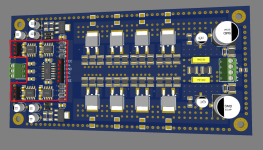

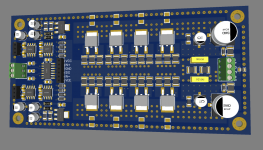

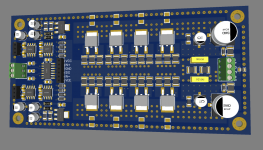

I'll use Vishay ThermaWick to transfer heat from the transistors to the chassis gnd pour & mouting holes. https://www.mouser.co.uk/datasheet/2/427/VISH_S_A0010295278_1-2571075.pdf

Added

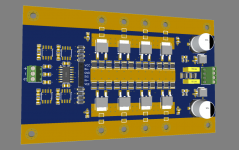

1). ThermaWick to transfer heat to the outer copper pours on top and bottom layers. These wick heat out to the four mounting holes (chassis gnd) too.

2). 6pin header to access input signal before it connects to the THAT1646s. Allows for "crossover boards" or additional filtering here. Both polarities exposed from the "SuperBal" input on the header.

3). Headers for offboard Vbe sensor boards.

1). ThermaWick to transfer heat to the outer copper pours on top and bottom layers. These wick heat out to the four mounting holes (chassis gnd) too.

2). 6pin header to access input signal before it connects to the THAT1646s. Allows for "crossover boards" or additional filtering here. Both polarities exposed from the "SuperBal" input on the header.

3). Headers for offboard Vbe sensor boards.

I would make provisions to also use a DRV134.

The DRV134 requires a voltage divider between the Vbe multiplier and pin 4 because it has a differential gain of "4" versus a gain of "2" for the 1646.

The DRV134 has better clipping behavior in the "common mode drive" configuration.

The 1646 is an excellent line driver in its "normal" application and a great headphone amp for mid-to-high sensitivity headphones but in an application in which it might clip, such as this one, I think you'll be happier with the DRV134.

When I was making headphone amps with this topology I built mine with DRV134s. My current headphone amp, the DCAO-II, uses op amps to emulate the 1646/DRV134.

The peak current you'll need will require a high Iq to maintain class-A. I honestly don't think you'll be able to get the heat out. My 10W amp used massive heatsinks.

I would also put the Vbe multiplier sense transistor in the middle of the output array and use the same type/geometry.

The DRV134 requires a voltage divider between the Vbe multiplier and pin 4 because it has a differential gain of "4" versus a gain of "2" for the 1646.

The DRV134 has better clipping behavior in the "common mode drive" configuration.

The 1646 is an excellent line driver in its "normal" application and a great headphone amp for mid-to-high sensitivity headphones but in an application in which it might clip, such as this one, I think you'll be happier with the DRV134.

When I was making headphone amps with this topology I built mine with DRV134s. My current headphone amp, the DCAO-II, uses op amps to emulate the 1646/DRV134.

The peak current you'll need will require a high Iq to maintain class-A. I honestly don't think you'll be able to get the heat out. My 10W amp used massive heatsinks.

I would also put the Vbe multiplier sense transistor in the middle of the output array and use the same type/geometry.

Last edited:

I would make provisions to also use a DRV134.

The DRV134 requires a voltage divider between the Vbe multiplier and pin 4 because it has a differential gain of "4" versus a gain of "2" for the 1646.

The DRV134 has better clipping behavior in the "common mode drive" configuration.

The 1646 is an excellent line driver in its "normal" application and a great headphone amp for mid-to-high sensitivity headphones but in an application in which it might clip, such as this one, I think you'll be happier with the DRV134.

When I was making headphone amps with this topology I built mine with DRV134s. My current headphone amp, the DCAO-II, uses op amps to emulate the 1646/DRV134.

The peak current you'll need will require a high Iq to maintain class-A. I honestly don't think you'll be able to get the heat out. My 10W amp used massive heatsinks.

I would also put the Vbe multiplier sense transistor in the middle of the output array and use the same type/geometry.

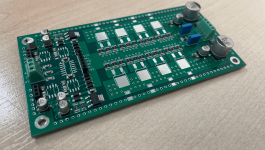

Thanks for the input! I’ve just finished the crossover sub board. It’s a high pass with a shelving filter and a notch - two OPA1602 parts. I have a plan for the heat. 😁

https://www.3m.co.uk/3M/en_GB/novec-uk/applications/immersion-cooling/

I’ve also made provision in v2 for a screw down copper AMD Opteron 1U heat sink

Cool project! If you can make single layer board on aluminum IMS substrate, you can heatsink the whole PCB for massive dissipation. Use of 0R resistor jumpers may be needed to cross traces when going single layer. IMS boards cost the same as FRP boards now at JLCPCB. They even make them in green mask vs the ugly white usual IMS board masks. I have a Class A headphone output stage on aluminum now. Just bolt it to metal plate for good heatsinking.

Now that’s a plan!!Cool project! If you can make single layer board on aluminum IMS substrate, you can heatsink the whole PCB for massive dissipation. Use of 0R resistor jumpers may be needed to cross traces when going single layer. IMS boards cost the same as FRP boards now at JLCPCB. They even make them in green mask vs the ugly white usual IMS board masks. I have a Class A headphone output stage on aluminum now. Just bolt it to metal plate for good heatsinking.

Still waiting for my batch of THAT1646 from Mouser. Should be here Monday. In the mean time I'm working on the firmware for my little CS43131 board. Struggling with bits. https://www.diyaudio.com/community/...dual-mono-dac-on-a-dip-24.384692/post-7003911

Last edited:

Thanks! I have a set of boards that await testing....Really glad to see more SMD in DIY!

I´m following your project!

This is very cool indeed! I was unaware of thermal jumpers until now 🙂

What was your final schematic?

What was your final schematic?

Yeah, they are a super good way to redirect heat to screw holes / chassis mounts.This is very cool indeed! I was unaware of thermal jumpers until now 🙂

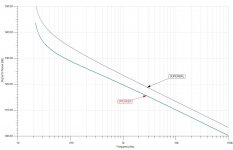

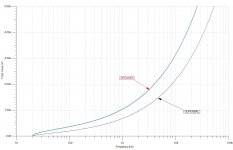

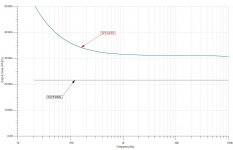

I'll release final schematic once done and tested. I have a feeling my routing is pretty dire. Here's the quad DRV134 Tina-TI file. I think this was the latest.

Attachments

Last edited:

- Home

- Amplifiers

- Headphone Systems

- SMD Class A Headphone Amp (THAT1646)