Currently simulating an asymmetrical 130 degree R-OSSE waveguide to be used with the Peerless DFM-2535 down to 1 kHz. I have some questions. Which R-OSSE operation or which combination of operators controlls the pattern with between 1-2 kHz? I am mostly satisfied with the device in general by now but would need to reduce vertical pattern width just above LF cut-off.

Last edited:

In my experience, between 1 - 2 kHz pretty much everything has an effect. But you could probably add some midrange narrowing by making the mouth termination less gradual, if that's what you want.

Is this good or bad? 🙂

It appears to be difficult to find criteria, let alone explanatios. In any case, this appears to be a common standard for studio monitors:

2.5 Decay time

The decay time ts is defined as the time taken for a reduction of the sound pressure to a value 1/e (about 0.37) times the initial value. A sinusoidal tone burst shall be used as an input signal.

The decay time should not exceed the following limit:

ts ≤ 2.5/f

where: f is the frequency.

EBU Tech. 3276 of the EBU Technical Recommendation R22-1999.

Less strict:

7.2.2.4 Transient fidelity

The decay time measured on an oscilloscope to a level of 1/e (approximately 0.37) of the original level, (on the main

axis only) should be:

ts < 5/f

where f: frequency.

That means the decay time of a sinusoidal tone burst may not exceed five times the period of the corresponding sine

wave.

Rec. ITU-R BS.1116-1

The latter is also the criterium of AESTD1001.1.01-10.

Last edited:

That sounds almost like a joke. Where do these numbers come from? 1/e, that's roughly -8.7 dB SPL.The decay time ts is defined as the time taken for a reduction of the sound pressure to a value 1/e (about 0.37) times the initial value.

It doesn't seem that strict though. With a smooth-enough frequency response, this is reasonable, IMO.

Thanks! 🙂1) yes, in the 2-profile geometry mode: https://www.diyaudio.com/community/...-design-the-easy-way-ath4.338806/post-7046022

2) not to my knowledge.

I will look into it, the formatting isn't quite that obvious to me, so some studying to do here 🙂

It's tau, or a time constant. It's a pretty standard way to describe decay rates in other engineering fields. You usually see it as 63% drop, and it's handy to work with when you're doing e^(-jwt) related math.That sounds almost like a joke. Where do these numbers come from? 1/e, that's roughly -8.7 dB SPL.

It doesn't seem that strict though. With a smooth-enough frequency response, this is reasonable, IMO.

tau is being used for decays in control theory (Fourier stuff etc) and other fields.The first time I see this in acoustics. Not sure about its utility, any number is as good I guess.

Almost never in acoustics, let alone being common and standard.

I'm testing a new idea of the assembly scheme. All simple, easy-to-print parts with some locks (which I've not decided how to do yet), so they can be easily added one by one in a straightforward way, including a complete dry run. And even if the seams remain apparent in the end, which they always tend to, in this case it could be still fine visually, I hope.

Last edited:

That’s very cool. And makes printing less perilous as if you get a print error it’s a much smaller piece of the whole that you’ve lost.

Potentially interesting for casting too? As few as 4 molds to cast the 3D patches. For example for Acrystal/Jesmonite which is an easy to handle material https://polyestershoppen.com/info/wat-is-acrystal4 different smaller shapes

Mabat, just to confirm before purchase, is the A460G on cults3d a segmented file like the E520G2?

Is there a way to design a horn in ATH4 that is curved at the termination? I.e. to match a baffle curved in one dimension?

I assume I could just use ath4 to make the throat and conical section and then truncate it in Fusion 360? But then I would need to make my own curve for the termination.

I assume I could just use ath4 to make the throat and conical section and then truncate it in Fusion 360? But then I would need to make my own curve for the termination.

You would need to do this by hand, there is no feature that does it for you.

I think I can answer that: The folder on Cults contains the stl files for the jig, the base and a 45° petal (and the ath file).Mabat, just to confirm before purchase, is the A460G on cults3d a segmented file like the E520G2?

Attachments

Currently testing printing a single piece EXAR400. Plan to drive it with a LaVoce DF10.142k

Attachments

Last edited:

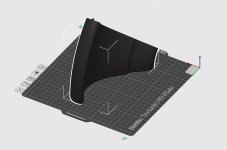

Has anyone explored further designs using the superformula feature? I know there were some posts early on in the thread about it, but it seems like interest died off. It may be a dead end, but given that the complexity increases substantially once you add in the superformula variables, I've been using a genetic algorithm to improve on this style waveguide over a few hundred iterations. Drawing inspiration from @Patrick Bateman's extensive research on the image control waveguide. This one measures at 320x320x140mm with a 1" throat.

I've got a few other variations of this that I've printed and tested, but so far this one looks to be the most promising, so I'll start on a physical prototype next week.

I've got a few other variations of this that I've printed and tested, but so far this one looks to be the most promising, so I'll start on a physical prototype next week.

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)

![20240831_211252[1].jpg](/community/data/attachments/1259/1259040-9b53d351008b80f526b3813e32f7bddf.jpg?hash=m1PTUQCLgP)