I guess that's the point I was making. You have to experience the problems as they come up and often we're unwittingly avoiding them, simply because were doing a number of things differently at the same time. Anyways, BJTs in class AB can produce low distortion with as little as 35 mA (Emitter Follower) or even 10 mA bias for complementary feedback or Quasi-complementary pairs). That means they can run much cooler than mosfets in similar applications and partly why the heatsink of NAD's 3020 models is effectively so small and simple, much like the basic, entry level Japanese amps of the 1960-70s.

Just for interest, I cranked up my little Naim clone that has look-alike MT200 size semis mounted in one of those little extruded aluminium shoebox style cases. It's just been playing bearably loud for half an hour but the case (i.e heatsink) is still virtually at room temperature which, here in Oz, was a midwinter 15C. For comparison, I have a little Creek Audio 4330 clone which is hex-mosfet and the chunky external heatsink is as hot as I can bear within 20 mins. It dissipates near 20W/channel just idling - ouch! Which sounds best though? I have to admit, the cool-running Naim clone sounds nicer by a country mile but that's only my impression

So, I'm not suggesting that everyon'e Mosfet amp should be roasting but they do require significantly more bias current to be in their sweet spot and consequently more heatsinking than BJTs in typical configurations. I've been building latfet amps since 1980 and I think I know by now, the sound of "mosfet mist" when bias is insufficient. It's often accompanied by a steely, hard edge to the midrange that to my ears, dulls the stereo image and renders even fine orchestral music as much an irritation as a pleasure.

Just for interest, I cranked up my little Naim clone that has look-alike MT200 size semis mounted in one of those little extruded aluminium shoebox style cases. It's just been playing bearably loud for half an hour but the case (i.e heatsink) is still virtually at room temperature which, here in Oz, was a midwinter 15C. For comparison, I have a little Creek Audio 4330 clone which is hex-mosfet and the chunky external heatsink is as hot as I can bear within 20 mins. It dissipates near 20W/channel just idling - ouch! Which sounds best though? I have to admit, the cool-running Naim clone sounds nicer by a country mile but that's only my impression

So, I'm not suggesting that everyon'e Mosfet amp should be roasting but they do require significantly more bias current to be in their sweet spot and consequently more heatsinking than BJTs in typical configurations. I've been building latfet amps since 1980 and I think I know by now, the sound of "mosfet mist" when bias is insufficient. It's often accompanied by a steely, hard edge to the midrange that to my ears, dulls the stereo image and renders even fine orchestral music as much an irritation as a pleasure.

yep i get that, and you guys would know by experience far more than i probably ever will, so i take on board what you have said and will monitor it closelyI guess that's the point I was making. You have to experience the problems as they come up and often we're unwittingly avoiding them, simply because were doing a number of things differently at the same time. Anyways, BJTs in class AB can produce low distortion with as little as 35 mA (Emitter Follower) or even 10 mA bias for complementary feedback or Quasi-complementary pairs). That means they can run much cooler than mosfets in similar applications and partly why the heatsink of NAD's 3020 models is effectively so small and simple, much like the basic, entry level Japanese amps of the 1960-70s.

Just for interest, I cranked up my little Naim clone that has look-alike MT200 size semis mounted in one of those little extruded aluminium shoebox style cases. It's just been playing bearably loud for half an hour but the case (i.e heatsink) is still virtually at room temperature which, here in Oz, was a midwinter 15C. For comparison, I have a little Creek Audio 4330 clone which is hex-mosfet and the chunky external heatsink is as hot as I can bear within 20 mins. It dissipates near 20W/channel just idling - ouch! Which sounds best though? I have to admit, the cool-running Naim clone sounds nicer by a country mile but that's only my impression

So, I'm not suggesting that everyon'e Mosfet amp should be roasting but they do require significantly more bias current to be in their sweet spot and consequently more heatsinking than BJTs in typical configurations. I've been building latfet amps since 1980 and I think I know by now, the sound of "mosfet mist" when bias is insufficient. It's often accompanied by a steely, hard edge to the midrange that to my ears, dulls the stereo image and renders even fine orchestral music as much an irritation as a pleasure.

There will be other options available, but it will mean a new build heatsink from scratch to try and fit in with that very small footprint, and maybe even a mod with a heatsink or case fan, but i think that would look a bit silly and would take a bit more development, especially when it came to what temperatures the fan would be trigged by 👍

If that anodized alumimium section were cheap enough, I'd be tempted to cut lengths of it or something similar which, with the fins aligned vertically, were still well within the height limit inside the case. Bolt them with only a smear of conductive type heatsink compound between, to the "L" backplate and maybe add a very thin spray of coloured lacquer to just the cut edge, for looks. Avoid coating other surfaces as it only slows heat transfer to the air.

I think you're quite right about fans and further complexity. When you decide to sell, they become another potential liability too.

I think you're quite right about fans and further complexity. When you decide to sell, they become another potential liability too.

Turn on time tomorrow👍Eh 😀 Is it getting to be nearly turn on time.

So initial turn on and I've got a realy bright lamp so I'm going to re chack everything. Not that I haven't already but I'll do it again

I've got 800mv on each of the speaker terminals. Now the centre voltage was 0v to start with because I checked it. I've checked all the new connections and they are correct so I'm not sure why the lamp is on

So initial turn on and I've got a realy bright lamp so I'm going to re chack everything. Not that I haven't already but I'll do it again

Check the voltage between the two gates of the FET's. It needs to be zero initially and this depends on the bias generator and the preset adjustment..

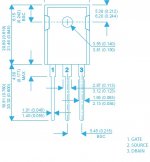

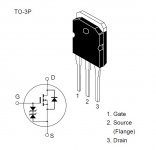

I’d be wondering about those kluge connections on the back side of the board - as to why they were needed. Gate needs a stopper for sure, but every mosfet I’ve fooled with went GDS, which fits BCE basing without rewiring. Unless things were physically reversed wouldn’t they go the same way as the TIPs you used on the last one?

Lateral FET's are the odd ones out and that fact is good for identifying fakes such as IRF's rebranded as LatFet's.but every mosfet I’ve fooled with went GDS, which fits BCE basing without rewiring. Unless things were physically reversed wouldn’t they go the same way as the TIPs you used on the last one?

I think its fair to say the swap went fine electrically but I know one channel of the NAD put up a fight with some odd problems 😉

Give it a really good listen to now, let the music flow.

Give it a really good listen to now, let the music flow.

- Home

- Amplifiers

- Solid State

- NAD 3020 Series 20 mk-3 MOSFET Output Conversion