According to the specifications for your power transformer, Signal DP-241-8-20, it is centre tapped 20VAC and dual primaries. Do you have the primary windings connected in parallel and in phase? Since it is centre tapped, how are you measuring two secondary voltages?

Since the transformer is only 100VA, there will be some sag in the voltage if you draw close to the specified design power. The DC voltage at the first capacitor will not be 1.4xVAC. It may be in the neighbourhood of 1.25 to 1.3 x VAC. If you draw even more current, the output voltage will sag even more.

Typically for Class A amplifier power supplies, the power transformer is sized for two times power requirement.

The 2 - 5.6R resistors in parallel to each channel is quite a high value, dropping a large amount of voltage. Typical FW power supplies have approximately 0.1R as the filter resistor.

Since the transformer is only 100VA, there will be some sag in the voltage if you draw close to the specified design power. The DC voltage at the first capacitor will not be 1.4xVAC. It may be in the neighbourhood of 1.25 to 1.3 x VAC. If you draw even more current, the output voltage will sag even more.

Typically for Class A amplifier power supplies, the power transformer is sized for two times power requirement.

The 2 - 5.6R resistors in parallel to each channel is quite a high value, dropping a large amount of voltage. Typical FW power supplies have approximately 0.1R as the filter resistor.

I have the primaries in parallel, my mains is 120V (per my measurement today - the Texas grid is surviving). I measured the secondaries at the two outside tabs on the top of the transformer. The middle is the center tap per documentation.

I mistakenly thought the ACA was 24v at 1A for each channel. I thought I had a transformer with twice the requirement. Maybe a 150-200 watt transformer with 18v secondaries.

Also, on the Power Supply forum, I was told the 1N5822 rectifier diodes I used were marginal at best for this use. And funnily, it was suggested that the PS looked like one for a tube amp. Well, that Morgan Jones "Valve Amplifiers" book does come in handy!

The choke' DCR is too high along with the resistors. I should have selected a choke with lower mH and lower DCR. Maybe a 150-200 watt transformer with 18v secondaries.

Oh well, I've learned a lot and it's not the end of the world with this little experiment.

I might rethink it. Or I might buy a couple Meanwell chassis mount SMPS' like I used before. They are so cheap and so good.

Thanks all,

Dan

I mistakenly thought the ACA was 24v at 1A for each channel. I thought I had a transformer with twice the requirement. Maybe a 150-200 watt transformer with 18v secondaries.

Also, on the Power Supply forum, I was told the 1N5822 rectifier diodes I used were marginal at best for this use. And funnily, it was suggested that the PS looked like one for a tube amp. Well, that Morgan Jones "Valve Amplifiers" book does come in handy!

The choke' DCR is too high along with the resistors. I should have selected a choke with lower mH and lower DCR. Maybe a 150-200 watt transformer with 18v secondaries.

Oh well, I've learned a lot and it's not the end of the world with this little experiment.

I might rethink it. Or I might buy a couple Meanwell chassis mount SMPS' like I used before. They are so cheap and so good.

Thanks all,

Dan

Tube amplifier circuits are usually high voltage, in the hundreds of Volts, and low current, usually in the milliVolts. So the higher choke DCR and filter resistor resistance does not drop the DC voltage much. For solid state amplifiers the voltages are usually low and the current is high.

To measure the AC voltage of the centre tapped secondary, place a probe on each of the outer tabs.

To measure the AC voltage of the centre tapped secondary, place a probe on each of the outer tabs.

Not sure why you need such high value series resistors for the CRC section. You lose around 4VDC across them, in each leg.

Lower their values to 0.22 - 0.47R and check again.

Plus 100W trafo for 2 ACA channels is not really sufficient, hence the sagging.

Make it at least 160W.

Lower their values to 0.22 - 0.47R and check again.

Plus 100W trafo for 2 ACA channels is not really sufficient, hence the sagging.

Make it at least 160W.

Yeah, I see a Hammond on digikey for 80 bucks. Just getting to be expensive PSU's. My CLC project is now on hold.

So......

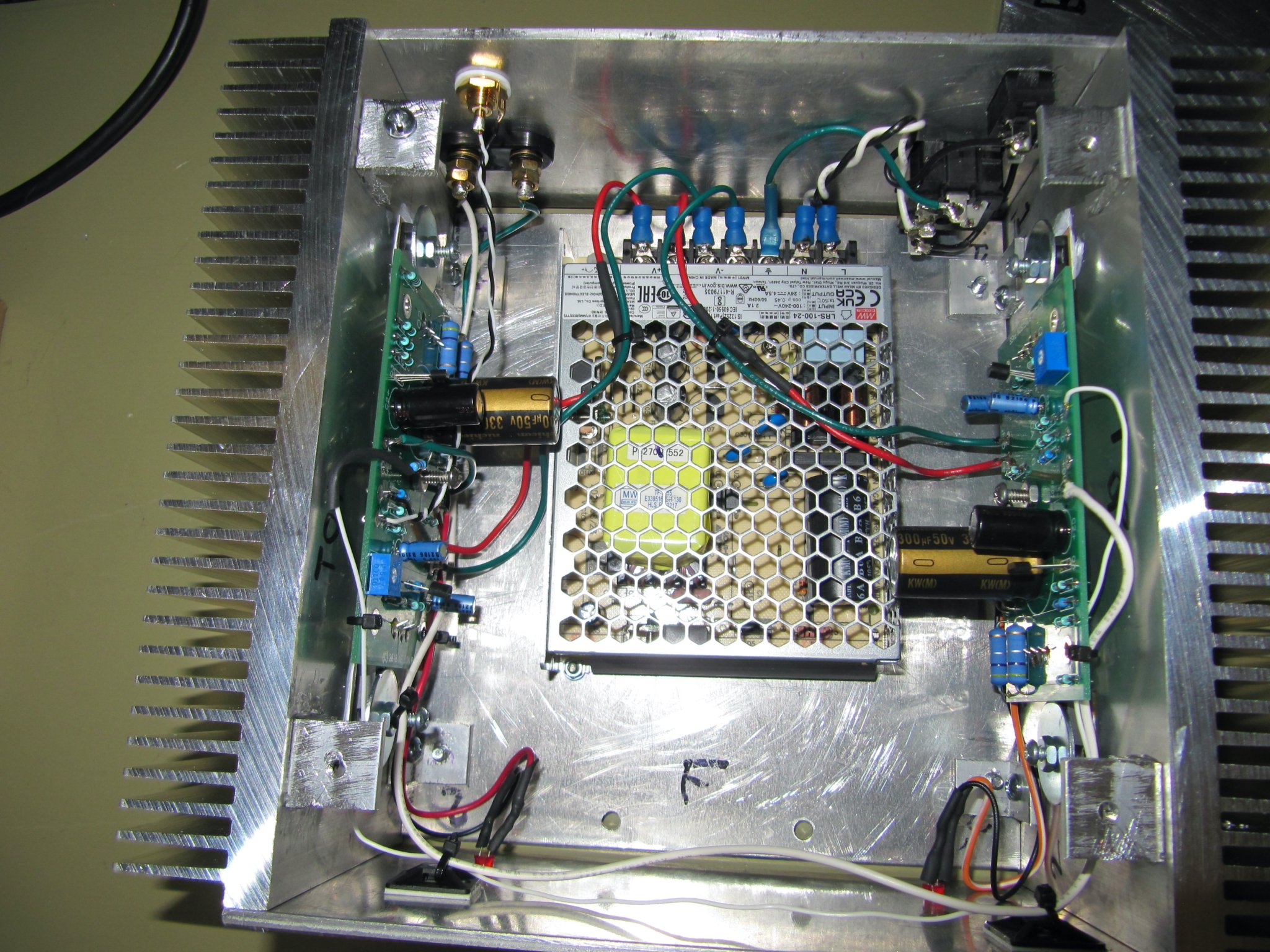

I removed all that linear power supply CLCRC crap 😉 and put in my tried and try MeanWell 24v 100w SMPS.

I got 24.1V on the rails.

I set the current source drains to 12v per instructions. And let it run for a while.

Man it ran hot! About 135F measured with a gun. The left channel current source mosfet got fried. After cooking, measured 1.5v at the drain.

Replaced that and it is back up and running.

Set the bias at 10v. That will allow it to run cooler, right?

I haven't had this problem with other builds using the same parts. The heat sink is 8"x4"x1 3/8" bought from the vendor here Heat Sink USA.

BTW, it is 103F today. It is 80F in my house, a/c can't keep up.

Dan

I removed all that linear power supply CLCRC crap 😉 and put in my tried and try MeanWell 24v 100w SMPS.

I got 24.1V on the rails.

I set the current source drains to 12v per instructions. And let it run for a while.

Man it ran hot! About 135F measured with a gun. The left channel current source mosfet got fried. After cooking, measured 1.5v at the drain.

Replaced that and it is back up and running.

Set the bias at 10v. That will allow it to run cooler, right?

I haven't had this problem with other builds using the same parts. The heat sink is 8"x4"x1 3/8" bought from the vendor here Heat Sink USA.

BTW, it is 103F today. It is 80F in my house, a/c can't keep up.

Dan

Set the bias at 10v.That will allow it to run cooler, right?

nope

it is setting of output node voltage, practically how much of rail voltage is across one mosfet and how much across second one

heat is still rail multiplied with Iq, which you're not changing

Preparing for my first ACA build and would like to build my own enclosure - but I am struggling to appreciate heat sink requirements.

I’m keen to combine both boards/channels onto a single sink. There is good guidance online for calculating the required thermal resistance of a heat sink but generally these calculations are based on one component being fixed to it. If I combine the boards onto one - how would I account for this?

The sinks with the recommended case are 0.67C/W. If combined is it as simple as ensuring the sink resistance is 0.335C/W or less?

Thanks in advance.

I’m keen to combine both boards/channels onto a single sink. There is good guidance online for calculating the required thermal resistance of a heat sink but generally these calculations are based on one component being fixed to it. If I combine the boards onto one - how would I account for this?

The sinks with the recommended case are 0.67C/W. If combined is it as simple as ensuring the sink resistance is 0.335C/W or less?

Thanks in advance.

Pass DIY Addict

Joined 2000

Paid Member

Yes, you are on the right track. The sinks that come with the kit are 8" wide, 3" tall, and the fins extend up off of the back plate by 1.25". Each channel dissipates 20w (10w per transistor). With both channels on the same sink, you are looking at 40w dissipation. I have built a 3-channel version of the ACA (60w) all on a single sink that is 10"w by 7" tall, with fins that are about 1.5" tall that stays cool enough.

If you have a calculator, just tell it that you are using a single device that is dissipating 40w - it will get you in the ballpark.

If you have a calculator, just tell it that you are using a single device that is dissipating 40w - it will get you in the ballpark.

Spread out the transistors. Two ACA channels = four FETs, so give each one a "quadrant" of the heatsink. For a heatsink with vertical fins (the typical way) you want them a bit below centerline, rule of thumb is 1/3 of the total distance from the bottom.I’m keen to combine both boards/channels onto a single sink. There is good guidance online for calculating the required thermal resistance of a heat sink but generally these calculations are based on one component being fixed to it. If I combine the boards onto one - how would I account for this?

Transistor orientation doesn't matter, do whatever works best for your assembly. I have them "upside down" in the attached pic.

For what we do, it really is that simple. You may find that a heatsink with half the thermal resistance is more than twice as large because it doesn't get as much cool fresh air over then fins.The sinks with the recommended case are 0.67C/W. If combined is it as simple as ensuring the sink resistance is 0.335C/W or less?

FWIW, my ACAs kits used heatsinks around 0.77°C/W and I'm listening to an earlier prototype that's a bit smaller at ~0.88°C/W.

Another rule of thumb is to aim for a surface temperature under 60°C. The FETs could handle much higher, but that's where it starts to get too hot to touch with bare skin.

Attachments

Following what Eric said, if you need to dissipate a total of 40W, a single heatsink of 0.5 C/W or less would be perfect.

40W x 0.5 therefore a temperature rise of 20 so if your room ambient is 25C your heatsink will be at about 45C, slightly more for the mosfet themselves.

As an idea, a Hafler DH-220 comes with heatsinks of roughly 0.5 C/W

BR

Eric

40W x 0.5 therefore a temperature rise of 20 so if your room ambient is 25C your heatsink will be at about 45C, slightly more for the mosfet themselves.

As an idea, a Hafler DH-220 comes with heatsinks of roughly 0.5 C/W

BR

Eric

Pass DIY Addict

Joined 2000

Paid Member

Follow this link to an image of my 3-ch ACA build on a single 10" by 7" sink.

https://www.diyaudio.com/community/threads/pictures-of-your-diy-pass-amplifier.166784/post-5641306

https://www.diyaudio.com/community/threads/pictures-of-your-diy-pass-amplifier.166784/post-5641306

It’s wise to consider the temp of where the amp is located AND if it is exposed to free air all around. If you don’t have AC and it’s hot, you need more cooling. If you put the amp on a narrow shelf 2’ wide with sidewalls, another shelf a foot above, and against a wall you’ll probably want about twice the heatsink. We love to over spec on a lot of stuff with DIY, it makes sense with heat sinks.

If you direct even a slow moving fan at the sinks, they can easily be twice as efficient or much more!

If you direct even a slow moving fan at the sinks, they can easily be twice as efficient or much more!

Pass DIY Addict

Joined 2000

Paid Member

And now with Mark's comments, the last four people who have replied have a combined experience of more than 70 years of building things here. Keep asking questions, you've got lots of experience here to support you

Absolutely. Thanks, N Brock, e_fortier, Eric, Variac. Great responses - I can confidently move on with my ACA with this.And now with Mark's comments, the last four people who have replied have a combined experience of more than 70 years of building things here.

Could someone please identify the make, model and value of the four transistors currently used in the amp camp amp 1.18 kit? I believe I may have to replace one or two.

Thank you.

Thank you.

I have a question about the possibility of adjusting the ACA circuit so that it is more suited to nominal 4 ohm speakers in monoblock mode? Would this be a matter of different value/wattage resistors, or larger value caps, etc?

- Home

- Amplifiers

- Pass Labs

- Amp Camp Amp - ACA