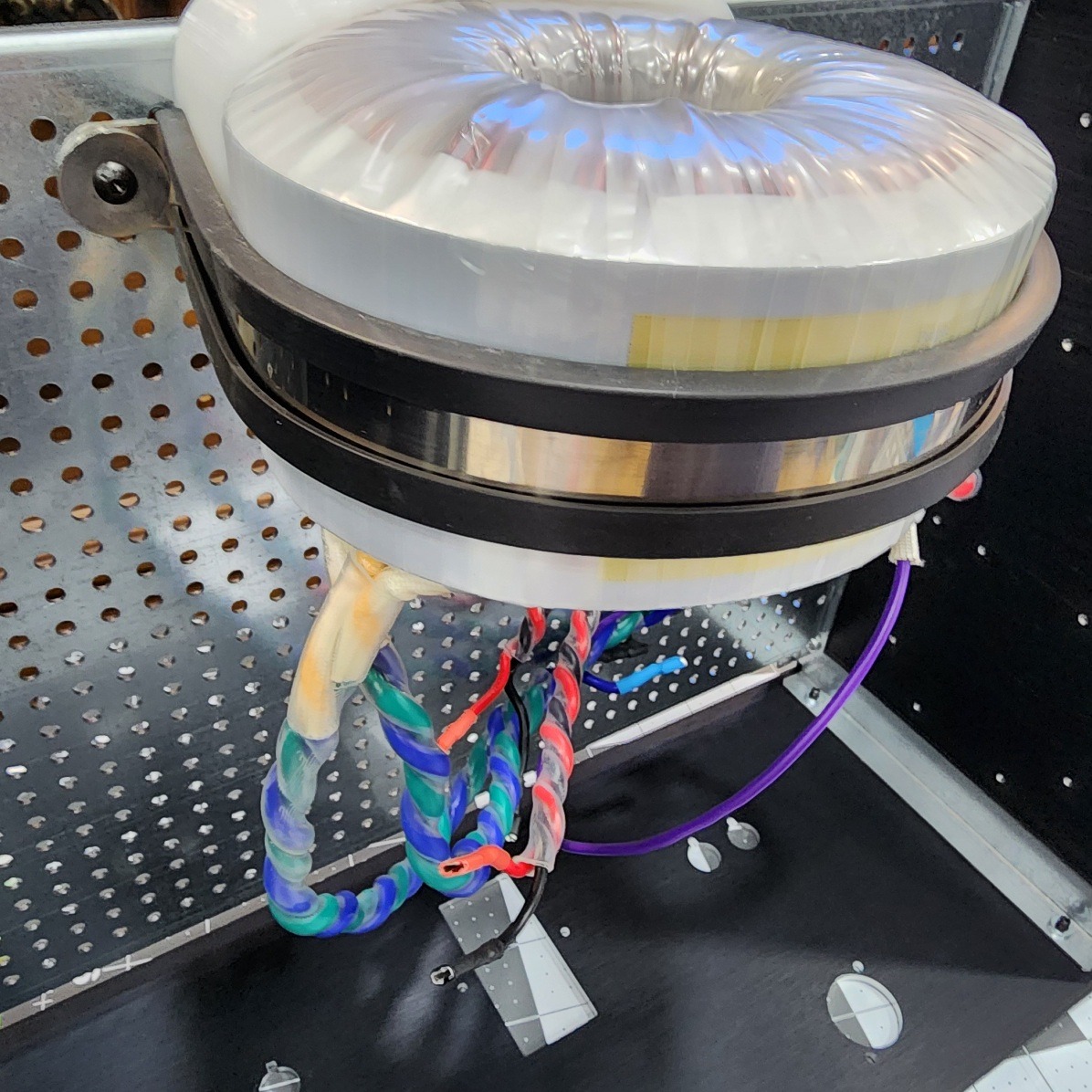

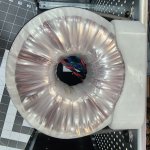

Yeah, that's pretty much it, "Transformer Chassis Seat". It's super secure as is (I can pick up entire chassis by grabbing the donut) no need to redesign for this amp. Happy to share the STL file for others to try. The pipe strap was $2/ea (I bought a 12 pack). So, under $4 total cost for app the parts: M4 bolts/nuts, fender washers, 42gr TPU material, and the strap. Of course, you need access to a 3D printer that has direct drive for TPU prints.

Attachments

-

20240312_192923.jpg397.7 KB · Views: 170

20240312_192923.jpg397.7 KB · Views: 170 -

20240312_193230.jpg410.6 KB · Views: 167

20240312_193230.jpg410.6 KB · Views: 167 -

20240312_193243.jpg408.8 KB · Views: 161

20240312_193243.jpg408.8 KB · Views: 161 -

20240312_194744.jpg403.7 KB · Views: 161

20240312_194744.jpg403.7 KB · Views: 161 -

20240312_194341.jpg369.7 KB · Views: 163

20240312_194341.jpg369.7 KB · Views: 163 -

20240312_194322.jpg418.9 KB · Views: 212

20240312_194322.jpg418.9 KB · Views: 212 -

Screenshot_20240312_194919_Chrome.jpg224.8 KB · Views: 192

Screenshot_20240312_194919_Chrome.jpg224.8 KB · Views: 192 -

Antek Chassis Mount AS-3218 Ver-3-12-24.zip402.1 KB · Views: 103

Last edited:

The pipe strap is an excellent idea! Sadly I don't have a 3D printer. I might figure something else out!Yeah, that's pretty much it, "Transformer Chassis Seat". It's super secure as is (I can pick up entire chassis by grabbing the donut) no need to redesign for this amp. Happy to share the STL file for others to try. The pipe strap was $2/ea (I bought a 12 pack). So, under $4 total cost for app the parts: M4 bolts/nuts, fender washers, 42gr TPU material, and the strap. Of course, you need access to a 3D printer that has direct drive for TPU prints.

No "preorder" option as far as I'm aware. However, you can sign up for the email alert ("Notify me when available") for when it's back in stock at the store.can we preorder these boards?

https://diyaudiostore.com/products/f5m-essentials

@Jacruzer787

My backup plan for mounting the transformer vertically was to use a Simpson Tie (L-bracket) from a big box hardware store, and just drill some holes to mount to chassis perforated plate and the bolt that comes with the transformer. Others have recommended that as an affordable diy option. The 3D printed idea just seemed a little cleaner, easier for me to do, a fun design challenge, and slightly less expensive.

There's always a 3D printer house that will do it pretty cheap, or you find a Makerspace near where you live, ask your buddies buddies if they have a 3D printer (there are pretty common for "diy-ers" to have), or PM me and I'll hook ya up.

My backup plan for mounting the transformer vertically was to use a Simpson Tie (L-bracket) from a big box hardware store, and just drill some holes to mount to chassis perforated plate and the bolt that comes with the transformer. Others have recommended that as an affordable diy option. The 3D printed idea just seemed a little cleaner, easier for me to do, a fun design challenge, and slightly less expensive.

There's always a 3D printer house that will do it pretty cheap, or you find a Makerspace near where you live, ask your buddies buddies if they have a 3D printer (there are pretty common for "diy-ers" to have), or PM me and I'll hook ya up.

Last edited:

The vertical mounting is a great option. I'm going that route with my monoblock rebuild since I need every millimeter of front-to-back floor space in my chassis for the other bulky components that need to go in there.

That’s a good idea and will do. 👍

I’m not 100% in love with this arrangement and should come up with something a little better, including insulating all the legs. The safety cap might be better installed on the PEM, which would make the terminal block wiring even simpler… will think about it a bit.

I’m not 100% in love with this arrangement and should come up with something a little better, including insulating all the legs. The safety cap might be better installed on the PEM, which would make the terminal block wiring even simpler… will think about it a bit.

You don’t really need a 3D printer, all you need is the 3D cad STL file (if the designer doesn’t mind sharing) and then simply send it to JLCPCB, they do very good work, are fast, not expensive and lots of materials to choose from.The pipe strap is an excellent idea! Sadly I don't have a 3D printer. I might figure something else out!

I've been known to use heat shrink tubing to cover the leads on my CL-60s and safety caps. Pick a small size and cut to the length you need. Keeps pokey fingers from getting zapped.

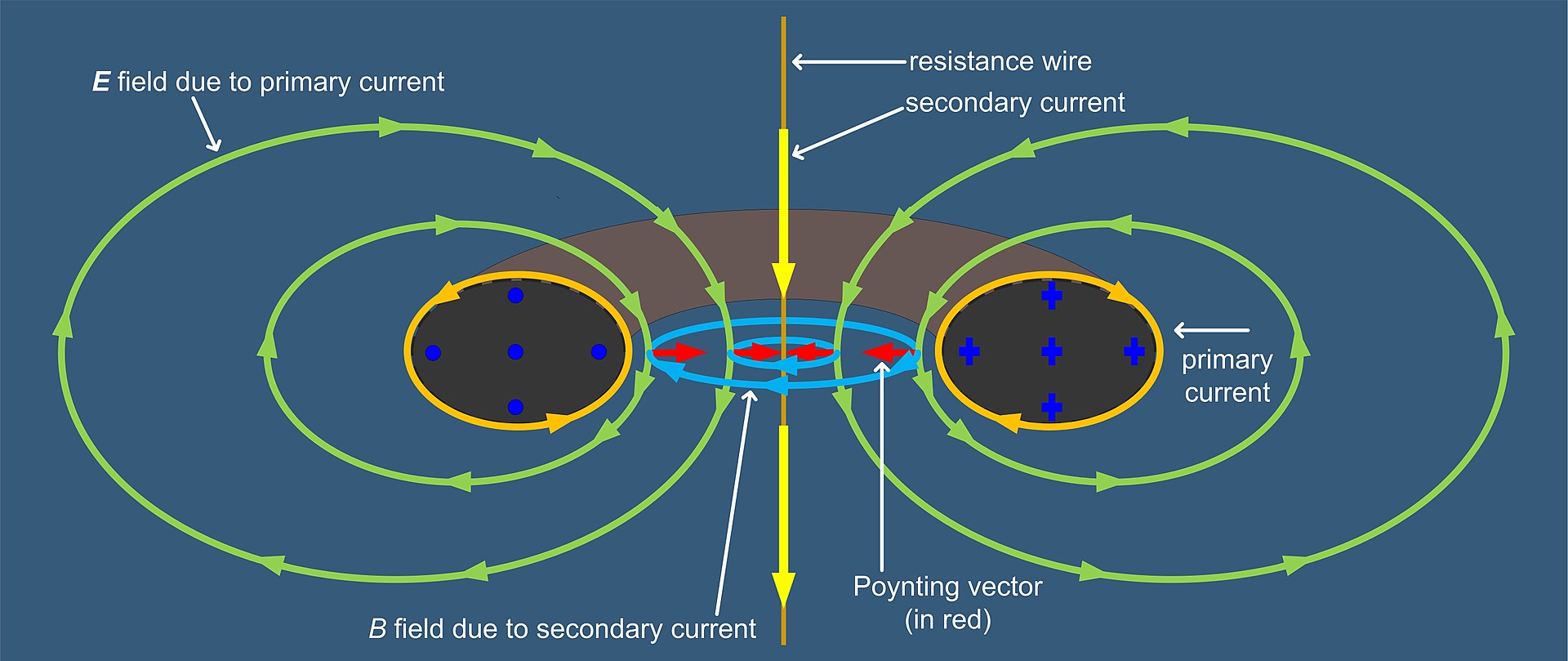

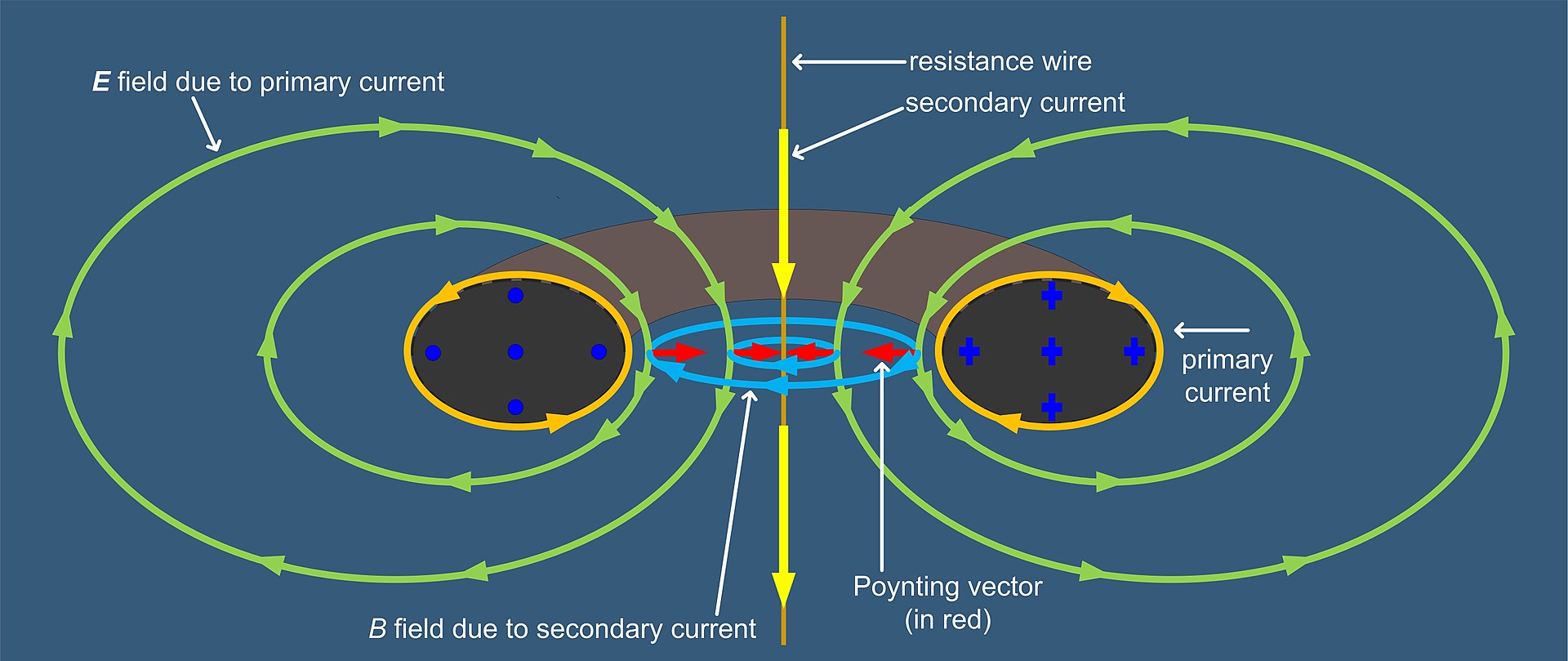

Is there any benefit, specifically regarding magnetic fields, to mounting the toroid horizontal vs vertical?

Donuts are usually having lesser emanating field along center axis

3 4 words in ggl image search

https://www.google.com/search?as_st...imgtype=&cr=&as_sitesearch=&as_filetype=&tbs=

https://www.google.com/search?as_st...imgtype=&cr=&as_sitesearch=&as_filetype=&tbs=

- Home

- Amplifiers

- Pass Labs

- F5m kit