Living on the edge!

Sounds like Zen Mod's idea of a makeshift lever to apply pressure could be enough.

Sounds like Zen Mod's idea of a makeshift lever to apply pressure could be enough.

Last edited:

On my F3 build I bough a couple of the heatsinks below and drilled out the spring that was riveted on the small sink. I then had to just drill and tap 1 hole on the amp heatsinks for the spring. Worked great.

H0639 Clip On TO220 Heatsink - Altronics

H0639 Clip On TO220 Heatsink - Altronics

Living on the edge!

Sounds like Zen Mod's idea of a makeshift lever to apply pressure could be enough.

read datasheet of LU

its sturdy little bugger

as used in LuDEF, 2V4 @1A5, it'll live zillion years, with no sweat

with 1.8C/W , as junction to case figure, I'm sleeping well

just take in account that, say, IRF510 and similar, are often used at 1W, without heatsink** ......... and when there is heatsink, it's usually small piece of Al plate in air, not big chunk of Al as here, being fast to draw from little bugger

**not that I'm doing that, ZM Chicken

so, nice clamp, piece of Keratherm under, no biggie

tricks are necessary for lhquam's future adventures, not LuDEF

On my F3 build I bough a couple of the heatsinks below and drilled out the spring that was riveted on the small sink. I then had to just drill and tap 1 hole on the amp heatsinks for the spring. Worked great.

H0639 Clip On TO220 Heatsink - Altronics

Did you use only the spring from that heatsink assembly?

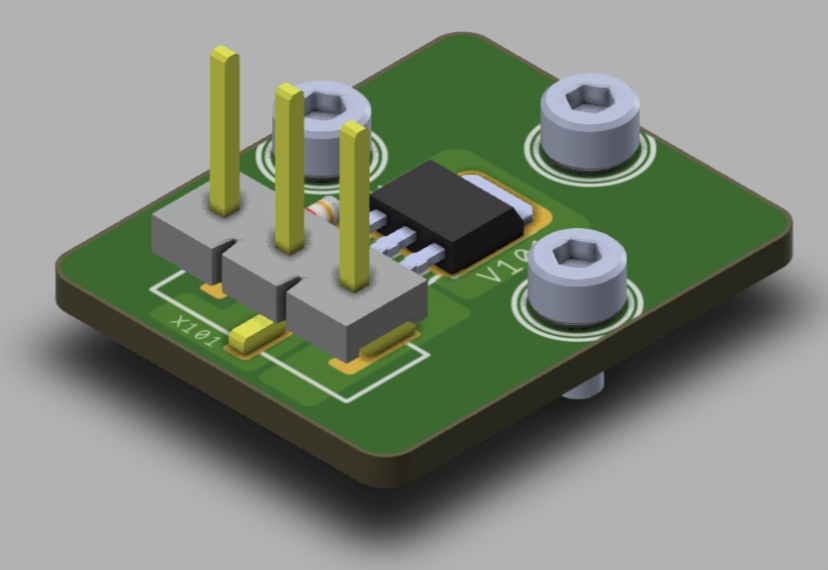

Updated Gerber files for TO-247 adapter with no thermal reliefs. Not that the bolt pattern should allow clamping with UMS heatsinks. The aluminum IMS PCB provides thermal transfer, extended legs for underhung PCB mount, and easy mounting as TO-247 or as clamp with lateral bolt holes on UMS heatsink.

Attachments

I held the tab to the sink with a large flat washer (at an angle) and

counted on the silicone and anodizing to withstand the couple volts...

Arrrrrr...

The LU1014D in the F3 is operated common-source and thus the drain voltage of the JFET is only about 3.5V, which should not present an aluminum oxide dielectric breakdown problem.

But, with the LU1014D operating as a source-follower, the drain-to-heatsink voltage can approach the rail voltage, which could be a problem with the anodized (aluminum oxide) insulator.

Did you use only the spring from that heatsink assembly?

Yes, just the spring. I cut a small square of mica and used goop and there's plenty enough clamping pressure to hold it all down. I'd show a photo but a friend has the amp.

I held the tab to the sink with a large flat washer (at an angle) and

counted on the silicone and anodizing to withstand the couple volts...

A premium thermal grease has a thermal conductivity of 8.5W/mK.

Optimal grease thickness is 0.1mm.

For 3.6W dissipation, and the LU1014 footprint of 6x7mm, temperature difference across a single layer of grease is 1.01°C.

Total temperature difference from heatsink to LU1014 substrate is 7.53°C.

Assume a copper spreader of 20x7mm with 2x 2.7mm mounting holes for M2.5 screws.

https://www.diyaudio.com/forums/att...ch-lu1014-power-jfet-buy-lu1014d-heatsink-jpg

Assume insulation by Kerafol 86/82.

Further assume 0.2mm SnAg solder between LU1014 and spreader.

Lovoltech LU1014 Power Jfet Group Buy

Temperature drop across the Kerafol is 0.98°C, that across the solder joint is 0.22°C.

Total temperature difference from heatsink to Lu1014 case is 1.2°C.

Total dT heatsink to substrate is 7.72°C.

I guess 0.2°C more for electrical insulation up to 1kV is not a bad deal. 😉

Cheers,

Patrick

How about just using LU1014 on its own, with 0.05mm mica, and grease on both sides ?

Mica has a rather poor thermal conductivity of 0.53W/mK.

https://www.mouser.com/catalog/specsheets/Aavid_560295G.pdf

So just the mica alone is responsible for 8.1°C drop.

Add two layers of grease, total temperature difference heatsink to case is 10.1°C.

dT heatsink to substrate is 16.6°C.

Patrick

Mica has a rather poor thermal conductivity of 0.53W/mK.

https://www.mouser.com/catalog/specsheets/Aavid_560295G.pdf

So just the mica alone is responsible for 8.1°C drop.

Add two layers of grease, total temperature difference heatsink to case is 10.1°C.

dT heatsink to substrate is 16.6°C.

Patrick

EUVL: I am happy to see you weigh in on this issue. The copper spreader in post #330 is also my preferred choice, but with the drain attachment to the copper spreader.

Last edited:

Fuses received

They don't look like Papa's stash here: https://www.diyaudio.com/forums/pas...-genuine-lovoltech-lu1014d-2.html#post4935667

Even the dimensions of the legs are not according to the datasheet. So pretty much as expected. Now we know. I hope to curve trace them soon anyway.

They don't look like Papa's stash here: https://www.diyaudio.com/forums/pas...-genuine-lovoltech-lu1014d-2.html#post4935667

Even the dimensions of the legs are not according to the datasheet. So pretty much as expected. Now we know. I hope to curve trace them soon anyway.

In fairness to the seller until the parts have been curve traced. Mine look a lot like the ones ZM shows here. https://www.diyaudio.com/forums/pass-labs/369990-ludef.html#post6588646. I'll report back.

Correct, new legs have been crimped on them,

refurbished with new legs 🙂

They look the same like mine

refurbished with new legs 🙂

They look the same like mine

- Home

- Amplifiers

- Pass Labs

- LuDEF