I'm about to take a trio ka-3700 power switch apart to clean it and will replace the two 0.1 2000v caps that are placed across it.

What is the current advise on replacements? X2 rated at sensible ac voltage ~ 275v?

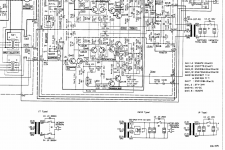

I've attached a relevant snip of the schematic my version is 'T' type 240v.

What is the current advise on replacements? X2 rated at sensible ac voltage ~ 275v?

I've attached a relevant snip of the schematic my version is 'T' type 240v.

Attachments

You mean 0.01uF, not 0.1uF which would be a little to large electrically and also safety wise if you grabbed the plug top at an inopportune moment.

You mean 0.01uF, not 0.1uF which would be a little to large electrically and also safety wise if you grabbed the plug top at an inopportune moment.

I do. Must proof read posts in future.

Any opinions about using a triac to take the stress off the switch?

I see no reason not to use a straightforward 0.01uF film capacitor replacement, provided its voltage rating is no less that 630VDC.

I've just had the switch suppression capacitor fail dead short in my >50 year old valve amp. The series resistor burnt out, but not before the 3A fuse in the plugtop blew and the RCD on the supply board tripped! Replaced the cap with a WIMA film capacitor and the switch's future is secured!

I've just had the switch suppression capacitor fail dead short in my >50 year old valve amp. The series resistor burnt out, but not before the 3A fuse in the plugtop blew and the RCD on the supply board tripped! Replaced the cap with a WIMA film capacitor and the switch's future is secured!

I see no reason not to use a straightforward 0.01uF film capacitor replacement, provided its voltage rating is no less that 630VDC.

I've just had the switch suppression capacitor fail dead short in my >50 year old valve amp. The series resistor burnt out, but not before the 3A fuse in the plugtop blew and the RCD on the supply board tripped! Replaced the cap with a WIMA film capacitor and the switch's future is secured!

I've been installing 0.01 to 0.047uf 630v poly's across power switches for decades and never had an issue yet.

The 2000 v rating on the cap was reasonable. A simple household refrigerator would produce 1300 vdc on the AC line when it shut off at the peak of the sine wave. Saw it all the time on the test line where a new refrigerator was overloaded(stalled) to test the thermal overload protector every 15 seconds.

Household refrigerators no longer use 1/3 hp compressor motors, but A/C units do and larger. Also there are lightning strikes. I had a 1000 v rated .01 cap across the power switch of the PAS2 vaporize in an afternoon storm in Kansas in 1981. Gone, 2 leads left.

The AC rated X2 film caps may take these rediculous spikes on the line below their rated AC voltage in their stride, but I don't have any experience with them. I can't buy even 1000 vdc rated ceramic caps anymore in onesies, the distributors carry 500 v max. If your OEM 2000 v rated cap still measures .01 uf, I'd leave it in place. The ceramics don't burn through and self heal the way the X2 film caps are designed to do; giving them a limited service life.

The ceramics fail by exploding & vaporizing. In a steel chassis like a dynakit PAS2, not a hazard to the eyes. Mine did not blow the fuse. In a plastic chassis left at eye level, owner of such arrangement had better evaluate the risk of shrapnel damage to his eyes, the dependents, visitors, or heirs.

Household refrigerators no longer use 1/3 hp compressor motors, but A/C units do and larger. Also there are lightning strikes. I had a 1000 v rated .01 cap across the power switch of the PAS2 vaporize in an afternoon storm in Kansas in 1981. Gone, 2 leads left.

The AC rated X2 film caps may take these rediculous spikes on the line below their rated AC voltage in their stride, but I don't have any experience with them. I can't buy even 1000 vdc rated ceramic caps anymore in onesies, the distributors carry 500 v max. If your OEM 2000 v rated cap still measures .01 uf, I'd leave it in place. The ceramics don't burn through and self heal the way the X2 film caps are designed to do; giving them a limited service life.

The ceramics fail by exploding & vaporizing. In a steel chassis like a dynakit PAS2, not a hazard to the eyes. Mine did not blow the fuse. In a plastic chassis left at eye level, owner of such arrangement had better evaluate the risk of shrapnel damage to his eyes, the dependents, visitors, or heirs.

Last edited:

I'd hate to find that I was uninsured because loss assessors found my repaired audio gear no longer met underwriter safety requirements. Perhaps that's unlikely in the case of a housefire but underwriter regulations are not based on anecdotal evidence and in this case, they could apply anywhere, globally.

X2 rated caps don't seem to be harder to find or much more expensive than standard 630V film caps so is there any reason to avoid them when you will probably have to buy such high voltage replacements anyway?

X2 rated caps don't seem to be harder to find or much more expensive than standard 630V film caps so is there any reason to avoid them when you will probably have to buy such high voltage replacements anyway?

Seriously.

Why do you seek the advice of unknown strangers about a matter of LEGAL LIABILITY? Are you willing to risk losing the totality of assets which a judge can legally appropriate from you, because you don't-feel-like-double-checking some random remarks made by random people on a nonmoderated chat hive?

Really?

Seriously?

Why do you seek the advice of unknown strangers about a matter of LEGAL LIABILITY? Are you willing to risk losing the totality of assets which a judge can legally appropriate from you, because you don't-feel-like-double-checking some random remarks made by random people on a nonmoderated chat hive?

Really?

Seriously?

Consider adding a MOV across the transformer primary. This will prevent transients generated by the transformer.

https://www.mouser.com/datasheet/2/427/vdrh-1762122.pdf

https://www.mouser.com/datasheet/2/427/vdrh-1762122.pdf

I do. Must proof read posts in future.

Any opinions about using a triac to take the stress off the switch?

Why overcomplicate things 🙂 It has worked well for many decades (and presumably still does). A triac would also alter the DPDT arrangement unless you made it even more complex.

I think one of the purpose of that capacitor is to provide a lowly AC supply to the trafo and to trickle charge the cap to avoid inrush current surge during switch on especially for high uF Capacitors. just like soft start of other kind. I tried to use 0.1uf/630v in parallel with 1.5uf motor start cap and it works, my since i use two 47,00uf caps as filters. before, i use to blow fuse on the primary without it. 0.1uf i think is okay but i just tried to jack up a bit. Any Dangers with it?

Your thinking is interesting, but no, the purpose of a small cap across the switch is to quench any contact arcing.

Not just arcing. Without such capacitor, occasionally I had loud thumps on power-on , but never on power-off (in spite arcing being very likely then).

Last edited:

Yes, that's why turntables have had quenching caps in them, to silence the pop when they shut off.

the purpose of a small cap across the switch is to quench any contact arcing.

there was a thread some time ago about this, and it was deemed better to place the cap across the primary of the txfr, not the switch.

In commercial equipment I've never seen that done.

Always a spark arresting cap across the power switch.

And for those insistent ones touting the X type caps, I rarely seen them used in commercial equipment, usually ceramics, or film/mylar types.

Always a spark arresting cap across the power switch.

And for those insistent ones touting the X type caps, I rarely seen them used in commercial equipment, usually ceramics, or film/mylar types.

- Home

- Amplifiers

- Solid State

- Capacitors across power switch