This thread was split from another. Split begins here.

This thread was split from another. Split begins here.you may have a build up of carbonate down in those grooves. Usually the carbonate is the highest at the lead in groove, but sometimes there are excessive amounts towards the label. Try super cleaning that record and see if it helps. Few vinyl collectors know much about carbonate, but the vinyl is loaded with it. Not easy to remove but once you do, your vinyl will sound so much more open, and natural sounding.

Hi johnss, do you have a link for more information carbonate build-up? Done a few searches but no hits.

Kevin

Kevin

Calcium carbonate is used in the production of PVC products to improve stiffness and impact resistance.

Calcium carbonate has been used as a filler in vinyl records:

https://pdfs.semanticscholar.org/2163/fb4fdf482275c9ce04e06595e10df29d6449.pdf

Calcium carbonate has been used as a filler in vinyl records:

https://pdfs.semanticscholar.org/2163/fb4fdf482275c9ce04e06595e10df29d6449.pdf

I never heard of this. I heard about plasticizers in vinyl. Calcium carbonate I think is an abrasive material (grind stone). Why is it highest at the lead in groove? And how could it be removed? Or is it a contamination on the surface?

@Galu is correct.

Carbonate, (Calcium Carbonate – Chemical name CaCO3) is added to the vinyl mix before pelletizing at the resin producer. Calcium Carbonate is an impact modifier that is added to the raw PVC resin (along with other ingredients during mixing) before it is pelletized.

Carbonate has been used in PVC, Polypropylene, and Polyethylene plastics for consumer goods for over 60 years. It is not used in medical grade plastics, since many of the drugs will interact with it and leach it out of the plastic and into suspension in the solution.

The finished pellets are shipped off to record stamping or pressing plants.

The resin is used to make a puck (a donut shaped piece of resin with the labels attached.

During the pressing operation, The donut is squeezed into a vinyl record from the heat and pressure coming from the press. At the end of the heating cycle, the steam is shut off, and chilled water enters the press jackets to cool the vinyl. During this stage, the carbonate comes out of suspension and collects on the pressing tooling and the bottom of the groove.

All vinyl records have it to varying degrees. The worst offenders are high volume run pop / rock titles, Christmas titles, anything that has a huge market demand creating big orders for the pressing companies.

I have looked at over 100 vinyl records from the US, Europe and Japan. The best looking (cleanest) are of course from the Japan pressing plants. They use a finer grade of Calcium carbonate, run gentler, longer cooling cycles, so maintain a better homogenous mix of carbonate within the resin mix even during the cooling cycle.

If you have ever listened to a vinyl record pressed in Japan, you will find they are very quiet and do not exhibit much in the way of ticks and pops.

The carbonate is not a covalent bond to the vinyl but a static bond, so it can be removed, but takes some doing. A single pass on a vac machine (nitty gritty, VPI, Pro-Ject) will not do much.

Would need to make between 6x-8x passes on a vac machine to really make a dent in the particles. And then only with a solution using a really good surfactant. Without the surfactant in the cleaning solution, the person cleaning records is not really doing much cleaning.

The particle sizes of the carbonate vary widely. At the bottom of the groove they range from 5um to 12um, with a few in the 15-20um range (these larger particles are big enough to hit the bottom of your stylus when it comes through the groove.

Then there are tons and tons of submicron particles clinging to the groove walls. These range in size from 10nm to 100nm. They are constantly pushed around by the stylus tip when playing a vinyl record, the same way snow is pushed around by a snow plow.

Need evidence?

Take a look at your stylus cleaning solution. It will be loaded with fine particles.

Or look at the bottom of the phono cartridge and stylus, they will be coated with fine white particles.

I have quite a few photo micrographs of groove images. If there is an interest, I can look for them. If not that is OK too.

Carbonate, (Calcium Carbonate – Chemical name CaCO3) is added to the vinyl mix before pelletizing at the resin producer. Calcium Carbonate is an impact modifier that is added to the raw PVC resin (along with other ingredients during mixing) before it is pelletized.

Carbonate has been used in PVC, Polypropylene, and Polyethylene plastics for consumer goods for over 60 years. It is not used in medical grade plastics, since many of the drugs will interact with it and leach it out of the plastic and into suspension in the solution.

The finished pellets are shipped off to record stamping or pressing plants.

The resin is used to make a puck (a donut shaped piece of resin with the labels attached.

During the pressing operation, The donut is squeezed into a vinyl record from the heat and pressure coming from the press. At the end of the heating cycle, the steam is shut off, and chilled water enters the press jackets to cool the vinyl. During this stage, the carbonate comes out of suspension and collects on the pressing tooling and the bottom of the groove.

All vinyl records have it to varying degrees. The worst offenders are high volume run pop / rock titles, Christmas titles, anything that has a huge market demand creating big orders for the pressing companies.

I have looked at over 100 vinyl records from the US, Europe and Japan. The best looking (cleanest) are of course from the Japan pressing plants. They use a finer grade of Calcium carbonate, run gentler, longer cooling cycles, so maintain a better homogenous mix of carbonate within the resin mix even during the cooling cycle.

If you have ever listened to a vinyl record pressed in Japan, you will find they are very quiet and do not exhibit much in the way of ticks and pops.

The carbonate is not a covalent bond to the vinyl but a static bond, so it can be removed, but takes some doing. A single pass on a vac machine (nitty gritty, VPI, Pro-Ject) will not do much.

Would need to make between 6x-8x passes on a vac machine to really make a dent in the particles. And then only with a solution using a really good surfactant. Without the surfactant in the cleaning solution, the person cleaning records is not really doing much cleaning.

The particle sizes of the carbonate vary widely. At the bottom of the groove they range from 5um to 12um, with a few in the 15-20um range (these larger particles are big enough to hit the bottom of your stylus when it comes through the groove.

Then there are tons and tons of submicron particles clinging to the groove walls. These range in size from 10nm to 100nm. They are constantly pushed around by the stylus tip when playing a vinyl record, the same way snow is pushed around by a snow plow.

Need evidence?

Take a look at your stylus cleaning solution. It will be loaded with fine particles.

Or look at the bottom of the phono cartridge and stylus, they will be coated with fine white particles.

I have quite a few photo micrographs of groove images. If there is an interest, I can look for them. If not that is OK too.

It become a good discussion. I had different quality types of vinyl which sound better or not so much at the inner tracks. The question is how is it on your side? Is it worth listening like this? Do you have so precise set which ignores this fact? Do you fight such problems with better nail with a special profile or different?

I'd be keen to see them. Please post. We'll probably split it off into a new thread.I have quite a few photo micrographs of groove images. If there is an interest, I can look for them. If not that is OK too.

I have quite a few photo micrographs of groove images. If there is an interest, I can look for them. If not that is OK too.

I'm interested, mainly because the analysis Shure did back in the day did not mention this amongst everything they found in record grooves so I wonder how they missed it.

It become a good discussion. I had different quality types of vinyl which sound better or not so much at the inner tracks. The question is how is it on your side? Is it worth listening like this? Do you have so precise set which ignores this fact? Do you fight such problems with better nail with a special profile or different?

would agree with you. Not all pressing plants used the same vinyl formulation.

Not sure I comprehend your 3rd question "Do you have a precise set which ignores this fact"

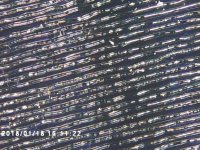

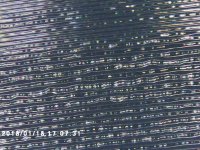

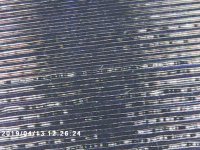

Here are a few of the first photos. The first is a 1970s rock pressing uncleaned.

The second image is the same record with 1x pass on a VPI VAC machine

As you can see, not much difference other than the surface contamination is now gone.

The second image is the same record with 1x pass on a VPI VAC machine

As you can see, not much difference other than the surface contamination is now gone.

Attachments

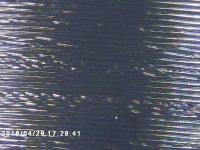

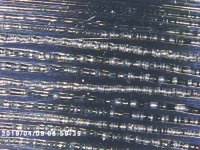

Next are 4 images of an OJC (original Jazz Classics) US pressing from the early 1990s. These images were taken after 4 passes on a VPI vac machine. You see there are still a few particles, but most are now gone.

Attachments

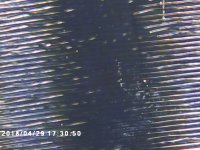

a few shots of a brand new 180 gram pressing uncleaned. the carbonate level in the bottom of the groove is roughly 25-30% less that older pressings, but you can clearly see much of it is still there.

the third image is taken of the famous RCA Reiner Pines of Rome after multiple passes on a VAC machine. You can see the grooves are clean but still some areas where the Carbonate is still present. The faint white marks in the images are paper sleeve scratches on the land area (flat area between grooves) caused by sliding the vinyl in and out of the paper sleeve.

the third image is taken of the famous RCA Reiner Pines of Rome after multiple passes on a VAC machine. You can see the grooves are clean but still some areas where the Carbonate is still present. The faint white marks in the images are paper sleeve scratches on the land area (flat area between grooves) caused by sliding the vinyl in and out of the paper sleeve.

Attachments

should also note these images were taken with a high res scope, not an SEM. Most images on the web are SEM images. To get these images, you first must clean, and coat the object with a conductive compound. This process washes away most of the carbonate, hence it will not be there in an SEM image.

Thanks for the pics. They certainly show a lot of white spots, but those spots look a lot like specular reflections to me. Could they be that?

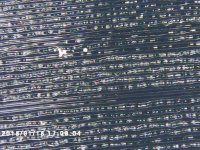

and lastly a few more of uncleaned vs. 4x-6x multiple pass cleaning on a VAC machine. I have 2 Nitty Grittys, a VPI and a Pro-Ject vac machine. I can not really detect a cleaning difference between them, but prefer the Pro-Ject since its build quality is better and can run for extended periods without overheating.

Note: if you have a vac machine, you can do this yourself (achieve this level of groove cleaning) as long as you are using plenty of surfactant in your cleaning solution. If you are using H2O/IPA mix only, it will not budge these particles.

This set of images is off the David Bowie 45 RPM vinyl of CATS, if You have heard this recording, you know its quite dynamic. Uncleaned the grooves are packed with Carbonate. Post clean they are mostly clean but still have a few areas that carbonate remains in. Post clean there is much more information coming off the vinyl, much more 3 dimensional sounding or more of that high speed tape type of sound (am willing to admit, I have a severe case of the audio disease so am heavy into 15 IPS 2 track tape as well as vinyl).

And one last image of a post cleaned Fagen Nightly album.

If the original poster was located in the US I would offer to clean 2 of their vinyl records for them, take photos pre and post cleaning and return the records with the images, but overseas shipping gets expensive.

And have to reiterate, like most, I originally had not a clue these particles were there. Removing them though makes a bigger improvement than installing a new phono cartridge or a new phono preamp.

happy spinning.

best

Note: if you have a vac machine, you can do this yourself (achieve this level of groove cleaning) as long as you are using plenty of surfactant in your cleaning solution. If you are using H2O/IPA mix only, it will not budge these particles.

This set of images is off the David Bowie 45 RPM vinyl of CATS, if You have heard this recording, you know its quite dynamic. Uncleaned the grooves are packed with Carbonate. Post clean they are mostly clean but still have a few areas that carbonate remains in. Post clean there is much more information coming off the vinyl, much more 3 dimensional sounding or more of that high speed tape type of sound (am willing to admit, I have a severe case of the audio disease so am heavy into 15 IPS 2 track tape as well as vinyl).

And one last image of a post cleaned Fagen Nightly album.

If the original poster was located in the US I would offer to clean 2 of their vinyl records for them, take photos pre and post cleaning and return the records with the images, but overseas shipping gets expensive.

And have to reiterate, like most, I originally had not a clue these particles were there. Removing them though makes a bigger improvement than installing a new phono cartridge or a new phono preamp.

happy spinning.

best

Attachments

-

PICT0144 Bowie 45 grooves packed w carbonate .jpg450.6 KB · Views: 201

PICT0144 Bowie 45 grooves packed w carbonate .jpg450.6 KB · Views: 201 -

PICT0145 Bowie 45 grooves packed w carbonate.jpg480.6 KB · Views: 165

PICT0145 Bowie 45 grooves packed w carbonate.jpg480.6 KB · Views: 165 -

PICT0148 Bowie 45 post clean .jpg404.2 KB · Views: 158

PICT0148 Bowie 45 post clean .jpg404.2 KB · Views: 158 -

PICT0149 Bowie 45 post clean.jpg405.2 KB · Views: 155

PICT0149 Bowie 45 post clean.jpg405.2 KB · Views: 155 -

PICT0158 Night fly post clean .jpg312.5 KB · Views: 176

PICT0158 Night fly post clean .jpg312.5 KB · Views: 176

the reflections are coming off the particles, if you notice the clean photos show the reflections and particles are gone.

and forgot to add, have made a positive particle ID at work, 99.9% certainty the particles are CaCo3, but those images are proprietary so can not post them.

Johnss,

sorry, but I don't get it.

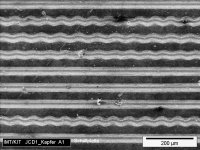

This is how an LP record is looking like.

Your pics show something with obscure reflections. I can see nothing but reflections and very bad picture quality on them. Never had I saw such thing as your pics, that should be LP record pics.

But I can show you another pic. And this one doesn't show the problems you mentioned.

Nothing, nada, zero of what you try to show as a "problem" occurs on this pic.

Myself, I own some thousand records, mostly bought used, in various conditions.

I run them with mono and stereo pick ups.

I had never those described problems. And I don't own a disc washing machine.

If a record is badly dirty, I just use soft materials and wipe it with a mix of destilled water and pure alcohol. Thats it. After that procedure, the record plays just fine.

That may happen with every fifty used bought record or so, because I don't buy crappy records, just good ones. But sometimes, they are a little dirty, of course. Just the usual dirt that comes from the room dust, for that the vinyl record is a magnet it seems.

I collect records since some decades, never had any problems with them.

Just look at my pic, what you show is something very unusual and your picture quality is so obscure that its impossible to justify anything with it.

What you describe is simply not possible to manifest at your pics.

P.S. When I read about six to eight cleaning cycles for every record, I would have to clean my whole life long. But I've done nothing like this. And I've even invested nearly nothing for cleaning, too. Just two good ears, good records and a high efficiency (99dB) audio system. I really think, if your described problems existed, I would have been a good candidate to hear them with my system.

sorry, but I don't get it.

This is how an LP record is looking like.

Your pics show something with obscure reflections. I can see nothing but reflections and very bad picture quality on them. Never had I saw such thing as your pics, that should be LP record pics.

But I can show you another pic. And this one doesn't show the problems you mentioned.

Nothing, nada, zero of what you try to show as a "problem" occurs on this pic.

Myself, I own some thousand records, mostly bought used, in various conditions.

I run them with mono and stereo pick ups.

I had never those described problems. And I don't own a disc washing machine.

If a record is badly dirty, I just use soft materials and wipe it with a mix of destilled water and pure alcohol. Thats it. After that procedure, the record plays just fine.

That may happen with every fifty used bought record or so, because I don't buy crappy records, just good ones. But sometimes, they are a little dirty, of course. Just the usual dirt that comes from the room dust, for that the vinyl record is a magnet it seems.

I collect records since some decades, never had any problems with them.

Just look at my pic, what you show is something very unusual and your picture quality is so obscure that its impossible to justify anything with it.

What you describe is simply not possible to manifest at your pics.

P.S. When I read about six to eight cleaning cycles for every record, I would have to clean my whole life long. But I've done nothing like this. And I've even invested nearly nothing for cleaning, too. Just two good ears, good records and a high efficiency (99dB) audio system. I really think, if your described problems existed, I would have been a good candidate to hear them with my system.

Attachments

Last edited:

@Schmitz77,

yes I was just like you, did not believe those particles were there. And also agree with you on people who have thousands of records - would be a lot of cleaning time to do them all.

In the photo you attached, you can still see the carbonate particles.

Should also note I work in the pharmaceutical industry so have access to all sorts of high tech analytical tools. I have been able to identify those particles as Calcium carbonate with 99.9% accuracy. The groove images I took at work are much higher resolution, but I cannot post since they are company property.

But once you get them removed, you will be shocked at the sonic improvement you can hear even with an inexpensive turntable, cartridge and phono preamp.

yes I was just like you, did not believe those particles were there. And also agree with you on people who have thousands of records - would be a lot of cleaning time to do them all.

In the photo you attached, you can still see the carbonate particles.

Should also note I work in the pharmaceutical industry so have access to all sorts of high tech analytical tools. I have been able to identify those particles as Calcium carbonate with 99.9% accuracy. The groove images I took at work are much higher resolution, but I cannot post since they are company property.

But once you get them removed, you will be shocked at the sonic improvement you can hear even with an inexpensive turntable, cartridge and phono preamp.

- Home

- Source & Line

- Analogue Source

- Calcium carbonate in record grooves