I have a (probally noob) question, and the search did not give me an answer...

Many use voltage regulators like the LM317 for their regulated dc heaters in tube amps/preamps. But that require a whole circuit arround it. Why do you not use a fixed voltage regulator at 6.3v like the NJR NJM2396F63 for this? It makes the circuit much more simpler. Or is there a good reason that i do not know yet?

Thanks for your arguments pro and contra.

Many use voltage regulators like the LM317 for their regulated dc heaters in tube amps/preamps. But that require a whole circuit arround it. Why do you not use a fixed voltage regulator at 6.3v like the NJR NJM2396F63 for this? It makes the circuit much more simpler. Or is there a good reason that i do not know yet?

Thanks for your arguments pro and contra.

I think the 317's were simply more common when people started using them in tube circuits.

You'll still need the capacitors, so the only parts you are avoiding are a couple resistors.

You'll still need the capacitors, so the only parts you are avoiding are a couple resistors.

If you look around there are examples of 6V and 6.3V 3 terminal regulators for constant voltage DC being used, so it's not like it is taboo or frowned upon.

One major reason you see more LM317's is you can do different things with them: high voltage regulation, current regulation, multiple (switchable) voltage setpoints, etc.

One major reason you see more LM317's is you can do different things with them: high voltage regulation, current regulation, multiple (switchable) voltage setpoints, etc.

There is the "trick" of inserting a PN diode in the common line of a 7805.

Starting with 6.3 VAC, I avoid the low dropout issue by "full wave" voltage doubling with Schottkys and a 7812 for regulation. 12 VDC is outstanding for a 12AX7 based phono preamp, as it's within 5% of nominal, on the low side.

Starting with 6.3 VAC, I avoid the low dropout issue by "full wave" voltage doubling with Schottkys and a 7812 for regulation. 12 VDC is outstanding for a 12AX7 based phono preamp, as it's within 5% of nominal, on the low side.

What is even simpler is AC heaters.

The only time I used DC heaters it didn't fix the hum problem.

The heater transformer limits the current on power up so is ideal power source.

The only time I used DC heaters it didn't fix the hum problem.

The heater transformer limits the current on power up so is ideal power source.

It is possible to build a phono preamp that employs AC heating and has an acceptable hum level. HOWEVER, the task is extremely difficult and (IMO) not worth the bother.

To build a phono preamp with AC heating, acquire genuine 7025 equivalents (read culled Sovtek 12AX7LPS stock) and bias the heaters off B+ at approx. 60 V. I wish good fortune to all who make the attempt, as you will need it.

FWIW, take a look at the original passive EQ RCA design. It calls for 7025s. 😉 RCA's engineers were good. Post WW2, semiconductors were 1st being understood and DC heater supplies were anything but easy to build. RCA's people did the best they could with what was currently available. That best was the 7025, with its hum bucking, spiral wound, heater.

To build a phono preamp with AC heating, acquire genuine 7025 equivalents (read culled Sovtek 12AX7LPS stock) and bias the heaters off B+ at approx. 60 V. I wish good fortune to all who make the attempt, as you will need it.

FWIW, take a look at the original passive EQ RCA design. It calls for 7025s. 😉 RCA's engineers were good. Post WW2, semiconductors were 1st being understood and DC heater supplies were anything but easy to build. RCA's people did the best they could with what was currently available. That best was the 7025, with its hum bucking, spiral wound, heater.

Attachments

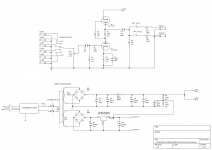

I'm also more convinced that DC heaters are needed in preamps. The design i was working on (primaly as case study, i don't know if i'm going to build it yet) was a line preamp with a 12au7 with the second halve of the double triode as cathode follower per channel. Still work in progress and probally still have some design faults in it as i'm still a noob on tube design... I try to keep the circuit as simple as possible in this design.

Attachments

Last edited:

You can do this and get 6.3V DC out of 6.3V AC. Which is rather handy.

You don't need very big heat sinks either.

What I did for dc heaters for the driver portion of a 2A3 amp that I built was rectify the 6.3v, use .22 ohm resistors prior to the filter cap, filter it through a cap, a common mode choke, and then you have to fiddle with sub ohm resistors on the output until you get the voltage right. I used another .22.

No heat sinks, noise free (on idht), and it cured most of my hum problems. You just have to keep in mind that you have to load the circuit when you are fiddling with the values of the resistors or else you will end up with something like 3 or 4 volts when you hook it to the heaters.

It works fine though. You just need enough current in the 6.3v winding. I was only powering two 12ax7 tubes with the heaters wired for 6.3 instead of 12.6. I ended up with 6.2v across the heaters of both tubes. Prior to that the hum was awful. I tried ct to ground, elevating heater voltage, nothing really helped. This did the trick and was simple to do.

My 2 cents

Otherwise known as a genuine ECC83. Not all modern valves marked ECC83 are actually ECC83; many are just 12AX7 (conventional heater). To confuse things further, some valves marked 12AX7 are actually ECC83/7025 (spiral wound heater).Eli Duttman said:That best was the 7025, with its hum bucking, spiral wound, heater.

OS tubes known to be true 7025 are pricey. That's why I suggested the Sovtek 12AX7LPS. The 'LPS is a genuine 7025 equivalent that sounds good and doesn't cause "sticker shock".

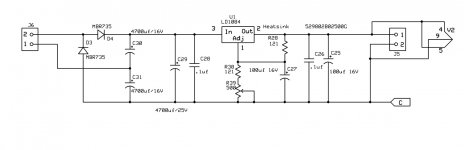

Here is a really good scheme for heaters, especially when you only have 6VAC taps on trafos! It uses two fast recover Schottky diodes as doubters to a LD1084

Adj. it comes in handy when you want to dial down the heater voltage in high gain circuits as well. I use this in all my SP and LS series preamps. Bump up those cap sizes to 10000uf for higher current draws and lower noise as well.

Adj. it comes in handy when you want to dial down the heater voltage in high gain circuits as well. I use this in all my SP and LS series preamps. Bump up those cap sizes to 10000uf for higher current draws and lower noise as well.

Attachments

Last edited:

Has anybody bothered to model and then measure out the effects of all these DC heater voltage doubling schemes? The ripple of a voltage doubler at large currents is very substantial. I have modeled it, quite easy in PSUD II. I suspect this is one example where the cure is worse than the disease.

Has anybody bothered to model and then measure out the effects of all these DC heater voltage doubling schemes? The ripple of a voltage doubler at large currents is very substantial. I have modeled it, quite easy in PSUD II. I suspect this is one example where the cure is worse than the disease.

I’ve had very good success using the 10k uf caps with currents as high as 3A and very quiet! And a plus is the 1084 regulator has built in thermal protection in case of overheating, and I’ve only had that happen once or twice, and I’ve built 100 or more of these in various preamplifiers I’ve sold.

low noise SS front end followed by RIAA then 12AX7 final gain and 6922 buffer should guarantee low noise on all fronts.

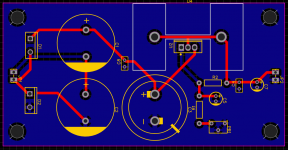

EasyEDA schematic and PCB for your filament voltage regulator

Hi. Thanks for sharing your schematic design for the filament heater voltage regulator. I really appreciate it.

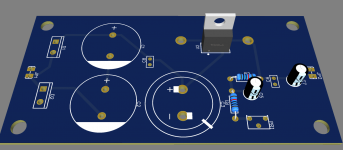

I laid out the schematic and made a PCB layout in EasyEDA to make up a small prototype board for a tube amp I'm building. I was hoping you'd take a minute to look at my design to see if it looks ok. Also, what heatsink (part #) would you use on the MBR735 (if you think they need one)? Sorry, I am very new to this part of the process, never custom designed a PCB before.

Check out the image attachments.

If you were interested I'd be happy to send you a couple of the PCBs as a thank you (assuming you have not made up your own (better! 🙂 version.

Here is a really good scheme for heaters, especially when you only have 6VAC taps on trafos! It uses two fast recover Schottky diodes as doubters to a LD1084

Adj. it comes in handy when you want to dial down the heater voltage in high gain circuits as well. I use this in all my SP and LS series preamps. Bump up those cap sizes to 10000uf for higher current draws and lower noise as well.

Hi. Thanks for sharing your schematic design for the filament heater voltage regulator. I really appreciate it.

I laid out the schematic and made a PCB layout in EasyEDA to make up a small prototype board for a tube amp I'm building. I was hoping you'd take a minute to look at my design to see if it looks ok. Also, what heatsink (part #) would you use on the MBR735 (if you think they need one)? Sorry, I am very new to this part of the process, never custom designed a PCB before.

Check out the image attachments.

If you were interested I'd be happy to send you a couple of the PCBs as a thank you (assuming you have not made up your own (better! 🙂 version.

Attachments

You'd have to give a current draw in order for dissipation on the MBR735 to be estimated.

I might suggest using a heatsink isolation mounting kit and either let the heatsink float or earth it.

I might suggest using a heatsink isolation mounting kit and either let the heatsink float or earth it.

Thanks. This will be powering 2x KT88 and an ECC85 tube filaments. So 1.6Ax2 + 300mA = 3.5A? This sounds like it will definitely need heatsink on the MBR735, is this part # good enough?

287-1ABE Wakefield-Vette | Fans, Thermal Management | DigiKey

Sorry I'm still fairly new to this, and don't know how much current the 2 Schottky diodes will draw each.

287-1ABE Wakefield-Vette | Fans, Thermal Management | DigiKey

Sorry I'm still fairly new to this, and don't know how much current the 2 Schottky diodes will draw each.

- Home

- Amplifiers

- Tubes / Valves

- Tube heater voltage regulator