Okay, how accurate do you need it to be. maybe not accurate. I drill holes for 3mm tap on aluminum heatsinks with a rigid drill press. it certainly works fine when following the proper procedures. it would be nice to have more accuracy just because it would be nice

If you want X size hole and you have bit X with runout the hole will be bigger than X and not symmetrical

If needed, use a x-y system, mark a grid, then at each point, gently punch a depression.

A ground down old bit, even a nail works as a center punch.

Then use a small center drill, start the holes.

Then use the right size drill.

It is used for center holes in machining...

These are center drills. Image off the net, no ties to seller...

It works, and is quite effective.

A ground down old bit, even a nail works as a center punch.

Then use a small center drill, start the holes.

Then use the right size drill.

It is used for center holes in machining...

These are center drills. Image off the net, no ties to seller...

It works, and is quite effective.

Last edited:

I'm little obsessive. I'm looking at this unit. a little expensive but much less than accurate high quality machinists type of equipment.

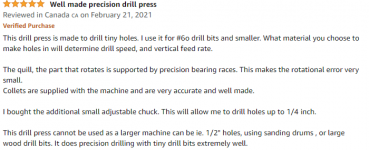

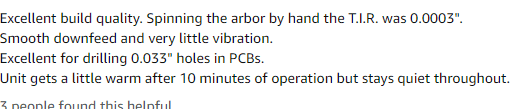

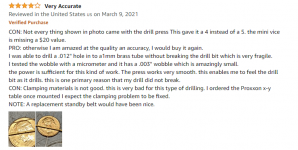

Might be a little small as I would like it to drill heatsink holes to rear panel connector holes for rca's and binding posts. it has some negative reviews but the attached positive reviews indicate it might be what i'm looking for

https://www.amazon.ca/Proxxon-38128-Bench-Drill-Machine/dp/B0017PUR1Y

Might be a little small as I would like it to drill heatsink holes to rear panel connector holes for rca's and binding posts. it has some negative reviews but the attached positive reviews indicate it might be what i'm looking for

https://www.amazon.ca/Proxxon-38128-Bench-Drill-Machine/dp/B0017PUR1Y

Attachments

I bought a WEN 4208T and have been very happy with it.

I've used it to drill various chassis holes as well as heat sinks. Mine has been solid and accurate.

It was about $90 when I bought it in 2020 but it is now $109 on Amazon.

I've used it to drill various chassis holes as well as heat sinks. Mine has been solid and accurate.

It was about $90 when I bought it in 2020 but it is now $109 on Amazon.

I have this one exactly. Out of the box is to be avoided... It's wobbling awfully. But I fixed it with an old bicycle stem - partially hidden behind those aluminum plates. And a wheel quick release for adjusting height. Very accurate now!View attachment 1148524

This is an image off the net, the thing is called a drill stand here, allows the use of a portable drill as a drill press.

There are versions with magnetic bases as well, to drill holes in structures, where a normal drill is too weak.

Price is about $15 or so for the stand here in India.

I do not have any ties to seller, cannot vouch for the quality.

Attachments

About 15 years ago I bought a Jet JDP-12 drill press. It's served me well. I replaced the (garbage) handles it came with with some ball-shaped ones I bought at McMaster-Carr. The depth stop could be better and it could run a bit smoother (the belt tends to cause some vibration) but that aside it's a pretty nice drill press. I certainly feel I got my $300 worth.

Tom

Tom

I'll stick with my Rigid floor press for now and look for more precise drill bits and center drill for heatsink drilling👍

I generally draw the holes on paper using CAD - centre mark, 3mm pilot & full diameter.

I then glue stick the paper to the metal.

Centre pop the marks.

3mm pilot drill first then full size drill.

Having the circles marked on the paper means I can see if the drill has wandered & correct before it's too late.

Patience counts for more than expensive equipment and this system also works for items too awkward to fit under the drill press.

I then glue stick the paper to the metal.

Centre pop the marks.

3mm pilot drill first then full size drill.

Having the circles marked on the paper means I can see if the drill has wandered & correct before it's too late.

Patience counts for more than expensive equipment and this system also works for items too awkward to fit under the drill press.

Do you have a better pic of how you used the bike stem. I have similar stand and it is not great… would be cool to make it useful.I have this one exactly. Out of the box is to be avoided... It's wobbling awfully. But I fixed it with an old bicycle stem - partially hidden behind those aluminum plates. And a wheel quick release for adjusting height. Very accurate now!

I've made a SHARP point on a steel rod that works like a dream.So it comes down to accurately marking the hole for drilling. I’ve used those spring loaded center punches but it’s difficult to get exact center for all holes

Or even a sharpened 3" nail works.

I've got one that's quite powerful and leaves a decent 'crater' to start drilling. For casework I've usually got a paper template stuck (double sided tape) over the metal with accurate crosshairs and it's easy to punch into.So it comes down to accurately marking the hole for drilling. I’ve used those spring loaded center punches but it’s difficult to get exact center for all holes

Expensive, but worth the investment: https://www.mcmaster.com/optical-center-punches/ for accurate centers. Start with a small (1/32") pilot hole and progress from there. Inspect the cutting edges of your drills before using them to avoid disappointments! E

Best I could do. The stem is of the adjustable type -two pieces. One part waits for a light duty lathe project since the stand is now very stable. The other part is attached with a 10mm bolt as shown - aluminum plate, nut, washer, stem, washer, nut, plate. The plates are attached to the stand with small bolts, then everything is aligned and tighten. You may want to control wobbling with the stem's bolts but in my case it wasn't necessary. And a photo of the quick release that makes height adjustment easy.Do you have a better pic of how you used the bike stem. I have similar stand and it is not great… would be cool to make it useful.

Attachments

I bought this model Proxxon new about 5 years ago and still have it in addition to a Dremel drill press stand. The Proxxon is light but solid, very well made for precision modeling, and absolutely worth about half (!!) what they sell for new in my opinion.I'm little obsessive. I'm looking at this unit. a little expensive but much less than accurate high quality machinists type of equipment.

Might be a little small as I would like it to drill heatsink holes to rear panel connector holes for rca's and binding posts. it has some negative reviews but the attached positive reviews indicate it might be what i'm looking for

https://www.amazon.ca/Proxxon-38128-Bench-Drill-Machine/dp/B0017PUR1Y

The good news is that they sell used for about $125 US on the auction site fairly regularly. At $125 it is a reasonable value for a good condition example.

Good tip, thanks. I've been using clear box tape.glue stick the paper to the metal

My spring loaded centre punches are all too rando. Switched to a sharpened pointer followed by a hammer struck centre punch. All placed with a magnifying glass.

- Home

- Design & Build

- Equipment & Tools

- Small drill press