Hi folks

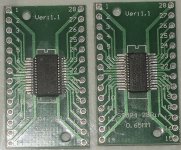

I had a go at using my kitchen oven to reflow solder some DAC chips onto adapter boards and it was only a partial success.

I put on a liberal amount of solder paste and have ended up with the chips securely soldered onto the boards, but a lot of left over solder paste. I tried soaking them in a bath of Isopropyl and scrubbing them with a soft cloth, which took most of the paste off, but there is still loads left in the nooks and crannies.

I take it I need to get rid of all of the leftover paste as it will be somewhat conductive. Question is, how to do it, try different solvents or put them back in the oven?

Three came out aligned nicely, the CS4398 is wonky and will need to be redone.

Next attempt, I take it I need to use as little solder paste as possible? Any tips for applying the paste and how much to use?

I had a go at using my kitchen oven to reflow solder some DAC chips onto adapter boards and it was only a partial success.

I put on a liberal amount of solder paste and have ended up with the chips securely soldered onto the boards, but a lot of left over solder paste. I tried soaking them in a bath of Isopropyl and scrubbing them with a soft cloth, which took most of the paste off, but there is still loads left in the nooks and crannies.

I take it I need to get rid of all of the leftover paste as it will be somewhat conductive. Question is, how to do it, try different solvents or put them back in the oven?

Three came out aligned nicely, the CS4398 is wonky and will need to be redone.

Next attempt, I take it I need to use as little solder paste as possible? Any tips for applying the paste and how much to use?

Attachments

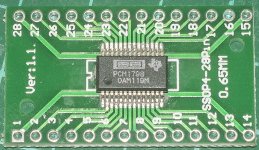

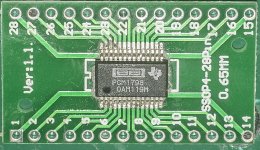

Solder paste only needs to be applied to the component pads, the first photo shows way too much solder paste. In a production environment a stencil is used to apply the solder paste.

It seems you managed to clean most of the solder paste off the pcb, I think the best way forward is to either put the boards back in the oven to reflow the solder or to run a soldering iron over the components pins with some solder wick to remove the excess paste. Its difficult to judge from the photos. Solvents wont remove partially melted solder.

Alternatively and this maybe the better way to attack the problem, remove the DAC IC's, remove the solder paste from the pcb with a soldering iron and solder wick and start over with solder paste applied to the component pads only or depending on your soldering technique you could just remove the ic's clean the board and handsolder the ic's back onto the pcb.

Do you have a syringe to apply the solder paste ?

It seems you managed to clean most of the solder paste off the pcb, I think the best way forward is to either put the boards back in the oven to reflow the solder or to run a soldering iron over the components pins with some solder wick to remove the excess paste. Its difficult to judge from the photos. Solvents wont remove partially melted solder.

Alternatively and this maybe the better way to attack the problem, remove the DAC IC's, remove the solder paste from the pcb with a soldering iron and solder wick and start over with solder paste applied to the component pads only or depending on your soldering technique you could just remove the ic's clean the board and handsolder the ic's back onto the pcb.

Do you have a syringe to apply the solder paste ?

I don't have a syringe, I have a pot of solder paste, I could try a toothpick I suppose.

I think I'll put them back in the oven, remove the chips and have another go.

Maybe I don't have the right solder paste. It's Mechanic XG50, supposed to melt at 183C.

I think I'll put them back in the oven, remove the chips and have another go.

Maybe I don't have the right solder paste. It's Mechanic XG50, supposed to melt at 183C.

The solder paste is okay, it's the delivery method increasing the degree of difficulty in the application, if you have the patience of a saint, a toothpick should be okay.

For rework purposes solder paste is available in a syringe for these types of applications.

For rework purposes solder paste is available in a syringe for these types of applications.

Attachments

Last edited:

I am not sure why you want to use paste, reflow when you can hand solder in much less time and eliminate a lot of process. Reflow has its place but not for a few comps. If you can’t solder each pin individually then create a bridge and use solder wick to clean up excess. I use aim no clean 15 mil solder pb/sn

Put flux on the pads, and dip the component leads in paste.

Place the components on the board, after checking orientation.

Then use a directed flow of hot air, as the soldering temperature and time can damage the components if excessive.

No need for tooth picks

There are special SMD work stations, I use a heat gun, basically the big brother of hair dryers, as I rarely repair SMD parts.

Place the components on the board, after checking orientation.

Then use a directed flow of hot air, as the soldering temperature and time can damage the components if excessive.

No need for tooth picks

There are special SMD work stations, I use a heat gun, basically the big brother of hair dryers, as I rarely repair SMD parts.

I've developed a method that makes SMD soldering a piece of cake! First I tin the pcb pads with ordinary resin core solder and my soldering iron. I just brush across the pads with fresh solder and they only hold just the necessary solder nice and clean. Then without cleaning off the flux, I place the chip in position and heat it with a hot air gun set at low air pressure and relatively high temperature. At a very early point the residual flux sticks the chip in place and after a while the solder will flow. The result is 100% repeatable and looks really pro!

I have a hot air gun for stripping wallpaper, I can give that a try.

Soldering with a hand iron and cleaning up any bridges is something I have tried and failed to do, I found it impossible to get rid of all the bridges, ruined several chips trying.

Soldering with a hand iron and cleaning up any bridges is something I have tried and failed to do, I found it impossible to get rid of all the bridges, ruined several chips trying.

I am not sure why you want to use paste, reflow when you can hand solder in much less time and eliminate a lot of process. Reflow has its place but not for a few comps. If you can’t solder each pin individually then create a bridge and use solder wick to clean up excess. I use aim no clean 15 mil solder pb/sn

For one IC I would just drag solder the pins. Done in seconds.

Use flux paste on pads.

Put IC on pads.

Tack solder pin 1.

Drag solder opposite side to pin 1.

Drag solder pin 1 side.

To get rid of bridges remove all solder from iron and drag iron away from pad to pull excess solder away.

Any stubborn shorts can be removed with copper braid.

That's exactly how I did it Nigel, I have a pair of PCM1798s here soldered on boards that have bridges that just will not shift despite spending a lot of time with the copper wick trying to clean them up. If you'd like to have them, I'll pop them in the post, you might have more luck than I did.

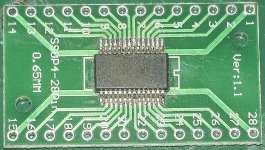

I tried cleaning up the chips I did in the oven with the soldering iron and wick, they have come up quite clean, but there is still some crap lurking underneath, do I need to get rid of every trace of the gunk from the paste? If so, I'll have to remove them from the boards.

I tried cleaning up the chips I did in the oven with the soldering iron and wick, they have come up quite clean, but there is still some crap lurking underneath, do I need to get rid of every trace of the gunk from the paste? If so, I'll have to remove them from the boards.

Attachments

Sometimes putting flux paste on the pins then removing all solder from iron then drawing solder away from the pin works. It sometimes takes a few attempts before it removes the solder.

A last resort is to heat up solder bridge then flick the pcb and the solder comes off.

A last resort is to heat up solder bridge then flick the pcb and the solder comes off.

I'll give them a coating of flux and try that, thanks for the tip.

BTW I'm a fellow Cumbrian, but I'm way down in Millom.

BTW I'm a fellow Cumbrian, but I'm way down in Millom.

I have had lots of practice.

The copper braid is supposed to have flux in it.

Sometimes a little extra flux helps.

The copper braid is supposed to have flux in it.

Sometimes a little extra flux helps.

I don't think this braid has any flux, it's cheap Chinese 'Goot wick'. No problem though, I have a couple of ancient but still very useful pots of Fluxite.

Well flux me, Nigel's tip worked. A liberal application of flux was what it needed, all the excess came off onto the copper wick, a real eureka moment.

Thanks Nigel.

You probably want to check for shorts between pins with an ohmmeter, some pins at the bottom row look shorted.

Jan

For one IC I would just drag solder the pins. Done in seconds.

Use flux paste on pads.

Put IC on pads.

Tack solder pin 1.

Drag solder opposite side to pin 1.

Drag solder pin 1 side.

To get rid of bridges remove all solder from iron and drag iron away from pad to pull excess solder away.

Any stubborn shorts can be removed with copper braid.

There are special tips,made for this method. They have a concave area at the tip to hold a pool of solder.I took a very good smd soldering course way back and that is what we used,they work very well.Make sure and use flux,always.

You probably want to check for shorts between pins with an ohmmeter, some pins at the bottom row look shorted.

Jan

Yes, I will do that, cheers Jan.

Your feet has to be comfortable too, when using the microscope filling up the small pads., if you have the patience of a saint,.

- Home

- Design & Build

- Construction Tips

- First attempt at reflow soldering