Very interesting! No cap in the signal path this way. How about using AC filament instead?Sorry for my crude hand drawing - I am posting from my cell phone.

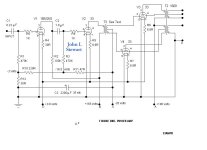

The input is 10-step autotransformer attenuator, followed by transformer phase splitter. The 3D6s are independently biased by Li-ion cells whose voltage can be finely adjusted from 3.2 to 4.0 V. 3D6 filaments (connected parallel) are powered by a NiMH cell, which is automatically recharged when the amplifier is off (charger and it's connection are not shown). Filament battery switch is ganged with power switch. The choke between primary CT and B+ serves as CCS, ensuring strict Class A differential operation. The choke is sectionally wound (to reduce winding capacitance) on 2-bobbin nanocrystalline C-core; it is a custom job. Solid state CCS can be used instead, but choke sounds better. Depending on the source signal level, the output power is 50-100 mW. The amplifier is intended for the Sennheiser HD650 phones.

3D6 has interesting filament - two closely spaced parallel strands. When the filament is powered with 3 VAC, its halves are in opposite phase, so there is very little modulation of tube's Gm. So, yes, this particular tube can be used with AC filament, especially in PP. I powered filaments from center-tapped 3 VAC winding, center tap grounded, and there was no hum audible on headphones.Very interesting! No cap in the signal path this way. How about using AC filament instead?

That’s good to know. Thanks for sharing! What’s Mu of 3D6 in triode operation?3D6 has interesting filament - two closely spaced parallel strands. When the filament is powered with 3 VAC, its halves are in opposite phase, so there is very little modulation of tube's Gm. So, yes, this particular tube can be used with AC filament, especially in PP. I powered filaments from center-tapped 3 VAC winding, center tap grounded, and there was no hum audible on headphones.

Mu about 9 timesThat’s good to know. Thanks for sharing! What’s Mu of 3D6 in triode operation?

Then plate resistance is close to 4k ohm per tube. I wonder what would be the optimal load? Would it be better to go for higher than 8k ohm for the differential circuit?Mu about 9 times

Then plate resistance is close to 4k ohm per tube. I wonder what would be the optimal load? Would it be better to go for higher than 8k ohm for the differential circuit?

Minimum load is about 10 K P-P, but the higher the better. Less distortion with higher output impedance, and for headphone power doesn't matter. My output transformer is 15 K two plates to line.

An alternative to additional voltage amplifying stage is a good quality step-up transformer in place of 1:1 input transformer.

An alternative to additional voltage amplifying stage is a good quality step-up transformer in place of 1:1 input transformer.

Thanks! What I am thinking is to add a SE DHT pre and use 2-3 times of load in the 3D6 differential amp.Minimum load is about 10 K P-P, but the higher the better. Less distortion with higher output impedance, and for headphone power doesn't matter. My output transformer is 15 K two plates to line.

An alternative to additional voltage amplifying stage is a good quality step-up transformer in place of 1:1 input transformer.

Forgot to ask, do you use 1 transformer 1 winding shared by two 3D6 tubes? Or each tube uses a separate winding? Thanks.3D6 has interesting filament - two closely spaced parallel strands. When the filament is powered with 3 VAC, its halves are in opposite phase, so there is very little modulation of tube's Gm. So, yes, this particular tube can be used with AC filament, especially in PP. I powered filaments from center-tapped 3 VAC winding, center tap grounded, and there was no hum audible on headphones.

AC filament supply (CT winding/center tap grounded) works for these tubes in SE circuit without noise issue too?

Any recommendation for tube socket that fits 3D6 easily? The few loctal 8-pin sockets I bought don’t seem to work.

What did you buy? I have had some Chinese ceramic ones and they can be a tight fit but were OK in the end. I bought a load of NOS wafer style ones to make a tube adaptor on an Octal base, and they have been excellent (though no one likes them here). Otherwise the best source is auction sites and NOS.

I bought the Chinese ceramic ones from ebay. That seems to be too tight - I could try harder, but am afraid that I will break the tube.

I also bought the russian ones for 4P1L - they were too loose.

I also bought the russian ones for 4P1L - they were too loose.

Yes, here is what I did with three of 33s & a 1B5 about 20 yrs ago.Could 3D6 be used in a two-stage amp with another DH tube (let’s say 1J24 or maybe 3A5) in the first stage?

Same thing could be done with three of 3D6 with or without a first stage,

Attachments

I have read here that the pin 'holders' (is that the right word?) can be 'eased' with a suitable size small drill, for example.I could try harder, but am afraid that I will break the tube

I use only American or Russian NOS sockets. With little patience can buy them on eBay. Prices tend to be high, but worth the expense. I had too many problems with new production sockets.

Are the russian and american loctals the same spacing? I'm a little unclear on the specifications.

I'm using 2P29L's and using the chinese ceramic ones. They were super duper tight, but I removed the metal spring thingy in the socket, and works perfectly now.

I was also thinking of trying out these 3D6's myself, in a line stage

I'm using 2P29L's and using the chinese ceramic ones. They were super duper tight, but I removed the metal spring thingy in the socket, and works perfectly now.

I was also thinking of trying out these 3D6's myself, in a line stage

Last edited:

- Home

- Amplifiers

- Tubes / Valves

- 3D6 headphone amplifier