Looking for a similar solution to my descent sub, similar symptoms. I ordered the 500a module off parts express, realized the main connector is a black 8 pin molex versus a 4 pin spade type connectors. The pinout for the 500a seems like only 4 different inputs are used and it's just jumpered together. I ordered a connector with pigtails and plan to splice into the existing descent subwoofer harness.

Fingers crossed, anything I should check before I give this is shot? There's a mention of measuring something to confirm but it isn't clear what to do. Parts just ordered from parts express, hopefully arrive middle of next week.

Fingers crossed, anything I should check before I give this is shot? There's a mention of measuring something to confirm but it isn't clear what to do. Parts just ordered from parts express, hopefully arrive middle of next week.

@bchow,

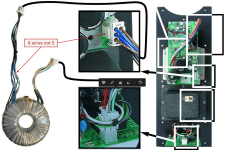

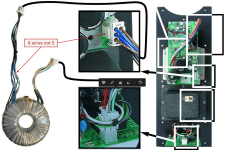

According the the schematic you posted, you should find an ICE 1000A amplifier module underneath the main circuit board attached directly to the back plate with bolts circled in red.

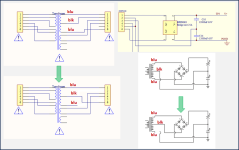

View attachment 1136411 View attachment 1136406

I'm guessing this is what Martin Logan thinks is wrong and is no longer being manufacturing.

They show as "no longer available" pretty much everywhere on line. For example:

https://icepoweraudio.com/buy/a-series/1000a/

https://www.parts-express.com/ICEpo...Amplifier-Module-1-x-1000W-326-202?quantity=1

But I did find one place that still showed them available. You would have to contact them to see if they actually have any.

https://shop.ampman.co.uk/icepower-1000a-amplifier-module-2061-p.asp

If you can't get a replacement 1000A module, you have might consider replacing it with a 500A module which is still readily available and has the exact same input/output connections. It is slightly smaller so you would have to drill one new attachment hole in the back plate for mounting.

https://icepoweraudio.com/buy/a-series/500a/

https://www.parts-express.com/ICEpo...-Amplifier-Module-1-x-500W-326-200?quantity=1

According to the schematic, the filter capacitors of the main power supply for the amp module are rated at 63V, so this should put it well within the allowable voltage range of the 500A module.

You would want to measure to confirm, but it is in line with the 400W RMS rating for the output power in the manual.

Another alternative is to ditch the Martin Logan backplate completely and replace it with something like a YUNG 500W plate amp.

https://www.parts-express.com/Yung-...oofer-Amp-Module-w-6dB25Hz-301-514?quantity=1

You would need to measure the impedance of the woofers to make sure driving 3 in parallel will be ok.

The downside to this approach is you lose the distortion reduction advantage of the servo feedback system built in to the Martin Logan electronics.

Feel free to contact me off list if you need additional guidance measuring the power supply voltage or woofer impedance.

Congrats on your successful outcome.

I am not sure why ML decided to use the 1000A instead of the 500A for this subwoofer. It is possible that the limited bandwidth of the 1000A made the servo control loop easier to stabilize than it would have been for the full-range 500A. Or, it may just have come down to $$$, in that they may have used the 1000A for several different models with varying power requirements and it was cheaper to just stock one amp module.

I did not work on mine yet. I have five and two do not work. It turns out I did not need the two when the setup was re-calibrated. I don't have urgency issues regarding getting this done.

Ok I think I see it. You're talking about the Pin 4 Vp voltage off the 4 pin connector (V+) going into the 1000a? The 1000a is rated to 120V max and the 500a is 80V. Unfortunately, I just put a meter on that pin and it measures 99V, so it looks like it's over the rated input voltage for the 500a. Any suggestions? This might make sense since it's a series of caps rated at 63V each, or 126V combined, which lines up with the 120V max rating, on page 6 of 15 schematic.@bchow,

According the the schematic you posted, you should find an ICE 1000A amplifier module underneath the main circuit board attached directly to the back plate with bolts circled in red.

View attachment 1136411 View attachment 1136406

I'm guessing this is what Martin Logan thinks is wrong and is no longer being manufacturing.

They show as "no longer available" pretty much everywhere on line. For example:

https://icepoweraudio.com/buy/a-series/1000a/

https://www.parts-express.com/ICEpo...Amplifier-Module-1-x-1000W-326-202?quantity=1

But I did find one place that still showed them available. You would have to contact them to see if they actually have any.

https://shop.ampman.co.uk/icepower-1000a-amplifier-module-2061-p.asp

If you can't get a replacement 1000A module, you have might consider replacing it with a 500A module which is still readily available and has the exact same input/output connections. It is slightly smaller so you would have to drill one new attachment hole in the back plate for mounting.

https://icepoweraudio.com/buy/a-series/500a/

https://www.parts-express.com/ICEpo...-Amplifier-Module-1-x-500W-326-200?quantity=1

According to the schematic, the filter capacitors of the main power supply for the amp module are rated at 63V, so this should put it well within the allowable voltage range of the 500A module.

You would want to measure to confirm, but it is in line with the 400W RMS rating for the output power in the manual.

Another alternative is to ditch the Martin Logan backplate completely and replace it with something like a YUNG 500W plate amp.

https://www.parts-express.com/Yung-...oofer-Amp-Module-w-6dB25Hz-301-514?quantity=1

You would need to measure the impedance of the woofers to make sure driving 3 in parallel will be ok.

The downside to this approach is you lose the distortion reduction advantage of the servo feedback system built in to the Martin Logan electronics.

Feel free to contact me off list if you need additional guidance measuring the power supply voltage or woofer impedance.

Last edited:

Being new to this, would the best way to address this is with a DC to DC step down that'll drop the 100v to 75v? Do I just need something rated to 500w+? Anything else to look for?

Yes, check the voltage from pin 4 (Vp) to pin 3 (PGND) going into the 1000A.Ok I think I see it. You're talking about the Pin 4 Vp voltage off the 4 pin connector (V+) going into the 1000a? The 1000a is rated to 120V max and the 500a is 80V. Unfortunately, I just put a meter on that pin and it measures 99V, so it looks like it's over the rated input voltage for the 500a. Any suggestions? This might make sense since it's a series of caps rated at 63V each, or 126V combined, which lines up with the 120V max rating, on page 6 of 15 schematic.

Can you confirm that is where you measured 99VDC?

If so, you should definitely reduce the supply voltage for the amp module before hooking up the 500A.

The supply voltage level can easily by cut in half by swapping some wires going between the transformer and bridge rectifier.

I'll provide details tomorrow if you can confirm the 99VDC was measured between pin 3 and 4.

Yes that is where I measured 99V. The 1000a was disconnected, with the meter on the connector off the harness that would plug into the 1000a

Can you confirm that is where you measured 99VDC?

Some info, the transformer looks like it has 120v and 100v taps, with the 120v feeding the rectifier. I'm able to get a partial part number, KBPC250???.

I was just putting some directions together for you on what wires to remove/swap on the power plug and noticed something.

In the schematic it shows pin 5 of the power connector as not having anything connected to it. But in the service manual pics, it shows 6 wires...looks to be 2 blue, 2 brown and 2 black.

Can you confirm this is what you have? and can you measure the AC voltage between each of the wires pairs?

Blue - blue (pin 5 to pin 6)

Brown - brown (pin 3 to pin 4)

black - black (pin 1 to pin 2)

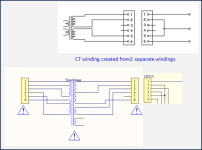

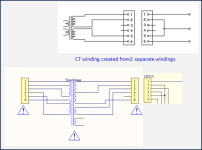

I think they have two separate high voltage windings and made them into the center-tapped configuration shown in the schematic by connected pin 2 to pin 5 on the circuit board side of the connector.

In the schematic it shows pin 5 of the power connector as not having anything connected to it. But in the service manual pics, it shows 6 wires...looks to be 2 blue, 2 brown and 2 black.

Can you confirm this is what you have? and can you measure the AC voltage between each of the wires pairs?

Blue - blue (pin 5 to pin 6)

Brown - brown (pin 3 to pin 4)

black - black (pin 1 to pin 2)

I think they have two separate high voltage windings and made them into the center-tapped configuration shown in the schematic by connected pin 2 to pin 5 on the circuit board side of the connector.

Last edited:

Only 5 wires coming out of the transformer to the 6 pin harness and pin 5 is not connected. Voltages are as follows, with the harness unplugged:

Blue/blk 1/2 35.7 VAC

Brn/brn 3/4 13 VAC

Blk**/brn 2/6 35.6 VAC assuming 2 and 5 should be tied via the board and are ground.

Blue/blk 1/2 35.7 VAC

Brn/brn 3/4 13 VAC

Blk**/brn 2/6 35.6 VAC assuming 2 and 5 should be tied via the board and are ground.

Can you confirm this is what you have? and can you measure the AC voltage between each of the wires pairs?

Blue - blue (pin 5 to pin 6)

Brown - brown (pin 3 to pin 4)

black - black (pin 1 to pin 2)

Great! thanks for the detailed results including pin numbers and wire colors.

So your transformer matches the schematic not the service manual pic.

Here are the steps to lower the voltage from ~100VDC to ~50VDC for the 500A:

1) Remove pin 6 (blu) from the transformer side of the connector and cap it off or carefully cover it in electrical tape.

2) Remove pin 2 (blk) from the transformer side of the connector

3) Insert the (blk) wire you just removed from pin 2 into the now vacant pin 6 location.

4) Before plugging things back in check the voltage at pins 3 and 4 of the 1000A. If it is > 50VDC I would recommend discharging the 2 power supply capacitors by connecting a resistor between pins 3 and 4 of the 1000A connector. I usually use something like a 10K resistor. Monitor the voltage until it decays to < 50VDC...would likely take around 30 seconds if it was up at 100VDC.

5) Plug in and turn on power, verify you now get ~50VDC at pins 3 and 4 of the 1000A connector.

Not sure if you have messed with Molex connectors before, but you can usually get the male pins removed with just a jeweler's screwdriver or a safety pin if you don't have a removal tool handy.

Youtube should have plenty of videos showing how. Here is the first one that popped up when I searched:

EDIT: wire color changes per Post#32 below.

So your transformer matches the schematic not the service manual pic.

Here are the steps to lower the voltage from ~100VDC to ~50VDC for the 500A:

1) Remove pin 6 (blu) from the transformer side of the connector and cap it off or carefully cover it in electrical tape.

2) Remove pin 2 (blk) from the transformer side of the connector

3) Insert the (blk) wire you just removed from pin 2 into the now vacant pin 6 location.

4) Before plugging things back in check the voltage at pins 3 and 4 of the 1000A. If it is > 50VDC I would recommend discharging the 2 power supply capacitors by connecting a resistor between pins 3 and 4 of the 1000A connector. I usually use something like a 10K resistor. Monitor the voltage until it decays to < 50VDC...would likely take around 30 seconds if it was up at 100VDC.

5) Plug in and turn on power, verify you now get ~50VDC at pins 3 and 4 of the 1000A connector.

Not sure if you have messed with Molex connectors before, but you can usually get the male pins removed with just a jeweler's screwdriver or a safety pin if you don't have a removal tool handy.

Youtube should have plenty of videos showing how. Here is the first one that popped up when I searched:

EDIT: wire color changes per Post#32 below.

Last edited:

Correction, last pair is as follows:

Blk**/BLUE 2/6 35.6 VAC assuming 2 and 5 should be tied via the board and are ground.

Blk**/BLUE 2/6 35.6 VAC assuming 2 and 5 should be tied via the board and are ground.

thx for quick response; was able to get wire color corrections into Post#31 within the edit time window.

Looks like it worked! I'm getting 50.6VDC at the 1000a connector. My old pin 6 is taped and swapped pin 2 as directed. So I should be good to give the 500a a shot? I have the correct 8 pin connector wired with leads coming for the 500a so will need to cut the old 1000a 4 pin and match it up the 4 needed wires. I'd rather make an adapter but can't figure out what the existing 4 pin connector would be to replace the 1000a end.Great! thanks for the detailed results including pin numbers and wire colors.

So your transformer matches the schematic not the service manual pic.

Here are the steps to lower the voltage from ~100VDC to ~50VDC for the 500A:

1) Remove pin 6 (blu) from the transformer side of the connector and cap it off or carefully cover it in electrical tape.

2) Remove pin 2 (blk) from the transformer side of the connector

3) Insert the (blk) wire you just removed from pin 2 into the now vacant pin 6 location.

4) Before plugging things back in check the voltage at pins 3 and 4 of the 1000A. If it is > 50VDC I would recommend discharging the 2 power supply capacitors by connecting a resistor between pins 3 and 4 of the 1000A connector. I usually use something like a 10K resistor. Monitor the voltage until it decays to < 50VDC...would likely take around 30 seconds if it was up at 100VDC.

5) Plug in and turn on power, verify you now get ~50VDC at pins 3 and 4 of the 1000A connector.

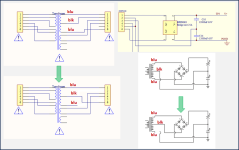

View attachment 1223629

Not sure if you have messed with Molex connectors before, but you can usually get the male pins removed with just a jeweler's screwdriver or a safety pin if you don't have a removal tool handy.

Youtube should have plenty of videos showing how. Here is the first one that popped up when I searched:

EDIT: wire color changes per Post#32 below.

Thanks for your help. Appreciate all your help so far and any insights for the rest of this if you've got any.

Last edited:

Yes, you are good to go to try the 500a.

Best case scenario you turn it on and it works and is completely stable.

If you notice some instability (ie woofers flapping about with no signal input) the schematic(pg 8) shows a rotary switch to adjust the servo gain that could be turned down until stable.

Perhaps you could use individual spades instead of a 4 pin block?

Alternatively, if you can remove the wires from the connector you could use individual insulated spades.

Best case scenario you turn it on and it works and is completely stable.

If you notice some instability (ie woofers flapping about with no signal input) the schematic(pg 8) shows a rotary switch to adjust the servo gain that could be turned down until stable.

Perhaps you could use individual spades instead of a 4 pin block?

Alternatively, if you can remove the wires from the connector you could use individual insulated spades.

Perfect! I think I found the switch to make as needed adjustments.

Got a pack of crimps from Home Depot. 500A should arrive tomorrow, can't wait to give it a shot.

Thanks so much.

Got a pack of crimps from Home Depot. 500A should arrive tomorrow, can't wait to give it a shot.

Thanks so much.

Yes, you are good to go to try the 500a.

Best case scenario you turn it on and it works and is completely stable.

If you notice some instability (ie woofers flapping about with no signal input) the schematic(pg 8) shows a rotary switch to adjust the servo gain that could be turned down until stable.

Perhaps you could use individual spades instead of a 4 pin block?

View attachment 1223958

Alternatively, if you can remove the wires from the connector you could use individual insulated spades.

View attachment 1223959

All hooked up and it worked! I was a little stressed getting it hooked up. Tested it out a bit tonight for maybe 20 minutes.

Probably the one thing I'm "worried" about is the main connector wiring hardness coming out of the 500A. I used this premade from parts express.

https://www.parts-express.com/ICEpo...D71uUOde-49xdTrysld-sSncPD-Y3EChoCibMQAvD_BwE

The existing wiring is 14awg while the new one is 20awg. I'm assuming it's not an actual issue. I honestly don't know what each and every piece within the sub does so I don't know the actual power that's passing through the 20awg wire, but the thought of 500W going through it seems scary.

Thanks again for all your help.

That is great news! Glad to hear of another successful amp board transplant.

Regarding the 20awg wiring harness, your assumption is correct...not an issue.

Each power and speaker line is run thru two of the wires in parallel, so effectively ~17awg.

With the short length, only about 0.5Watt is lost heating the wires at full power.

Generally you lose more than that just due to contact resistance of the connectors.

Speaking of heat, just wanted to make sure you were able get 2 mounting screws thru the back plate into the heat spreader on the amp board.

This is important for efficient transfer of heat away from the amp's electrical components for best reliability.

It looked like you might have to drill a new hole for at least one of the mounting screws.

Regarding the 20awg wiring harness, your assumption is correct...not an issue.

Each power and speaker line is run thru two of the wires in parallel, so effectively ~17awg.

With the short length, only about 0.5Watt is lost heating the wires at full power.

Generally you lose more than that just due to contact resistance of the connectors.

Speaking of heat, just wanted to make sure you were able get 2 mounting screws thru the back plate into the heat spreader on the amp board.

This is important for efficient transfer of heat away from the amp's electrical components for best reliability.

It looked like you might have to drill a new hole for at least one of the mounting screws.

Regarding sharing the signal through two wires, I only attached one of the two wires. I did not believe it was good practice to run two wires of same signal to the same place. If you think it'll help, I can rework that. For now, the 2nd wires are just taped over the end and zip tied to the harness to be secure.That is great news! Glad to hear of another successful amp board transplant.

Regarding the 20awg wiring harness, your assumption is correct...not an issue.

Each power and speaker line is run thru two of the wires in parallel, so effectively ~17awg.

With the short length, only about 0.5Watt is lost heating the wires at full power.

Generally you lose more than that just due to contact resistance of the connectors.

Speaking of heat, just wanted to make sure you were able get 2 mounting screws thru the back plate into the heat spreader on the amp board.

This is important for efficient transfer of heat away from the amp's electrical components for best reliability.

It looked like you might have to drill a new hole for at least one of the mounting screws.

Yes, I drilled a second hole to line up with the shorter distance between mounting holes. A surprise for me was the mounting hole was an M4, while the 1000A was larger, I assume M6. Had to make a last minute run to the store to get some screws.

- Home

- Loudspeakers

- Subwoofers

- Martin Logan Descent subwoofer blown amp