http://dayton%20audio%20https//www.daytonaudio.com%20%E2%80%BA%20p...%20PHT1-6%20Planar%20Horn%20Tweeter%206%20Ohm

Dayton Audio PHT1-6

Dayton Audio PHT1-6

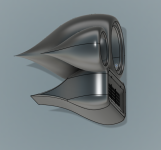

Please expand. Have you measured these?You should check out the design of the Dayton Audio PHT1-6.

it uses a spilt throat to raise upper cutoff directivity. These sound very good for a horn of this design. I've used it in monitor builds and light duty PA, but there's nothing really light duty about them.

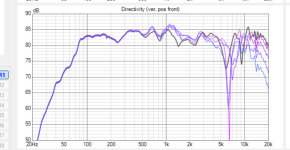

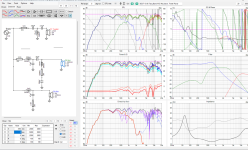

You say you've used them. Could you elaborate on just how & why you say they're heavy duty?@mikessi Yes, I've measured them. I'll post before the weekend when I'm back at my computer.

@mikessi I deem them to be a HD driver based on the extra cooling measures they implemented coupled with the high sensitivity. Any planar HF driver which measures above 100 dB/2.83V should be considered for professional use. I cross them 4k 2nd order or 3.5k 3rd order. The acoustic center of most mids lines up perfectly with this tweeter. It will easily hang with most linearized horn drivers and any cone mid. It sounds particularly good with the Audax PR170MO (BW3 3.5k HP) and the B&C 8PE21 (LR24 3k HP).

As a hifi driver, it does well compared to any larger HF dome and most AMTs as long as its crossed above 4k LR12. You have to consider the narrow vertical response, typical of any tall planar driver. Thats why a higher xover works well, as practically all cone mids will start to beam at those frequencies, matching the narrow vertical directivity.

As a hifi driver, it does well compared to any larger HF dome and most AMTs as long as its crossed above 4k LR12. You have to consider the narrow vertical response, typical of any tall planar driver. Thats why a higher xover works well, as practically all cone mids will start to beam at those frequencies, matching the narrow vertical directivity.

Last edited:

One thing to observe with the PHT1-6 is the screen it comes with protecting the diaphragm. I've found it hurts HF performance above 10k coupled with the horn. Removing it cleans up the very top end, but its not so evident looking at the measured FR, especially not with a bunch of smoothing applied to the graph. I observe this with some comp drivers as well. Perhaps its some type of reflection in the horn mouth. Either way, its sometimes beneficial to try when noticing something weird in the very top end with select horn and driver combos.

Indeed, I've removed the screens of virtually all horn CDs meant for only HIFI/HT apps and while most of them made little/no difference to me, many guys, but the women sure could tell, which often led me and others to tweak/fine tune the horns enough that even us guys could hear (sometimes a major) difference.

And what do you think (or recall) the dispersion to be? vertical & horizontal.

TBH, I'm surprised you cross it so high. Spec sheet says 2.5~18kHz & low end droop doesn't start till 2.7 kHz. Maybe because you're using it for PA & want the insurance from overload?

TBH, I'm surprised you cross it so high. Spec sheet says 2.5~18kHz & low end droop doesn't start till 2.7 kHz. Maybe because you're using it for PA & want the insurance from overload?

I actually did run of these. It helps smooth out the upper range a bit. The range I won't be using it for. That center split acts acts a phase plug. I did one where I put phase plugs in-between every little square outlet. It has minimal effect but there was an effect.You should check out the design of the Dayton Audio PHT1-6.

it uses a spilt throat to raise upper cutoff directivity. These sound very good for a horn of this design. I've used it in monitor builds and light duty PA, but there's nothing really light duty about them.

3mm is my minimum thickness for anything. Definitely enough for this application.And is 3mm thick enough for reasonable rigidity?

I'd happily accept your STEP file offer. Or STL? Can't recall what my 3D print provider prefers.

Use PETG, not PLA. PLA is very stiff and it rings very badly.

Attachments

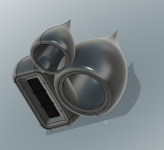

The main issue I ran into with the horn is that it forces the point source so far back that it has very negative effects on dispesion cancelation.

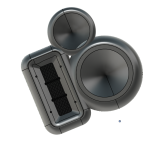

I'm actually just going to use a waveguide. This will be used as my nearfield in my office.

Planar mid

GRS ribbon tweeter

SB acoustics ceramic woofer.

Kind of all pretty exotic stuff but I have come to realize that you need all weird drivers if you want to use even one weird driver.

This will all be 3d printed in one piece, sanded, painted, and matte clear coat. I'll design a small stand for it. I imagine this will be a crazy detailed near field monitor.

I'm actually just going to use a waveguide. This will be used as my nearfield in my office.

Planar mid

GRS ribbon tweeter

SB acoustics ceramic woofer.

Kind of all pretty exotic stuff but I have come to realize that you need all weird drivers if you want to use even one weird driver.

This will all be 3d printed in one piece, sanded, painted, and matte clear coat. I'll design a small stand for it. I imagine this will be a crazy detailed near field monitor.

Attachments

Interesting. The GRS planar tweeter has some sort of very fine mesh screen over it. Its not the cheapest driver in the world so I'd be wary of cutting it out.One thing to observe with the PHT1-6 is the screen it comes with protecting the diaphragm. I've found it hurts HF performance above 10k coupled with the horn. Removing it cleans up the very top end, but its not so evident looking at the measured FR, especially not with a bunch of smoothing applied to the graph. I observe this with some comp drivers as well. Perhaps its some type of reflection in the horn mouth. Either way, its sometimes beneficial to try when noticing something weird in the very top end with select horn and driver combos.

Here's the tweeter I am going to use. You can see the sort of opaque coloration of said mesh that covers that metal grill. This thing does have a throat horn if you look at it very closely. So actually, it is a horn loaded ribbon tweeter.

https://www.parts-express.com/GRS-R...Ha6oXtmmaXAaNoRw2_jlaSwZoill9NHQK17Gzyf4UljFl

Last edited:

I'm not sure I understand what you're saying about dispersion cancellation.. is it something with the horn or with two drivers when you combine them? Also noting I see 'point source' as more of a shape, not a location and not a point of origin.The main issue I ran into with the horn is that it forces the point source so far back that it has very negative effects on dispesion cancelation.

Moving a driver back causes some big cancellations in the XO region. In the near field that is going to be a problem and quite audible.

This is the transducer moved back the length average length of a horn that is effective.

This is the transducer moved back the length average length of a horn that is effective.

Attachments

Thank you. This is a matter of correcting their phase relationship since the increased delay alters phase.

Allen,

Correct, and I think that is out of my scope at my current skill level. I do not know how to fix that.

Correct, and I think that is out of my scope at my current skill level. I do not know how to fix that.

Delay changes the slope of phase. You could find an opposing effect by changing the filter order of one of the filters. You may need to tweak it a bit to get the response and phase together as needed. Alternately you could try an all-pass filter (lattice network).

Allpass filters are tricky to implement without causing other issues. The trick is to sim it with multiple tools and see what they say. Be aware the parts can get expensive if the frequencies are lower. If its the only option you have and require passive delay, do some listening before you nail down a solution based on sim.

@Bmsluite Real ribbon tweeters have a very fragile, thin element which requires protection from curious fingers, debris and even having air blown onto them.

The compromise of having a shielding mesh in place is worth it. Having such mechanical protection is important IMO, as the alternative is regular replacement of the moving element, if its even available on the GRS tweeter.

I learned all this the hard way many years ago with a Raven R1 ribbon in a large 4way build for a good customer. A few days after receiving the speakers he says all annoyed that one of the tweeters quit working. It made me all upset as well given the cost of these ribbons. Turns out his cleaning lady managed to destroy the moving element with her vacuum cleaner (despite grille cloth and mesh wire shield). It was easy to repair but it happened again twice despite the cleaning person being told to not touch the speakers.

The compromise of having a shielding mesh in place is worth it. Having such mechanical protection is important IMO, as the alternative is regular replacement of the moving element, if its even available on the GRS tweeter.

I learned all this the hard way many years ago with a Raven R1 ribbon in a large 4way build for a good customer. A few days after receiving the speakers he says all annoyed that one of the tweeters quit working. It made me all upset as well given the cost of these ribbons. Turns out his cleaning lady managed to destroy the moving element with her vacuum cleaner (despite grille cloth and mesh wire shield). It was easy to repair but it happened again twice despite the cleaning person being told to not touch the speakers.

Last edited:

Pro,

I figured this was the case. I have been storing it face down so no shop debris falls on the screen. I have heard that vacuums can ruin them. I have actually told the wire to only hand dust any speakers we have. No vacuum on any of them.

Something interesting of note related to ribbon/planar drivers is that I was breaking in some new film and foil caps a couple weeks ago so we ran headphone break in for a whole week, 9 hours a day while we were at work. Now the Hivi planar tweeter sounds AMAZING. I guess even planar/ribbons need breaking in just as much as cones do. I wouldn't have thought that. Just to bring the story full circle, I ended up putting back in electrolytic caps. I do not like the way it sounded with the film and foil caps.

I figured this was the case. I have been storing it face down so no shop debris falls on the screen. I have heard that vacuums can ruin them. I have actually told the wire to only hand dust any speakers we have. No vacuum on any of them.

Something interesting of note related to ribbon/planar drivers is that I was breaking in some new film and foil caps a couple weeks ago so we ran headphone break in for a whole week, 9 hours a day while we were at work. Now the Hivi planar tweeter sounds AMAZING. I guess even planar/ribbons need breaking in just as much as cones do. I wouldn't have thought that. Just to bring the story full circle, I ended up putting back in electrolytic caps. I do not like the way it sounded with the film and foil caps.

- Home

- Loudspeakers

- Multi-Way

- Planar Horn Research - Findings