Now you mention it my pic above could very well be shredded Grana Pardano or Parmesan . . .

The outcome of my sawdusty day may come as no surprise to you Eucy.

455 kg/3M - 3 mm Poplar Ply sounds better , cleaner , Sharper than 1.8 mm Sassafras.

The Sass' was originally stated by Doctor Google as being 495 Kg3M , so i thought it worth a test against the poplar however the Sass' sample provided by Plyco was in fact 695 kg3M .

The difference between the two was like a Hang Drum being played while wearing leather gloves and the other with bare skin.

If you dont try you just never know !

I still have tests with 10 mm EPS to do when i can get the ACT girls to freight me a couple of 600 x 600 sheets.

A work in progress . . .

The outcome of my sawdusty day may come as no surprise to you Eucy.

455 kg/3M - 3 mm Poplar Ply sounds better , cleaner , Sharper than 1.8 mm Sassafras.

The Sass' was originally stated by Doctor Google as being 495 Kg3M , so i thought it worth a test against the poplar however the Sass' sample provided by Plyco was in fact 695 kg3M .

The difference between the two was like a Hang Drum being played while wearing leather gloves and the other with bare skin.

If you dont try you just never know !

I still have tests with 10 mm EPS to do when i can get the ACT girls to freight me a couple of 600 x 600 sheets.

A work in progress . . .

"Well where is everyone?"

Probably losing interest in this thread as it's practically turned into a "how to" for recording instead of actually building panels.

Probably losing interest in this thread as it's practically turned into a "how to" for recording instead of actually building panels.

I was about to call it a night anyway, so this is as good a time as any to pull the plug. It has been a good run, guys. Take it easy.

Hello,

If it can have an interest for somebody...

After a long time on the theoretical approach, I decided to start a new pair based on the use of a 3mm corrugated polypropylene I got recently. The goal is to explore ways I haven't explore for now with the idea to end with a realization that gives decent music.

I learnt from a first measurement cession few thinks I would like to share :

More detail in the attached pdf.

If it can have an interest for somebody...

After a long time on the theoretical approach, I decided to start a new pair based on the use of a 3mm corrugated polypropylene I got recently. The goal is to explore ways I haven't explore for now with the idea to end with a realization that gives decent music.

I learnt from a first measurement cession few thinks I would like to share :

- to make this design different from my previous one, I decided to start with a non rectangular shape, inspired from the Yamaha JA natural sound speaker series. For now, I can't say there is an advantage...

- an other difference from previous design is the material. Polypropylene seems to have the advantage of a good damping given some not too irregular FR. It has probably the drawback of this advantage which is a limited HF extension. Not a problem here, I will test with a tweeter. A question might be to understand if a smaller panel still have this problem (to be confirm by the impedance measurement but the 1st resonance is perhaps unnecessarily low.

- those tests confirm there is little difference between the FR from a logsweep (standard REW measure) and from pink noise with a 1/6 octave RTA. The interesting consequence behind that is the pink noise with RTA is a continous measurement so it is possible to start it, make changes or researches and see immediately the results. This I think is the way Steve use to adjust his panels. Today, it helped to find place to add mass in order to mitigate a 300Hz hump.

- to add mass was already mention in this thread but as far as I remember not in detail in the way to proceed neither in the results. By the way, I just recently understand that most (all?) of the DML commercial realizations have such mass corrections

- even if not used, a tweeter is a good tool to evaluate the efficiency and check the HF extension of the panel.

- the origin of the hump at 2.5kHz was more difficult to find... seems due to what Steve called the exciter noise. In my plywood panels, i thought the origin of sch hump was due to the "too large" exciter fixation I had. Seems not as here, there is only the exciter at the back side. So beware of the rear wave. My intention in the next steps is to see if some solution is possible. At least the today measurements give a method to check the origin of such hump. For now the best countermeasure (only from measure point of view) is to attenuate the rear wave.

- as I need some passive crossover in this application to limit the power going to the panel, I have tested a second order LC filter with the component I had... Not to bad result

More detail in the attached pdf.

Attachments

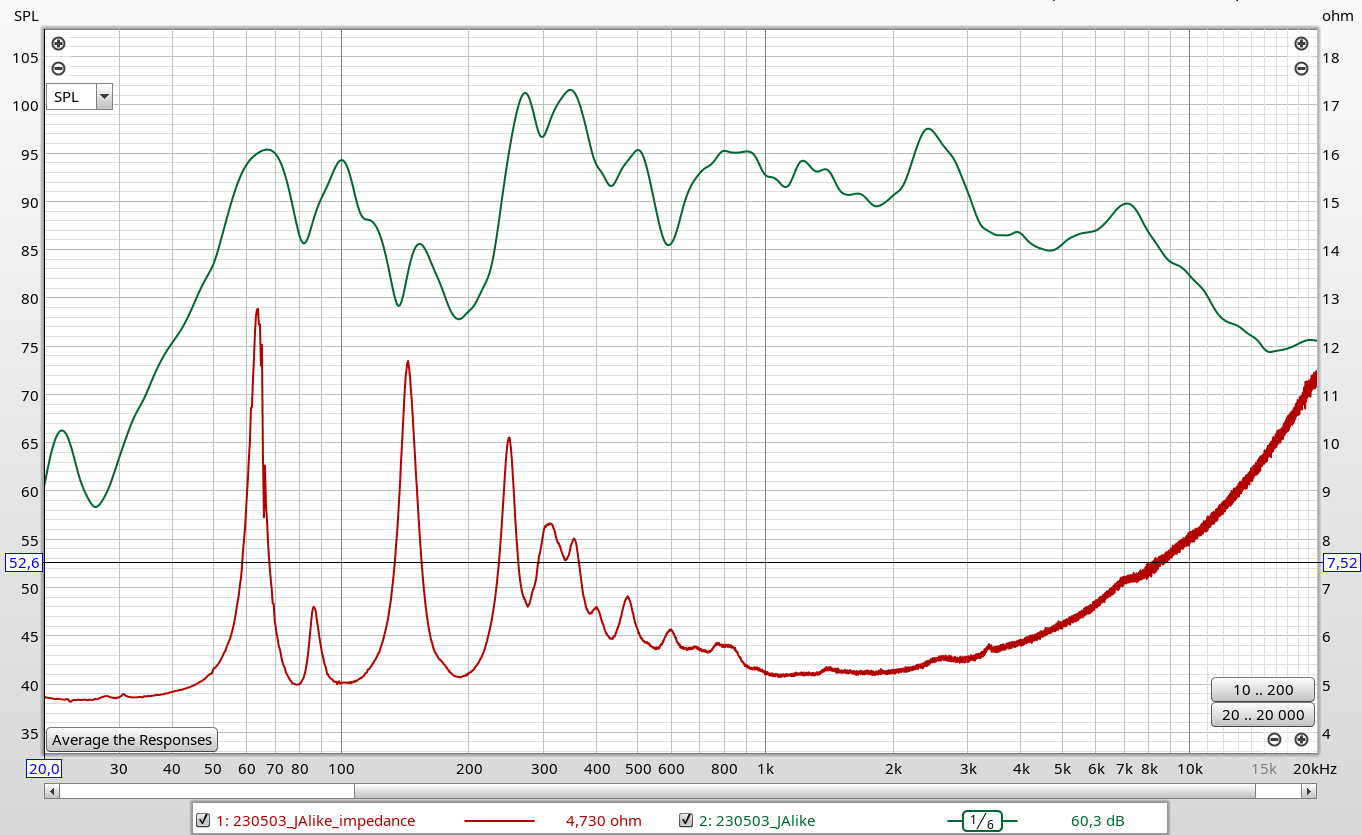

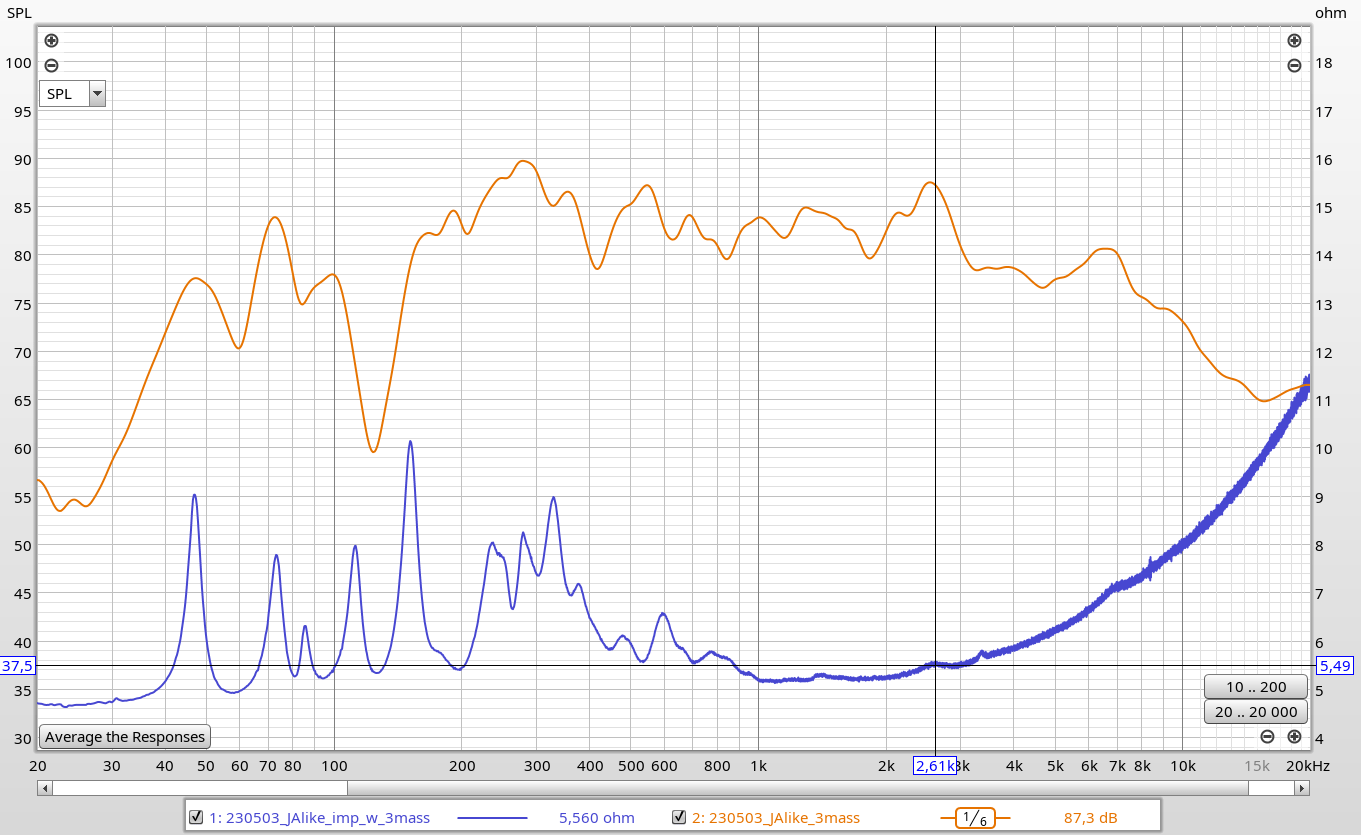

In addition to the yesterday tests, here are 2 impedance measurements (without and with added masses) in regard to the FR.

The added masses shift the modes.

The 2.5/2.6kHz hump is also visible on the impedance curve... Might it be the mini DML made by the spider?

The added masses shift the modes.

The 2.5/2.6kHz hump is also visible on the impedance curve... Might it be the mini DML made by the spider?

Hi Christian.

Thanks for the interesting trial and data.

What mass values did you add, (or did I miss that detail??)

So far, I have completely failed to get anyone to try the coke dome....It's now your turn to be encouraged, even harassed to try it 🤞🙏... Particularly with the PP material, as it does have a 'soft' sound.

It will make a difference to the brightness, and it may also mitigate your 2.5k hump

Another idea I had for PP and have commenced a trial of (suspended until I return home) is this:

At the location of the exciter, I drilled small holes in the rear face into each flute, moving the location of each hole so they don't line up. I then injected PU foam into each hole, and was surprised at how easily and far it spread along the internal flutes (see attached photos) It made a mess on the injection face, but it trimmed off easily when cured.

I haven't had a chance to test this yet but I'm hoping it will assist transfer to the panel and brighten the output.

With a more organised technique, you could even do a whole panel like this with way less mess/wastage. You can see by the changes in shading that the filling was somewhat uneven, but it was a rough first attempt and can be improved if it proves to be worth it.

When I get the chance I'll do a comparison test with an exciter both on and off the treated area

Cheers

Eucy

Thanks for the interesting trial and data.

What mass values did you add, (or did I miss that detail??)

So far, I have completely failed to get anyone to try the coke dome....It's now your turn to be encouraged, even harassed to try it 🤞🙏... Particularly with the PP material, as it does have a 'soft' sound.

It will make a difference to the brightness, and it may also mitigate your 2.5k hump

Another idea I had for PP and have commenced a trial of (suspended until I return home) is this:

At the location of the exciter, I drilled small holes in the rear face into each flute, moving the location of each hole so they don't line up. I then injected PU foam into each hole, and was surprised at how easily and far it spread along the internal flutes (see attached photos) It made a mess on the injection face, but it trimmed off easily when cured.

I haven't had a chance to test this yet but I'm hoping it will assist transfer to the panel and brighten the output.

With a more organised technique, you could even do a whole panel like this with way less mess/wastage. You can see by the changes in shading that the filling was somewhat uneven, but it was a rough first attempt and can be improved if it proves to be worth it.

When I get the chance I'll do a comparison test with an exciter both on and off the treated area

Cheers

Eucy

Attachments

Last edited:

Unfortunately recording and analysis is part of the build engineering."Well where is everyone?"

Probably losing interest in this thread as it's practically turned into a "how to" for recording instead of actually building panels.

Our mind can "think" that we hear things but a recording plotted on a chart does not lie.

I am new to this and i knew zero about recording and charting until a few weeks ago and i do find the science enjoyable.

Eucy , I read your posts way back on the coke can dome and i am surprised at how small a dome you used , Did you do tests on larger coke can domes but find them less suitable or did you feel that you nailed it first up and stuck with that size ?So far, I have completely failed to get anyone to try the coke dome....It's now your turn to be encouraged, even harassed to try it 🤞🙏... Particularly with the PP material, as it does have a 'soft' sound.

It will make a difference to the brightness, and it may also mitigate your 2.5k hump

Cheers

Eucy

I wont use them on my 970 x 600 x 3mm Poplar panels because i want clean visual aesthetics but i will be pairing those panels up with 600 x 600 EPS with speaker cloth covers so the coke dome wont be visible on those , The EPS should have more HF anyway due to the lighter panel mass and smaller 25 mm exciters versus 32 mm on the Poplar.

With all the experience gained since that time what are your thoughts on the dome diameter now ?

thankyou.

Can someone advise if PM's (personal messages) can be exchanged between members here ?

I have gone through account settings on this forum and cant find anything other than the reference to "start a conversation" is that the same as a PM or does that message become a public message on the forum ?

I have gone through account settings on this forum and cant find anything other than the reference to "start a conversation" is that the same as a PM or does that message become a public message on the forum ?

Man I love the way this panel sounds..... uh oh ...... the chart looks like s#!t ..... oh well, I guess I'll throw it out, it cant possibly be any good, why must you lie to me mind.Our mind can "think" that we hear things but a recording plotted on a chart does not lie.

Go with what's most pleasing to your ears, damn the charts. If your going for a studio monitor dml build then chart away.

I think I'll stick with my mind working with my ears to choose what I like to hear, thank you.

And that "my way or the highway" in a nutshell is why people are leaving this thread.

Last edited:

Christian,In addition to the yesterday tests, here are 2 impedance measurements (without and with added masses) in regard to the FR.

I'm curious if the impedance peaks correlate with panel natural frequencies. Did you (or would you) do some tap tasting to find the natural frequencies?

Eric

You can indeed. Click the envelop icon:Can someone advise if PM's (personal messages) can be exchanged between members here ?

Eric

The whole aim of the dome is that it transfers the voice coil movement more directly to the face of the panel, and if course it vibrates as well. So the diameter of the dome should match that of the exciter voice coil.Eucy , I read your posts way back on the coke can dome and i am surprised at how small a dome you used , Did you do tests on larger coke can domes but find them less suitable or did you feel that you nailed it first up and stuck with that size ?

I wont use them on my 970 x 600 x 3mm Poplar panels because i want clean visual aesthetics but i will be pairing those panels up with 600 x 600 EPS with speaker cloth covers so the coke dome wont be visible on those , The EPS should have more HF anyway due to the lighter panel mass and smaller 25 mm exciters versus 32 mm on the Poplar.

With all the experience gained since that time what are your thoughts on the dome diameter now ?

thankyou.

I carefully damp mine at the rear as previously described, but you can also incorporate that in a thin coat on the front to colour the dome to match the panel aesthetics

Eucy

I do a lot of measuring in my process, and it guides a lot of what I do and try. For many reasons. One is because it is more objective than just listening. It's too easy to convince yourself you have made an improvement when you really want to believe it badly enough. And another simple reason is that I try way too many variations to be able to remember what they all sounded like. Having the measurements helps me compare something I tried today with something I tried a year ago. Finally, I think big improvements come from lots of little improvements, and sometime the little improvements are hard to detect by listening. Combine five different improvements and now you've made a difference. But without measuring you may not have realized that any of those five things were improvements at all.Unfortunately recording and analysis is part of the build engineering.

Our mind can "think" that we hear things but a recording plotted on a chart does not lie.

But be careful, measurement charts may not "lie" to you but they can mislead you. Measurements are so sensitive to so many things! Measured frequency response is so sensitive to the precise location of the mic relative to the speaker, and to the location of the mic and speaker in the room, and a million other things, that you have to take every measurement with a very big grain of salt, unless you really know what you are doing. And I'm the first to admit that I don't.

Eric

I would, and do, trust an outfit like GR-Research to test properly because they take the variables out of it by having a fixed room and recording method/tolerance to pretty much guaranteed an A to A comparison.But be careful, measurement charts may not "lie" to you but they can mislead you. Measurements are so sensitive to so many things! Measured frequency response is so sensitive to the precise location of the mic relative to the speaker, and to the location of the mic and speaker in the room, and a million other things, that you have to take every measurement with a very big grain of salt, unless you really know what you are doing. And I'm the first to admit that I don't.

I agree that testing is a good thing and can help to smooth out any outstanding swings in the different ranges, that's just common sense, but if you find a panel and exciter combo that you really enjoy but it doesn't look as flat as others, so what. Sound quality is a subjective thing and that one slight hump in a certain range may be what is doing it for a persons individual taste.

A DML panel is so finicky that just running your finger along the edge during testing would make the chart look like the Rocky Mountains, good luck recreating an A to A test a year later.

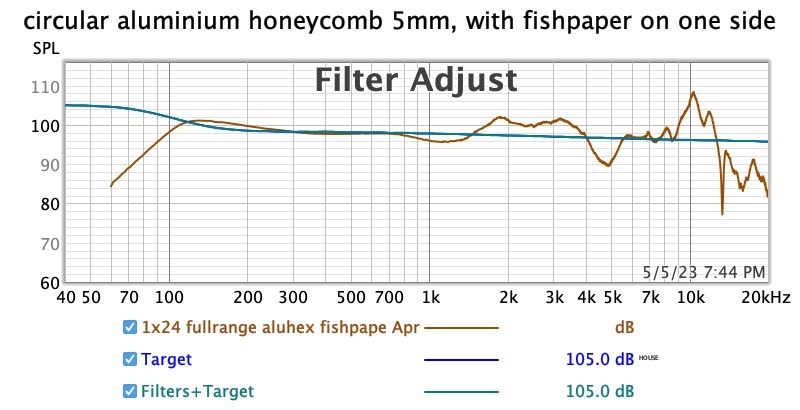

Hi, I have been following this thread for a few months.

I have been on my own material testing journey.

I have recently been able to get great results.

One is with aluminum honeycomb which has fish paper on one side.

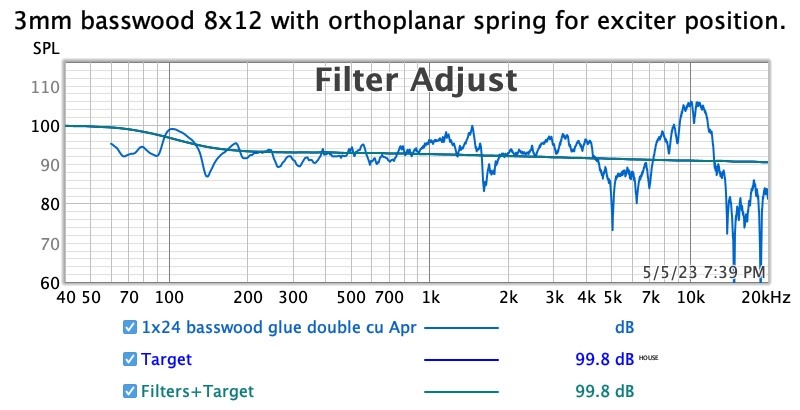

Graph below is with the Dayton calibration mic at 10cm.

I have been on my own material testing journey.

I have recently been able to get great results.

One is with aluminum honeycomb which has fish paper on one side.

Graph below is with the Dayton calibration mic at 10cm.

Attachments

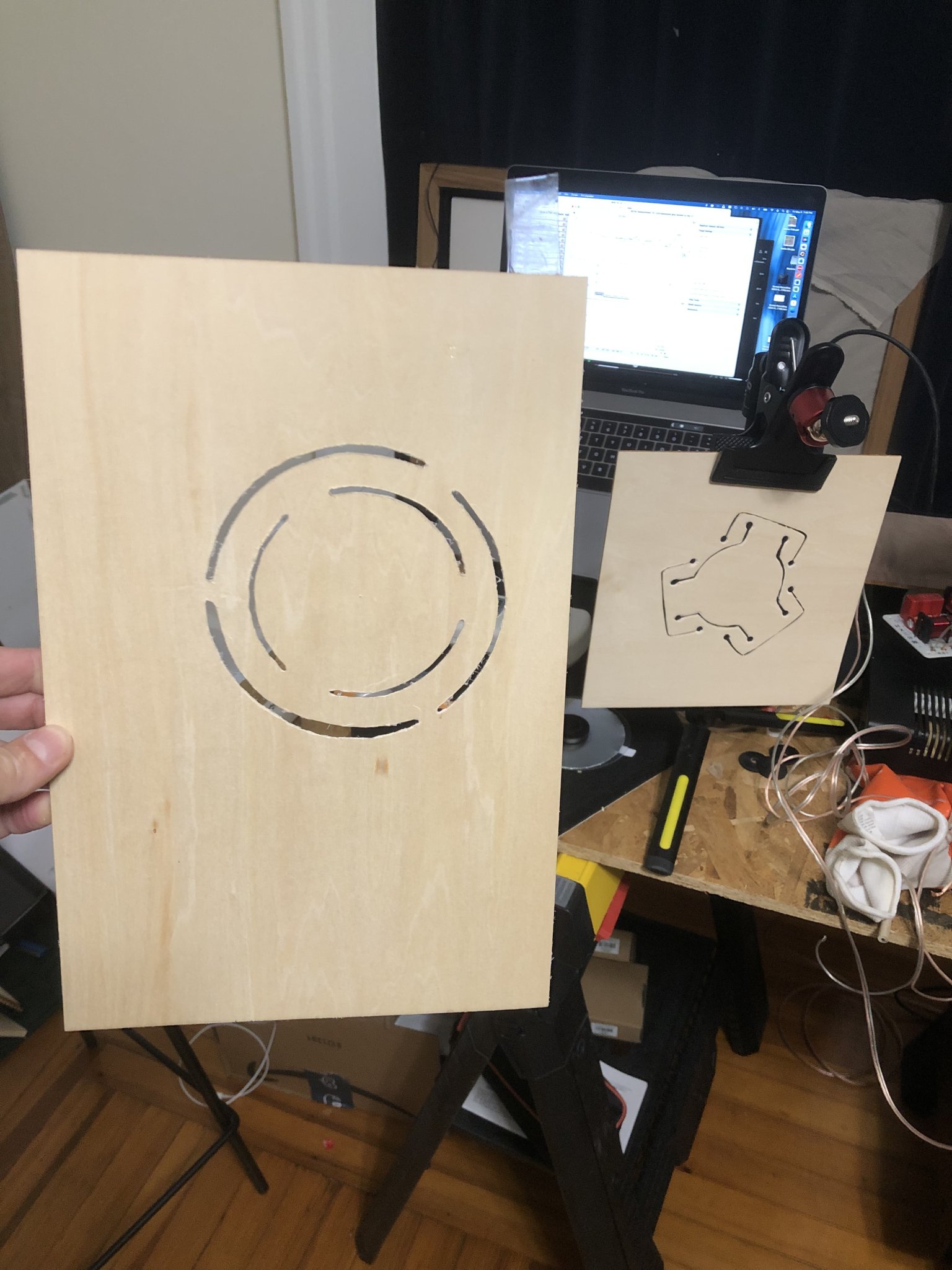

My second and more favorite option for dml panels has been by cutting ortho-planar springs into the board, and then covering it 3mm neoprene.

The neoprene dampens the standing waves very nicely.

I will post a few of those builds next week.

The neoprene dampens the standing waves very nicely.

I will post a few of those builds next week.

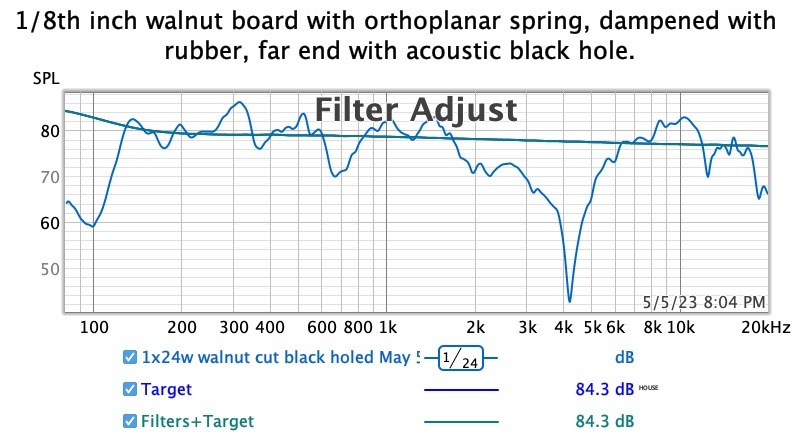

Other ortho-planar springs, this one in heavy 1/8th inch maple, it’s a work in progress - given the crazy dip at 4khz.

I just realized that having a comparison of the board prior to the cuts would be good…

I’ll get some of those shortly

I just realized that having a comparison of the board prior to the cuts would be good…

I’ll get some of those shortly

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker