Hello AVWERK, dtut, nigel63, yespsb & hottattoo,

Thank you very much for the kind words.

I hope all of you don't mind my lumping you all together into a single post. I guess I am basically lazy.

Hottattoo, I know you were working on a tangential tone arm some time ago.

Have you finished it? Did I miss you posting it here?

Sincerely,

Ralf

Thank you very much for the kind words.

I hope all of you don't mind my lumping you all together into a single post. I guess I am basically lazy.

Hottattoo, I know you were working on a tangential tone arm some time ago.

Have you finished it? Did I miss you posting it here?

Sincerely,

Ralf

Hi,Ralf

I have been sidetracked by looking after an elderly aunt and house repairs, maintenance that has to be taken care of but managed to upgraded the crossovers on my horn speakers. The linear arm is near complete with some minor issues to work out and some arm boards to make for the turntable. Hope to get work done soon on these projects.

Joe

I have been sidetracked by looking after an elderly aunt and house repairs, maintenance that has to be taken care of but managed to upgraded the crossovers on my horn speakers. The linear arm is near complete with some minor issues to work out and some arm boards to make for the turntable. Hope to get work done soon on these projects.

Joe

Hi Ralf,

Up front, I must congratulate you on breaking through the orthodoxy barrier and following the physics rather than the doctrine.

Although all the physics was well-known to the more technical minded way back when, I have never seen even a hint at your approach.

Most designs worked the other way, constrain the cartridge as tightly as possible and force it to follow a predetermined path, no matter how ''wrong'' that path was. In an attempt to improve things, the old school linear TTs altered the location of the pivot but again the cartridge was constrained in the arm. Some have used various pivots at the headshell end of their arms to improve tracking. But aligning the cantilever to be tangential using the very forces acting on that cantilever from playing the record? No, not even whiff of a hint.

I found this thread through a search looking for the tonearm that is suspended by thread and 'tuned' with guitar machine-heads, in the hope of finding anyone who attempted to replicate it. I don't take that tonearm seriously as a tonearm (not yet anyhow) but was thinking more of a conversation-piece/party-trick. It also looked like something I could easily make out of wood laminates. If anyone out there knows more info on that arm, don't hesitate to let me know.

I myself have just returned to turntables after a 35+-year hiatus. Sadly, my turntables did not do well in storage and the one I lent to one of my best friends fared much worse.

Back to your arm, the minute you mentioned the headshell had a horizontal degree of freedom from the arm, the penny dropped. Way back, I had many conversations with friends (and fiends) over cartridge tracking and old school linear trackers (I have several including the linear solenoid Pioneer TTs). Often these talks would descend into arguments about skating forces, mostly because a lot of people are confused about what it is, how it is generated and how to correct for it. I have only scanned through the comments here but is quite clear that things haven't improved (no offence meant to thread participants).

I can't suggest the best way to explain how your arm works, every time I try, I drop into jargon. I am sure some marketing guy could work how to do it. Mind you, I think much of the misunderstanding about everything was caused by marketing.

I do have a difficulty, you claim in the specifications "Head-shell tracks in a straight line for zero eccentricity wow." I can't see how any tonearm can eliminate eccentricity wow. The wow is a function of the change in radius from the platter centre to the stylus. Assuming the turntable has constant angular velocity, the change in radius causes a change in tangential velocity and thus we get wow. The only way to eliminate it is to realign the LP relative to the platter vertical axis (Nakamichi TTs).

It will, however, eliminate the change in tracking angle due to eccentricity. I am unsure if anyone has properly determined the distortion due to this change. I can remember an article in Audio (I think, and a very long time ago at that) that calculated distortion due to tracking error in general and postulated that it was not a huge problem. Surely this must have been investigated and reported to the AES.

While we are on the subject of eccentricity and tracking error, I have, in the dim past, run my B&O 4002 with the cover off for long periods of time sampling my record collection. For about 95% of LPs, the servo only moves the arm once per revolution - the position that the servo operates is always around the same place in the record. So, most LPs I have in my collection are eccentric, even if it is not obvious to the naked eye.

For most (but not all) old school linear tracking TTs, the servo will only drive the sled inwards. This means that the tracking error can get quite large in the outward direction. I did some back of coaster calculations. I used what I think is a reasonably large spiral pitch of about .12mm. For this the maximum inward tracking error is about .045 degrees but probably less (150 mm tonearm pivot to stylus), the negative tracking error depends on the amount of eccentricity.

I have an idea about a possible reason to maintain an angled headshell carrier. As we know, the headshell will align itself to reduce the energy and forces as low as possible. This occurs when the drag from the record is aligned along the cantilever. Thus the cantilever is ''tangential''. All good. However this force is then transferred to the carrier and thus the arm itself. For an angled carrier, the forces will resolve into a radial component and a tangential component. This provides all the movable parts (bearings, cams, etc) with a relatively constant load reducing, if not eliminating, all possible ''play'' in the machinery (both horizontal axes). Just an initial thought and probably off the mark.

I do not wish to be too much of a downer, but, what makes your arm work is also a problem with selling it. It is unorthodox and many of the people who buy high-end gear are orthodox, they might think they aren't, but they are.

Indeed most HiFi is sold on the back of fashion and at the moment (to me) the fashion is not only orthodox (established dogma) but also golden age thinking. The most expensive turntables are in a war of increasing momentum and as many different polished metals as possible. Their platter masses are often much larger than any cutting lathe of which I am aware. Amplifiers have reverted through some sort of reverse evolution back to single ended triode output stages, even returning to valve rectifiers - as many valves as possible!

Even in the past, the HiFi press have made fun of the new. I remember two very well know reviewers who used to get together each year and poke fun at the new stuff they had seen. I remember one year in particular, they poked fun at the Heil Air Motion Transformers. My first speakers of any note were indeed ESS AMTs (I still have the tweeters). It was remarkable how many people aped the reviewers and poked fun at them and dismissed them even without hearing them. I got my revenge on a few of them. Now, since the patents have lapsed, there are a number of manufacturers making variants. Recently, a well known high-end speaker manufacturer announced a brand new type of tweeter with some fancy name of their making, even implying that they created it, it turned out to be an AMT.

So you must tread a narrow path, breakthrough but too out there.

I think you know there is still a way to go in the design process. ATM the arm has a relatively high mass, I haven't thought much about the 2nd order resonance, where it is and how to damp it, if necessary. Then there are all the rest of the resonant modes in the structure of the arm to consider.

I know the current fashion is the billet look but it is a really inefficient way of making identical parts with a high degree of accuracy and precision. Great for custom work but lousy for production.

Costs could be significantly reduced if precision casting was used to manufacture some parts. Further, other materials could be considered in both critical and non critical components. I have not seen it much used in HiFi, but some materials produced using powder metallurgy are quite remarkable.

Despite all the impediments I came up with, I do hope you get it into production.

Regards

Bob

BTW

I should see if I could fit a slimmed down version of your cradle and headshell on one of the linear trackers, I have a few cheap ones recently bought for the purpose of experimenting.

Up front, I must congratulate you on breaking through the orthodoxy barrier and following the physics rather than the doctrine.

Although all the physics was well-known to the more technical minded way back when, I have never seen even a hint at your approach.

Most designs worked the other way, constrain the cartridge as tightly as possible and force it to follow a predetermined path, no matter how ''wrong'' that path was. In an attempt to improve things, the old school linear TTs altered the location of the pivot but again the cartridge was constrained in the arm. Some have used various pivots at the headshell end of their arms to improve tracking. But aligning the cantilever to be tangential using the very forces acting on that cantilever from playing the record? No, not even whiff of a hint.

I found this thread through a search looking for the tonearm that is suspended by thread and 'tuned' with guitar machine-heads, in the hope of finding anyone who attempted to replicate it. I don't take that tonearm seriously as a tonearm (not yet anyhow) but was thinking more of a conversation-piece/party-trick. It also looked like something I could easily make out of wood laminates. If anyone out there knows more info on that arm, don't hesitate to let me know.

I myself have just returned to turntables after a 35+-year hiatus. Sadly, my turntables did not do well in storage and the one I lent to one of my best friends fared much worse.

Back to your arm, the minute you mentioned the headshell had a horizontal degree of freedom from the arm, the penny dropped. Way back, I had many conversations with friends (and fiends) over cartridge tracking and old school linear trackers (I have several including the linear solenoid Pioneer TTs). Often these talks would descend into arguments about skating forces, mostly because a lot of people are confused about what it is, how it is generated and how to correct for it. I have only scanned through the comments here but is quite clear that things haven't improved (no offence meant to thread participants).

I can't suggest the best way to explain how your arm works, every time I try, I drop into jargon. I am sure some marketing guy could work how to do it. Mind you, I think much of the misunderstanding about everything was caused by marketing.

I do have a difficulty, you claim in the specifications "Head-shell tracks in a straight line for zero eccentricity wow." I can't see how any tonearm can eliminate eccentricity wow. The wow is a function of the change in radius from the platter centre to the stylus. Assuming the turntable has constant angular velocity, the change in radius causes a change in tangential velocity and thus we get wow. The only way to eliminate it is to realign the LP relative to the platter vertical axis (Nakamichi TTs).

It will, however, eliminate the change in tracking angle due to eccentricity. I am unsure if anyone has properly determined the distortion due to this change. I can remember an article in Audio (I think, and a very long time ago at that) that calculated distortion due to tracking error in general and postulated that it was not a huge problem. Surely this must have been investigated and reported to the AES.

While we are on the subject of eccentricity and tracking error, I have, in the dim past, run my B&O 4002 with the cover off for long periods of time sampling my record collection. For about 95% of LPs, the servo only moves the arm once per revolution - the position that the servo operates is always around the same place in the record. So, most LPs I have in my collection are eccentric, even if it is not obvious to the naked eye.

For most (but not all) old school linear tracking TTs, the servo will only drive the sled inwards. This means that the tracking error can get quite large in the outward direction. I did some back of coaster calculations. I used what I think is a reasonably large spiral pitch of about .12mm. For this the maximum inward tracking error is about .045 degrees but probably less (150 mm tonearm pivot to stylus), the negative tracking error depends on the amount of eccentricity.

I have an idea about a possible reason to maintain an angled headshell carrier. As we know, the headshell will align itself to reduce the energy and forces as low as possible. This occurs when the drag from the record is aligned along the cantilever. Thus the cantilever is ''tangential''. All good. However this force is then transferred to the carrier and thus the arm itself. For an angled carrier, the forces will resolve into a radial component and a tangential component. This provides all the movable parts (bearings, cams, etc) with a relatively constant load reducing, if not eliminating, all possible ''play'' in the machinery (both horizontal axes). Just an initial thought and probably off the mark.

I do not wish to be too much of a downer, but, what makes your arm work is also a problem with selling it. It is unorthodox and many of the people who buy high-end gear are orthodox, they might think they aren't, but they are.

Indeed most HiFi is sold on the back of fashion and at the moment (to me) the fashion is not only orthodox (established dogma) but also golden age thinking. The most expensive turntables are in a war of increasing momentum and as many different polished metals as possible. Their platter masses are often much larger than any cutting lathe of which I am aware. Amplifiers have reverted through some sort of reverse evolution back to single ended triode output stages, even returning to valve rectifiers - as many valves as possible!

Even in the past, the HiFi press have made fun of the new. I remember two very well know reviewers who used to get together each year and poke fun at the new stuff they had seen. I remember one year in particular, they poked fun at the Heil Air Motion Transformers. My first speakers of any note were indeed ESS AMTs (I still have the tweeters). It was remarkable how many people aped the reviewers and poked fun at them and dismissed them even without hearing them. I got my revenge on a few of them. Now, since the patents have lapsed, there are a number of manufacturers making variants. Recently, a well known high-end speaker manufacturer announced a brand new type of tweeter with some fancy name of their making, even implying that they created it, it turned out to be an AMT.

So you must tread a narrow path, breakthrough but too out there.

I think you know there is still a way to go in the design process. ATM the arm has a relatively high mass, I haven't thought much about the 2nd order resonance, where it is and how to damp it, if necessary. Then there are all the rest of the resonant modes in the structure of the arm to consider.

I know the current fashion is the billet look but it is a really inefficient way of making identical parts with a high degree of accuracy and precision. Great for custom work but lousy for production.

Costs could be significantly reduced if precision casting was used to manufacture some parts. Further, other materials could be considered in both critical and non critical components. I have not seen it much used in HiFi, but some materials produced using powder metallurgy are quite remarkable.

Despite all the impediments I came up with, I do hope you get it into production.

Regards

Bob

BTW

I should see if I could fit a slimmed down version of your cradle and headshell on one of the linear trackers, I have a few cheap ones recently bought for the purpose of experimenting.

ooops...

''So you must tread a narrow path, breakthrough but too out there.'' should be ''So you must tread a narrow path, breakthrough but NOT too out there.''

Sorry about that,

Bob

''So you must tread a narrow path, breakthrough but too out there.'' should be ''So you must tread a narrow path, breakthrough but NOT too out there.''

Sorry about that,

Bob

Hi,

On second thought, my explanation for the offset doesn't feel right. I suspect I have typed before thinking.

I will give the subject some time when I get some.

Bob

On second thought, my explanation for the offset doesn't feel right. I suspect I have typed before thinking.

I will give the subject some time when I get some.

Bob

The linear arm is near complete with some minor issues to work out and some arm boards to make for the turntable.

Hello hottattoo,

I am looking forward to read about your finished tone arm.

Sincerely,

Ralf

Hi Ralf,

Up front, I must congratulate you on breaking through the orthodoxy barrier and following the physics rather than the doctrine.

Hello Bob,

Thank you for the kind words.

I do have a difficulty, you claim in the specifications "Head-shell tracks in a straight line for zero eccentricity wow." I can't see how any tonearm can eliminate eccentricity wow. The wow is a function of the change in radius from the platter centre to the stylus. Assuming the turntable has constant angular velocity, the change in radius causes a change in tangential velocity and thus we get wow. The only way to eliminate it is to realign the LP relative to the platter vertical axis (Nakamichi TTs).

I made a mistake there. What I meant to say is that, my tone arm has less eccentricity wow than a purely pivoting tone arm because the head-shell only moves in and out along a straight line, whereas a pivoting tone arm also advances and backs up as it moves in and out.

I have an idea about a possible reason to maintain an angled headshell carrier. As we know, the headshell will align itself to reduce the energy and forces as low as possible. This occurs when the drag from the record is aligned along the cantilever. Thus the cantilever is ''tangential''. All good. However this force is then transferred to the carrier and thus the arm itself. For an angled carrier, the forces will resolve into a radial component and a tangential component. This provides all the movable parts (bearings, cams, etc) with a relatively constant load reducing, if not eliminating, all possible ''play'' in the machinery (both horizontal axes). Just an initial thought and probably off the mark.

I find that explanation quite good. the offset cradle causes the tone arm to be "self propelled", in other words, the spiral groove does not have to move the tone arm toward the label, record friction alone does that.

But there is another reason for the offset cradle/head-shell. In order for a pivoting tone arm to become a tangentially tracking one, its pivot has to be moved a certain distance. If you analyze the geometry you will find that a tone arm with an offset cradle/head-shell requires that its pivot be moved one half the distance that a tone arm with an in-line head-shell would require! Thus, my tone arm requires less installation real estate and any mechanical noise generated by moving the entire tone arm is less.

Costs could be significantly reduced if precision casting was used to manufacture some parts. Further, other materials could be considered in both critical and non critical components. I have not seen it much used in HiFi, but some materials produced using powder metallurgy are quite remarkable.

I was involved with precision investment castings and powdered metal parts all of my professional life. Those technologies are only cost effective when large quantities of parts are required.[/QUOTE]

Sincerely,

Ralf

Last edited:

Hi Ralf,

I have now read this thread and I realise that some parts of my previous posts were redundant, I apologise for wasting your time.

I was under the impression that small batch precision investment casting costs had fallen a fair bit in recent years but I will bow to your knowledge and experience in that field.

With power metallurgy, I was more thinking about Magnesium based metal matrix composites rather than the more tradition materials such as sintered bronze.

I do have a couple of questions:

1. Are the bearings on the carrier running on straight aluminium in the headshell? If so, would it be better to use a harder material on the bearing surface? Or, is the headshell hard anodised?

2. Does the wiring influence the behaviour of the headshell through stiffness, etc? This has already been mentioned in this thread and extensively elsewhere such as Angling for 90° - tangential pivot tonearms

3. Have you looked into the fundamental resonance of the tonearm cartridge system both in the horizontal and vertical plane? If damping is required, I am not sure how it could be implemented in your arm for the horizontal plane.

It has been a long time since I had to look into static friction, especially on the smaller scale. The big problem being the transition from static resistance to rolling resistance. If the jump is high enough, potential energy will be stored in the suspension of the cartridge and then 'suddenly' released - if this occurs, it will no doubt excite the horizontal primary resonance.

I must say that I have noticed a general lack of damping in modern tonearm design.

Perhaps I have been away from Hi-Fi too long. Certainly the compliance of most of the cartridges are lower than was the case in the 'old days'. I wonder how systems are coping with all the subsonic (and subsonic creating) trash that exists in your average production run vinyl record. Maybe it is time for some reading.

Bob

BTW

I think one of the problems you will have with your arm is with terminology. I said the same in the previous post and after reading this thread I am further convinced.

BTW2

As you have filed previous patents you will know that you need to detail as many variants as you can on the fundamental difference between this and other arms. That includes the non-servo linear track version both with the bearing surface in front of the stylus (not sure how you get it to track vertically) and behind the stylus, i.e., a Revox style arm with your carrier and headshell attached - both servo assisted and non-servo assisted. The short tonearm of a Revox style arm will cause issues with the change in VTA due to disc irregularities and 'overhand/underhang ' issues on eccentricities (mine not included).

BTW3 I would not rule China out as someone has in this thread. With China, you can get accuracy and precision, you just have to pay for it. Just look at laptop computers, you can buy a $300 computer and end up with all plastic etc - still works. I have recently bought my wife a new computer, an HP Spectre (it is so pretty <sigh>), absolutely beautiful fit and finish and the whole thing is a class act, guess where it is made.

I have now read this thread and I realise that some parts of my previous posts were redundant, I apologise for wasting your time.

I was under the impression that small batch precision investment casting costs had fallen a fair bit in recent years but I will bow to your knowledge and experience in that field.

With power metallurgy, I was more thinking about Magnesium based metal matrix composites rather than the more tradition materials such as sintered bronze.

I do have a couple of questions:

1. Are the bearings on the carrier running on straight aluminium in the headshell? If so, would it be better to use a harder material on the bearing surface? Or, is the headshell hard anodised?

2. Does the wiring influence the behaviour of the headshell through stiffness, etc? This has already been mentioned in this thread and extensively elsewhere such as Angling for 90° - tangential pivot tonearms

3. Have you looked into the fundamental resonance of the tonearm cartridge system both in the horizontal and vertical plane? If damping is required, I am not sure how it could be implemented in your arm for the horizontal plane.

It has been a long time since I had to look into static friction, especially on the smaller scale. The big problem being the transition from static resistance to rolling resistance. If the jump is high enough, potential energy will be stored in the suspension of the cartridge and then 'suddenly' released - if this occurs, it will no doubt excite the horizontal primary resonance.

I must say that I have noticed a general lack of damping in modern tonearm design.

Perhaps I have been away from Hi-Fi too long. Certainly the compliance of most of the cartridges are lower than was the case in the 'old days'. I wonder how systems are coping with all the subsonic (and subsonic creating) trash that exists in your average production run vinyl record. Maybe it is time for some reading.

Bob

BTW

I think one of the problems you will have with your arm is with terminology. I said the same in the previous post and after reading this thread I am further convinced.

BTW2

As you have filed previous patents you will know that you need to detail as many variants as you can on the fundamental difference between this and other arms. That includes the non-servo linear track version both with the bearing surface in front of the stylus (not sure how you get it to track vertically) and behind the stylus, i.e., a Revox style arm with your carrier and headshell attached - both servo assisted and non-servo assisted. The short tonearm of a Revox style arm will cause issues with the change in VTA due to disc irregularities and 'overhand/underhang ' issues on eccentricities (mine not included).

BTW3 I would not rule China out as someone has in this thread. With China, you can get accuracy and precision, you just have to pay for it. Just look at laptop computers, you can buy a $300 computer and end up with all plastic etc - still works. I have recently bought my wife a new computer, an HP Spectre (it is so pretty <sigh>), absolutely beautiful fit and finish and the whole thing is a class act, guess where it is made.

Hi Ralf,

I apologise for wasting your time.

Hi Bob,

You are not wasting my time

1. Are the bearings on the carrier running on straight aluminium in the headshell? If so, would it be better to use a harder material on the bearing surface? Or, is the headshell hard anodised?

None of the parts are anodized. It is mostly a matter of cost and convenience. The nearest anodizer is located in Phoenix. I have heard of parts getting lost in the tanks etc. Sometimes in the future I'll have that done though. I have had zero problems with the tone arm as is.[/QUOTE]

2. Does the wiring influence the behaviour of the headshell through stiffness, etc? This has already been mentioned in this thread and extensively elsewhere such as Angling for 90° - tangential pivot tonearms

The wiring forms a generous 3/4" diameter helical loop as it transitions from the tone arm tube to the phono cartridge. The head-shell only moves a few thousands of an inch which results in negligible tension in the wires.

3. Have you looked into the fundamental resonance of the tonearm cartridge system both in the horizontal and vertical plane? If damping is required, I am not sure how it could be implemented in your arm for the horizontal plane.

I have done some basic resonance testing with a CBS test record. Beyond that, I don't have the knowledge and the necessary test equipment to do much more.

BTW I would not rule China out as someone has in this thread. With China, you can get accuracy and precision, you just have to pay for it.

I would not rule out China if I was confronted with having to make that decision.

Sincerely,

Ralf

Last edited:

Hi Ralf,

It will, however, eliminate the change in tracking angle due to eccentricity. I am unsure if anyone has properly determined the distortion due to this change. I can remember an article in Audio (I think, and a very long time ago at that) that calculated distortion due to tracking error in general and postulated that it was not a huge problem. Surely this must have been investigated and reported to the AES.

Not to impune Ralf’s design, but no, it won’t eliminate the change in tracking angle due to eccentricity. In fact, no arm will, and it’s not the fault of the arm.

Hi Ralf,

While we are on the subject of eccentricity and tracking error, I have, in the dim past, run my B&O 4002 with the cover off for long periods of time sampling my record collection. For about 95% of LPs, the servo only moves the arm once per revolution - the position that the servo operates is always around the same place in the record. So, most LPs I have in my collection are eccentric, even if it is not obvious to the naked eye.

Sounds like the servo in your 4002 is designed competently and is operating effectively, correcting as needed with no overshoot.

Hi Ralf,

For most (but not all) old school linear tracking TTs, the servo will only drive the sled inwards. This means that the tracking error can get quite large in the outward direction. I did some back of coaster calculations. I used what I think is a reasonably large spiral pitch of about .12mm. For this the maximum inward tracking error is about .045 degrees but probably less (150 mm tonearm pivot to stylus), the negative tracking error depends on the amount of eccentricity.

If you really think about it, the servo does not need to be bi-directional. All it needs to do is keep the tracking error below some threshold level of audibility. I submit that that threshold level is established as the give-or-take 1.9 degree tracking error of the 9-inch $53,600 pivoted arm currently ranked A+ in a popular audiophile magazine’s recommended components list. I found some blank space left over on the back of your coaster and did some more calculations. Let’s say the servo skipped a 0.12mm beat on one revolution and resulted in the 0.045 degree tracking error. That’s still way better than the $53,600 arm on its best day. Record eccentricity does come into play by challenging the servo, but the eccentricity also causes an intrinsic tracking error due to the eccentricity itself. As the eccentricity vacillates left and right 0.12mm it plays games with the servo. As the eccentricity vacillates fore and aft 0.12mm the tangency point of the groove will skew under the stylus. At an outer groove radius of 146mm the ‘skew’ tracking error will be +/- 0.047 degree. At an inner groove radius of 60mm the ‘skew’ tracking error will be +/- 0.114 degree. This eccentricity induced tracking error is not tied to the servo action of the LT and will add to the mix of tracking errors in a conventional pivoted arm. True linear tracking arms such as passive mechanical arms and air bearing arms are also not immune to this ‘skew’ tracking error. The eccentricity induced tracking error is not a fault of any of those arms, but it’s there. It’s popular on the web to poke at servo control errors and argue this-and-that and the-other-thing, but when you put even ‘back of the coaster’ numbers on it the anti-servo arguments fall apart. The autopilot servo system on a commercial airliner will keep the plane level and on-course without even causing a ripple in the coffee on your tray table, and the error corrections it makes for normal flight conditions are imperceptible. Now, if I could only get some more leg room...

Ray K

Sounds like the servo in your 4002 is designed competently and is operating effectively, correcting as needed with no overshoot.

The B&Os were very good turntables. A lot of people view them as more about style than substance.

They were very carefully engineered, the original 4000 had some 11 logic ICs and 45 transistors, the 4002 did all the same things that the 4000 did with 1 IC (to run the servo platter motor) and about 27 transistors (some darlingtons). A remarkable job of optimising the circuit, also, no custom ICs to go wrong. The turntable also had very good reviews in its day and in a number of reviews had the best measured isolation of all the turntables. The MCC20CL cartridge was an excellent cartridge, the Moving Micro Cross is the basis of the Soundsmith cartridges. I see that Ralf has a SoundSmith fitted to his arm.

I also have had two Pioneer PL-L1000A turntables from new. For a while I had the B&O as the meat in the sandwich between the two Pioneers. This svelte looking piece of modern art between two big, black (slightly ugly) monoliths. The thing that most people were surprised by was that the B&O weighted 12KG (about 26 lbs) to the Pioneer's 13.5kg (30 lbs). Of course the Pioneer has a big chunk of steel bar bolted to one side of the sub-chassis to even up the load on the suspension - was a bit of a shock when I first opened one up! Then I thought, the ba........ 😀

If you really think about it, the servo does not need to be bi-directional. All it needs to do is keep the tracking error below some threshold level of audibility. I submit that that threshold level is established as the give-or-take 1.9 degree tracking error of the 9-inch $53,600 pivoted arm currently ranked A+ in a popular audiophile magazine’s recommended components list.

That is one way of deciding the threshold, the real question is: how accurate is the alignment of the stylus to the axis of the cantilever of a production cartridge or even a hand made cartridge? Do they mount the nude diamonds on the cantilever and then grind the stylus to shape? I would think it a more precise way of aligning the stylus. While people can hear ''fantastic changes to the music by changing interconnects'' they apparently have no ability to hear a difference between different cartridges of the same model.

I recently went to a Hi-Fi shop to listen to some headphones in which I was interested. I took my own source material and an ifi MicroDSD DAC and headphone amp. The guy in the shop looked at the USB cable and told me it was holding the ifi back (he didn't even know the ifi existed before this). I carefully explained that the data into the ifi via USB was asynchronous and provided no clocking to the DAC and that the ifi's clock was very good. He told me he understood it was asynchronous, but, he could still easily pick the change. He demonstrated that he could hear the difference (by his own word) using his open backed headphones, with my source material, using my DAC and amp, in a shop, with road noise. <sigh>

I found some blank space left over on the back of your coaster and did some more calculations. Let’s say the servo skipped a 0.12mm beat on one revolution and resulted in the 0.045 degree tracking error. That’s still way better than the $53,600 arm on its best day. Record eccentricity does come into play by challenging the servo, but the eccentricity also causes an intrinsic tracking error due to the eccentricity itself. As the eccentricity vacillates left and right 0.12mm it plays games with the servo. As the eccentricity vacillates fore and aft 0.12mm the tangency point of the groove will skew under the stylus. At an outer groove radius of 146mm the ‘skew’ tracking error will be +/- 0.047 degree. At an inner groove radius of 60mm the ‘skew’ tracking error will be +/- 0.114 degree. This eccentricity induced tracking error is not tied to the servo action of the LT and will add to the mix of tracking errors in a conventional pivoted arm. True linear tracking arms such as passive mechanical arms and air bearing arms are also not immune to this ‘skew’ tracking error. The eccentricity induced tracking error is not a fault of any of those arms, but it’s there.

Very good, I hadn't thought of it in those terms, yes, any overhang/underhang caused by the eccentricity when it is orthogonal to the cantilever will give a relative skew to the cantilever axis. The thing is that all of these tracking errors are far less than what can be achieved even in the best setup and alignment of a TT. I very much doubt that anyone could pick the errors. The question is: can the variation in these parameters be heard? I would wager not, but then, I used to be an engineer - skewed thinking... 🙄

Interestingly, Ralf's tonearm will always maintain tangency, thus eliminating the tracking errors from all sources. Not the eccentricity wow, but nevertheless, I think a very worthwhile contribution.

As to audibility, well I get high def recordings where possible not so much because I believe there is an audible difference between PCM768 and PCM88 but to put it beyond doubt, also, the higher def recordings generally have far more care taken with the original source material.

I would feel a lot better knowing that the tangency is beyond doubt.

It’s popular on the web to poke at servo control errors and argue this-and-that and the-other-thing, but when you put even ‘back of the coaster’ numbers on it the anti-servo arguments fall apart. The autopilot servo system on a commercial airliner will keep the plane level and on-course without even causing a ripple in the coffee on your tray table, and the error corrections it makes for normal flight conditions are imperceptible. Now, if I could only get some more leg room...

Ray K

Ahhhh, the old crabbing across the record schlock, well I like crabs, very tasty.

The B&O moves quite slowly when correcting the errors probably at least an eighth rotation, a very slow crab, much easier to catch.

Now the Pioneers are very different, instead of a geared motor hauling the sled along with a string, they use a long solenoid that acts in concert with permanent magnets in the base of the sled, no gears, wires, motors, etc. Also, once the stylus is down on the record it is completely analog controlled, the whole thing is quite simple. So, I can't look at anything to know what the Pioneer is doing. I have been thinking of pulling one apart and attaching a ribbon cable to a number of test points to see what the electronics is doing. It is certainly capable of following the eccentricities, the question is: does it?

It would be better checking the later PL-L800, as the design had been optimised both mechanically and electrically, it also looked a lot better. Whereas the PL-L1000A had an open loop servo drive of the sled, the PL-L800 has a closed loop with a small DC generator on the sled providing the feedback signal, monitor the DC generator and the behaviour of the sled will be evident. Unfortunately I don't have one and the bargain buys are no longer to be had, especially in Australia. Although, through stupidity, during Coronavirus lockdown, I missed out on a Technics SL10 with original MC cartridge in VGC for $120AUD, still really p.....😡

Tomorrow I am picking up a Realistic linear TT (which was bought very cheaply), don't laugh they were built by NEC who supplied many marketing brands. I might see if it is suitable for modifying to take a smaller version of Ralf's headshell. I am thinking of putting one of my old Shibata stylus Panasonic strain gauges cartridges in it. They can go much lower into the subsonics than the magnetic cartridges. First I will have to build a replacement preamp stage and see if they are any good. Like the Win strain gauges, you really need to set up and equalize each cartridge separately. It is a bit annoying when you have more than one. They are pretty old so the suspension is suspect.

I reckon the best classic old school linear TT would use the B&O 8000 eddy current platter drive, the Pioneer PL-L800 sled drive, and the Sony Biotracer arm off the PS-X555ES.

Bob

Yes I know it is long.

When I flew weekly for work, I used to go cattle class but since I flew so often I usually got allocated to the emergency exit rows, heaps of room on the A320. Occasionally, I would get upgraded to business (if I flew later at night I was more likely to get upgraded - a quandary) and twice to FIRST, huge seats, real knives and forks, China plates, cloth napkins, and not only edible food but enjoyable food.🙂

Not to impune Ralf’s design, but no, it won’t eliminate the change in tracking angle due to eccentricity. In fact, no arm will, and it’s not the fault of the arm.

Ray K

Hi, I just reread your post and saw that I missed something out. As I have posted in my earlier reply, I think it can eliminate all tracking angle problems. This is inherent in the design as the stylus drag must always align itself along the cantilever.

Assuming no friction in the bearings, no torquing of wiring, or forces from the cartridge (a big assumption), the stylus drag is the only force acting on the headshell. The headshell will always travel to the lowest energy state which is to exactly oppose the stylus drag, thus alignment is guaranteed by the physics of the thing.

Looking down on the turntable, as the outward bound eccentricity rotates to 12 o'clock from the 9 o'çlock position, the cartridge will start tilting (relative to the arm) with the back of the cartridge moving to the right.

I will have to give it some extra thought as to exactly what is happening to eccentricity wow, which relative to a fixed cartridge will resolve into two orthogonal sinewaves in the x and y axes. But Ralf's cartridge is not fixed, it has two degrees of freedom, it can make way athwartships and yaw (avast me hearties). Ahhhggg, too late in the night to be thinking at all let alone about this.😕 I will see if I can get to it at a more civilised time and with less Coonawarra red.

Bob

Ralf,

I've just now finished reading this thread. I first saw the video of your tonearm at RMAF on Michael Fremer's channel. As an engineer and audiophile my very first thought seeing that video was, "What a great design! This is the tonearm I want!" I very much hope you make it to manufacturing with a reputable brand. I would very much love to own the tonearm some day. Its like one of the very best I could hope to own.

I've just now finished reading this thread. I first saw the video of your tonearm at RMAF on Michael Fremer's channel. As an engineer and audiophile my very first thought seeing that video was, "What a great design! This is the tonearm I want!" I very much hope you make it to manufacturing with a reputable brand. I would very much love to own the tonearm some day. Its like one of the very best I could hope to own.

Ralf,

I've just now finished reading this thread. I first saw the video of your tonearm at RMAF on Michael Fremer's channel. As an engineer and audiophile my very first thought seeing that video was, "What a great design! This is the tonearm I want!" I very much hope you make it to manufacturing with a reputable brand. I would very much love to own the tonearm some day. Its like one of the very best I could hope to own.

Hello DarPhyve,

Thank you very much for your kind words. I'll do my best to make it available some day. And, sorry for the late reply.

Sincerely,

Ralf

My tone arm's tangential position is solely controlled by a set of two cams and their cam followers. They are not shown in the drawing posted by super10018. The geometry is perfect and there is no tracking error!

Sincerely,

Ralf

Ralf,

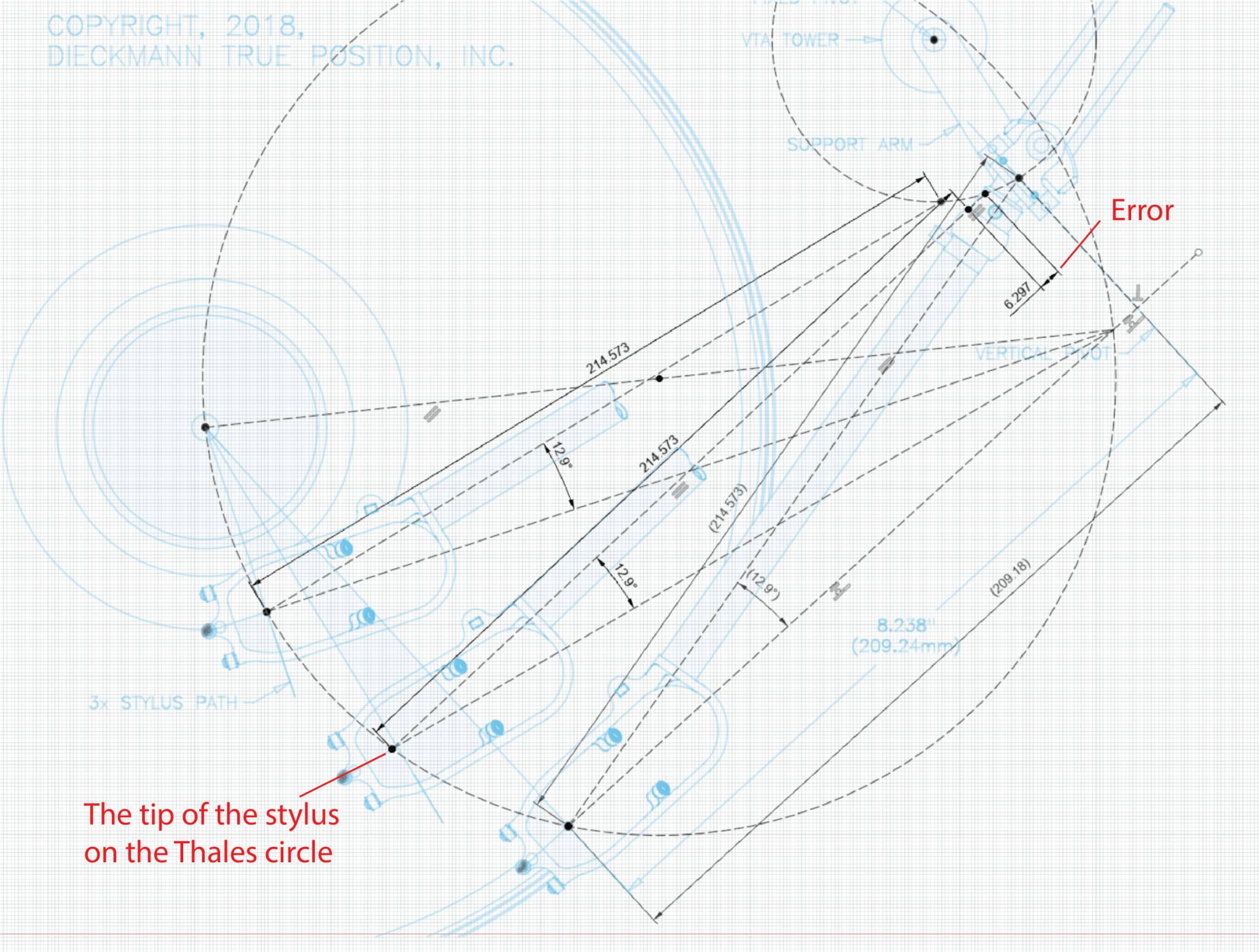

I would like to get your answer about the following geometry. If it is correct, we may continue. Otherwise, the discussion will be different.

I used your diagram as the template. Please see following diagram.

The following diagram is an enlarged version of the above diagram to show the detail. You can the tip of the stylus for the middle arm is not located on the Thales circle. It means there are tracking errors.

As long as you agree with my statement that your arm is a variant of Birch-style arm, tracking errors are inevitable.

Jim

Attachments

Ralf,

I did error analysis again, but this time, I did it differently. I forced the tip of the stylus for the middle arm exactly on the Thales circle and kept the offset angle 12.9 and arm length 214.573 mm for all three arms. You can see there is an error in the rear pivot for the middle arm. It is 6.297 mm. It means tracking errors do exist.

I did error analysis again, but this time, I did it differently. I forced the tip of the stylus for the middle arm exactly on the Thales circle and kept the offset angle 12.9 and arm length 214.573 mm for all three arms. You can see there is an error in the rear pivot for the middle arm. It is 6.297 mm. It means tracking errors do exist.

Hi super10018,Ralf,

I did error analysis again, but this time, I did it differently. I forced the tip of the stylus for the middle arm exactly on the Thales circle and kept the offset angle 12.9 and arm length 214.573 mm for all three arms. You can see there is an error in the rear pivot for the middle arm. It is 6.297 mm. It means tracking errors do exist.

View attachment 1018505

I have been working on some CAD drawings tonight which I will have ready to post tomorrow. The should clarify how my tone arm works beyond a shadow of a doubt.

Sincerely,

Ralf

The offset cradle/head-shell deliberately introduces the "inward force" so that the tone arm becomes "self propelled" across the surface of the LP. Because the tone arm and the head-shell move independently of each other, some means of preventing a collision between the tone arm and the head-shell had to be devised. That is the purpose of the "servo". It simply controls the "inward force". You might call it electronic anti skating!

Ralf,

I also disagree with your assessment about introducing "inward force".

Adding an offset angle alone doesn't add inward force. In other words, offset angle alone can't propel the arm. There will be no inward force without interaction of stylus and groove even you add an offset angle on the arm. So, if you want an inward force to propel the arm inward, you have to put the interaction between stylus and groove into your equation. If your headshell is completely independent of the arm, you call it cradle, there will be no inward force at all. Purposely adding inward force is to add more stress on the cantilever. This was why I said I didn't see the need to add a small linear bearing on the headshell. In addition, I believe adding a moving structure direct over the cartridge is highly undesirable.

Furthermore, you add a servo to add an anti-skating force to control the inward force. If the anti-skating force is equal to the inward force, the servo is useless for your goal because the inward force is canceled. If the inward force is larger than the anti-skating force, the inward force will drive the arm inward, but in the meantime, the inward force will put stress on the cantilever. It is not desirable. The arm skates. I just don't see any benefits to adding such inward force. You create an inward force, then, you create a servo to encounter the inward force. Isn't it better not to add any external force initially?

My belief is to eliminate all the side forces and let the cartridge do its work naturally without any interfering.

Jim

Last edited:

I am late to the party so I apologise if what I raise has already bean dealt with. Please note I am not suggesting that the tonearm isn't a masterful achievement, so don't take my words as criticism. I am not a designer and I don't pretend to be, however I am a troubleshooter and often find technical flaws in commercial implementations of turntables and other things.

In the video video showing the playing a a record side I placed a ruler from two different perpendicular lines across the headshell float, one in front of the stylus position and one behind. As far as I can tell the tracking angle does appear to vary across the playing surface. Is this an optical illusion?

It has been repeatedly said there is no skating force with this design, however a sideways force on the stylus tip and cantilever is necessary to push the cartridge sideways to align with the groove. The real different is that the force on the cantilever is only moving the effective mass of the cartridge and slide, not the angular momentum of a pivoting arm as well. Depending on the mass of the sliding assemble, this could well be less, or more, than the sideways force on the cantilever of the same cartridge in a pivoting tonearm.

It seems to me that to a greater or lessor degree the same issues of record eccentricity apply to this tonearm as a pivoting tonearm; whether this design mitigates those issues to a significant degree is not clear to me. I would suggest using a high frequency track or wow & flutter test record to look at the phase relationship between left and right channels on a CRO which I expect will show any variation in stylus angle. After many decades of setting up other peoples tonearms professionally I would be interested to see a comparison between the peak channel differential phase error of this tonearm implementation and a convention pivoting arm (and for that matter a linear tracking tonearm, passive or servo) on the same test track.

In the video video showing the playing a a record side I placed a ruler from two different perpendicular lines across the headshell float, one in front of the stylus position and one behind. As far as I can tell the tracking angle does appear to vary across the playing surface. Is this an optical illusion?

It has been repeatedly said there is no skating force with this design, however a sideways force on the stylus tip and cantilever is necessary to push the cartridge sideways to align with the groove. The real different is that the force on the cantilever is only moving the effective mass of the cartridge and slide, not the angular momentum of a pivoting arm as well. Depending on the mass of the sliding assemble, this could well be less, or more, than the sideways force on the cantilever of the same cartridge in a pivoting tonearm.

It seems to me that to a greater or lessor degree the same issues of record eccentricity apply to this tonearm as a pivoting tonearm; whether this design mitigates those issues to a significant degree is not clear to me. I would suggest using a high frequency track or wow & flutter test record to look at the phase relationship between left and right channels on a CRO which I expect will show any variation in stylus angle. After many decades of setting up other peoples tonearms professionally I would be interested to see a comparison between the peak channel differential phase error of this tonearm implementation and a convention pivoting arm (and for that matter a linear tracking tonearm, passive or servo) on the same test track.

- Home

- Source & Line

- Analogue Source

- A Revolutionary Pivoting Tangential Tone Arm