I have found the exact same thing with regard to cathode bypass. Anything you do there has a large impact on the sound. Fixed bias with cathode grounded sounds best to me. Sometimes, it is unavoidable though and in that case Wima and co. to the rescue.

WoW! Just look at their description of the audio qualities of these capacitors. We should all settle for these! Right?

● Due to the silk fiber's pliability, the capacitor makes a dream of the high quality sound. For examples ;

● To relieve the music's vibration energy.

● To decrease the peak feeling sound at high compass and rough quality sound at middle compass.

● To increase massive sound at low compass.

● Due to the silk fiber's pliability, the capacitor makes a dream of the high quality sound. For examples ;

● To relieve the music's vibration energy.

● To decrease the peak feeling sound at high compass and rough quality sound at middle compass.

● To increase massive sound at low compass.

https://www.partsconnexion.com/Jupiter-cosmos.htmlECap selection and evaluation is always entertaining and sometimes enlightening like I have never heard of Jupiter branded parts

But you have only touched on a few types to evaluate, so it’s kind of limited as far as recommendations go.

Hi, you mean actual alligator terminated test leads were involved, or you just used alligators to press hold capacitor legs directly on the circuit points?The capacitors were alligator clipped in and out for relatively fast comparison of two different types.

Hi, you mean actual alligator terminated test leads were involved, or you just used alligators to press hold capacitor legs directly on the circuit points?

Alligator clip test leads were used from the circuit connection points to the positive / negative terminals of the capacitor for the sake of swapping parts quickly.

LEDs do have a dynamic resistance. Thus they can also be AC bypassed with a capacitor. But maybe larger in uF value. Try that. I had in the past.I subsequently A-B compared the Jupiter in the same circuit vs. a series of LEDs

Oops! Parasitic inductance and parasitic resistance were added. How long were the alligator test leads?Alligator clip test leads were used from the circuit connection points to the positive / negative terminals of the capacitor for the sake of swapping parts quickly.

Rick, that 360Ω is static resistance. Dynamic resistance is how much the current changes if you vary the voltage a bit (or vice versa).

Jan

Jan

Oops! Parasitic inductance and parasitic resistance were added. How long were the alligator test leads?

I recognize it isn't ideal, if nothing else these parasitics were applied to all capacitors involved. I won't be submitting these findings to a peer-reviewed journal, thankfully.

No its not trivial, the leads do make a difference. I had problems with crock leads when testing parts in point to point tube circuits, on speaker crossovers etc. From outright oscillations to simply sounding nothing like before when soldered in place. Short thick cables and Wago 211 inline connectors is the best easiest method I found to swap parts in. Traditional white nylon ones with screws do the job too, only slower to swap a part.

nice test , the green nichicon es bipolar test very low hd ....Hello people. I recently did a shootout of audio grade electrolytic cathode bypass capacitors in an E88CC gain stage. I was searching for "the one" a particular circuit I am working on.

Here is a basic schematic of the stage I was using to compare, this is in a transformer coupled headphone amplifier, I will leave the output stage to the imagination.

View attachment 1048605

I have a prototyping board I use for testing my designs, pictured below. The capacitors were alligator clipped in and out for relatively fast comparison of two different types.

View attachment 1048600

All listening tests were done on headphones, specifically the new ZMF Atrium, an excellent new open back 300ohm dynamic from them. I was seeking a 220uF 16V electrolytic for my circuit, some were only available in 250uF or 25V models, so the closest available values were used. The capacitors tested were the following.

Audio Note Kaisei

Audio Note Seiryu

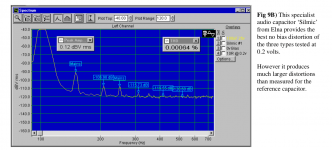

Elna Silmic II

Jupiter Cosmos

MOD

Nichicon FG

Nichicon KZ

Vishay Sprague Atom

View attachment 1048602

This listening test was done over four hours or so, it was not blinded (sorry, but I don't have the time or patience to set that up), I did a first pass to rule out the capacitors that I felt sounded "bad" and which one I felt was "best" off the bat, then did successive listening comparisons of the best sounding capacitors until I had a hierarchy worked out.

I know some people, especially the hard objectivists, feel there will be no difference. There is, and you would have to be deaf not to hear it! At least in this particular application.

Anyway, the winner of the competition was the Jupiter Cosmos, with the runner up being the Elna Silmic II.

View attachment 1048603

Both of these caps have very good clarity and don't tend to have the stridency some electrolytics add to the treble. The Elna Silmic II are pretty highly respected and are dirt cheap, so a great budget option if you are trying to save a few dollars. But the Jupiter Comos have a larger stage and better air / imaging. Either one are a great choice, the Jupiter Caps aren't terribly expensive like their film products.

The general hierarchy would go like this.

S: Jupiter Cosmos, Elna Silmic II

A: Audio Note Kaisei, Nichicon FG

B: Nichicon KZ, Vishay Sprague Atom

C: Audio Note Seiryu, MOD

It's a little vague in the middle, but the Audio Note Seiryu and MOD caps were just bad, harsh and not musical, small sound stage. All of the others sounded pretty good, but the Jupiter and Elna were clearly a cut above them.

Is this audiophoolery nonsense? You be the judge, I did this for myself, but thought maybe others might be interested. My findings seem to align well with the sentiment on the first post of this thread, and that guy seems to be doing pretty well for himself 🙂

Attachments

No its not trivial, the leads do make a difference. I had problems with crock leads when testing parts in point to point tube circuits, on speaker crossovers etc. From outright oscillations to simply sounding nothing like before when soldered in place. Short thick cables and Wago 211 inline connectors is the best easiest method I found to swap parts in. Traditional white nylon ones with screws do the job too, only slower to swap a part.

Fair enough, frankly I did not intend to publish any test results, only after the fact did I think others might be interested in trying these Jupiter capacitors, otherwise I probably would have been more rigorous. I did not hear or measure anything that would suggest parasitic oscillations however. I have had the opposite experience - what I have prototyped has largely resembled the sound of the final circuit, alligator leads notwithstanding. But I am predominantly working on single-ended class A designs without NFB, so the propensity for instability is low(er).

My circuit needs to be tested again when new parts arrive, I can always go back and compare again with alligator clips soldered directly to the capacitor leads, like below, although this is much more time consuming (and I will need more alligator clips).

Last edited:

Might be a good idea to put spaghetti on the wires and insulating boots on the clips if you are going near high voltage with that.

All parts tests will sound cleaner and bolder connected this way. Why not solder short wires on the test nodes instead and swap caps through electrician's inline screw connectors like those white ones in your test bed picture.My circuit needs to be tested again when new parts arrive, I can always go back and compare again with alligator clips soldered directly to the capacitor leads, like below, although this is much more time consuming (and I will need more alligator clips).

View attachment 1048688

Why not try just one cathode bypass cap on alligator leads vs your best direct to nodes method first. So to know if there is enough clarity to gain for your subjectives before retesting them all.I have had the opposite experience - what I have prototyped has largely resembled the sound of the final circuit, alligator leads notwithstanding. But I am predominantly working on single-ended class A designs without NFB, so the propensity for instability is low(er).

Why not try just one cathode bypass cap on alligator leads vs your best direct to nodes method first. So to know if there is enough clarity to gain for your subjectives before retesting them all.

Here's what I'll do - when testing the final circuit, I'll buy a second set of Jupiter capacitors and will compare directly soldered alligator clips vs. alligator test leads. I will take some measurements of both as well and report back. It will be a month or so until I have the components.

All of the electrolytic capacitors must be broken in for a significant period of time before testing.Here's what I'll do - when testing the final circuit, I'll buy a second set of Jupiter capacitors and will compare directly soldered alligator clips vs. alligator test leads. I will take some measurements of both as well and report back. It will be a month or so until I have the components.

Wow, really?

ESR is a useless measurement for audio coupling and decoupling applications. If the capacitor is the right size, it has to be pretty bad to make an audible difference. Honestly, this entire subject is rife with inaccuracies and people who are wedded to a specific outcome.

What is effective is D-A at the various frequencies, it correlates with listening tests. But it isn't any brand of capacitor, it is a dielectric as long as the cap is constructed decently. Same for electrolytic caps. I've been testing capacitors for this since the early 80's continuously - with feedback from customers across that entire time. No one had a horse in that race and I was just curious since I studied parts and also test equipment circuits. Test equipment engineers agree and had the truth figured out long before I came on the scene.

Do you know why people measure ESR? Because it is cheap to do and generates a number. None of you understand what the number means sadly. When you compare an ESR figure to the impedance of the circuit it's in, what do you realise? Think about it for a moment and get back to - yourself. Use some common sense. Distortion is caused by non-linear signal energy loss in the circuit. Now think, what can cause that? There are situations where a circuit is sensitive to these effects, and I'm not going to give you the answer. Many of us know and are not posting in this thread.

At any rate, this argument rages on across the internet on many web sites. Argued by audio folk who aren't trained and really don't know. Clue #1, one brand is better than another. As long as the part is made by a quality manufacturer, you can't hear it really. What you do hear is something called expectation bias. I know I just offended a ton of people out there, oh well. The truth is often inconvenient and people who sell parts love these debates.

You know what is extremely important? Try installing these parts without damaging the rubber seal. Some old caps are still in excellent condition, and most are not subjected to stress. That leaves the very cheap ones and the odd failure. For that I see a constant stream of abused equipment that has been "recapped". You are better off leaving it alone, or replacing parts you know have failed.

To heck with it. Too many people are heavily invested in this debate.

ESR is a useless measurement for audio coupling and decoupling applications. If the capacitor is the right size, it has to be pretty bad to make an audible difference. Honestly, this entire subject is rife with inaccuracies and people who are wedded to a specific outcome.

What is effective is D-A at the various frequencies, it correlates with listening tests. But it isn't any brand of capacitor, it is a dielectric as long as the cap is constructed decently. Same for electrolytic caps. I've been testing capacitors for this since the early 80's continuously - with feedback from customers across that entire time. No one had a horse in that race and I was just curious since I studied parts and also test equipment circuits. Test equipment engineers agree and had the truth figured out long before I came on the scene.

Do you know why people measure ESR? Because it is cheap to do and generates a number. None of you understand what the number means sadly. When you compare an ESR figure to the impedance of the circuit it's in, what do you realise? Think about it for a moment and get back to - yourself. Use some common sense. Distortion is caused by non-linear signal energy loss in the circuit. Now think, what can cause that? There are situations where a circuit is sensitive to these effects, and I'm not going to give you the answer. Many of us know and are not posting in this thread.

At any rate, this argument rages on across the internet on many web sites. Argued by audio folk who aren't trained and really don't know. Clue #1, one brand is better than another. As long as the part is made by a quality manufacturer, you can't hear it really. What you do hear is something called expectation bias. I know I just offended a ton of people out there, oh well. The truth is often inconvenient and people who sell parts love these debates.

You know what is extremely important? Try installing these parts without damaging the rubber seal. Some old caps are still in excellent condition, and most are not subjected to stress. That leaves the very cheap ones and the odd failure. For that I see a constant stream of abused equipment that has been "recapped". You are better off leaving it alone, or replacing parts you know have failed.

To heck with it. Too many people are heavily invested in this debate.

- Home

- Design & Build

- Parts

- Best electrolytic capacitors