You pay 2k for an amplifier just to listen to 2 5cent diodes, tantalums are good, bloody good...if you know what i mean 😛

Last edited:

Hi

I bought a clone 2-channel nap200 populated board from TB and they had omitted the 2 diodes in reverse across the +/- rails (RHS of schematic).

What are these diodes for and is the omission OK? Can I use, say, 1N4148 in that position?

They have also omitted the Baxadall diode. Is this a critical omission in terms of the 'Naim' sound?

I bought a clone 2-channel nap200 populated board from TB and they had omitted the 2 diodes in reverse across the +/- rails (RHS of schematic).

What are these diodes for and is the omission OK? Can I use, say, 1N4148 in that position?

They have also omitted the Baxadall diode. Is this a critical omission in terms of the 'Naim' sound?

add it, you can use 1n4007 or like that.Hi

I bought a clone 2-channel nap200 populated board from TB and they had omitted the 2 diodes in reverse across the +/- rails (RHS of schematic).

What are these diodes for and is the omission OK? Can I use, say, 1N4148 in that position?

They have also omitted the Baxadall diode. Is this a critical omission in terms of the 'Naim' sound?

Those are so-called "flying catch" diodes which in theory, catch or short any reverse current peaks and glitches generated in the speaker + crossover network, before they enter the feedback loop and cause trouble. Use the higher rated diode specified. These aren't really essential but don't affect SQ and offer a little safety and assurance that your amp will live through some types of accidental disasters. 'Easy enough to tack them on the underside of the board.

You can add the little 1N4148 and a resistor to reinstate the Baxandall diode in that cheaped-out board, if you really want to use it and still have a proper clone. Otherwise, it won't really be a Naim clone.

You can add the little 1N4148 and a resistor to reinstate the Baxandall diode in that cheaped-out board, if you really want to use it and still have a proper clone. Otherwise, it won't really be a Naim clone.

The Baxandall diode is important for approximating a complementary output stage. I expect that omitting it will sound worse and will affect bias adjustment.

The 1N4148 is usually used; it isn’t optimum but that’s another story.

The 1N4148 is usually used; it isn’t optimum but that’s another story.

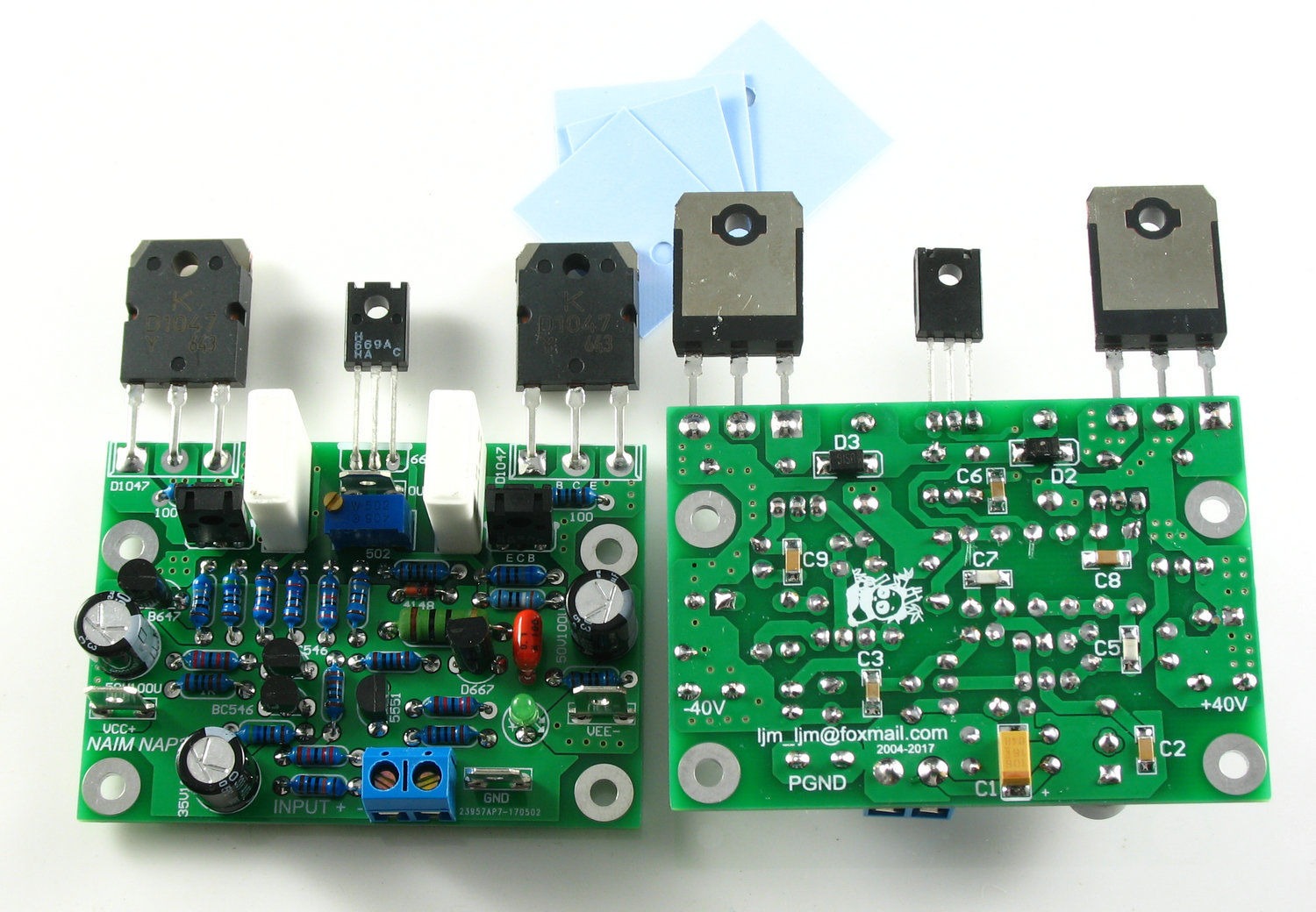

I was having another look at the LJM version of the nap250. AT a glance, the component count seems reduced so my guess is that he has omitted the protection circuit. The transistor count seems to indicate that but there is this odd looking transistor that he placed on top, supposedly to sit on the same heatsink as the output transistors.

The transistors in the typical NAP schematic seems to go in pairs. Any idea why is it 5+1 instead of 6 TO92 (?) in this version?

The transistors in the typical NAP schematic seems to go in pairs. Any idea why is it 5+1 instead of 6 TO92 (?) in this version?

It's an LJM adaptation (lower power, no regulators or current limiters, as you suggest) version of The NAP 250 design. LJM though, is a real engineer and a good audio designer who knows how to achieve excellent performance within the scope of the cheap parts and PCBs available to Chinese kitsellers. I like a number of his kit designs better than most other kits, which often prove to be poorly designed junk. Of course, if you assemble something yourself, the parts and build quality are still your responsibility because cheap kits contain only low cost items.

What you wind up with is something like NAP140 without much Pace, Rhythm, timing sound effect. 'Not bad sound quality but not as engaging as the original product. If we could build high-end gear for the cost of an assembled kit though, we'd be richer than you can imagine.

What you wind up with is something like NAP140 without much Pace, Rhythm, timing sound effect. 'Not bad sound quality but not as engaging as the original product. If we could build high-end gear for the cost of an assembled kit though, we'd be richer than you can imagine.

Last edited:

Since you asked about the number of TO92 transistors, don't forget that the D669 transistor, shown as mounted between the power transistors, will also be bolted to the heatsink in this build, since it's more reliable and easier to fit that way rather than fiddle about with clamps, heatsink grease or big holes for TO92 size transistors, in order to maintain thermal sensing of the output transistors. It's often called the Vbe multiplier because it multiplies their Vbe variation with temperature and this output is used to regulate bias current and thus prevent thermal runaway and disaster.

Last edited:

In the original design Vereker relied on the ambient temp inside the closed, heavy aluminum enclosure to allow the Vbe multiplier to thermally track the output devices.

it's a "Naim like" but definitely nothing to do with a Naim.

There are really two ways of seeing things, either we start with an amp that produces "a sound", or we start with a clone and there it takes work and ideally, to have the original product to compare , I chose the second way, and I kept the clone and sold the original to finance other projects.

something also to know about Naim from the Vereker era is that they only really work well with a Naim preamp, it's the only way to approach the original, and yet I I've tried preamps, but nothing to do, it only really works well with a full Vereker design.

Must be a reason for this that escapes me, it's just an observation after months of testing.

this is one of the few amps that has remained at home and that I always take so much pleasure in putting back into service.

There are really two ways of seeing things, either we start with an amp that produces "a sound", or we start with a clone and there it takes work and ideally, to have the original product to compare , I chose the second way, and I kept the clone and sold the original to finance other projects.

something also to know about Naim from the Vereker era is that they only really work well with a Naim preamp, it's the only way to approach the original, and yet I I've tried preamps, but nothing to do, it only really works well with a full Vereker design.

Must be a reason for this that escapes me, it's just an observation after months of testing.

this is one of the few amps that has remained at home and that I always take so much pleasure in putting back into service.

Putting the Vbe multiplier on the heatsink seems odd to me, because on a CFP output stage, you want the bias to track the drivers, not the output transistors.

Well, the other half is an EF, so it's like picking the optimum bias: there's no good answer. Maybe that's why Vereker used ambient temp. 😉

I've watched maybe 60 NAP clones assembled and scratch-built in almost every possible way. Some attempts at assembly were headed for disaster before the first solder joint because the teenagers assembling them had no clue about electronics or soldering to PCBs, prototyping boards etc. until they had finished the projects anyway.

The point about that intro is that some bias control arrangements that looked hopeless, actually worked well over a comfortable range of indoor temperature and vice versa for what we assumed were technically better arrangements.

Points to bear in mind that get mentioned here periodically, are:

The air inside the box is warmed initially by the power transistors, then by the chassis or a heat spreader plate they are bolted to, which shares the transfer of heat that flows out progressively slower as the area increases over a widening front. It's a slow process because the bias current and hence heating power, is so small. Only around 20 mA current is flowing through each pair of output transistors, as required for lowest THD. Driver current and dissipation is negligible in typical home use and MJE243/253 drivers could be run without their tiny heatsinks IMV. A glance at NAP90 and early Naits shows only tiny E-line driver transistors so let's maintain a sense of proportion about the heat contribution there.

Warming can be sped up considerably by bringing the Vbe multiplier into closer proximity with the output stage than it was originally sited, in the middle of the PCB and taking forever to normalise. Essentially, all Naim did was flip the transistors to the underside of the PCB and closer to the heatsink, being the bottom cover plate and somewhat closer to the output stage, which by now had the power transistors laying in a slot cut in the PCB and clamped or bolted to the bottom plate. Plenty of clearance between the plate and board is necessary with a larger, single board model like NAP200, as the bottom may flex in careless handling and foul the transistor, or even smash it into the board. Naim were assembling midrange models this way from the olive and black front series on but they worked it out well, even incorporating vibration isolating pads.

I'm aware that many people think you can just crank up bias until the power transformer's fuse blows and it will just sound better and better but no, this isn't class A or a wobbly EF output stage. Quasi-comp. designs work and sound quite well at only a whisker over optimum CFP current. If your quasi amplifier actually sounds better with high bias but doesn't have thermal runaway problems, it must be a diabolic old design with other unresolved issues.

The point about that intro is that some bias control arrangements that looked hopeless, actually worked well over a comfortable range of indoor temperature and vice versa for what we assumed were technically better arrangements.

Points to bear in mind that get mentioned here periodically, are:

The air inside the box is warmed initially by the power transistors, then by the chassis or a heat spreader plate they are bolted to, which shares the transfer of heat that flows out progressively slower as the area increases over a widening front. It's a slow process because the bias current and hence heating power, is so small. Only around 20 mA current is flowing through each pair of output transistors, as required for lowest THD. Driver current and dissipation is negligible in typical home use and MJE243/253 drivers could be run without their tiny heatsinks IMV. A glance at NAP90 and early Naits shows only tiny E-line driver transistors so let's maintain a sense of proportion about the heat contribution there.

Warming can be sped up considerably by bringing the Vbe multiplier into closer proximity with the output stage than it was originally sited, in the middle of the PCB and taking forever to normalise. Essentially, all Naim did was flip the transistors to the underside of the PCB and closer to the heatsink, being the bottom cover plate and somewhat closer to the output stage, which by now had the power transistors laying in a slot cut in the PCB and clamped or bolted to the bottom plate. Plenty of clearance between the plate and board is necessary with a larger, single board model like NAP200, as the bottom may flex in careless handling and foul the transistor, or even smash it into the board. Naim were assembling midrange models this way from the olive and black front series on but they worked it out well, even incorporating vibration isolating pads.

I'm aware that many people think you can just crank up bias until the power transformer's fuse blows and it will just sound better and better but no, this isn't class A or a wobbly EF output stage. Quasi-comp. designs work and sound quite well at only a whisker over optimum CFP current. If your quasi amplifier actually sounds better with high bias but doesn't have thermal runaway problems, it must be a diabolic old design with other unresolved issues.

I was reminded by a recent post in another thread that was defending Naim's choice of DIN standard signal cable connectors. It seems the different system impedances and grounding are not sufficiently compatible if you simply substitute the connector(s) of one system (typically RCA type) to allow it to connect the other (DIN std. 45332 or 41524, for example). If the amplifier input impedance were redesigned to match true RCA or at least Naim's own RCA compatible connectors impedance, the match could sound appreciably better.it's a "Naim like" but definitely nothing to do with a Naim.......

.......something also to know about Naim from the Vereker era is that they only really work well with a Naim preamp, it's the only way to approach the original......Must be a reason for this that escapes me, it's just an observation after months of

I have only adjusted impedance on a Nain clone a couple of times for testing, so I couldn't say what the problems and limitations are so you could need to do some circuit analysis before hacking into the input stage circuits. I'd certainly be interested to see/hear how you fare though.

This is Naim's official story & justification for fitting up to 3 different 5 pin DIN signal connector types, some being for other purposes: https://community.naimaudio.com/t/why-naim-use-din-connectors/63

Last edited:

I think that Richard Dane article is largely complete bollocks. I reckon Naim used DIN connectors mostly because they were cheaper than using multiple RCAs. It also created an Apple-style incompatibility with other brands.

Good day this is bad clone 🙂)) because China boys use of ceramic caps in all boardI was having another look at the LJM version of the nap250. AT a glance, the component count seems reduced so my guess is that he has omitted the protection circuit. The transistor count seems to indicate that but there is this odd looking transistor that he placed on top, supposedly to sit on the same heatsink as the output transistors.

The transistors in the typical NAP schematic seems to go in pairs. Any idea why is it 5+1 instead of 6 TO92 (?) in this version?

View attachment 1062717

- Home

- Amplifiers

- Solid State

- NAP-140 Clone Amp Kit on eBay