will not run exe-files.

By right-clicking the file and selecting "properties" there should be an "unblock" tick box at the bottom under "security" that allows execution of the file.

Attachments

That said, There is an 'unblock' in the 'General' tab, but checking it changed nothing with a new setup.exe download/install, so still only have the hornresp.exe 250210.......or was I supposed to delete it too? With these updates historically 'transparent', really clueless

Exactly that was my point - how can DIY enthusiast measure Vas of the compression driver?The same as for any other driver - Sd, Re, fs, Vas, Qes, Qms.

Normally the electro-mechanical equivalents would be used instead, but the manufacturer is unlikely to release that information.

I did just now and got this error

1. Right-click on your existing Hornresp shortcut and delete it.

2. Using Windows Explorer, create folder C:\Hornresp if you don't already have one.

3. Download Setup.exe, unzip it and save the four files to the C:\Hornresp folder.

4. Right-click on the Hornresp.exe filename in the C:\Hornresp folder and create a new shortcut.

5. Run Hornresp.

6. Close Hornresp.

7. Find your existing Hornresp.dat data file, wherever it is, and copy it into the C:\Hornresp\Data folder, overwriting the default one that Hornresp has just created.

how can DIY enthusiast measure Vas of the compression driver?

I have no idea - that's why Hornresp has a constant diaphragm velocity option.

For a compression driver it would also be better to use the electromechanical parameters used in Hornresp rather than TS-parameters. The electromechanical parameters relate directly to the physical parameters of the driver, like the physical mass of the diaphragm and stiffness of the suspension. TS-parameters are derived parameters based on a specific direct radiator model, and they include the air mass in the model, which is not correct when used in horn speaker. Hornresp takes this into account in the conversion, but that also means that measuring the TS-parameters of a compression driver as if it was a direct radiator, and then converting in Hornresp, is unlikely to give you the right results.

It is possible to measure the parameters of a compression driver, but it is much more involved than measuring the TS-parameters of a woofer. The most efficient is to use a vacuum chamber and a laser vibrometer, and fit the measurements to a model, but that is hardly DIY-friendly. Diaphragm+coil mass can be measured by cutting out the diaphragm and 1/3 of the surround from the diaphragm assembly, using accurate scales. BL can be calculated from wire length and gap flux (requires a flux meter). Some of the acoustic parameters, like compression ratio etc can be estimated from physical measurements. Suspension + rear cavity stiffness can be hard to find, and will probably require plane wave tube measurements.

It is possible to measure the parameters of a compression driver, but it is much more involved than measuring the TS-parameters of a woofer. The most efficient is to use a vacuum chamber and a laser vibrometer, and fit the measurements to a model, but that is hardly DIY-friendly. Diaphragm+coil mass can be measured by cutting out the diaphragm and 1/3 of the surround from the diaphragm assembly, using accurate scales. BL can be calculated from wire length and gap flux (requires a flux meter). Some of the acoustic parameters, like compression ratio etc can be estimated from physical measurements. Suspension + rear cavity stiffness can be hard to find, and will probably require plane wave tube measurements.

I work in a company where I am trained and share my experience (you can learn more by looking at my thread), and I am currently revising existing loudspeakers, and the speaker with this driver is loaded with its own milled MDF horn, and the measurements showed that it is not good enough. This is an installation loudspeaker that needs to be small in size. There is a commercial horn, the B&C ME10, which would be a good solution, but it is expensive for such a speaker system. I'll attach the measurements of our horn and the ME10 off-axis in 10 degree increments

The easiest option for the simulation is probably to use the constant diaphragm velocity option David mentioned. You can try to model the ME10 in Hornresp to get a feeling for how close to reality Hornresp can get for this kind of horn.

But if the ME10 works, and you need to design a horn yourself, why not use the geometry of the ME10 as a starting point?

seems there are some mixups on your PC, maybe multiple copies of hornresp.exe or shortcuts......That said, There is an 'unblock' in the 'General' tab, but checking it changed nothing with a new setup.exe download/install, so still only have the hornresp.exe 250210.......or was I supposed to delete it too? With these updates historically 'transparent', really clueless

make a backup of the folder you know is working with an old version to safe you designs. You could put all the contents in a ZIP file for example and store it somehwere safe.

download "search everyhting" tool. This scans ALL of your harddisk and is able to find ANY file within a fraction of a second, once it has scanned the drive initially.

with "evrything", search for "hornresp.exe"... This will show you EVERY Copy of hornresp - as well as shortcuts pointing to any of these files.

If you have your backup safe (see above), delete ALL copies of honresp, folders, shortcuts...

Now go to the security center in windows and check, if there are leftover warnings which might have falsly appointed a security risk to any hornresp.exe files. If there are some left, windows might have put a copy of horensp.exe in the quarantine... Make sure there is no infinished business left in the security section.

now download a fresh setup.exe and install a new version of hornresp to the folder of your choice. Pay attention to any popups from windows. Windows might think hornresp is not safe to download or install. If any popoups show up - tell windows, its all good and safe and that you really want to download, keep the file and install it (according choices are presented to you in the dialogs from windows).

now you should be ok - recheck with everything if you really have only ONE copy of hornresp. If you have started hornresp prio to checking with everything, you might also encounter another file looking similar - this could be a new shortcut, a "recent opened files" shortcut or maybe a prefetch version (.pf ending)... This should not be harmfull and be ok...

now start hornresp.exe and ccheck if it runs and is the most recent version...

if so, close hornresp again - go over to your backup and restore your old folder with your projects into the new hornresp folder...

Should be finde now 🙂

Hope that helps, looking forward to your response.

Either I found a bug, or Mark doesn't know how this part of Hornresp works.

In 25 years of using this program this is only the second time that I modeled a passive radiator.

Input screen. Custom Driver and Custom P.R.

Setting up for max SPL and checking the P.R. excursion.

We get this. Now this is limited to 17mm X-max. The surface area is about 1/3 smaller than the P.R. so the P.R. should be about a 1/3 less.

How?

If I do a proper 250 watt input from the input screen I get a realistic result:

This is what should be the result.

In 25 years of using this program this is only the second time that I modeled a passive radiator.

Input screen. Custom Driver and Custom P.R.

Setting up for max SPL and checking the P.R. excursion.

We get this. Now this is limited to 17mm X-max. The surface area is about 1/3 smaller than the P.R. so the P.R. should be about a 1/3 less.

How?

If I do a proper 250 watt input from the input screen I get a realistic result:

This is what should be the result.

- Home

- Loudspeakers

- Subwoofers

- Hornresp