Nice 🙂 Do you have an idea how to simulate that? "cheap" additive manufacturing of today would enable objects like that be built easily but shouldn't there be some notions of system like that from the old days if it worked even though it would have been tedious to manufacture back in the golden age of audio? Is this what was showed few pages ago, some new phase plug or something that had many horns inside horns in the picture? Something new nevertheless. Would be nice if it worked. I predict it will beam the high frequencies (the axial modes from the driver).

Last edited:

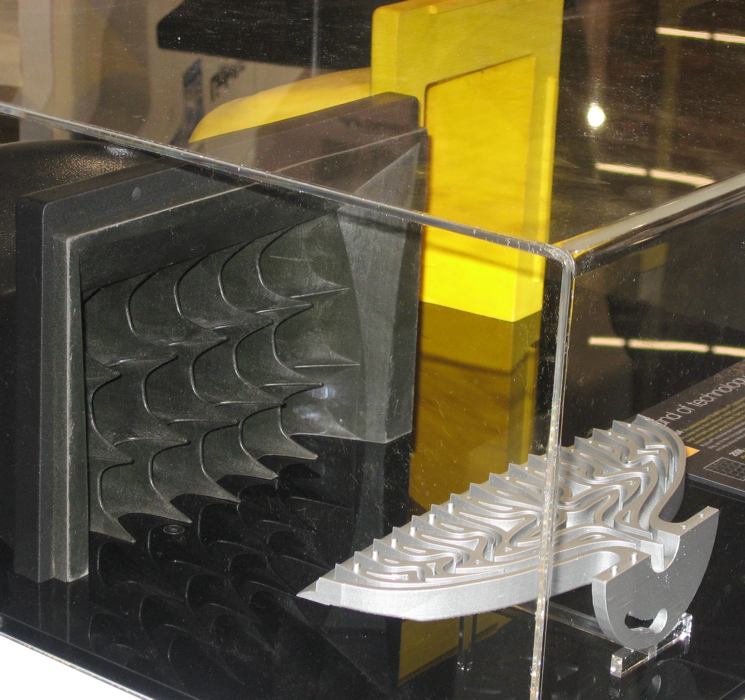

Looking at the pictures, what about a "coaxial multicell" horn? I suppose it wouldn't work for some reason, right?

I think that it would work. It just seems to me to be problematic with construction. The HOM cut-ins would be much higher, but if this isn't important then it likely wouldn't be much of an improvement.

A single internal vane might work well for 2" waveguides. I could see stamping the inner cone in some metal and suspending it inside with foam. A very tough cut of the foam however.

Last edited:

Give me a few days, I'll make it an Ath feature. I'm woking on just that, it's not difficult.Do you have an idea how to simulate that?

Yeah, that's the reason for my doubts. I don't know.... but shouldn't there be some notions of system like that from the old days if it worked even though it would have been tedious to manufacture back in the golden age of audio?

After all it's not a problem to simulate driver axial modes as well.I predict it will beam the high frequencies (the axial modes from the driver).

Isn't it that the path lengths will be different on average inside each section? In that case I would assume a pretty wild acoustic summing at the end.I think that it would work.

Edit: Hmm, but maybe it doesn't make a difference. It's difficult for me to imagine what's happening there.

Last edited:

As long as the vanes end before the combining terminus.....its all good

If vanes all run to the end of the line, thats another story...

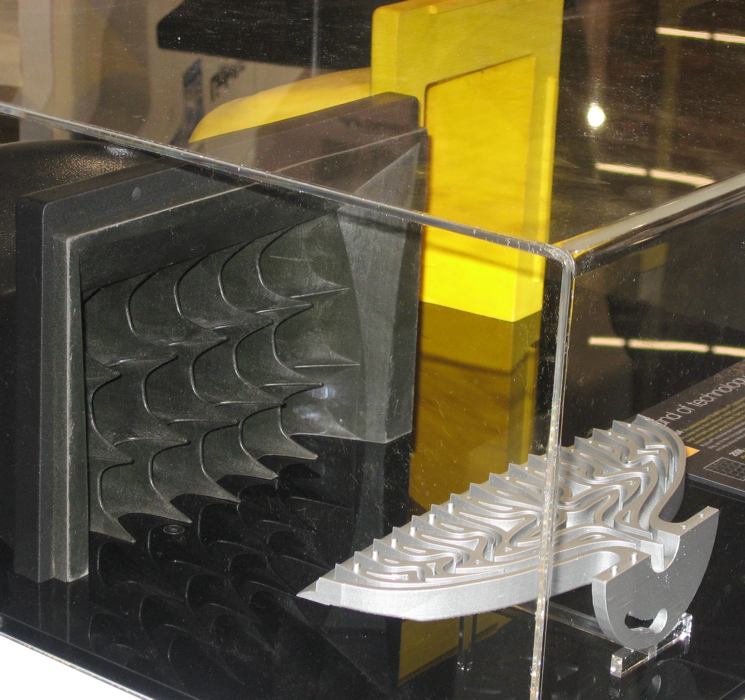

First image that comes to mind...a reverse phase plug of a compression driver?

If vanes all run to the end of the line, thats another story...

First image that comes to mind...a reverse phase plug of a compression driver?

Last edited:

The combining terminus will be always at the end of the vanes, that's the same thing. There's no other "combining place", is there.

reflection

In a CD the phase plug starts close to the diaphragm so that there are no unwanted cavities with reflections. Unless you can make the vanes thin, even blade-like, or otherwise minimize reflections, I would be concerned that the reflections back into the CD will be problematic, at least for some designs where the cavity is too big.

As soon as you mentioned this, I wondered if there's a CD with suitable phase-plug termination to use the ends of the phase plug rings as the start of your vanes - allowing any cavities to be minimized. Otherwise, unless I'm mistaken, this - nice idea - is going to be rather hit and miss with different CDs.

For example, many 2" CDs are made with a long front section, and I will be surprised if that works well with finite-thickness vane(s).

It's a great way to build on the 1P nature of OS.

Ken

In a CD the phase plug starts close to the diaphragm so that there are no unwanted cavities with reflections. Unless you can make the vanes thin, even blade-like, or otherwise minimize reflections, I would be concerned that the reflections back into the CD will be problematic, at least for some designs where the cavity is too big.

As soon as you mentioned this, I wondered if there's a CD with suitable phase-plug termination to use the ends of the phase plug rings as the start of your vanes - allowing any cavities to be minimized. Otherwise, unless I'm mistaken, this - nice idea - is going to be rather hit and miss with different CDs.

For example, many 2" CDs are made with a long front section, and I will be surprised if that works well with finite-thickness vane(s).

It's a great way to build on the 1P nature of OS.

Ken

The combining terminus will be always at the end of the vanes, that's the same thing. There's no other "combining place", is there.

If you stop the inner vanes and continue the outer boundary it is not the same result as running all boundaries directly to the end of the line...

If you take 3" diameter line...split it in half, from beginning to end the tuning is not the same of take the same, but the division wall is terminated before the end of the whole 3" line.

Isn't it that the path lengths will be different on average inside each section? In that case I would assume a pretty wild acoustic summing at the end.

Edit: Hmm, but maybe it doesn't make a difference. It's difficult for me to imagine what's happening there.

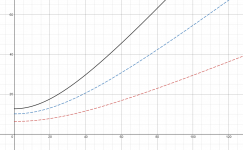

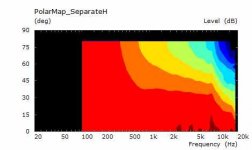

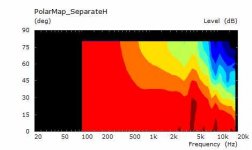

The path length difference is what creates a spherical wavefront. In an OS waveguide, the 0th mode travels along the radial coordinate and normal to ALL angular coordinates. This means that insertion of vanes that are angular coordinates themselves will always be normal to the wavefront and if the vanes are thin enough, then they will do nothing to the 0th mode. They will raise the cut-in for any HOM however, quite possibly pushing them out-of-band.

The thickness is an issue as the vanes need to be thin.

But isn't the behaviour you just described made possible only when there are no vanes? But I know what you mean, that was my initial idea as well.

I think a ripple tank will help me to sort this out. If I only remembered how was it...

I think a ripple tank will help me to sort this out. If I only remembered how was it...

isn't the behaviour you just described made possible only when there are no vanes?

No. A plane wave traveling down a tube is undisturbed by a vane along the tube. As long as the vanes are normal to the wave motion, they are essentially not there.

Yeah, the tube example occured to me as well, but that's a true 1P solution. If I understand correctly, with an OS that's actually not the case. Or it doesn't have any relevance for the 0th mode at all?

Last edited:

It is true that OS is not 1P, but that's why HOMs are created. The idea of inserting a vane will change the math, but in such a way that the 0th mode is unaffected while the HOMs are. The same is true for the tube, implying that 1P is not an issue here.

It is quite interesting that is for sure.

I have always wondered about a waveguide where the inner section is solid. This will create a spherical annulus wavefront. Not sure this has any benefits, but it does fall out directly from this discussion.

I have always wondered about a waveguide where the inner section is solid. This will create a spherical annulus wavefront. Not sure this has any benefits, but it does fall out directly from this discussion.

I remember Turbosound used to have a model that used something that reminded of a multicell

Last edited:

How did you generate the profile and the vanes? It would be interesting to see the mesh. (Beware that it probably must be a real OS, i.e. with k = 1.)I tried doing a simulation with a coaxial multicell with 3 "tubes" that followed the OS contour and were 2cm long on a 2" throat and didn't get great results.

I think it's probably my simulation that wasn't good.

Haven't you tried the vanes longer?

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)