update time:

Well, i truly hate to have come to the following conclusion....

the secondary flares, the detachable XPS foamboard flares wrapped in glass cloth and epoxy....... are a bust.

They are wonderful at low volume, but push them and i've yet to find a way to keep them from resonating.

For a while i thought it was because they are detachable, and just need better attaching techniques. But I've come to accept they simply vibrate no matter what I do.

Funny thing is, within the synergy bandwidth itself, 100Hz up, they work well enough without vibrating, even at pretty high volume.

But it's the sub that rattles them beyond any damping attempts so far.

Just not enough rigid mass i think.

Soooo....i"m going to move to straight-wall wood secondary flares, as per Mr Waslo's spreadsheet.

Hey, at least they will be detachable, and maintain the portability goal 🙂

Until they vibrate too lol

What will most likely be of interest in all this, is the sonic effect of the large horn, and are secondary flares worth it.

My vote says size matters....the tonal balance defintely shifts downward, and authoritatively, when the flares are on vs off.

Balls of steel kinda sound, without loosing delicacy. (Jeez, plz forgive that audiophool BS 🙄)

And why i must now build them out of wood.....

Well, i truly hate to have come to the following conclusion....

the secondary flares, the detachable XPS foamboard flares wrapped in glass cloth and epoxy....... are a bust.

They are wonderful at low volume, but push them and i've yet to find a way to keep them from resonating.

For a while i thought it was because they are detachable, and just need better attaching techniques. But I've come to accept they simply vibrate no matter what I do.

Funny thing is, within the synergy bandwidth itself, 100Hz up, they work well enough without vibrating, even at pretty high volume.

But it's the sub that rattles them beyond any damping attempts so far.

Just not enough rigid mass i think.

Soooo....i"m going to move to straight-wall wood secondary flares, as per Mr Waslo's spreadsheet.

Hey, at least they will be detachable, and maintain the portability goal 🙂

Until they vibrate too lol

What will most likely be of interest in all this, is the sonic effect of the large horn, and are secondary flares worth it.

My vote says size matters....the tonal balance defintely shifts downward, and authoritatively, when the flares are on vs off.

Balls of steel kinda sound, without loosing delicacy. (Jeez, plz forgive that audiophool BS 🙄)

And why i must now build them out of wood.....

Mark,the secondary flares, the detachable XPS foamboard flares wrapped in glass cloth and epoxy....... are a bust.

They are wonderful at low volume, but push them and i've yet to find a way to keep them from resonating.

Funny thing is, within the synergy bandwidth itself, 100Hz up, they work well enough without vibrating, even at pretty high volume.

But it's the sub that rattles them beyond any damping attempts so far.

Just not enough rigid mass i think.

And why i must now build them out of wood.....

"Resonating", "vibrating" and "rattles" point to separate issues.

Vibrations resulting in resonance that increases in level relative to the signal at higher amplitudes could be material related. That said, I'd think plywood would have a less mass to stiffness ratio than fiberglassed foam board, so don't think it would cure a resonance problem.

No fasteners are visible in your secondary horn attachment in the corners, that may be a "buzz/rattle" location.

While driving the sub only, listening to the output of a mic on a long boom close to the various parts of the secondary horn through noise isolating headphones (like GK-Ultraphones) could help you identify where the issue(s) are originating without damaging your hearing.

Art

Attachments

sorry if it's mentioned earlier in this thread but how are you handling x-over (passive, active, passive line-level etc). Just curious

4 way active, 18", 10" coax-mid, high

From Post#68:

"A QSC q-sys core110f processor.

Software is FirDesigner..."

From Post#68:

"A QSC q-sys core110f processor.

Software is FirDesigner..."

Last edited:

Hey Art, always lots of good advice.

And you're right.....a number of separate issues floating around.

That's probably why i'm calling them a bust....I'll get back to that in a second...

The fact the corners don't have any fasteners has been an obvious weakness from the gitgo.

I've tried different dampening materials stuck in between the corners...speaker gasket tape, etc, and now moving to sorborthane. It helps bigtime.

But problem is, the whole 'flare picture frame', and its tight fitting geometry gets screwed a little with the corners push out ever so slightly.

And then the fit between then flares and the horn, where the flares bolt on, isn't as tight/flush and starts to talk back some.

I'm thinking to try some very thin sorborthane, 0.04", as a gasket material anywhere the flares bolt to the wood, or the flares meet flares in the corners.

If this doesn't solve most all problems...which can manifest as sub induced, particular song induced without sub, etc, ,...I'll probably ditch the foamboard flares entirely.

Cause even if i can't come up with a good secondary solution...this is the finest overall speaker i've head the pleasure to enjoy.

Both ripping & beautiful sound, flares or no.

I just played a track I've heard many times on lots of good speakers, and never before heard Robbie Robertson's very quiet "thank you" at the end.

I love the mic on a boom idea to localize issues !!!!!

Super trouble shooting idea 😀 thx again

And you're right.....a number of separate issues floating around.

That's probably why i'm calling them a bust....I'll get back to that in a second...

The fact the corners don't have any fasteners has been an obvious weakness from the gitgo.

I've tried different dampening materials stuck in between the corners...speaker gasket tape, etc, and now moving to sorborthane. It helps bigtime.

But problem is, the whole 'flare picture frame', and its tight fitting geometry gets screwed a little with the corners push out ever so slightly.

And then the fit between then flares and the horn, where the flares bolt on, isn't as tight/flush and starts to talk back some.

I'm thinking to try some very thin sorborthane, 0.04", as a gasket material anywhere the flares bolt to the wood, or the flares meet flares in the corners.

If this doesn't solve most all problems...which can manifest as sub induced, particular song induced without sub, etc, ,...I'll probably ditch the foamboard flares entirely.

Cause even if i can't come up with a good secondary solution...this is the finest overall speaker i've head the pleasure to enjoy.

Both ripping & beautiful sound, flares or no.

I just played a track I've heard many times on lots of good speakers, and never before heard Robbie Robertson's very quiet "thank you" at the end.

I love the mic on a boom idea to localize issues !!!!!

Super trouble shooting idea 😀 thx again

sorry if it's mentioned earlier in this thread but how are you handling x-over (passive, active, passive line-level etc). Just curious

Hi zobsky, like Art pitched in....4-way active, linear phase x-overs, 4096 FIR taps per channel at 48kHz

Mark,The fact the corners don't have any fasteners has been an obvious weakness from the gitgo.

...most all problems...which can manifest as sub induced, particular song induced without sub, etc, ,...

I love the mic on a boom idea to localize issues !!!!!

Super trouble shooting idea 😀 thx again

Unfortunately, hadn't thought of the idea before already sticking my head into far too many horns to determine which speaker was bad..

I once individually tested 12 cabinets (28 eight inch mid speakers) in my Paraline system to find just one of them had loose mounting screws. From the distortion I had heard from front of house, I was expecting to find a bunch of partially cooked voice coils or shifted magnets, not just a simple vibration buzz.

From what you describe, bolting on four exterior corner "L" plates probably will solve the problem without requiring gasket material anywhere but the corners.

At any rate, using a manually swept sine wave signal and the mic on a boom would go a long way to identifying the problem.

My bet is the "corner chatter" is excited at several different frequencies and amplitudes, then each of those is reinforced by the longer or shorter pieces.

Art

Last edited:

Hi zobsky, like Art pitched in....4-way active, linear phase x-overs, 4096 FIR taps per channel at 48kHz

Thanks. All I have at my disposal is a minidsp2x4 HD 🙂

Mark,

Unfortunately, hadn't thought of the idea before already sticking my head into far too many horns to determine which speaker was bad..

I once individually tested 12 cabinets (28 eight inch mid speakers) in my Paraline system to find just one of them had loose mounting screws. From the distortion I had heard from front of house, I was expecting to find a bunch of partially cooked voice coils or shifted magnets, not just a simple vibration buzz.

From what you describe, bolting on four exterior corner "L" plates probably will solve the problem without requiring gasket material anywhere but the corners.

At any rate, using a manually swept sine wave signal and the mic on a boom would go a long way to identifying the problem.

My bet is the "corner chatter" is excited at several different frequencies and amplitudes, then each of those is reinforced by the longer or shorter pieces.

Art

Your bet seems dead on...i've heard a number of sine tones cause problems.

It's been hard to figure out a corner bracket....damn angles, and even with one, how to pull inward.

Epoxy on foam is too thin a surface to allow any kind of machine screw bearing into the the surface, except on the backside where big washers, etc, can be used without visible consequence.

The idea just came to mind, to pull it together with low stretch black fishing line.....out in front pulling the flares together visibly.... strings streching across the mouth...

Probably another dumb / doomed to fail idea....jeez, gotta love diy .....huh? 🙂

Mark,

You might try lacing the corners with 1/8" bungee cord (AKA shock cord). It would look a little Frankenstein, but probably would work, although it sounds like you may need to put washers (or a few layers of Gorilla Tape, my favorite semi-structural adhesive) around the stitch holes to keep the thin glass intact.

Back in 1978 made bass cabinets ("Collapsible Crunchers") with a 30" x 36" x 48" four part horn, flat tops and bottoms, curved sides, using 3 rods and turnbuckles to connect the top and bottom.

Slow assembly, (and hard to explain turnbuckle operation to stagehands) the users later replaced the hardware with rubber bungee cords. I was surprised to find that the bungees provided enough tension to keep them from flapping.

Art

You might try lacing the corners with 1/8" bungee cord (AKA shock cord). It would look a little Frankenstein, but probably would work, although it sounds like you may need to put washers (or a few layers of Gorilla Tape, my favorite semi-structural adhesive) around the stitch holes to keep the thin glass intact.

Back in 1978 made bass cabinets ("Collapsible Crunchers") with a 30" x 36" x 48" four part horn, flat tops and bottoms, curved sides, using 3 rods and turnbuckles to connect the top and bottom.

Slow assembly, (and hard to explain turnbuckle operation to stagehands) the users later replaced the hardware with rubber bungee cords. I was surprised to find that the bungees provided enough tension to keep them from flapping.

Art

Attachments

Last edited:

Soooo....i"m going to move to straight-wall wood secondary flares,

Could you glue the foam flares to a wooden backer and attach the wooden pieces together and to the horn? That would let you keep the flare profile and maybe stop the vibration. A strip of neoprene between the flare and horn might help too.

Are the horns sitting directly on the subs? If they are you could try and decouple them. The LX521 Bridge was to stop the woofer box from vibrating the mid and tweeter baffle.

Thx Art,

Yeah, i've played around with the bungee cord idea too, although not per your good idea.

I've only pictured it as a big wraparound so far.

I think whatever i come up with has to do more than just tighten up the corners.

When I feel the fares, and have put tension on opposing pairs, pulling them towards each other, vibration clearly diminishes.

Yeah, i've played around with the bungee cord idea too, although not per your good idea.

I've only pictured it as a big wraparound so far.

I think whatever i come up with has to do more than just tighten up the corners.

When I feel the fares, and have put tension on opposing pairs, pulling them towards each other, vibration clearly diminishes.

Could you glue the foam flares to a wooden backer and attach the wooden pieces together and to the horn? That would let you keep the flare profile and maybe stop the vibration. A strip of neoprene between the flare and horn might help too.

Are the horns sitting directly on the subs? If they are you could try and decouple them. The LX521 Bridge was to stop the woofer box from vibrating the mid and tweeter baffle.

Hi fluid,

the flares have about a 7cm wide bearing connection to the wood horn, across their entire length. It's like a big rabbited joint, and is pretty sturdy. I do think a sheet of thin neoprene anywhere foam meets wood, is a good idea.

Some thin neoprene is due to arrive tomorrow. First attempt was too thick sorborthane and screwed up the fit.

Art helped convince me not to give up on them...heck, I have far more work in the foam flares, epoxy, glass, hot wire rig, giant scrap pile of 2" XPS... than i do in the entire rest of the synergy.

Plus I've got an adjustable speaker pole mount in the base that needs the lightweight flares to keep the center of gravity right.

So thx to you too, for helping me stay with it. 🙂

The horns do sit on the sub, but the sub doesn't induce enough vibration to even consider. It's a dual 18" push-push slot loaded bass reflex. You have to crank the dog-doo out of it, to even get it to toss a beer 😀

The vibration in the flares...easily felt...is from airborne bass.

It's like the flares are a funky passive radiator. They just need the right bracing or tension to raise resonance i think...

I don't think you quite understood my idea, the wood was to make it easier to connect the backer and flares together more easily and sturdily, then that can be attached to the horn in the same way. You could then screw or glue a cross brace or other piece behind. Long grain glue joints are very strong in wood and I would imagine it being similar with the wood to foam.

The point was to allow you to brace the corners and have something to fix or pull from other than the foam itself 🙂

I would still try and test it without the horn sitting on the sub, if it makes no difference then it didn't take much effort to confirm. If it does make a difference ...

The point was to allow you to brace the corners and have something to fix or pull from other than the foam itself 🙂

I would still try and test it without the horn sitting on the sub, if it makes no difference then it didn't take much effort to confirm. If it does make a difference ...

I think i understand what you're saying on both posts.

I've considered a number of such ways to add wood backing, braces, etc.

Biggest [problem with any idea so far, is that the extra backing and bracing has to go on the back side of the fares where it can't be seen or be in the horn , and where it can only try to push the corners together.

That might solve corner resonances, but it's become obvious the entire 4 sided foam frame needs to be pulled together for extra tension and tight fit to horn.

And what adds to the design difficulty, is the need for he fares to be quickly and easily taken on and off.

Currently working on putting 1mm neoprene on all foam surfaces that mate either with wood or other foam.

And then adding 2 horiz and 3 vertical bungee cords that hook to the mouth of the flares, to provided inward tension.

Oh, if you felt the sub-driven air move your body and the flares, and the lack of any vibration from your hand hand laying on the sub at the same time ...

well, no worries at all about sitting directly on sub 😉

I've considered a number of such ways to add wood backing, braces, etc.

Biggest [problem with any idea so far, is that the extra backing and bracing has to go on the back side of the fares where it can't be seen or be in the horn , and where it can only try to push the corners together.

That might solve corner resonances, but it's become obvious the entire 4 sided foam frame needs to be pulled together for extra tension and tight fit to horn.

And what adds to the design difficulty, is the need for he fares to be quickly and easily taken on and off.

Currently working on putting 1mm neoprene on all foam surfaces that mate either with wood or other foam.

And then adding 2 horiz and 3 vertical bungee cords that hook to the mouth of the flares, to provided inward tension.

Oh, if you felt the sub-driven air move your body and the flares, and the lack of any vibration from your hand hand laying on the sub at the same time ...

well, no worries at all about sitting directly on sub 😉

I hope you can find a solution you are happy with. I have been doing a lot of waveguide simulations recently and a smooth termination makes a really big difference in those.

Thank you fluid,

I was very encouraged yesterday by first efforts to apply thin rubber to flare mating surfaces.

The already excellent mono image from within the horn tightened up some more, reminding me of the killer sound of the previous all wood synergy.

I think Tom D has posted about this....how eliminating unknown or unrecognized resonances, multiple signal paths, diffraction, etc ... tighten up the sense of imaging.

As all those issues give spacial clues that smear out the attempt of being a point source.

I guess mouth termination issues fall soundly into that group too..?

What have your sims been showing?

On synergies in particular, or general horns?

I was very encouraged yesterday by first efforts to apply thin rubber to flare mating surfaces.

The already excellent mono image from within the horn tightened up some more, reminding me of the killer sound of the previous all wood synergy.

I think Tom D has posted about this....how eliminating unknown or unrecognized resonances, multiple signal paths, diffraction, etc ... tighten up the sense of imaging.

As all those issues give spacial clues that smear out the attempt of being a point source.

I guess mouth termination issues fall soundly into that group too..?

What have your sims been showing?

On synergies in particular, or general horns?

Possibly, Earl Geddes describes it as a standing wave forming across the mouth which causes a reflection to the throat. The smoother the termination the less chance of any reflections occurring. In simulations it is seen in the Radiation Impedance. The smoother the Radiation Impedance is the smoother the output of the horn is.

The simulations I am running are BEM through ABEC and are compression drivers on a horn, so not specifically of synergies but would apply pretty well to your latest as without the mids there isn't a massive difference from 500Hz up.

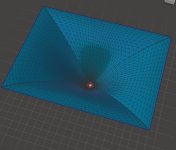

If you want I could make you a mesh of a conical horn with a smooth mouth boundary to compare visually. Would need the W H D of your horn to make it similar.

The simulations I am running are BEM through ABEC and are compression drivers on a horn, so not specifically of synergies but would apply pretty well to your latest as without the mids there isn't a massive difference from 500Hz up.

If you want I could make you a mesh of a conical horn with a smooth mouth boundary to compare visually. Would need the W H D of your horn to make it similar.

Horn resonances

Two factors claimed to create horn distortions are Geddes' Higher Order Modes (HOM, search here) and the various factors in this classic article:

Factors Affecting Sonic Quality of Mid & HF Horns & Waveguides

The "towel mod" or equivalent is perhaps the most basic: the goal is to reduce the reflection and delay back into the horn. Putting a towel cowl around a fancy speaker is not to everyone's taste, but less horrific equivalents may be found 😀

Two factors claimed to create horn distortions are Geddes' Higher Order Modes (HOM, search here) and the various factors in this classic article:

Factors Affecting Sonic Quality of Mid & HF Horns & Waveguides

The "towel mod" or equivalent is perhaps the most basic: the goal is to reduce the reflection and delay back into the horn. Putting a towel cowl around a fancy speaker is not to everyone's taste, but less horrific equivalents may be found 😀

- Home

- Loudspeakers

- Multi-Way

- synergy.....Take #7