OK, I dont have access to the opposite side of the panel. So I used the hole tool to scribe and the used the jig saw to chase the slot. I set the saw to 20 deg to flare toward the cabinet interior.

Hit the inside walls with the blade, so the flares are straight by the cab walls, and 20 deg half moons, top and bottom. At least it's something; couldnt mount the driver on the inside if I wanted to, by cabinet dimensions - unless I routed out the side panels to accommodate the driver flange.

Looks like it is what it is, regarding the baffle thickness interfering with sound coming out the speaker back side, with the speaker mounted flat to the baffle surface. My tooling just wont accommodate a flush mount cutout, so I'm limited in the features I can construct.

Hopefully the port is OK; I got a 4" length on the base part, plus a 1" length going up into the cabinet interior for 5". Hopefully I got the port area correct.

Hit the inside walls with the blade, so the flares are straight by the cab walls, and 20 deg half moons, top and bottom. At least it's something; couldnt mount the driver on the inside if I wanted to, by cabinet dimensions - unless I routed out the side panels to accommodate the driver flange.

Looks like it is what it is, regarding the baffle thickness interfering with sound coming out the speaker back side, with the speaker mounted flat to the baffle surface. My tooling just wont accommodate a flush mount cutout, so I'm limited in the features I can construct.

Hopefully the port is OK; I got a 4" length on the base part, plus a 1" length going up into the cabinet interior for 5". Hopefully I got the port area correct.

Hi jjasniew,

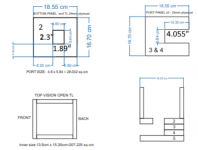

if you got a 4" (101.6mm ) length on the base part is impossible have 1" ( 25.40mm) remaining with layer of 16mm MDF or wood, you must remember that the port length have to be measured on the middle of the 28 square cm port, I make a quick draw for better understanding, if you already did it forget my comment....all the best

if you got a 4" (101.6mm ) length on the base part is impossible have 1" ( 25.40mm) remaining with layer of 16mm MDF or wood, you must remember that the port length have to be measured on the middle of the 28 square cm port, I make a quick draw for better understanding, if you already did it forget my comment....all the best

Attachments

I based off these drawings, which I found here. I however pushed section 2 up inside the enclosure (same with top piece) and made the cab ~2" taller to keep the 39" internal length. So you wont see section 2 from the outside.

I did this for strength and to have a piece the F/B and sides could wrap around, for assembly.

I didnt have 24mm, so I used laminated shelving probably at ~1" thick.

Thanks for your help, hopefully my change works out correctly.

I did this for strength and to have a piece the F/B and sides could wrap around, for assembly.

I didnt have 24mm, so I used laminated shelving probably at ~1" thick.

Thanks for your help, hopefully my change works out correctly.

Attachments

I got the tool today and - ooof! - it does plunge through a scrap piece, if I come in from both sides. That's not possible with my cabinet as built. So I'll have to use it to scribe a deep line and chase that with the jig saw...

Looking at how the speaker fits into the 16mm MDF, it appears its rear vents are almost completely blocked. I havent seen any details of how this is typically addressed for the W5 2143. I guess I'll have to pick an angle for the jig saw blade and hope for the best.

Is there a better way? Rear mounting the driver is not an option, with the cabinets as built. I've limited skill and cant mill out recesses or fancy beads about the speaker cutout. What's a "peasant" woodworker to do? I'm kinda stuck and would like to address this in some reasonable, doable way.

Thanks for any help!

I have used a dovetail bit in a router to clearance the back side of the driver hole before. Be very careful to not take too much material, and allow for fasteners... In other words mark where the holes will be, and where the frame is "solid" and only rout the areas where you need venting.

John

I based off these drawings, which I found here. I however pushed section 2 up inside the enclosure (same with top piece) and made the cab ~2" taller to keep the 39" internal length. So you wont see section 2 from the outside.

I did this for strength and to have a piece the F/B and sides could wrap around, for assembly.

I didnt have 24mm, so I used laminated shelving probably at ~1" thick.

Thanks for your help, hopefully my change works out correctly.

I see very good well done......all the best

I mentioned previously that the MDF I used is pretty low quality - a little bit better than Graham Crackers. I knew if I cut that hole before assy to the rest of the box, it would break at the two narrow parts handling.

If I were to do over, I'd cut out a square in the baffle about the speaker location and frame it so I could use an entirely different piece of wood for the speaker cutout and mounting.

This was an experiment to try out some things, using a stock of scrap wood I happened to have on hand. One was the cabinet itself. I need to finish up, get them into a presentable form and report back here.

I'm listening to them now, with the top "pipes" just set on the bases, the top part of the pipes - above the drivers - stuffed with a pad at the end and a jelly roll of some material I saved from an old KEF enclosure. Bass is very "polite" but definitely there. I think they're going to sound nice when complete from what I'm hearing.

I have stuffing for the lower part and understand I'd want to go a little lighter there. Something for the wall directly behind the driver. I realize the # of I/Os for the 4 screws going into the cracker jack MDF is limited - another reason supporting a better quality baffle board section.

If I were to do over, I'd cut out a square in the baffle about the speaker location and frame it so I could use an entirely different piece of wood for the speaker cutout and mounting.

This was an experiment to try out some things, using a stock of scrap wood I happened to have on hand. One was the cabinet itself. I need to finish up, get them into a presentable form and report back here.

I'm listening to them now, with the top "pipes" just set on the bases, the top part of the pipes - above the drivers - stuffed with a pad at the end and a jelly roll of some material I saved from an old KEF enclosure. Bass is very "polite" but definitely there. I think they're going to sound nice when complete from what I'm hearing.

I have stuffing for the lower part and understand I'd want to go a little lighter there. Something for the wall directly behind the driver. I realize the # of I/Os for the 4 screws going into the cracker jack MDF is limited - another reason supporting a better quality baffle board section.

Last edited:

Here they are;

My woodworking skills havent evolved since childhood and it shows in the fit / finish. I need a router and bits to do this kind of cabinetry in a better way, particularly making the rounded edges on MDF. Unique to the way I assembled these was the use of the Lanco Ultra-Siliconizer for both finish and adhesive.

As an adhesive, it's plenty strong and I'd hoped its visco-elastic property would make the assembly a bit less rigid, and therefore less "ringy". The adhesive part worked out - the stuff bonds stronger than the MDF holds itself together. There's no screws, glue or cleats holding the panels together. Just surface area painted with and then bonded with the same goo.

As a finish, it didnt do what I'd hoped. Which was to, when applied thick as thieves, stay as thick, make a nice "rubbery" coating - and especially obscure all the minor carpentry anomalies I made. Its thickness seems to disappear as it dries - it's waterbased and easily applicable inside the warmer home environment with zero stink - but no matter how many coats I put on, it almost makes everything wrong stand out, versus cover it up.

The nice rubbery coating aspect was something I'd hoped would turn the MDF a bit towards a meta-material. I have 4 coats on the inside faces and I lost count on the outside; 3/4 of a gallon of this stuff is on these boxes. I think it does some good in this regard, but I wasnt able to achieve the coating thickness I'd anticipated when I originally picked this stuff out. I'm open to trying other "rubberized" products with the visco-elastic property over MDF / wood.

It dries a nice powder-blue, which luckily matches the bedroom wall color. I spoke with the chemist at Lanco, who said it turns bright white when exposed to sunlight. I believe these cabinets will now tolerate 24/7 outdoor exposure - as long as I cover the port and driver when not listening. I'm looking forward to some outdoor-space listening this summer. I'm considering coating the clear plastic shipping covers with the paint to make sun proof driver covers.

I do like the sound of these cabinets, even though I've yet been unable to stuff down the recommended 2/3 of their length. I only have stuffing above the speaker and a fiber pad stapled directly behind it. As the back isnt removable, I'd have to create a support structure for the fiber to hit 2/3 length from the top (going in through the driver cut-out). I tried 0.25 lb of teased out poly-fil, but it dropped all the way to the bottom of the cabinet, interfering with the port. Didnt sound right.

With the interior below the driver open, they sound pretty good with some challenging bass program material. I hope to develop a way to record their performance, such that anyone with headphones that could "download and play the file" could hear what they sound like, from my listening perspective. Hopefully that scheme works out - Just a knuckle rap test between the sides of these and the top of my JBL HLS610 boxes, the ring seems to decay faster. I'd guess you'd have to hear for yourself.

I'm driving them using PiCorePlayer and a HiFiBerry 20 WPC amp, with 24V linear supply. I used the EQ (shown) for my baffle step, which made their sound a lot less shouty. Next step is measurement, one with and one without the EQ, probably pink noise / nth octave analysis and a second using REW. For now, this reply shows what I've done with the W5-2143 in my "experimental" TABAQ cab.

My woodworking skills havent evolved since childhood and it shows in the fit / finish. I need a router and bits to do this kind of cabinetry in a better way, particularly making the rounded edges on MDF. Unique to the way I assembled these was the use of the Lanco Ultra-Siliconizer for both finish and adhesive.

As an adhesive, it's plenty strong and I'd hoped its visco-elastic property would make the assembly a bit less rigid, and therefore less "ringy". The adhesive part worked out - the stuff bonds stronger than the MDF holds itself together. There's no screws, glue or cleats holding the panels together. Just surface area painted with and then bonded with the same goo.

As a finish, it didnt do what I'd hoped. Which was to, when applied thick as thieves, stay as thick, make a nice "rubbery" coating - and especially obscure all the minor carpentry anomalies I made. Its thickness seems to disappear as it dries - it's waterbased and easily applicable inside the warmer home environment with zero stink - but no matter how many coats I put on, it almost makes everything wrong stand out, versus cover it up.

The nice rubbery coating aspect was something I'd hoped would turn the MDF a bit towards a meta-material. I have 4 coats on the inside faces and I lost count on the outside; 3/4 of a gallon of this stuff is on these boxes. I think it does some good in this regard, but I wasnt able to achieve the coating thickness I'd anticipated when I originally picked this stuff out. I'm open to trying other "rubberized" products with the visco-elastic property over MDF / wood.

It dries a nice powder-blue, which luckily matches the bedroom wall color. I spoke with the chemist at Lanco, who said it turns bright white when exposed to sunlight. I believe these cabinets will now tolerate 24/7 outdoor exposure - as long as I cover the port and driver when not listening. I'm looking forward to some outdoor-space listening this summer. I'm considering coating the clear plastic shipping covers with the paint to make sun proof driver covers.

I do like the sound of these cabinets, even though I've yet been unable to stuff down the recommended 2/3 of their length. I only have stuffing above the speaker and a fiber pad stapled directly behind it. As the back isnt removable, I'd have to create a support structure for the fiber to hit 2/3 length from the top (going in through the driver cut-out). I tried 0.25 lb of teased out poly-fil, but it dropped all the way to the bottom of the cabinet, interfering with the port. Didnt sound right.

With the interior below the driver open, they sound pretty good with some challenging bass program material. I hope to develop a way to record their performance, such that anyone with headphones that could "download and play the file" could hear what they sound like, from my listening perspective. Hopefully that scheme works out - Just a knuckle rap test between the sides of these and the top of my JBL HLS610 boxes, the ring seems to decay faster. I'd guess you'd have to hear for yourself.

I'm driving them using PiCorePlayer and a HiFiBerry 20 WPC amp, with 24V linear supply. I used the EQ (shown) for my baffle step, which made their sound a lot less shouty. Next step is measurement, one with and one without the EQ, probably pink noise / nth octave analysis and a second using REW. For now, this reply shows what I've done with the W5-2143 in my "experimental" TABAQ cab.

Attachments

To support the stuffing below the driver, insert a couple of bits of stiff wire cut just longer than the internal dimensions with a long hemostat, then the stuffing won't fall all the way down to the bottom, and can be done through the driver hole... The hemostat's are available at Harbor Freight...

12 in. Locking Clamp Pliers

or,

10-1/2 in. Jumbo Curved Clamp Pliers

John

12 in. Locking Clamp Pliers

or,

10-1/2 in. Jumbo Curved Clamp Pliers

John

jjasniew,

Congratulations on completing your build!

Interesting choice of adhesive. A thought on the more than expected thinning out of multiple coats that you applied on the exterior - did you seal the MDF before applying? MDF is fairly porous and can soak up lot of material. Maybe you can try on a spare price of plywood / MDF - seal it first with wood sealer and then lay down the coats and see it builds up better?

Have fun listening. 🙂

Congratulations on completing your build!

Interesting choice of adhesive. A thought on the more than expected thinning out of multiple coats that you applied on the exterior - did you seal the MDF before applying? MDF is fairly porous and can soak up lot of material. Maybe you can try on a spare price of plywood / MDF - seal it first with wood sealer and then lay down the coats and see it builds up better?

Have fun listening. 🙂

I'd like to thank Bjørn Johannesen for doing the design for the W5-8143 driver!

If anyone wants to hear what they sound like, I've uploaded recordings to Google Drive.

The recordings were done using a binaural mic mounted to my head; I'm sitting on the stool in the middle of the room, about 8' back with the speakers ~7' apart. I find over-the-ear headphones seem to bring back the sound most faithfully. Also, when I playback using my PC "Realtek Audio" sound, it's nothing like playback through the DAC I recorded with, A Tascam US-122L. I'd suggest using an unmolested audio channel for headphone playback.

The selections below were chosen to show the bass response of the cabinets, plus the speed they respond to percussion - and other aspects. Remember, these 5" driver cones measures a little over 4", according to my ruler...

I'm playing 44.1k .flac through a raspberry Pi using PiCorePlayer, with the EQ set per my previous post. Amp is a HiFiBerry II, PSU is 6A linear set to 20V. Playback volume is 70% on all selections, FWIW.

Okay, have a listen if you care to; they're firmly on the chopping block and as they say in reddit, "roast me".

BC_Stool.flac - Google Drive

BF_Stool.flac - Google Drive

JLP_Stool.flac - Google Drive

MT_Stool.flac - Google Drive

SD_Stool.flac - Google Drive

https://drive.google.com/file/d/1blQmMwxtKcymPnoDKq70N0VVegkhLF0U/view?usp=sharing

If anyone wants to hear what they sound like, I've uploaded recordings to Google Drive.

The recordings were done using a binaural mic mounted to my head; I'm sitting on the stool in the middle of the room, about 8' back with the speakers ~7' apart. I find over-the-ear headphones seem to bring back the sound most faithfully. Also, when I playback using my PC "Realtek Audio" sound, it's nothing like playback through the DAC I recorded with, A Tascam US-122L. I'd suggest using an unmolested audio channel for headphone playback.

The selections below were chosen to show the bass response of the cabinets, plus the speed they respond to percussion - and other aspects. Remember, these 5" driver cones measures a little over 4", according to my ruler...

I'm playing 44.1k .flac through a raspberry Pi using PiCorePlayer, with the EQ set per my previous post. Amp is a HiFiBerry II, PSU is 6A linear set to 20V. Playback volume is 70% on all selections, FWIW.

Okay, have a listen if you care to; they're firmly on the chopping block and as they say in reddit, "roast me".

BC_Stool.flac - Google Drive

BF_Stool.flac - Google Drive

JLP_Stool.flac - Google Drive

MT_Stool.flac - Google Drive

SD_Stool.flac - Google Drive

https://drive.google.com/file/d/1blQmMwxtKcymPnoDKq70N0VVegkhLF0U/view?usp=sharing

Last edited:

I am wondering if the Hornresp file has been posted on this thread? At 326 pages, it is not practical to look for it.

Also, has anybody used the Tang Band W3-1878 driver in this design?

Tang Band W3-1878 3" Full-Range Driver

Also, has anybody used the Tang Band W3-1878 driver in this design?

Tang Band W3-1878 3" Full-Range Driver

You could try one of these things, if you don't have a router and a circle-cutting jig:

Mibro Adjustable-Radius Hole Cutter|Rockler Woodworking and Hardware

Is there such a tool that can cut larger than 6" holes - like 7.25" diameter?

Is there such a tool that can cut larger than 6" holes - like 7.25" diameter?

hows 11.8"

Adjustable Drywall and Ceiling Tile Hole Cutter 1.2" to 11.8"

Is there such a tool that can cut larger than 6" holes - like 7.25" diameter?

Nothing works better than a Jasper circle jig that you use with a good plunge router. It's not cheap but there is nothing better. Jasper makes a few different models. I have a small and a large model from them and having been using them for years.

https://www.amazon.com/Jasper-200J-...ocphy=1014570&hvtargid=pla-436216099905&psc=1

By the way, you can buy this straight from Jasper Tools (and avoid Amazon, and give Jasper possibly more profit?) for the same price: Jasper Tools

They have heavy duty versions for about $10 more, which seems to be worthwhile.

They have heavy duty versions for about $10 more, which seems to be worthwhile.

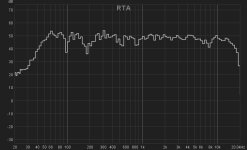

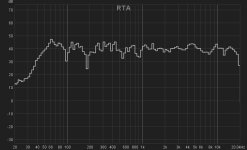

Here's a response I'm getting from one W5-2143 TABAQ speaker I built placed sorta in the middle of the room. Those two combs ~ 100 and 200? I think I'll have to measure outdoors to get rid of them. Far worse and at lower frequencies with both speakers driven, placed where I'd like them to be in the room. (pink noise, 1/12 octave, 1M, on axis)

For grins, I measured a second plot using one side of the binaural mic I used to make the stereo recordings.

For grins, I measured a second plot using one side of the binaural mic I used to make the stereo recordings.

Attachments

Nothing works better than a Jasper circle jig that you use with a good plunge router. It's not cheap but there is nothing better. Jasper makes a few different models. I have a small and a large model from them and having been using them for years.

https://www.amazon.com/Jasper-200J-...ocphy=1014570&hvtargid=pla-436216099905&psc=1

Works fine with a regular router (ie, not plunge) too, if you keep your cuts shallow.

- Home

- Loudspeakers

- Full Range

- TABAQ TL for Tangband