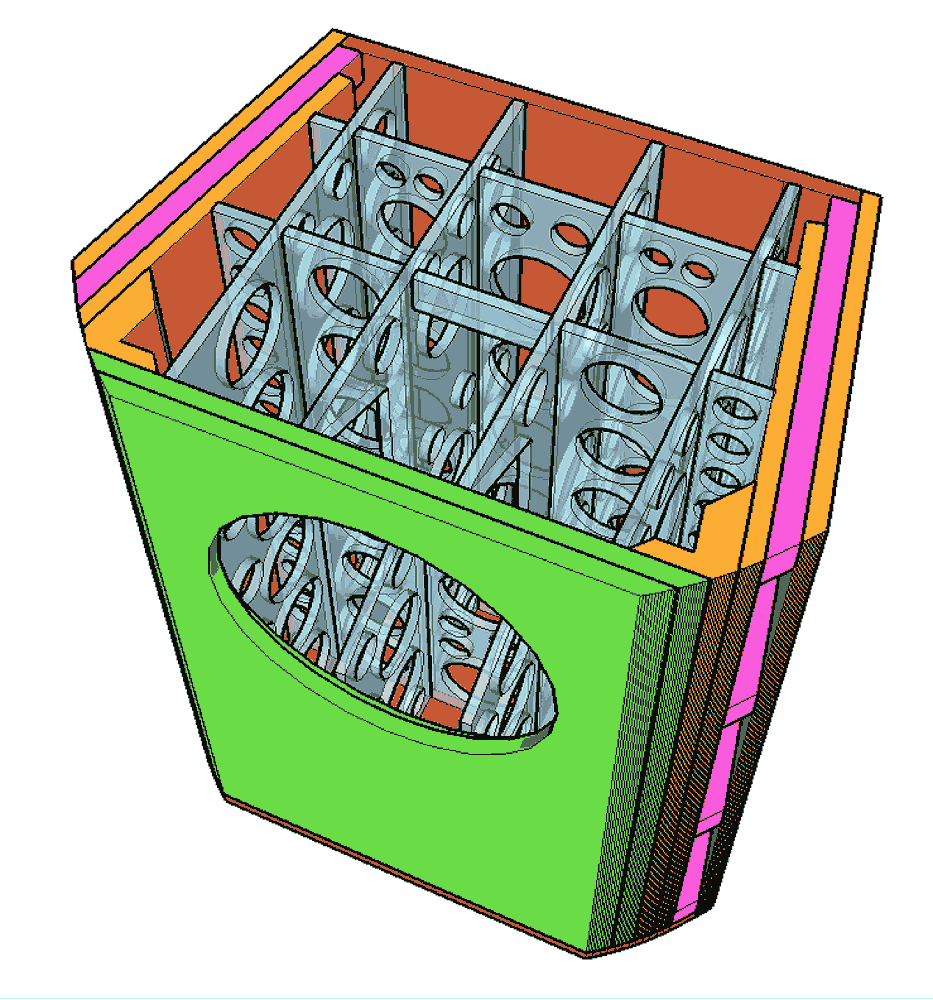

For me, form follows function. For what I had in mind, a rounded cabinet shape trumped a more traditional square shape. Not for looks, purely from audio performance perspective.

Translam was the easiest way I could envision being able to build it myself with limited tools. Interlocking shapes limited the waste I got, Which could have been even less if I would have used other methods than a jigsaw and router. 😉

That, to me, isn't a waste. Just functional.

Translam was the easiest way I could envision being able to build it myself with limited tools. Interlocking shapes limited the waste I got, Which could have been even less if I would have used other methods than a jigsaw and router. 😉

That, to me, isn't a waste. Just functional.

Our successfull attempts...

The panels were the right curve, and very stiff, before attaching to the skeleton.

The curved panels were also used to make a Pensil7.3

dave

They only provide forceover thin bands, that is how it was done th e1st time, the ones we burned. The vaccuum bag provides even force ove rthe entire panel with greater force.

dave

dave

I agree. When a one off is made, waste is kind of irrelevant. You made a functional, stunning loudspeaker that you will probably be happy with for the rest of your life.For me, form follows function. For what I had in mind, a rounded cabinet shape trumped a more traditional square shape. Not for looks, purely from audio performance perspective.

Translam was the easiest way I could envision being able to build it myself with limited tools. Interlocking shapes limited the waste I got, Which could have been even less if I would have used other methods than a jigsaw and router. 😉

That, to me, isn't a waste. Just functional.

If you want the plywood look, you could always cut 1/8" strips of ply and glue the to the outside of a conventional box, as I did with these. When I started the I glued them using a steel angle as a guide, but half way through I found out it wasn't quite 90 deg, so I just bodged them up to finish them, then used them to experiment with. When I glued ( pva ) the ply strips on, the soaked up the pva, expanded, and that caused them to curl up at the edges ( cured by sanding ). also the end grain ply drank up varnish like you wouldn't believe, if I were to do it again I would put pva on both sides to stop both the curling and varnish absorption. Seems to create quite a dead box though.

A better scan of that image in Post #33

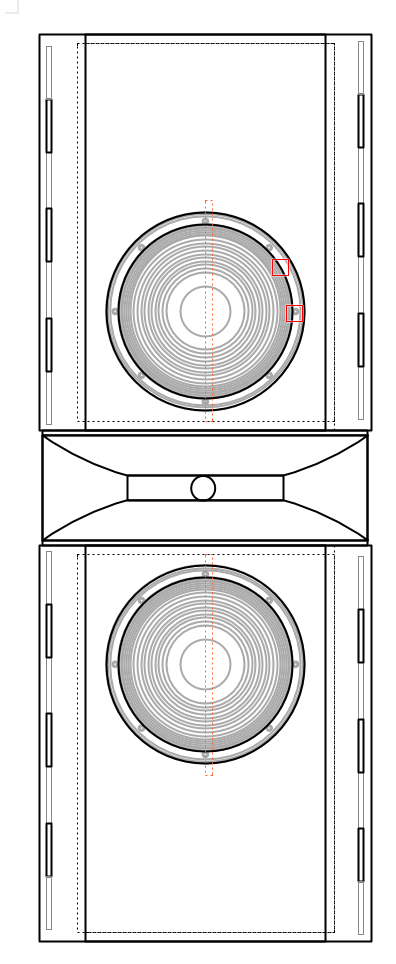

The 302 was a lovely speaker. I added 4 8” Peerless woofers for bass support. Then Acoustats, then a symphony of FR exploration.

dave

The 302 was a lovely speaker. I added 4 8” Peerless woofers for bass support. Then Acoustats, then a symphony of FR exploration.

dave

I'll bet that the B&W matrix enclosure not only effectively attenuates cabinet panel resonances, but does an excellent job of diffusing sound and breaking up internal standing waves too, which is why they probably no longer use the "Prism" method.

Yes, and if low density damping is placed over the braces one can get substanially more absorption of internal waves.

dave

dave

I'm not positive, but I believe B&W incorporates that into the design too. Acoustic foam fit into each separate cell.

I wonder if filling the cabinet with a rigid structural open ( large ) cell foam, that it would both make the cabinet much more rigid and eat up internal standing waves.

These were heavily inspired by those.

dave

Holy crap! Were "These" actually built?

Cracked case are those middle braces in the drawing compliant mechanisms?

Pretty cool stuff could be done with 3D printing. How about trying stiffness and damping on same honey comb structure?😀

Few examples of compliant mechanisms

Metamaterials create mechanisms from a single piece of plastic - YouTube

3D Printed Compliant Mechanisms: 10 Great 3D Models | All3DP

Pretty cool stuff could be done with 3D printing. How about trying stiffness and damping on same honey comb structure?😀

Few examples of compliant mechanisms

Metamaterials create mechanisms from a single piece of plastic - YouTube

3D Printed Compliant Mechanisms: 10 Great 3D Models | All3DP

Last edited:

Holy crap! Were "These" actually built?

Yes. Out of something exotic. Has a TAD 1601 installed.

They have done a Yucki 290 to do with them and a TAD superTweeter.

The Yuchi should give an idea of the end cosmetics. A custom digital XO is being developed by a well-known US XO maker.

dave

- Home

- Loudspeakers

- Multi-Way

- Now that's what I call a cabinet!